ASTM D1282-05(2009)

(Test Method)Standard Test Method for Resistance to Airflow as an Indication of Average Fiber Diameter of Wool Top, Card Sliver, and Scoured Wool (Withdrawn 2018)

Standard Test Method for Resistance to Airflow as an Indication of Average Fiber Diameter of Wool Top, Card Sliver, and Scoured Wool (Withdrawn 2018)

SIGNIFICANCE AND USE

This test method is not recommended for the acceptance testing of commercial shipments of wool top, card sliver, or scoured wool since the referee method, Test Method D 2130, is recommended for that purpose. Although this test method is not recommended for acceptance testing, it is useful for fast quality control checks.

.If there are differences of practical significance between reported test results for two laboratories (or more), comparative test should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use the samples for such a comparative test that are as homogenous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing and randomly assigned in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, a probability level chosen prior to the testing series. If bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

The specific area of the wool fibers is measured by the resistance in air flow. The resistance to air flow has been related to average fiber diameter measured by the microprojection method. The instruments have been calibrated to read average diameter in micrometres. Although the reading is affected by the average fiber diameter distribution of the specimen, the results secured by the instruments give no indication of this distribution. However, in converting the micrometres reading to millitex units (Annex A1), low, medium, and high standard deviations were used in the calculations to arrive at the range of millitex units which accordingly reflect the distribution of fiber diameters.

1) Balance Adjustment Knob 8) Porosity Calibration Control 2) Balance Pan 9) Compression Lever 3) Air Reservoir10) Calibrator Plug Plun...

SCOPE

1.1 This test method covers the estimation of the average fiber diameter of wool fibers by use of the Port-Ar and the WIRA Fiber Fineness Meter instrument, which operate on the air-flow principle. Other air-flow instruments have not been tested with this method. The method is directly applicable to non-medullated, carded wool and wool top.

1.2 This test method is applicable to grease wool and scoured wool after the samples of such materials have been prepared as directed in Test Method D 2130.

Note 1—The use of the Micronaire instrument for measuring the fineness of cotton fibers is covered in Test Method D 1448.

The assignment of grade for wool and mohair is covered in Specifications D 3991 and D 3992.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the estimation of the average fiber diameter of wool fibers by use of the Port-Ar and the WIRA Fiber Fineness Meter instrument, which operate on the air-flow principle.

Formerly under the jurisdiction of Committee D13 on Textiles, this test method was withdrawn in January 2018 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1282 −05 (Reapproved 2009)

Standard Test Method for

Resistance to Airflow as an Indication of Average Fiber

Diameter of Wool Top, Card Sliver, and Scoured Wool

This standard is issued under the fixed designation D1282; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Top and Assignment of Grade

D4845Terminology Relating to Wool

1.1 This test method covers the estimation of the average

2.2 Other Standard:

fiber diameter of wool fibers by use of the Port-Ar and the

IWTO-6-92(E)Method ofTest for the Determination ofThe

WIRAFiber Fineness Meter instrument, which operate on the

Mean Diameter of Wool Fibers in Combed Sliver Using

air-flow principle. Other air-flow instruments have not been

the Air-Flow Apparatus

tested with this method. The method is directly applicable to

IWTO-28-82(E)Determination By The Airflow Method of

non-medullated, carded wool and wool top.

the Mean Fibre Diameter of Core Samples of Raw Wool

1.2 This test method is applicable to grease wool and

scoured wool after the samples of such materials have been

3. Terminology

prepared as directed in Test Method D2130.

3.1 For all terminology related to wool and wool felt, refer

NOTE 1—The use of the Micronaire instrument for measuring the

to Terminology D4845.

fineness of cotton fibers is covered in Test Method D1448.

3.1.1 The following terms are relevant to this standard:

The assignment of grade for wool and mohair is covered in Specifica-

sliver, specific area, top, and wool.

tions D3991 and D3992.

3.2 For all other terminology related to textiles, see Termi-

1.3 This standard does not purport to address all of the

nology D123.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 The resistance to air flow of predetermined mass of

bility of regulatory limitations prior to use.

wool compressed to a fixed volume is measured. The instru-

2. Referenced Documents

ments approved for use have been calibrated to read average

diameterinmicrometres.Specimensofwooltopareratedwith

2.1 ASTM Standards:

a Wool Top Scale and specimens of carded, scoured wool and

D123Terminology Relating to Textiles

scoured ⁄2-in. (13.0-mm) cores are rated with a Scoured Wool

D1060PracticeforCoreSamplingofRawWoolinPackages

Scale. If instruments are properly calibrated, results are inter-

for Determination of Percentage of Clean Wool Fiber

changeable.

Present

D1448Test Method for Micronaire Reading of Cotton Fi-

5. Significance and Use

bers

D2130TestMethodforDiameterofWoolandOtherAnimal 5.1 Thistestmethodisnotrecommendedfortheacceptance

testing of commercial shipments of wool top, card sliver, or

Fibers by Microprojection

D3991Specifications for Fineness of Wool or Mohair and scoured wool since the referee method,Test Method D2130,is

recommended for that purpose. Although this test method is

Assignment of Grade

D3992Specifications for Fineness of Wool Top or Mohair not recommended for acceptance testing, it is useful for fast

quality control checks.

5.1.1 .If there are differences of practical significance be-

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextiles

tween reported test results for two laboratories (or more),

and is the direct responsibility of Subcommittee D13.13 on Wool and Felt.

comparative test should be performed to determine if there is a

Current edition approved July 1, 2009. Published August 2009. Originally

statistical bias between them, using competent statistical assis-

approved in 1953. Last previous edition approved in 2005 as D1282–05. DOI:

10.1520/D1282-05R09.

tance.As a minimum, use the samples for such a comparative

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

test that are as homogenous as possible, drawn from the same

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

lot of material as the samples that resulted in disparate results

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. during initial testing and randomly assigned in equal numbers

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1282−05 (2009)

