ASTM G143-03(2013)

(Test Method)Standard Test Method for Measurement of Web/Roller Friction Characteristics

Standard Test Method for Measurement of Web/Roller Friction Characteristics

SIGNIFICANCE AND USE

5.1 This test method is intended to simulate the slip of a flexible web on a roller in a machine or tribosystem that conveys web materials. Flexible webs such as plastic sheeting, paper, elastomers, metal foils, and cloth are often transported in manufacturing processes by combinations of driving and idler rollers. The friction characteristics of the web/roller interface often affects the web transport process. If the web/roller friction is too low, the web can slip on the rollers and be damaged or damage the roller. High friction on the other hand, can lead to steering problems and overloading of driving motors.

5.2 This test method can be used to rank rollers for their ability to resist slip versus a particular web material (high friction). Conversely this test method can assess web materials or web surface coatings such as waxes and lubricants. In this latter case, the goal may be a low-friction product made from a web (film, magnetic media, paper, and so forth).

5.3 If a tribosystem involves transport of a flexible web on a roller, this is an appropriate test to use to measure the friction characteristics of the roller/web couple.

SCOPE

1.1 This test method covers the simulation of a roller/web transport tribosystem and the measurement of the static and kinetic coefficient of friction of the web/roller couple when sliding occurs between the two. The objective of this test method is to provide users with web/roller friction information that can be used for process control, design calculations, and for any other function where web/roller friction needs to be known.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G143 − 03 (Reapproved 2013)

Standard Test Method for

Measurement of Web/Roller Friction Characteristics

This standard is issued under the fixed designation G143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G115 Guide for Measuring and Reporting Friction Coeffi-

cients

1.1 This test method covers the simulation of a roller/web

G117 Guide for Calculating and Reporting Measures of

transport tribosystem and the measurement of the static and

Precision Using Data from Interlaboratory Wear or Ero-

kinetic coefficient of friction of the web/roller couple when

sion Tests

sliding occurs between the two. The objective of this test

G163 Guide for Digital Data Acquisition in Wear and

method is to provide users with web/roller friction information

Friction Measurements

that can be used for process control, design calculations, and

for any other function where web/roller friction needs to be

3. Terminology

known.

3.1 Definitions of Terms Specific to This Standard:

1.2 The values stated in SI units are to be regarded as

3.1.1 blocking, n—unintentional adhesion between plastic

standard. No other units of measurement are included in this

films or between a film and another surface. D883

standard.

3.1.2 coeffıcient of friction, µ, n—in tribology—the dimen-

1.3 This standard does not purport to address all of the

sionlessratioofthefrictionforce(F)betweentwobodiestothe

safety concerns, if any, associated with its use. It is the

normal force (N) pressing these bodies together. G40

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3.1.3 friction force, n—the resisting force tangential to the

bility of regulatory limitations prior to use.

interface between two bodies when, under the action of

external force, one body moves or tends to move relative to the

2. Referenced Documents

other. G40

2.1 ASTM Standards:

3.1.4 kinetic coeffıcient of friction, n—the coefficient of

D883 Terminology Relating to Plastics

friction under conditions of macroscopic relative motion be-

D1894 Test Method for Static and Kinetic Coefficients of

tween two bodies. G40

Friction of Plastic Film and Sheeting

3.1.5 stick-slip, n—a cyclic fluctuation in the magnitudes of

D3108 Test Method for Coefficient of Friction,Yarn to Solid

friction force and relative velocity between two elements in

Material

sliding contact, usually associated with a relaxation oscillation

E8 Test Methods for Tension Testing of Metallic Materials

dependent on elasticity in the tribosystem and on a decrease of

E122 Practice for Calculating Sample Size to Estimate,With

the coefficient of friction with onset of sliding or with increase

Specified Precision, the Average for a Characteristic of a

of sliding velocity. G40

Lot or Process

3.1.5.1 Discussion—Classical or true stick-slip, in which

E177 Practice for Use of the Terms Precision and Bias in

each cycle consists of a stage of actual stick followed by a

ASTM Test Methods

stage of overshoot slip, requires that the kinetic coefficient is

E691 Practice for Conducting an Interlaboratory Study to

lower than the static coefficient.Amodified form of relaxation

Determine the Precision of a Test Method

oscillation, with near-harmonic fluctuation in motion, can

G40 Terminology Relating to Wear and Erosion

occur when the kinetic coefficient of friction decreases gradu-

ally with increasing velocity within a certain velocity range.A

1 third type of stick-slip can be due to spatial periodicity of the

This test method is under the jurisdiction of ASTM Committee G02 on Wear

and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

friction coefficient along the path of contact. Random varia-

Current edition approved Nov. 15, 2013. Published November 2013. Originally

tions in friction force measurement do not constitute stick-slip.

approved in 1996. Last previous edition approved in 2009 as G143–03(2009). DOI:

10.1520/G0143-03R13.

