ASTM A521/A521M-06

(Specification)Standard Specification for Steel, Closed-Impression Die Forgings for General Industrial Use

Standard Specification for Steel, Closed-Impression Die Forgings for General Industrial Use

ABSTRACT

This specification covers untreated and heat-treated steel closed-impression die forgings for general industrial use. The Grades of forgings are as follows: Grades CA, CC, CC1, CE, CF, CF1, CG, AA, AB, AC, AD, AE, AF, AG, and AH. These Grades shall be annealed, normalized, tempered and quenched. The manufactured forgings shall be free from harmful surface discontinuities, roughness, excessive scale, and fins which are indications of overheating, burning, or other injurious conditions. A tensile test shall be done in order to determine the yield strength of the heat-treated forgings. The forgings shall be furnished in a scale-free condition and may be cleaned by acid pickling, grit blasting, sand blasting, or other abrasive method.

SCOPE

1.1 This specification covers untreated and heat-treated steel, closed-impression die forgings (Note 1) for general industrial use. Note 1—For the definition of a forging, refer General Requirements Specification A 788/A 788M.

1.2 The Grades of forgings are as follows, the choice depending on design and stress or service to be imposed:

1.2.1 Grade CA Untreated, carbon steel forgings,

1.2.2 Grades CC, CC1, and CE Annealed, normalized and tempered, carbon steel forgings,

1.2.3 Grade CF Normalized and tempered carbon steel forgings,

1.2.4 Grade CF1 Double normalized and tempered carbon steel forgings,

1.2.5 Grade CG Quenched and tempered, or normalized, quenched and tempered carbon steel forgings,

1.2.6 Grade AA Annealed, normalized, or normalized and tempered alloy steel forgings,

1.2.7 Grades AB and AC Normalized and tempered alloy steel forgings, and

1.2.8 Grades AD, AE, AF, AG, and AH Normalized, quenched, and tempered alloy steel forgings.

1.3 Unless the order specifies the applicable "M" specification designation, the forgings shall be furnished with the inch-pound units.

1.4 The values stated in either inch-pound units or SI (metric) units are to be regarded separately as standard. Within the text and tables, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A521/A521M – 06

Standard Specification for

Steel, Closed-Impression Die Forgings for General Industrial

1

Use

This standard is issued under the fixed designationA521/A521M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers untreated and heat-treated 2.1 ASTM Standards:

steel, closed-impression die forgings (Note 1) for general A29/A29M Specification for Steel Bars, Carbon andAlloy,

industrial use. Hot-Wrought, General Requirements for

A275/A275M Practice for Magnetic Particle Examination

NOTE 1—For the definition of a forging, refer General Requirements

of Steel Forgings

Specification A788/A788M.

A322 Specification for Steel Bars, Alloy, Standard Grades

1.2 The Grades of forgings are as follows, the choice

A370 Test Methods and Definitions for Mechanical Testing

depending on design and stress or service to be imposed:

of Steel Products

1.2.1 Grade CA—Untreated, carbon steel forgings,

A388/A388M Practice for Ultrasonic Examination of Steel

1.2.2 GradesCC,CC1,andCE—Annealed,normalizedand

Forgings

tempered, carbon steel forgings,

A576 Specification for Steel Bars, Carbon, Hot-Wrought,

1.2.3 Grade CF—Normalized and tempered carbon steel

Special Quality

forgings,

A788/A788M Specification for Steel Forgings, General Re-

1.2.4 Grade CF1—Double normalized and tempered car-

quirements

bon steel forgings,

A921/A921M SpecificationforSteelBars,Microalloy,Hot-

1.2.5 Grade CG—Quenched and tempered, or normalized,

Wrought, Special Quality, for Subsequent Hot Forging

quenched and tempered carbon steel forgings,

E3 Guide for Preparation of Metallographic Specimens

1.2.6 Grade AA—Annealed, normalized, or normalized and

E45 TestMethodsforDeterminingtheInclusionContentof

tempered alloy steel forgings,

Steel

1.2.7 Grades AB and AC—Normalized and tempered alloy

E94 Guide for Radiographic Examination

steel forgings, and

E112 Test Methods for Determining Average Grain Size

1.2.8 Grades AD, AE, AF, AG, and AH—Normalized,

E340 Test Method for Macroetching Metals and Alloys

quenched, and tempered alloy steel forgings.