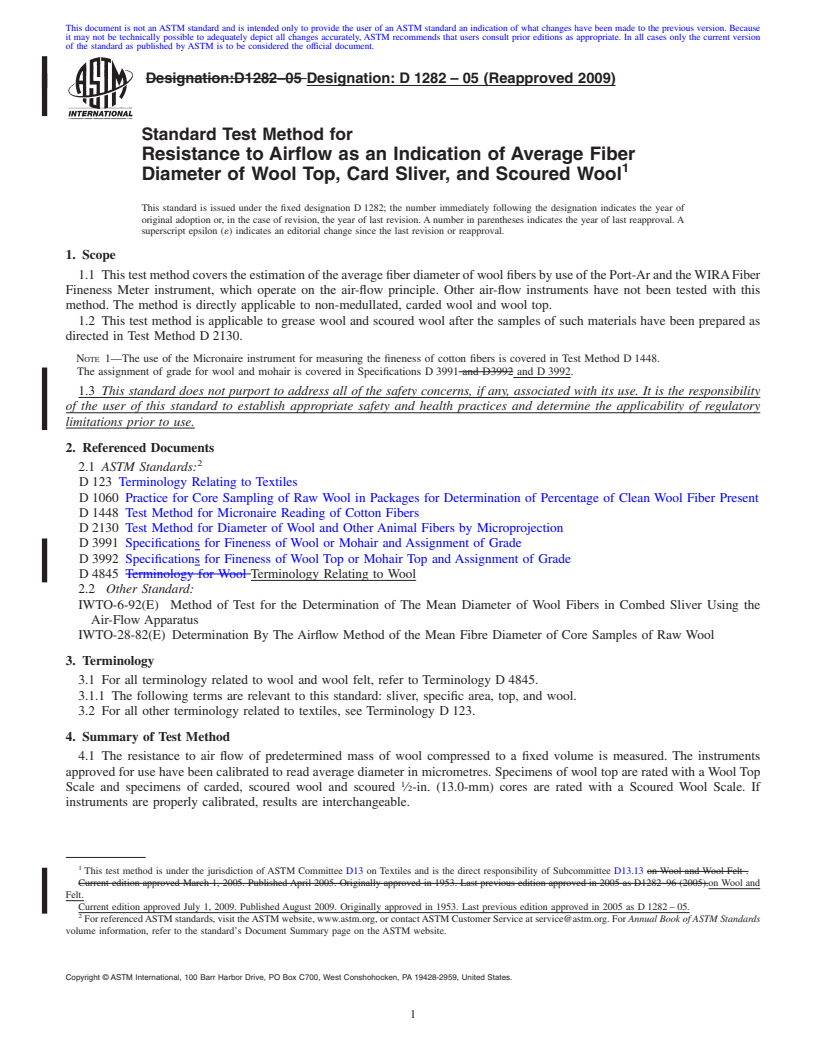

1) Balance Adjustment Knob 8) Porosity Calibration Control

2) Balance Pan 9) Compression Lever

3) Air Reservoir 10) Calibrator Plug Plunger

4) Meter Zero Adjustment Screw 11) Porosity Calibrator Plug

5) Porosity Test Chamber Lid 12) Calibration Weight

6) Differential Pressure Gage 13) Weighing Balance Mechanism

7) Porosity Zero Control 14) Atomizer Bulb

FIG. 1 Port-Ar Apparatus

to each laboratory. The test results from the laboratories

involved should be compared using a statistical test for

unpaired data, a probability level chosen prior to the testing

series. If bias is found, either its cause must be found and

corrected, or future test results for that material must be

adjusted in consideration of the known bias.

5.2 The specific area of the wool fibers is measured by the

resistanceinairflow.Theresistancetoairflowhasbeenrelated

to average fiber diameter measured by the microprojection

method. The instruments have been calibrated to read average

diameter in micrometres. Although the reading is affected by

the average fiber diameter distribution of the specimen, the

results secured by the instruments give no indication of this

distribution. However, in converting the micrometres reading

to millitex units (AnnexA1), low, medium, and high standard

deviations were used in the calculations to arrive at the range

of millitex units which accordingly reflect the distribution of

fiber diameters.