3.1.6 triboelement, n—one of two or more solid bodies

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

which comprise a sliding, rolling, or abrasive contact, or a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

body subjected to impingement or cavitation. G40

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 3.1.6.1 Discussion—Contacting triboelements may be in

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G143 − 03 (2013)

direct contact, or may be separated by an intervening lubricant,

oxide, or other film that affects tribological interactions be-

tween them.

3.1.7 tribosystem, n—any system that contains one or more

triboelements, including all mechanical, chemical, and envi-

ronmental factors relevant to tribological behavior. G40

4. Summary of Test Method

4.1 This test method can be used to measure the friction

characteristics of a flexible web as it slides on a cylindrical

surface.Thewebconformstothecylindricalsurfaceinthearea

of wrap.

4.2 The test method is conducted on a narrow web or strip

taken from a web of interest. One end of the strip is draped

over a stationary cylinder and the other end is affixed to a force

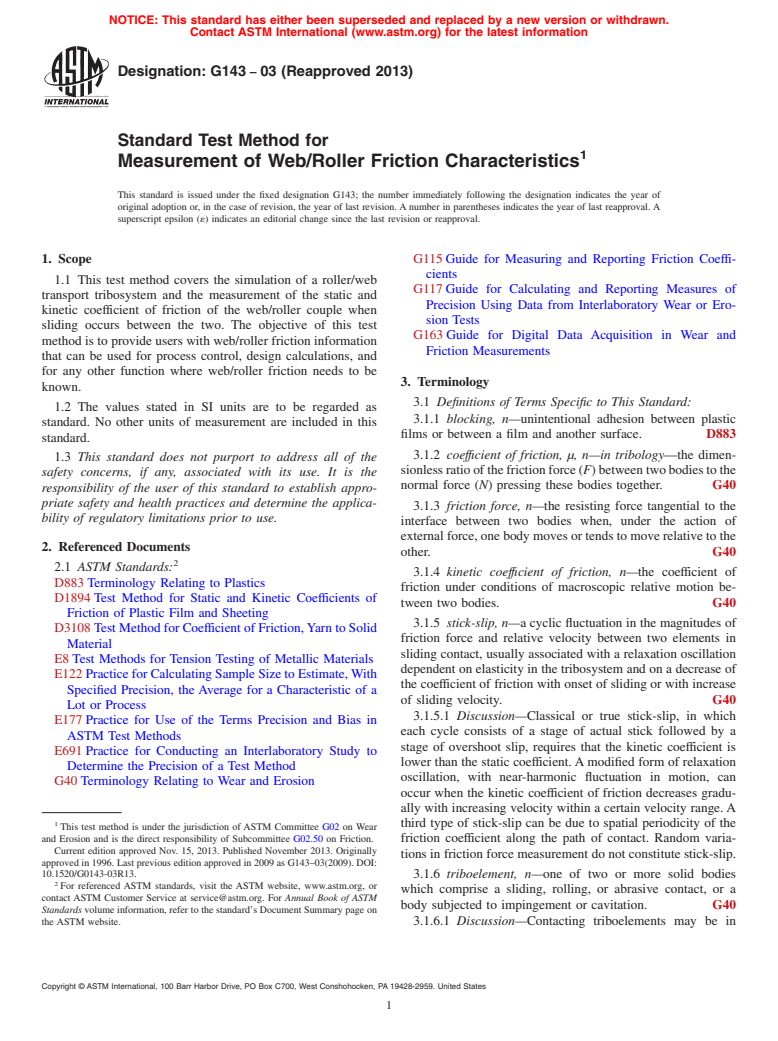

FIG. 1 Schematic of Capstan Friction Test

measuring device.Amass is applied to the free end of the strip

and the strip is pulled by a mechanism that moves the force

transducer perpendicular to the long axis of the cylindrical

surface. The force encountered in pulling the strip in contact

with the stationary cylinder (roller) is continuously measured

and recorded. The static and kinetic coefficients of friction are

calculated from the force measured by the force transducer.

5. Significance and Use

5.1 This test method is intended to simulate the slip of a

flexible web on a roller in a machine or tribosystem that

conveys web materials. Flexible webs such as plastic sheeting,

paper,elastomers,metalfoils,andclothareoftentransportedin

manufacturing processes by combinations of driving and idler

rollers. The friction characteristics of the web/roller interface

often affects the web transport process. If the web/roller

friction is too low, the web can slip on the rollers and be

damaged or damage the roller. High friction on the other hand,

can lead to steering problems and overloading of driving

motors.

