ASTM A524-96(2005)

(Specification)Standard Specification for Seamless Carbon Steel Pipe for Atmospheric and Lower Temperatures

Standard Specification for Seamless Carbon Steel Pipe for Atmospheric and Lower Temperatures

ABSTRACT

This specification covers seamless carbon steel pipe intended primarily service at atmospheric and lower temperatures. The steel shall be killed steel made by one or more of the following processes: open-hearth, electric-furnace, or basic-oxygen. The steel shall be made to fine grain practice and may be cast in ingots or may be strand cast. All hot-finished and cold-drawn pipe shall be heat treated and be cooled in air or in the cooling chamber of a controlled atmosphere furnace. The steel shall be subjected to flattening, hydrostatic, bend, and tensile tests. A retest shall be conducted if a specimen breaks in an inside or outside surface flaw.

SCOPE

1.1 This specification covers seamless carbon steel pipe intended primarily for service at atmospheric and lower temperatures, NPS 1/8 to 26 inclusive, with nominal (average) wall thickness as given in ANSI B36.10. Pipe having other dimensions may be furnished, provided such pipe complies with all other requirements of this specification. Pipe ordered to this specification shall be suitable both for welding, and for bending, flanging, and similar forming operations.

1.2 The values stated in inch-pound units are to be regarded as the standard.

Note 1—The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as "nominal diameter," "size," and "nominal size".

1.3 The following hazard caveat applies to the test methods portion, Section 16, only. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A524 −96(Reapproved 2005)

Standard Specification for

Seamless Carbon Steel Pipe for Atmospheric and Lower

1

Temperatures

This standard is issued under the fixed designation A524; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 American National Standards Institute Standard:

4

B36.10Welded and Seamless Wrought Steel Pipe

2

1.1 This specification covers seamless carbon steel pipe

intended primarily for service at atmospheric and lower

3. Ordering Information

1

temperatures, NPS ⁄8 to 26 inclusive, with nominal (average)

3.1 Orders for material under this specification should

wall thickness as given in ANSI B36.10. Pipe having other

include the following, as required, to describe the desired

dimensions may be furnished, provided such pipe complies

material adequately:

with all other requirements of this specification. Pipe ordered

3.1.1 Quantity (feet or number of lengths),

to this specification shall be suitable both for welding, and for

3.1.2 Name of material (seamless carbon steel pipe),

bending, flanging, and similar forming operations.

3.1.3 Grade (Table 1 and Table 2),

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

3.1.4 Manufacture (hot finished or cold drawn),

as standard. The values given in parentheses are mathematical

3.1.5 Size(eithernominalwallthicknessandweightclassor

conversions to SI units that are provided for information only

schedule number, or both, or outside diameter and nominal

and are not considered standard.

wall thickness, ANSI B36.10),

3.1.6 Length (17),

NOTE 1—The dimensionless designator NPS (nominal pipe size) has

3.1.7 Optional requirements ( Section 8 and Section 11 of

been substituted in this standard for such traditional terms as “nominal

diameter,” “size,” and “nominal size.” Specification A530/A530M),

3.1.8 Test report required (Certification Section of Specifi-

1.3 The following hazard caveat applies to the test methods

cation A530/A530M),

portion, Section 16, only.This standard does not purport to

3.1.9 Specification designation,

address all of the safety concerns, if any, associated with its

3.1.10 End use of material, and

use. It is the responsibility of the user of this standard to

3.1.11 Special requirements.

establish appropriate safety and health practices and deter-

mine the applicability of regulatory limitations prior to use.

4. General Requirements

4.1 Material furnished to this specification shall conform to

2. Referenced Documents

the applicable requirements of the current edition of Specifi-

3

2.1 ASTM Standards:

cation A530/A530M unless otherwise provided herein.

A530/A530MSpecification for General Requirements for

Specialized Carbon and Alloy Steel Pipe

5. Materials and Manufacture

E29Practice for Using Significant Digits in Test Data to

5.1 Process:

Determine Conformance with Specifications

5.1.1 The steel shall be killed steel made by one or more of

the following processes: open-hearth, electric-furnace, or

basic-oxygen.

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

5.1.2 The steel shall be made to fine grain practice.

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

5.1.3 Steel may be cast in ingots or may be strand cast.

A01.09 on Carbon Steel Tubular Products.

When steel of different grades are sequentially strand cast,

Current edition approved Oct. 1, 2005. Published November 2005. Originally

approved in 1965. Last previous edition approved in 2001 as A524–96 (2001). identification of the resultant transition material is required.

DOI: 10.1520/A0524-96R05.

The producer shall remove the transition material by any

2

For ASME Boiler and Pressure Vessel Code Applications see related Specifi-

established procedure that positively separates the grades.

cation SA-524 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute, 11 West 42nd St., 13th

the ASTM website. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A524−96 (2005)

TABLE 1 Chemical Requirements

180° around a cylindrical mandrel, the diameter of which is

Element Grades I and II, Composition, % eight times the nominal diameter of the pipe, without failure.

Carbon, max 0.21

9.2.2 Forpipewhosediameterexceeds25in.(635mm)an

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 524–96 (Reapproved 2001) Designation: A524 – 96 (Reapproved 2005)

Standard Specification for

Seamless Carbon Steel Pipe for Atmospheric and Lower

1

Temperatures

This standard is issued under the fixed designation A524; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

2

1.1 This specification covers seamless carbon steel pipe intended primarily for service at atmospheric and lower temperatures,

1

NPS ⁄8 to 26 inclusive, with nominal (average) wall thickness as given in ANSI B36.10. Pipe having other dimensions may be

furnished, provided such pipe complies with all other requirements of this specification. Pipe ordered to this specification shall be

suitable both for welding, and for bending, flanging, and similar forming operations.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

NOTE 1—The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as “nominal diameter,”

“size,” and “nominal size”. size.”