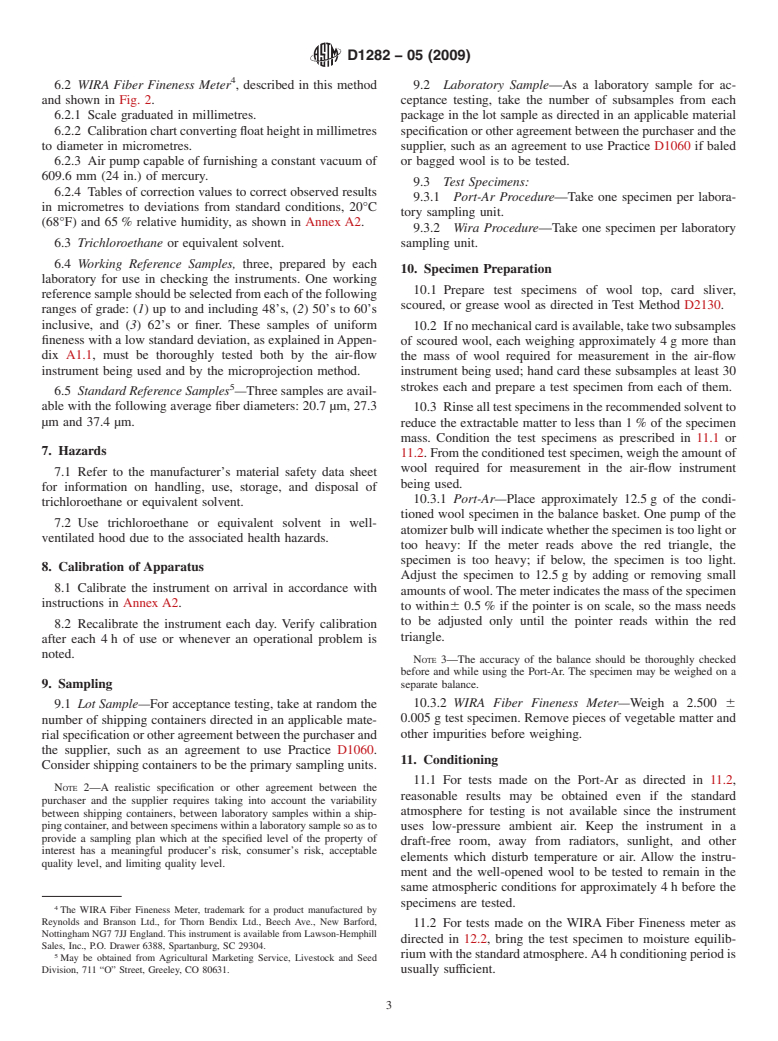

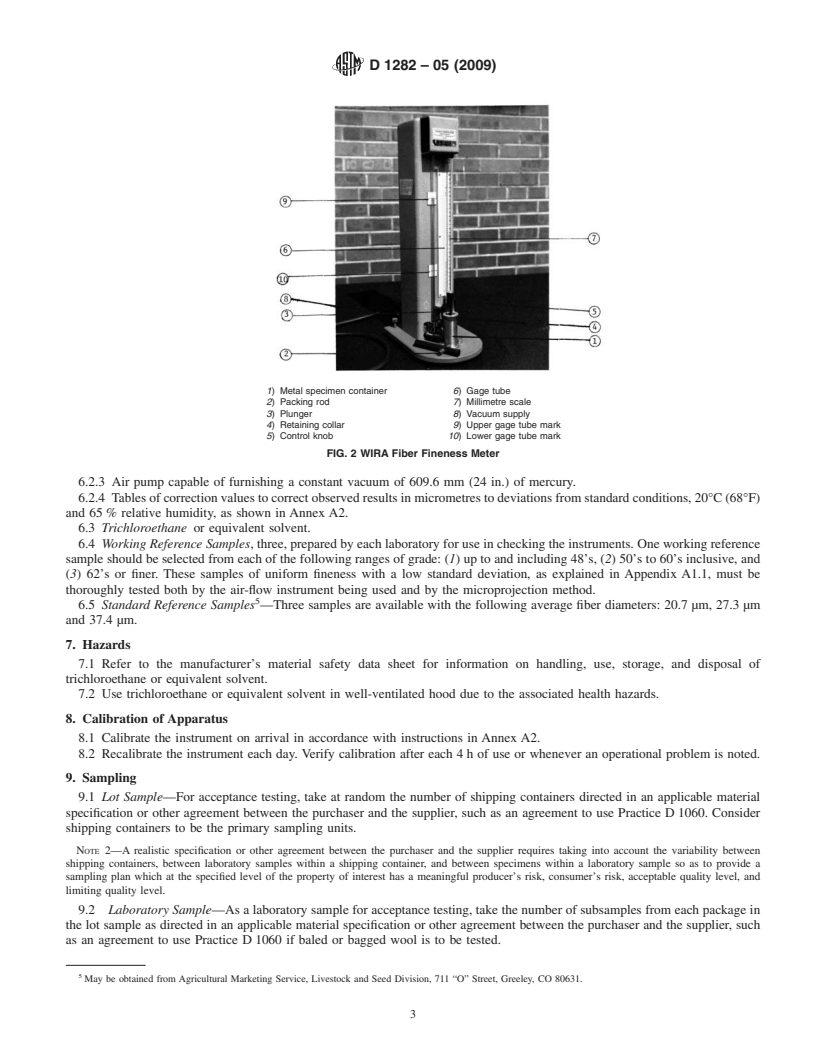

1) Metal specimen container 6) Gage tube

2) Packing rod 7) Millimetre scale

6. Apparatus, Materials, and Reagent

3) Plunger 8) Vacuum supply

6.1 Port-Ar , described in this method and shown in Fig. 1.

4) Retaining collar 9) Upper gage tube mark

5) Control knob 10) Lower gage tube mark

FIG. 2 WIRA Fiber Fineness Meter

The Port-Ar instrument, trademark for a product manufactured by Zellweger

Uster, 456 Troy Circle, P.O. Box 51720, Knoxville, TN 37950, has been found

satisfactory for this purpose.

D1282−05 (2009)

6.2 WIRA Fiber Fineness Meter , described in this method 9.2 Laboratory Sample—As a laboratory sample for ac-

and shown in Fig. 2. ceptance testing, take the number of subsamples from each

6.2.1 Scale graduated in millimetres. package in the lot sample as directed in an applicable material

6.2.2 Calibrationchartconvertingfloatheightinmillimetres specificationorotheragreementbetweenthepurchaserandthe

to diameter in micrometres. supplier, such as an agreement to use Practice D1060 if baled

6.2.3 Air pump capable of furnishing a constant vacuum of or bagged wool is to be tested.

609.6 mm (24 in.) of mercury.

9.3 Test Specimens:

6.2.4 Tables of correction values to correct observed results

9.3.1 Port-Ar Procedure—Take one specimen per labora-

in micrometres to deviations from standard conditions, 20°C

tory sampling unit.

(68°F) and 65% relative humidity, as shown in Annex A2.

9.3.2 Wira Procedure—Take one specimen per laboratory

6.3 Trichloroethane or equivalent solvent. sampling unit.

6.4 Working Reference Samples, three, prepared by each

10. Specimen Preparation

laboratory for use in checking the instruments. One working

10.1 Prepare test specimens of wool top, card sliver,

referencesampleshouldbeselectedfromeachofthefollowing

scoured, or grease wool as directed in Test Method D2130.

ranges of grade: (1) up to and including 48’s, (2) 50’s to 60’s

inclusive, and (3) 62’s or finer. These samples of uniform

10.2 Ifnomechanicalcardisavailable,taketwosubsamples

fineness with a low standard deviation, as explained inAppen-

of scoured wool, each weighing approximately 4g more than

dix A1.1, must be thoroughly tested both by the air-flow

the mass of wool required for measurement in the air-flow

instrument being used and by the microprojection method. instrument being used; hand card these subsamples at least 30

strokes each and prepare a test specimen from each of them.

6.5 StandardReferenceSamples —Threesamplesareavail-

able with the following average fiber diameters: 20.7 µm, 27.3 10.3 Rinsealltestspecimensintherecommendedsolventto

µm and 37.4 µm.

reduce the extractable matter to less than 1% of the specimen

mass. Condition the test specimens as prescribed in 11.1 or

7. Hazards

11.2.Fromtheconditionedtestspecimen,weightheamountof

wool required for measurement in the air-flow instrument

7.1 Refer to the manufacturer’s material safety data sheet

being used.

for information on handling, use, storage, and disposal of

10.3.1 Port-Ar—Place approximately 12.5g of the condi-

trichloroethane or equivalent solvent.

tioned wool specimen in the balance basket. One pump of the

7.2 Use trichloroethane or equivalent solvent in well-

atomizerbulbwillindicatewhetherthespecimenistoolightor

ventilated hood due to the associated health hazards.

too heavy: If the meter reads above the red triangle, the

specimen is too heavy; if below, the specimen is too light.

8. Calibration of Apparatus

Adjust the specimen to 12.5g by adding or removing small

8.1 Calibrate the instrument on arrival in accordance with

amountsofwool.Themeterindicatesthemassofthespecimen

instructions in Annex A2.

to within6 0.5% if the pointer is on scale, so the mass needs

to be adjusted only until the pointer reads within the red

8.2 Recalibrate the instrument each day. Verify calibration

triangle.

after each 4h of use or whenever an operational problem is

noted.

NOTE 3—The accuracy of the balance should be thoroughly checked

before and while using the Port-Ar. The specimen may be weighed on a

9. Sampling separate balance.

10.3.2 WIRA Fiber Fineness Meter—Weigh a 2.500 6

9.1 Lot Sample—For acceptance testing, take at random the

0.005 g test specimen. Remove pieces of vegetable matter and

number of shipping containers directed in an applicable mate-

other impurities before weighing.

rialspecificationorotheragreementbetweenthepurchaserand

the supplier, such as an agreement to use Practice D1060.