5.2 This test method can be used to rank rollers for their

ability to resist slip versus a particular web material (high

FIG. 2 Use of Tensile Test Machine to Perform the Capstan Fric-

friction). Conversely this test method can assess web materials tion Test

or web surface coatings such as waxes and lubricants. In this

latter case, the goal may be a low-friction product made from

6.2 Force Measurement—Commercially available or home-

a web (film, magnetic media, paper, and so forth).

made strain gage or similar force transducers are acceptable.

5.3 If a tribosystem involves transport of a flexible web on

The device should be linear in the force range anticipated in

a roller, this is an appropriate test to use to measure the friction

testing and the transducer shall be calibrated with known

characteristics of the roller/web couple.

masses or a similar system for each use.

6.2.1 Force transducers shall be accurate within 1 % of the

6. Apparatus

rated scale of the device and should have overload protection.

The friction force during the entire test should be recorded.

6.1 Two possible configurations of the test are shown in

(Warning—Digital filters can alter the force data to the point

Figs. 1 and 2. The essential features of the apparatus are:

where the data are not valid.Analog strip chart recorders have

6.1.1 A force measuring device attached to one member of

been shown to be acceptable recording devices for this test

the friction couple,

method. (See Guide G163 for details on digital data acquisi-

6.1.2 A stationary cylindrical surface to be used as one

tion))

member of the friction couple,

6.1.3 A system to move the flexible strip (web) member of

6.3 Cylindrical Surface—The recommended diameter of the

the friction couple, and test cylinder should be the same diameter as the rollers or

6.1.4 Masses to be used to tension the free end of the test curved surface that is simulated in the friction test. The

strip. cylinder surface texture and material of construction should be

G143 − 03 (2013)

the same as the tribosystem of interest. If materials are being 7. Test Procedure

evaluated without simulating a particular tribosystem, the test

7.1 Specimen Preparation:

roller can be the same as the roller used in the interlaboratory

7.1.1 Clean the roller surface in a manner that is consistent

tests of this test method: 100-mm diameter (100 mm long),

with the application that is under simulation. Cut virgin strips

50-µm thick hard coated (thick hard anodize) 6061-T6 alumi-

from the test web as the other friction member. Take care not

num with a surface roughness of 0.75 to 1 µm Ra (measured

to fingerprint or alter the test surface in handling the web.

parallel to the cylinder’s axis; surface was lathe generated).

Convenient sample dimensions are 25 mm wide with a length

6.4 Sliding Motion—The device shown schematically in

of about 500 mm. Practice E122 or other statistical methods

Fig. 1 uses a linear motor to pull the test strip. The cylinder is

can be used to determine the necessary number of test

stationary. Any device with controlled acceleration and veloc-

replicates. Three is the minimum.

ity is acceptable.Aball screw driven by a variable speed motor

7.1.2 Do not clean the web specimen unless that is part of

is suitable as is the crosshead on a tensile testing machine. In

thestudy.Ifpaperorplasticsheetsarebeingtested,theyshould

the latter case, it may be necessary to use a sheave with a

be tested with untouched as-manufactured surfaces. Cut the

free-wheeling rolling element bearing to transfer the motion

web specimen in such a fashion that there is no edge burr on

from a vertical to horizontal plane (see Fig. 2).

the side that contacts the roller. This is extremely important.

Ensure that the edges of the strip are parallel and in the desired

NOTE 1—Some devices rotate the cylinder and hold the web with a

force transducer. This was done in interlaboratory tests and produced the orientation with respect to the long axis of the host web. A

same results as pulling the web over a stationary cylinder.