1.3 The following hazard caveat applies to the test methods portion, Section 16, only.Thisstandarddoesnotpurporttoaddress

all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate

safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

A530/A530M Specification for General Requirements for Specialized Carbon and Alloy Steel Pipe

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

2.2 American National Standards Institute Standard:

4

B36.10 Welded and Seamless Wrought Steel Pipe

3. Ordering Information

3.1 Orders for material under this specification should include the following, as required, to describe the desired material

adequately:

3.1.1 Quantity (feet or number of lengths),

3.1.2 Name of material (seamless carbon steel pipe),

3.1.3 Grade (Table 1 and Table 2),

3.1.4 Manufacture (hot finished or cold drawn),

3.1.5 Size (either nominal wall thickness and weight class or schedule number, or both, or outside diameter and nominal wall

thickness, ANSI B36.10),

3.1.6 Length (17),

3.1.7 Optional requirements ( Section 8 and Section 11 of Specification A 530/A 530MA530/A530M),

3.1.8 Test report required (Certification Section of Specification A 530/A 530MA530/A530M),

3.1.9 Specification designation,

3.1.10 End use of material, and

3.1.11 Special requirements.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel,Steel and Related Alloys,Alloys and is the direct responsibility of

Subcommittee A01.09 on Carbon Steel Tubular Products.

Current edition approved Oct. 10, 1996. Published November 1997. Originally published as A 524–65. Last previous edition A 524–93.

Current edition approved Oct. 1, 2005. Published November 2005. Originally approved in 1965. Last previous edition approved in 2001 as A524 – 96 (2001). DOI:

10.1520/A0524-96R05.

2

For ASME Boiler and Pressure Vessel Code Applications see related Specification SA-524 in Section II of that Code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 01.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Annual Book of ASTM Standards, Vol 14.02.

4

Available from American National Standards Institute, 11 West 42nd St., 13th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A524 – 96 (2005)

TABLE 1 Chemical Requirements

Element Grades I and II, Composition, %

Carbon, max 0.21

Manganese 0.90–1.35

Phosphorus, max 0.035

Sulfur, max 0.035

Silicon 0.10–0.40

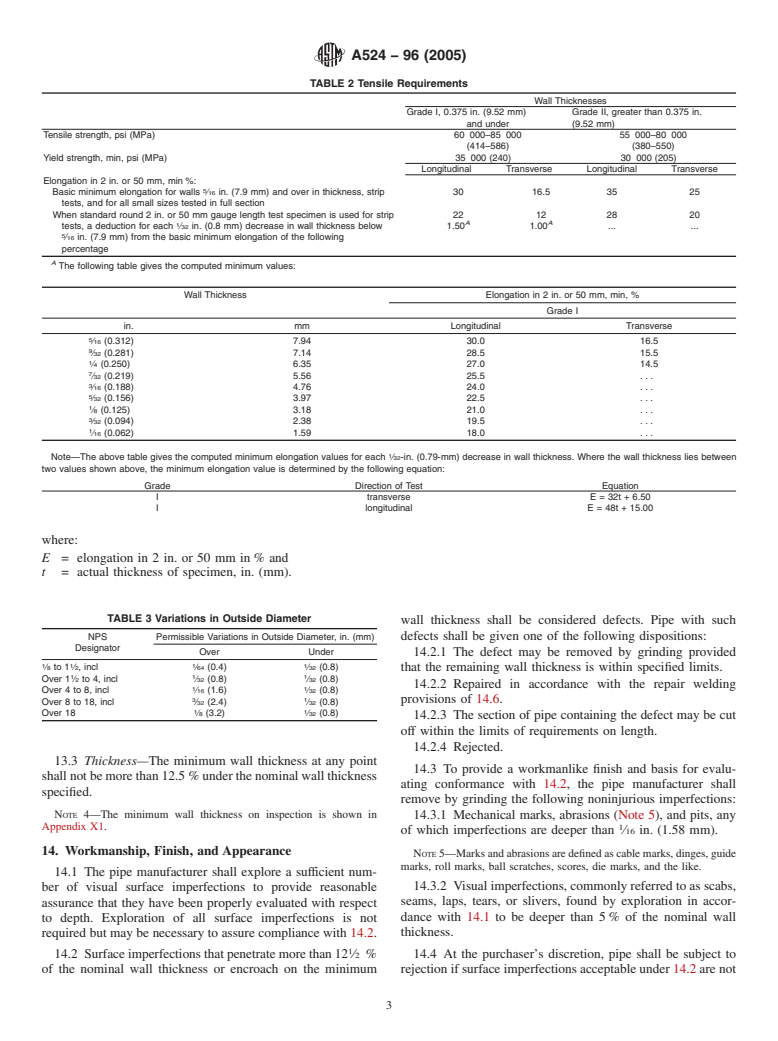

TABLE 2 Tensile Requirements

Wall Thicknesses

Grade I, 0.375 in. (9.52 mm) Grade II, greater than 0.375 in.

and under (9.52 mm)

Tensile strength, psi (MPa) 60 000–85 000 55 000–80 000

(414–586) (380–550)

Yield strength, min, psi (MPa) 35 000 (240) 30 000 (20

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.