11. Conditioning

Considershippingcontainerstobetheprimarysamplingunits.

11.1 For tests made on the Port-Ar as directed in 11.2,

NOTE 2—A realistic specification or other agreement between the

reasonable results may be obtained even if the standard

purchaser and the supplier requires taking into account the variability

atmosphere for testing is not available since the instrument

between shipping containers, between laboratory samples within a ship-

pingcontainer,andbetweenspecimenswithinalaboratorysamplesoasto

uses low-pressure ambient air. Keep the instrument in a

provide a sampling plan which at the specified level of the property of

draft-free room, away from radiators, sunlight, and other

interest has a meaningful producer’s risk, consumer’s risk, acceptable

elements which disturb temperature or air. Allow the instru-

quality level, and limiting quality level.

ment and the well-opened wool to be tested to remain in the

same atmospheric conditions for approximately 4h before the

specimens are tested.

The WIRA Fiber Fineness Meter, trademark for a product manufactured by

Reynolds and Branson Ltd., for Thorn Bendix Ltd., Beech Ave., New Barford,

11.2 For tests made on the WIRA Fiber Fineness meter as

Nottingham NG7 7JJ England.This instrument is available from Lawson-Hemphill

directed in 12.2, bring the test specimen to moisture equilib-

Sales, Inc., P.O. Drawer 6388, Spartanburg, SC 29304.

riumwiththestandardatmosphere.A4hconditioningperiodis

May be obtained from Agricultural Marketing Service, Livestock and Seed

Division, 711 “O” Street, Greeley, CO 80631. usually sufficient.

D1282−05 (2009)

TABLE 1 Components Of Variance As Standard Deviations, µm

Single-Operator Within-Laboratory Between-Laboratory

Names Of The Properties

Component Component Component

Fiber diameter,

Port-Ar procedure

Single-material comparisons 0.21 0.20 0.72

Multi-material comparisons 0.00 0.20 0.74

Fiber diameter,

WIRA procedure

Single-material comparisons 0.23 0.11 0.37

Multi-material comparisons 0.13 0.11 0.38

A

TABLE 2 Critical Differences, µm, For The Conditions Noted

Number Of

Single-Operator Within-Labora- Between-Labora-

Names Of The Properties Observations In

Precision tory Precision tory Precision

Each Average

Fiber diameter,

Port-Ar procedure

Single-material comparisons 1 0.57 0.79 2.14

2 0.41 0.68 2.10

4 0.29 0.61 2.08

8 0.20 0.58 2.07

Multi-material comparisons 1 0.57 0.79 2.20

2 0.41 0.68 2.17

4 0.29 0.61 2.15

8 0.20 0.58 2.14

Fiber diameter,

WIRA procedure

Single-material comparisons 1 0.64 0.71 1.25

2 0.46 0.55 1.16

4 0.32 0.44 1.11

8 0.23 0.38 1.09

Multi-material comparisons 1 0.73 0.79 1.32

2 0.57 0.65 1.24

4 0.48 0.56 1.20

8 0.42 0.52 1.18

A

The critical differences were calculated using t = 1.96, which is based on infinite degrees of freedom.

12. Procedure with the short end of the rod provided. It is important to use

this rod and nothing else for packing since it prevents tight

12.1 Procedure with the Port-Ar:

packingofthefibers.Thenpushinthemetalplunger(avoiding

12.1.1 WoolTop,CardSliver,ScouredWool,GreaseWool—

trapping any fibers) until it rests on the lip of the container and

Usingtheweighedtestspecimen,(see10.3.1)placeoneendof

screw down the retaining collar to the furthest extent, mean-

the sliver in the chamber and tamp in the remainder. Do not

whileholdingtheplateattachedtothemetalplungertoprevent

fold the wool top before placing in the chamber. When all of

it rotating.

the specimen has been forced into the chamber, close the

12.2.2 With the control knob in the OFF position switch on

compression chamber lid, 5, in place. Pull forward on the

compression lever, 9, until it locks in place.Apply air pressure the pump then turn the knob slowly until the liquid level in the

either by the atomizer bulb or by the electric pump to fill the gage tube falls to the lower mark reading at eye level.

pressure tank (Note 3). Read the diameter in micrometres on

12.2.3 Reading at eye level across the top of the spinner

the scale as the piston settles. Record the reading and remove

record the scale reading to the nearest millimetre.

thespecimen,carefullyreopenitbyhandtoeliminatecompact

12.2.4 Take out the specimen, reverse its direction, repack

areas, replace the specimen in the chamber and make a second

in the container using the

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D1282–96 (Reapproved 2005) Designation: D 1282 – 05 (Reapproved 2009)

Standard Test Method for

Resistance to Airflow as an Indication of Average Fiber

Diameter of Wool Top, Card Sliver, and Scoured Wool

This standard is issued under the fixed designation D1282; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 ThistestmethodcoverstheestimationoftheaveragefiberdiameterofwoolfibersbyuseofthePort-ArandtheWIRAFiber

Fineness Meter instrument, which operate on the air-flow principle. Other air-flow instruments have not been tested with this

method. The method is directly applicable to non-medullated, carded wool and wool top.

1.2 This test method is applicable to grease wool and scoured wool after the samples of such materials have been prepared as

directed in Test Method D2130.

NOTE 1—The use of the Micronaire instrument for measuring the fineness of cotton fibers is covered in Test Method D1448.

The assignment of grade for wool and mohair is covered in Specifications D3991 and D3992 and D3992.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D1060 Practice for Core Sampling of Raw Wool in Packages for Determination of Percentage of Clean Wool Fiber Present

D1448 Test Method for Micronaire Reading of Cotton Fibers

D2130 Test Method for Diameter of Wool and Other Animal Fibers by Microprojection

D3991 Specifications for Fineness of Wool or Mohair and Assignment of Grade

D3992 Specification for Fineness of Wool Top or Mohair Top and Assignment of Grade Specifications for Fineness of Wool

Top or Mohair Top and Assignment of Grade

D4845 Terminology Relating to Wool

2.2 Other Standard:

IWTO-6-92(E) Method of Test for the Determination of The Mean Diameter of Wool Fibers in Combed Sliver Using the

Air-Flow Apparatus

IWTO-28-82(E) Determination By The Airflow Method of the Mean Fibre Diameter of Core Samples of Raw Wool

3. Terminology

3.1Definitions:

3.1.1sliver, n—acontinuousstrandoflooselyassembledfibersthatisapproximatelyuniformincross-sectionalareaandwithout

twist.