E381 Method of Macroetch Testing Steel Bars, Billets,

1.3 Unless the order specifies the applicable “M” specifica-

Blooms, and Forgings

tion designation, the forgings shall be furnished with the

E407 Practice for Microetching Metals and Alloys

inch-pound units.

1.4 The values stated in either inch-pound units or SI

3. Ordering Information and General Requirements

(metric) units are to be regarded separately as standard.Within

3.1 Material supplied to this specification shall conform to

the text and tables, the SI units are shown in brackets. The

the requirements of Specification A788/A788M, which out-

values stated in each system are not exact equivalents; there-

lines additional ordering information, manufacturing require-

fore, each system shall be used independently of the other.

ments, testing and retesting methods and procedures, product

Combining values from the two systems may result in noncon-

analysis variations, marking, certification, and additional

formance with the specification.

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

2

A01.06 on Steel Forgings and Billets. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2006. Published September 2006. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1964. Last previous edition approved in 2003 as A521–03. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/A0521_A0521M-06. the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A521/A521M – 06

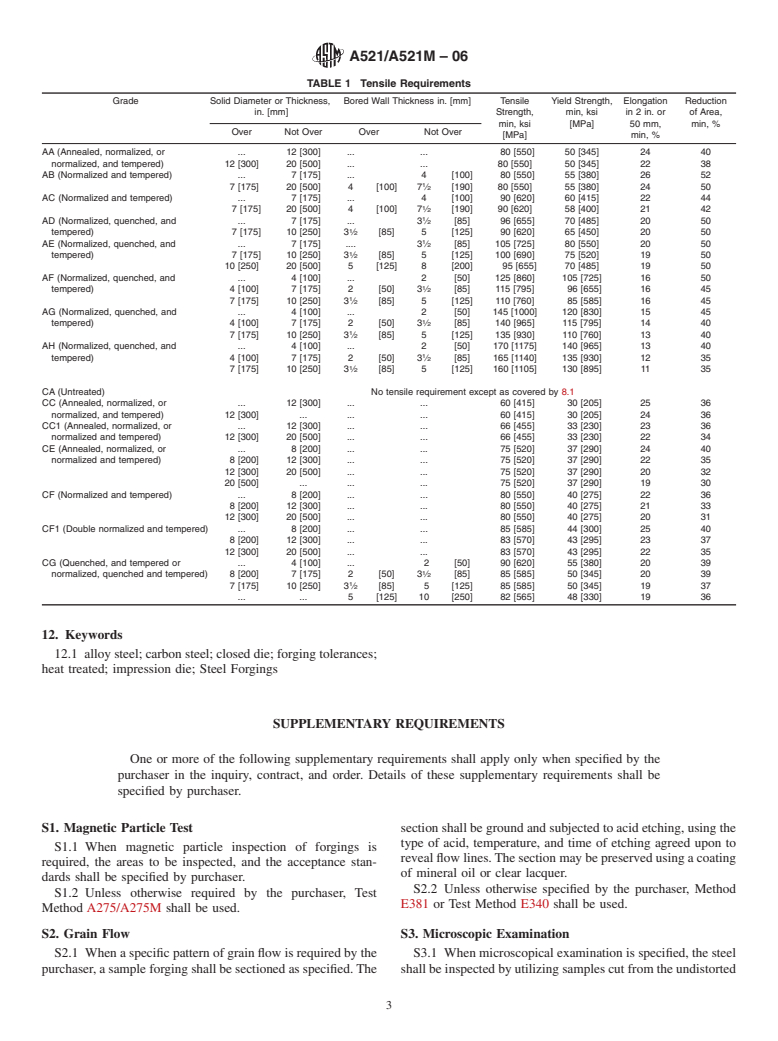

supplementary requirements. Failure to comply with the re- 8. Tensile Properties

quirements of Specification A788/A788M constitutes non-

8.1 The material shall conform to the requirements for

conformance with this specification

tensile properties prescribed in Table 1 when tested in accor-

3.2 In addition to the ordering information required by

dance with the latest issue of Test Methods and Definitions

SpecificationA788/A788M,thepurchasermayrequirethatthe A370.

tolerances stated in the appendices to this specification shall

8.2 The yield strength shall be determined by the offset

apply. method, using an offs

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.