useful tool for sample preparation is to affix two single-edged

razor blades to a block of wood spaced at the desired strip

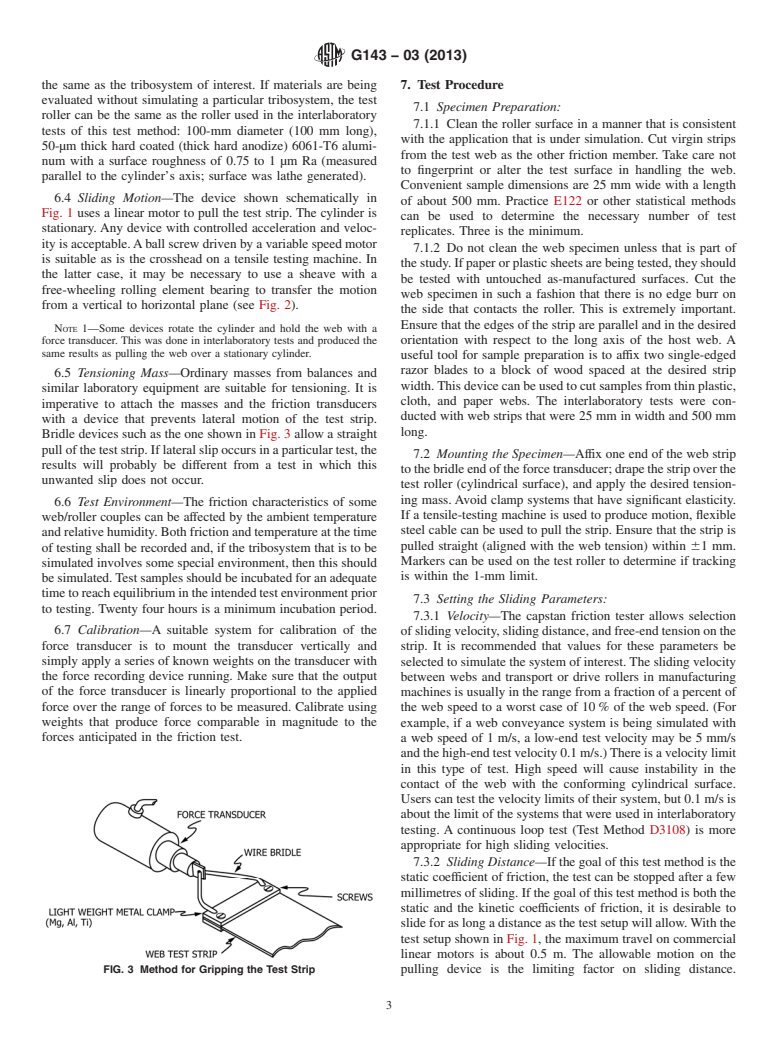

6.5 Tensioning Mass—Ordinary masses from balances and

width.Thisdevicecanbeusedtocutsamplesfromthinplastic,

similar laboratory equipment are suitable for tensioning. It is

cloth, and paper webs. The interlaboratory tests were con-

imperative to attach the masses and the friction transducers

ducted with web strips that were 25 mm in width and 500 mm

with a device that prevents lateral motion of the test strip.

long.

Bridle devices such as the one shown in Fig. 3 allow a straight

pulloftheteststrip.Iflateralslipoccursinaparticulartest,the

7.2 Mounting the Specimen—Affix one end of the web strip

results will probably be different from a test in which this

tothebridleendoftheforcetransducer;drapethestripoverthe

unwanted slip does not occur.

test roller (cylindrical surface), and apply the desired tension-

ing mass.Avoid clamp systems that have significant elasticity.

6.6 Test Environment—The friction characteristics of some

If a tensile-testing machine is used to produce motion, flexible

web/roller couples can be affected by the ambient temperature

steel cable can be used to pull the strip. Ensure that the strip is

andrelativehumidity.Bothfrictionandtemperatureatthetime

pulled straight (aligned with the web tension) within 61 mm.

of testing shall be recorded and, if the tribosystem that is to be

Markers can be used on the test roller to determine if tracking

simulated involves some special environment, then this should

is within the 1-mm limit.

besimulated.Testsamplesshouldbeincubatedforanadequate

timetoreachequilibriumintheintendedtestenvironmentprior

7.3 Setting the Sliding Parameters:

to testing. Twenty four hours is a minimum incubation period.

7.3.1 Velocity—The capstan friction tester allows selection

6.7 Calibration—A suitable system for calibration of the ofslidingvelocity,slidingdistance,andfree-endtensiononthe

force transducer is to mount the transducer vertically and

strip. It is recommended that values for these parameters be

simply apply a series of known weights on the transducer with selected to simulate the system of interest.The sliding velocity

the force recording device running. Make sure that the output

between webs and transport or drive rollers in manufacturing

of the force transducer is linearly proportional to the applied machines is usually in the range from a fraction of a percent of

force over the range of forces to be measured. Calibrate using

the web speed to a worst case of 10 % of the web speed. (For

weights that produce force comparable in magnitude to the example, if a web conveyance system is being simulated with

forces anticipated in the friction test.

a web speed of 1 m/s, a low-end test velocity may be 5 mm/s

andthehigh-endtestvelocity0.1m/s.)Thereisavelocitylimit

in this type of test. High speed will cause instability in the

contact of the web with the conforming cylindrical surface.

Users can test the velocity limits of their system, but 0.1 m/s is

about the limit of the systems that were used in interlaboratory

testing. A continuous loop test (Test Method D3108) is more

appropriate for high sliding velocities.

7.3.2 Sliding Distance—If the goal of this test method is the

static coefficient of friction, the test can be stopped after a few

millimetres of sliding. If the goal of this test method is both the

static and the kinetic coefficients of friction, it is desirable to

slide for as long a distance as the test setup will allow.With the

test setup shown in Fig. 1, the maximum travel on commercial

linear motors is about 0.5 m. The allowable motion on the

FIG. 3 Method for Gripping the Test Strip pulling device is the limiting factor on sliding distance.

G143 − 03 (2013)

Interlaboratory tests were conducted with a sliding distance of

T = force applied to the free end of the web by the hanging

150mm.Thisistherecommendeds

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.