3.1.2specific area, n— of wool, the ratio of the fiber surface to fiber volume.

3.1.3top, n—in wool, a continuous untwisted strand of wool fibers from which the shorter fibers or noils have been removed by

combing.

3.1.4wool, n—the fibrous covering of the sheep, ovis species.

3.1.5For definition of other textile terms used in the method, refer to Terminology D123

3.1 For all terminology related to wool and wool felt, refer to Terminology D4845.

3.1.1 The following terms are relevant to this standard: sliver, specific area, top, and wool.

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.13 on Wool and Wool Felt .

Current edition approved Jan. 1, 2005. Published March 2005. Originally approved in 1953. Last previous edition approved in 1996 as D1282–96.on Wool and Felt.

Current edition approved July 1, 2009. Published August 2009. Originally approved in 1953. Last previous edition approved in 2005 as D1282–05.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 1282 – 05 (2009)

3.2 For all other terminology related to textiles, see Terminology D123.

4. Summary of Test Method

4.1 The resistance to air flow of predetermined mass of wool compressed to a fixed volume is measured. The instruments

approved for use have been calibrated to read average diameter in micrometres. Specimens of wool top are rated with aWoolTop

Scale and specimens of carded, scoured wool and scoured ⁄2-in. (13.0-mm) cores are rated with a Scoured Wool Scale. If

instruments are properly calibrated, results are interchangeable.

5. Significance and Use

5.1 Thistestmethodisnotrecommendedfortheacceptancetestingofcommercialshipmentsofwooltop,cardsliver,orscoured

wool since the referee method, Test Method D2130, is recommended for that purpose. Although this test method is not

recommended for acceptance testing, it is useful for fast quality control checks.

5.1.1In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of

commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias

between their laboratories. Competent statistical assistance is recommended for the investigation of bias.As a minimum, the two

parties should take a group of test specimens which are as homogeneous as possible and which are from a lot of material of the

typeinquestion.Thetestspecimensshouldthenberandomlyassignedinequalnumberstoeachlaboratoryfortesting.Theaverage

results from the two laboratories should be compared using Student’s t-test for unpaired data and an acceptable probability level

chosen by the two parties before testing is begun. If a bias is found, either its cause must be found and corrected or the purchaser

and the supplier must agree to interpret future test results in view of the known bias.

5.1.1 .If there are differences of practical significance between reported test results for two laboratories (or more), comparative

test should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a

minimum, use the samples for such a comparative test that are as homogenous as possible, drawn from the same lot of material

as the samples that resulted in disparate results during initial testing and randomly assigned in equal numbers to each laboratory.

The test results from the laboratories involved should be compared using a statistical test for unpaired data, a probability level

chosenpriortothetestingseries.Ifbiasisfound,eitheritscausemustbefoundandcorrected,orfuturetestresultsforthatmaterial

must be adjusted in consideration of the known bias.

5.2 The specific area of the wool fibers is measured by the resistance in air flow. The resistance to air flow has been related to

average fiber diameter measured by the microprojection method. The instruments have been calibrated to read average diameter

1) Balance Adjustment Knob 8) Porosity Calibration Control

2) Balance Pan 9) Compression Lever

3) Air Reservoir 10) Calibrator Plug Plunger

4) Meter Zero Adjustment Screw 11) Porosity Calibrator Plug

5) Porosity Test Chamber Lid 12) Calibration Weight

6) Differential Pressure Gage 13) Weighing Balance Mechanism

7) Porosity Zero Control 14) Atomizer Bulb

FIG. 1 Port-Ar Apparatus

D 1282 – 05 (2009)

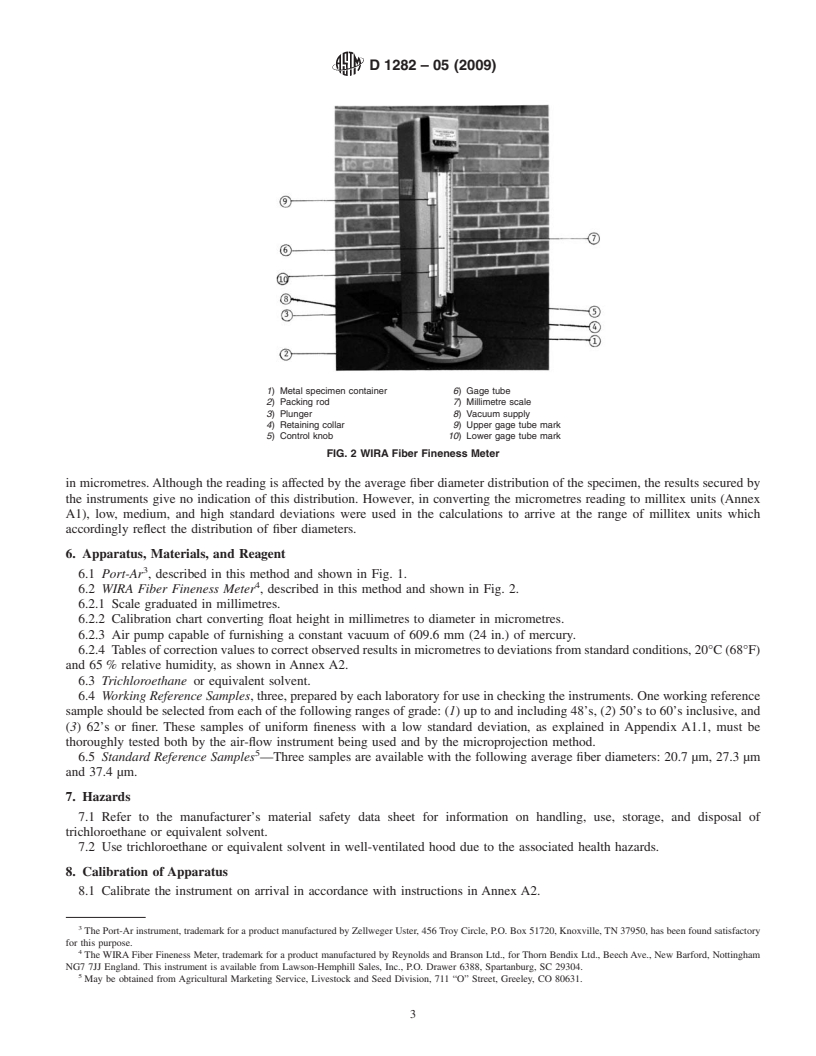

1) Metal specimen container 6) Gage tube

2) Packing rod 7) Millimetre scale

3) Plunger 8) Vacuum supply

4) Retaining collar 9) Upper gage tube mark

5) Control knob 10) Lower gage tube mark

FIG. 2 WIRA Fiber Fineness Meter

in micrometres.Although the reading is affected by the average fiber diameter distribution of the specimen, the results secured by

the instruments give no indication of this distribution. However, in converting the micrometres reading to millitex units (Annex

A1), low, medium, and high standard deviations were used in the calculations to arrive at the range of millitex units which

accordingly reflect the distribution of fiber diameters.

6. Apparatus, Materials, and Reagent

6.1 Port-Ar , described in this method and shown in Fig. 1.

6.2 WIRA Fiber Fineness Meter , described in this method and shown in Fig. 2.

6.2.1 Scale graduated in millimetres.

6.2.2 Calibration chart converting float height in millimetres to diameter in micrometres.

6.2.3 Air pump capable of furnishing a constant vacuum of 609.6 mm (24 in.) of mercury.

6.2.4 Tablesofcorrectionvaluestocorrectobservedresultsinmicrometrestodeviationsfromstandardconditions,20°C(68°F)

and 65% relative humidity, as shown in Annex A2.

6.3 Trichloroethane or equivalent solvent.

6.4 Working Reference Samples, three, prepared by each laboratory for use in checking the instruments. One working reference

sample should be selected from each of the following ranges of grade: (1) up to and including 48’s, (2) 50’s to 60’s inclusive, and

(3) 62’s or finer. These samples of uniform fineness with a low standard deviation, as explained in Appendix A1.1, must be

thoroughly tested both by the air-flow instrument being used and by the microprojection method.

6.5 Standard Reference Samples —Three samples are available with the following average fiber diameters: 20.7 µm, 27.3 µm

and 37.4 µm.

7. Hazards

7.1 Refer to the manufacturer’s material safety data sheet for information on handling, use, storage, and disposal of

trichloroethane or equivalent solvent.

7.2 Use trichloroethane or equivalent solvent in well-ventilated hood due to the associated health hazards.

8. Calibration of Apparatus

8.1 Calibrate the instrument on arrival in accordance with instructions in Annex A2.

The Port-Ar instrument, trademark for a product manufactured by Zellweger Uster, 456Troy Circle, P.O. Box 51720, Knoxville,TN 37950, has been found satisfactory

for this purpose.

The WIRAFiber Fineness Meter, trademark for a product manufactured by Reynolds and Branson Ltd., for Thorn Bendix Ltd., BeechAve., New Barford, Nottingham

NG7 7JJ England. This instrument is available from Lawson-Hemphill Sales, Inc., P.O. Drawer 6388, Spartanburg, SC 29304.

May be obtained from Agricultural Marketing Service, Livestock and Seed Division, 711 “O” Street, Greeley, CO 80631.

D 1282 – 05 (2009)

8.2 Recalibrate the instrument each day. Verify calibration after each 4h of use or whenever an operational problem is noted.

9. Sampling

9.1 Lot Sample—For acceptance testing, take at random the number of shipping containers directed in an applicable material

specification or other agreement between the purchaser and the supplier, such as an agreement to use Practice D1060. Consider

shipping containers to be the primary sampling units.

NOTE 2—A realistic specification or other agreement between the purchaser and the supplier requires taking into account the variability between

shipping containers, between laboratory samples within a shipping container, and between specimens within a laboratory sample so as to provide a

sampling plan which at the specified level of the property of interest has a meaningful producer’s risk, consumer’s risk, acceptable quality level, and

limiting quality level.

9.2 Laboratory Sample—As a laboratory sample for acceptance testing, take the number of subsamples from each package in

the lot sample as directed in an applicable material specification or other agreement between the purchaser and the supplier, such

as an agreement to use Practice D1060 if baled or bagged wool is to be tested.

9.3 Test Specimens:

9.3.1 Port-Ar Procedure—Take one specimen per laboratory sampling unit.

9.3.2 Wira Procedure—Take one specimen per laboratory sampling unit.

10. Specimen Preparation

10.1 Prepare test specimens of wool top, card sliver, scoured, or grease wool as directed in Test Method D2130.

10.2 If no mechanical card is available, take two subsamples of scoured wool, each weighing approximately 4g more than the

mass of wool required for measurement in the air-flow instrument being used; hand card these subsamples at least 30 strokes each

and prepare a test specimen from each of them.

10.3 Rinse all test specimens in the recommended solvent to reduce the extractable matter to less than 1% of the specimen

mass. Condition the test specimens as prescribed in 11.1 or 11.2. From the conditioned test specimen, weigh the amount of wool

required for measurement in the air-flow instrument being used.

10.3.1 Port-Ar—Placeapproximately12.5goftheconditionedwoolspecimeninthebalancebasket.Onepumpoftheatomizer

bulb will indicate whether the specimen is too light or too heavy: If the meter reads above the red triangle, the specimen is too

heavy;ifbelow,thespecimenistoolight.Adjustthespecimento12.5gbyaddingorremovingsmallamountsofwool.Themeter

indicates the mass of the specimen to within6 0.5% if the pointer is on scale, so the mass needs to be adjusted only until the

pointer reads within the red triangle.

NOTE 3—The accuracy of the balance should be thoroughly checked before and while using the Port-Ar.The specimen may be weighed on a separate

balance.

10.3.2 WIRA Fiber Fineness Meter—Weigh a 2.500 6 0.005 g test specimen. Remove pieces of vegetable matter and other

impurities before weighing.

11. Conditioning

11.1 For tests made on the Port-Ar as directed in 11.2, reasonable results may be obtained even if the standard atmosphere for

testing is not available since the instrument uses low-pressure ambient air. Keep the instrument in a draft-free room, away from

radiators,sunlight,andotherelementswhichdisturbtemperatureorair.Allowtheinstrumentandthewell-openedwooltobetested

to remain in the same atmospheric conditions for approximately 4h before the specimens are tested.

11.2 FortestsmadeontheWIRAFiberFinenessmeterasdirectedin12.2,bringthetestspecimentomoistureequilibriumwith

the standard atmosphere. A 4h conditioning period is usually sufficient.

12. Procedure

12.1 Procedure with the Port-Ar:

12.1.1 Wool Top, Card Sliver, Scoured Wool, Grease Wool—Using the weighed test specimen, (see 10.3.1) place one end of the

sliverinthechamberandtampintheremainder.Donotfoldthewooltopbeforeplacinginthechamber.Whenallofthespecimen

TABLE 1 Components Of Variance As Standard Deviations, µm

Single-Operator Within-Laboratory Between-Laboratory

Names Of The Properties

Component Component Component

Fiber diameter,

Port-Ar procedure

Single-material comparisons 0.21 0.20 0.72

Multi-material comparisons 0.00 0.20 0.74

Fiber diameter,

WIRA procedure

Single-material comparisons 0.23 0.11 0.37

Multi-material comparisons 0.13 0.11 0.38

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D1282–05 Designation: D 1282 – 05 (Reapproved 2009)

Standard Test Method for

Resistance to Airflow as an Indication of Average Fiber

Diameter of Wool Top, Card Sliver, and Scoured Wool

This standard is issued under the fixed designation D1282; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 ThistestmethodcoverstheestimationoftheaveragefiberdiameterofwoolfibersbyuseofthePort-ArandtheWIRAFiber

Fineness Meter instrument, which operate on the air-flow principle. Other air-flow instruments have not been tested with this

method. The method is directly applicable to non-medullated, carded wool and wool top.

1.2 This test method is applicable to grease wool and scoured wool after the samples of such materials have been prepared as

directed in Test Method D2130.

NOTE 1—The use of the Micronaire instrument for measuring the fineness of cotton fibers is covered in Test Method D1448.

The assignment of grade for wool and mohair is covered in Specifications D3991 and D3992 and D3992.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D1060 Practice for Core Sampling of Raw Wool in Packages for Determination of Percentage of Clean Wool Fiber Present

D1448 Test Method for Micronaire Reading of Cotton Fibers

D2130 Test Method for Diameter of Wool and Other Animal Fibers by Microprojection

D3991 Specifications for Fineness of Wool or Mohair and Assignment of Grade

D3992 Specifications for Fineness of Wool Top or Mohair Top and Assignment of Grade

D4845 Terminology for Wool Terminology Relating to Wool

2.2 Other Standard:

IWTO-6-92(E) Method of Test for the Determination of The Mean Diameter of Wool Fibers in Combed Sliver Using the

Air-Flow Apparatus

IWTO-28-82(E) Determination By The Airflow Method of the Mean Fibre Diameter of Core Samples of Raw Wool

3. Terminology

3.1 For all terminology related to wool and wool felt, refer to Terminology D4845.

3.1.1 The following terms are relevant to this standard: sliver, specific area, top, and wool.

3.2 For all other terminology related to textiles, see Terminology D123.

4. Summary of Test Method

4.1 The resistance to air flow of predetermined mass of wool compressed to a fixed volume is measured. The instruments

approved for use have been calibrated to read average diameter in micrometres. Specimens of wool top are rated with aWoolTop

Scale and specimens of carded, scoured wool and scoured ⁄2-in. (13.0-mm) cores are rated with a Scoured Wool Scale. If

instruments are properly calibrated, results are interchangeable.

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.13 on Wool and Wool Felt .

Current edition approved March 1, 2005. PublishedApril 2005. Originally approved in 1953. Last previous edition approved in 2005 as D1282–96 (2005).on Wool and

Felt.

Current edition approved July 1, 2009. Published August 2009. Originally approved in 1953. Last previous edition approved in 2005 as D1282–05.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 1282 – 05 (2009)

5. Significance and Use

5.1 Thistestmethodisnotrecommendedfortheacceptancetestingofcommercialshipmentsofwooltop,cardsliver,orscoured

wool since the referee method, Test Method D2130, is recommended for that purpose. Although this test method is not

recommended for acceptance testing, it is useful for fast quality control checks.

5.1.1 .If there are differences of practical significance between reported test results for two laboratories (or more), comparative

test should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a

minimum, use the samples for such a comparative test that are as homogenous as possible, drawn from the same lot of material

as the samples that resulted in disparate results during initial testing and randomly assigned in equal numbers to each laboratory.

The test results from the laboratories involved should be compared using a statistical test for unpaired data, a probability level

chosenpriortothetestingseries.Ifbiasisfound,eitheritscausemustbefoundandcorrected,orfuturetestresultsforthatmaterial

must be adjusted in consideration of the known bias.

5.2 The specific area of the wool fibers is measured by the resistance in air flow. The resistance to air flow has been related to

average fiber diameter measured by the microprojection method. The instruments have been calibrated to read average diameter

in micrometres.Although the reading is affected by the average fiber diameter distribution of the specimen, the results secured by

the instruments give no indication of this distribution. However, in converting the micrometres reading to millitex units (Annex

A1), low, medium, and high standard deviations were used in the calculations to arrive at the range of millitex units which

accordingly reflect the distribution of fiber diameters.

6. Apparatus, Materials, and Reagent

6.1 Port-Ar , described in this method and shown in Fig. 1.

6.2 WIRA Fiber Fineness Meter , described in this method and shown in Fig. 2.

6.2.1 Scale graduated in millimetres.

6.2.2 Calibration chart converting float height in millimetres to diameter in micrometres.

The Port-Ar instrument, trademark for a product manufactured by Zellweger Uster, 456Troy Circle, P.O. Box 51720, Knoxville,TN 37950, has been found satisfactory

for this purpose.

The WIRAFiber Fineness Meter, trademark for a product manufactured by Reynolds and Branson Ltd., for Thorn Bendix Ltd., BeechAve., New Barford, Nottingham

NG7 7JJ England. This instrument is available from Lawson-Hemphill Sales, Inc., P.O. Drawer 6388, Spartanburg, SC 29304.

1) Balance Adjustment Knob 8) Porosity Calibration Control

2) Balance Pan 9) Compression Lever

3) Air Reservoir 10) Calibrator Plug Plunger

4) Meter Zero Adjustment Screw 11) Porosity Calibrator Plug

5) Porosity Test Chamber Lid 12) Calibration Weight

6) Differential Pressure Gage 13) Weighing Balance Mechanism

7) Porosity Zero Control 14) Atomizer Bulb

FIG. 1 Port-Ar Apparatus

D 1282 – 05 (2009)

1) Metal specimen container 6) Gage tube

2) Packing rod 7) Millimetre scale

3) Plunger 8) Vacuum supply

4) Retaining collar 9) Upper gage tube mark

5) Control knob 10) Lower gage tube mark

FIG. 2 WIRA Fiber Fineness Meter

6.2.3 Air pump capable of furnishing a constant vacuum of 609.6 mm (24 in.) of mercury.

6.2.4 Tablesofcorrectionvaluestocorrectobservedresultsinmicrometrestodeviationsfromstandardconditions,20°C(68°F)

and 65% relative humidity, as shown in Annex A2.

6.3 Trichloroethane or equivalent solvent.

6.4 Working Reference Samples, three, prepared by each laboratory for use in checking the instruments. One working reference

sample should be selected from each of the following ranges of grade: (1) up to and including 48’s, (2) 50’s to 60’s inclusive, and

(3) 62’s or finer. These samples of uniform fineness with a low standard deviation, as explained in Appendix A1.1, must be

thoroughly tested both by the air-flow instrument being used and by the microprojection method.

6.5 Standard Reference Samples —Three samples are available with the following average fiber diameters: 20.7 µm, 27.3 µm

and 37.4 µm.

7. Hazards

7.1 Refer to the manufacturer’s material safety data sheet for information on handling, use, storage, and disposal of

trichloroethane or equivalent solvent.

7.2 Use trichloroethane or equivalent solvent in well-ventilated hood due to the associated health hazards.

8. Calibration of Apparatus

8.1 Calibrate the instrument on arrival in accordance with instructions in Annex A2.

8.2 Recalibrate the instrument each day. Verify calibration after each 4h of use or whenever an operational problem is noted.

9. Sampling

9.1 Lot Sample—For acceptance testing, take at random the number of shipping containers directed in an applicable material

specification or other agreement between the purchaser and the supplier, such as an agreement to use Practice D1060. Consider

shipping containers to be the primary sampling units.

NOTE 2—A realistic specification or other agreement between the purchaser and the supplier requires taking into account the variability between

shipping containers, between laboratory samples within a shipping container, and between specimens within a laboratory sample so as to provide a

sampling plan which at the specified level of the property of interest has a meaningful producer’s risk, consumer’s risk, acceptable quality level, and

limiting quality level.

9.2 Laboratory Sample—As a laboratory sample for acceptance testing, take the number of subsamples from each package in

the lot sample as directed in an applicable material specification or other agreement between the purchaser and the supplier, such

as an agreement to use Practice D1060 if baled or bagged wool is to be tested.

May be obtained from Agricultural Marketing Service, Livestock and Seed Division, 711 “O” Street, Greeley, CO 80631.

D 1282 – 05 (2009)

9.3 Test Specimens:

9.3.1 Port-Ar Procedure—Take one specimen per laboratory sampling unit.

9.3.2 Wira Procedure—Take one specimen per laboratory sampling unit.

10. Specimen Preparation

10.1 Prepare test specimens of wool top, card sliver, scoured, or grease wool as directed in Test Method D2130.

10.2 If no mechanical card is available, take two subsamples of scoured wool, each weighing approximately 4g more than the

mass of wool required for measurement in the air-flow instrument being used; hand card these subsamples at least 30 strokes each

and prepare a test specimen from each of them.

10.3 Rinse all test specimens in the recommended solvent to reduce the extractable matter to less than 1% of the specimen

mass. Condition the test specimens as prescribed in 11.1 or 11.2. From the conditioned test specimen, weigh the amount of wool

required for measurement in the air-flow instrument being used.

10.3.1 Port-Ar—Placeapproximately12.5goftheconditionedwoolspecimeninthebalancebasket.Onepumpoftheatomizer

bulb will indicate whether the specimen is too light or too heavy: If the meter reads above the red triangle, the specimen is too

heavy;ifbelow,thespecimenistoolight.Adjustthespecimento12.5gbyaddingorremovingsmallamountsofwool.Themeter

indicates the mass of the specimen to within6 0.5% if the pointer is on scale, so the mass needs to be adjusted only until the

pointer reads within the red triangle.

NOTE 3—The accuracy of the balance should be thoroughly checked before and while using the Port-Ar.The specimen may be weighed on a separate

balance.

10.3.2 WIRA Fiber Fineness Meter—Weigh a 2.500 6 0.005 g test specimen. Remove pieces of vegetable matter and other

impurities before weighing.

11. Conditioning

11.1 For tests made on the Port-Ar as directed in 11.2, reasonable results may be obtained even if the standard atmosphere for

testing is not available since the instrument uses low-pressure ambient air. Keep the instrument in a draft-free room, away from

radiators,sunlight,andotherelementswhichdisturbtemperatureorair.Allowtheinstrumentandthewell-openedwooltobetested

to remain in the same atmospheric conditions for approximately 4h before the specimens are tested.

11.2 FortestsmadeontheWIRAFiberFinenessmeterasdirectedin12.2,bringthetestspecimentomoistureequilibriumwith

the standard atmosphere. A 4h conditioning period is usually sufficient.

12. Procedure

12.1 Procedure with the Port-Ar:

12.1.1 Wool Top, Card Sliver, Scoured Wool, Grease Wool—Using the weighed test specimen, (see 10.3.1) place one end of the

sliverinthechamberandtampintheremainder.Donotfoldthewooltopbeforeplacinginthechamber.Whenallofthespecimen

has been forced into the chamber, close the compression chamber lid, 5, in place. Pull forward on the compression lever, 9, until

it locks in place. Apply air pressure either by the atomizer bulb or by the electric pump to fill the pressure tank (Note 3). Read

the diameter in micrometres on the scale as the piston settles. Record the reading and remove the specimen, carefully reopen it

by hand to eliminate compact areas, replace the specimen in the chamber and make a second reading.

NOTE 4—In using the electric pump, some operators find continuous operation advantageous. Satisfactory results will be obtained in this case if

calibrationadjustmentsarealsomadewiththepumprunningcontinuously.Asmallreservoirtankor“bladder”mountedintheairlinebetweenthepump

and the instrument will reduce needle vibration.

NOTE 5—Port-ArinstrumentdescribedinFig.1iscalibratedforwoolgrade(Topandwool).Port-Arinstrumentisalsoavailableformeasuringmohair

fibers.

12.2 Procedure with the WIRA Fiber Fineness Meter:

12.2.1 Feed the weighed specimen into the metal container, meanwhile pushing the wool down evenly into the container with

the short end of the rod provided. It is important to use this rod and nothing else for packing since it prevents tight packing of the

TABLE 1 Components Of Variance As Standard Deviations, µm

Single-Operator Within-Laboratory Between-Laboratory

Names Of The Properties

Component Component Component

Fiber diameter,

Port-Ar procedure

Single-material comparisons 0.21 0.20 0.72

Multi-material comparisons 0.00 0.20 0.74

Fiber diameter,

WIRA procedure

Single-material comparisons 0.23 0.11 0.37

Multi-material comparisons 0.13 0.11 0.38

D 1282 – 05 (2009)

A

TABLE 2 Critical Differences, µm, For The Conditions Noted

Number Of

Single-Operator Within-Labora- Between-Labora-

Names Of The Properties Observations In

Precision tory Precision tory Precision

Each Average

Fib

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.