ASTM G123-00

(Test Method)Standard Test Method for Evaluating Stress-Corrosion Cracking of Stainless Alloys with Different Nickel Content in Boiling Acidified Sodium Chloride Solution

Standard Test Method for Evaluating Stress-Corrosion Cracking of Stainless Alloys with Different Nickel Content in Boiling Acidified Sodium Chloride Solution

SCOPE

1.1 This test method describes a procedure for conducting stress-corrosion cracking tests in an acidified boiling sodium chloride solution. This test method is performed in 25% (by mass ) sodium chloride acidified to pH 1.5 with phosphoric acid. This test method is concerned primarily with the test solution and glassware, although a specific style of U-bend test specimen is suggested.

1.2 This test method is designed to provide better correlation with chemical process industry experience for stainless steels than the more severe boiling magnesium chloride test of Practice G36. Some stainless steels which have provided satisfactory service in many environments readily crack in Practice G36, but have not cracked during interlaboratory testing using this sodium chloride test method.

1.3 This boiling sodium chloride test method was used in an interlaboratory test program to evaluate wrought stainless steels, including duplex (ferrite-austenite) stainless and an alloy with up to about 33% nickel. It may also be employed to evaluate these types of materials in the cast or welded conditions.

1.4 This test method detects major effects of composition, heat treatment, microstructure, and stress on the susceptibility of materials to chloride stress-corrosion cracking. Small differences between samples such as heat-to-heat variations of the same grade are not likely to be detected.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 123 – 00

Standard Test Method for

Evaluating Stress-Corrosion Cracking of Stainless Alloys

with Different Nickel Content in Boiling Acidified Sodium

Chloride Solution

This standard is issued under the fixed designation G123; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method describes a procedure for conducting 2.1 ASTM Standards:

stress-corrosion cracking tests in an acidified boiling sodium D1193 Specification for Reagent Water

chloride solution. This test method is performed in 25% (by E8 TestMethodsforTensionTestingofMetallicMaterials

mass) sodium chloride acidified to pH 1.5 with phosphoric E691 Practice for Conducting an Interlaboratory Study to

acid. This test method is concerned primarily with the test Determine the Precision of a Test Method

solutionandglassware,althoughaspecificstyleofU-bendtest G15 Terminology Relating to Corrosion and Corrosion

specimen is suggested. Testing

1.2 This test method is designed to provide better correla- G16 GuideforApplyingStatisticstoAnalysisofCorrosion

tion with chemical process industry experience for stainless Data

steels than the more severe boiling magnesium chloride test of G30 Practice for Making and Using U-Bend Stress Corro-

Practice G36. Some stainless steels which have provided sion Test Specimens

satisfactory service in many environments readily crack in G36 Practice for Evaluating Stress-Corrosion-Cracking

Practice G36, but have not cracked during interlaboratory Resistance of Metals and Alloys in a Boiling Magnesium

testing using this sodium chloride test method. Chloride Solution

1.3 Thisboilingsodiumchloridetestmethodwasusedinan G49 Practice for Preparation and Use of Direct Tension

interlaboratory test program to evaluate wrought stainless Stress Corrosion Test Specimens

steels, including duplex (ferrite-austenite) stainless and an G107 GuideforFormatsforCollectionandCompilationof

alloywithuptoabout33%nickel.Itmayalsobeemployedto Corrosion Data for Metals for Computerized Database

evaluate these types of materials in the cast or welded Input

conditions.

3. Terminology

1.4 This test method detects major effects of composition,

heat treatment, microstructure, and stress on the susceptibility 3.1 Definitions:

3.1.1 For definitions of corrosion-related terms used in this

of materials to chloride stress-corrosion cracking. Small dif-

ferencesbetweensamplessuchasheat-to-heatvariationsofthe test method, see Terminology G15.

same grade are not likely to be detected.

4. Summary of Test Method

1.5 The values stated in SI units are to be regarded as the

4.1 Asolutionof25%sodiumchloride(by mass)inreagent

standard. The values given in parentheses are for information

water is mixed, and the pH is adjusted to 1.5 with phosphoric

only.

acid. The solution is boiled and U-bends (or other stressed

1.6 This standard does not purport to address all of the

specimens) are exposed in fresh solution for successive one-

safety concerns, if any, associated with its use. It is the

week periods.

responsibility of the user of this standard to establish appro-

4.2 The test may be continued for as many weeks as

priate safety and health practices and determine the applica-

necessary, but six weeks (about 1000 h) or less are expected to

bility of regulatory limitations prior to use. For specific hazard

be sufficient to crack susceptible materials. Longer exposures

statements, see Section 7 .

provide greater assurance of resistance for those materials

which do not crack.

This test method is under the jurisdiction of ASTM Committee G01 on

Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on

Stress Corrosion Cracking and Corrosion Fatigue.

Current edition approved Oct. 10, 2000. Published October 2000. Originally Annual Book of ASTM Standards, Vol 11.01.

published as G123–94. Last previous edition G123–96. Annual Book of ASTM Standards, Vol 03.01.

2 5

Interlaboratory test program including UNS S30400, S31600, S32550, and Annual Book of ASTM Standards, Vol 14.02.

N08020. These data are available at ASTM Headquarters. Request RR G01-1013. Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G123–00

4.3 It is recommended that samples of a susceptible mate-

rial, for example, UNS S30400 or S31600 (Type 304 or Type

316 stainless, respectively), be included as a control when

more resistant materials are evaluated.

5. Significance and Use

5.1 Thistestmethodisdesignedtocomparealloysandmay

be used as one method of screening materials prior to service.

In general, this test method is more useful for stainless steels

thantheboilingmagnesiumchloridetestofPracticeG36.The

boiling magnesium chloride test cracks materials with the

nickel levels found in relatively resistant austenitic and duplex

stainless steels, thus making comparisons and evaluations for

many service environments difficult.

5.2 This test method is intended to simulate cracking in

water, especially cooling waters that contain chloride. It is not

intended to simulate cracking that occurs at high temperatures

(greater than 200°C or 390°F) with chloride or hydroxide.

NOTE 1—The degree of cracking resistance found in full-immersion

tests may not be indicative of that for some service conditions comprising

exposure to the water-line or in the vapor phase where chlorides may

concentrate.

5.3 Correlation with service experience should be obtained

when possible. Different chloride environments may rank

materials in a different order.

5.4 In interlaboratory testing, this test method cracked

annealed UNS S30400 and S31600 but not more resistant

materials, such as annealed duplex stainless steels or higher

nickelalloys,forexample,UNSN08020(forexample20Cb-3

stainless).These more resistant materials are expected to crack

when exposed to Practice G36 as U-bends. Materials which

FIG. 1 Apparatus Used for Stress-Corrosion Cracking Test

withstand this sodium chloride test for a longer period than

UNS S30400 or S31600 may be candidates for more severe

6.1.3 Hot Plate, capable of maintaining the solution at its

service applications.

boiling point.

5.5 The repeatability and reproducibility data from Section

11 and Appendix X1 must be considered prior to use. Inter-

7. Reagents

laboratory variation in results may be expected as occurs with

7.1 Purity of Reagents—Reagent grade chemicals shall be

many corrosion tests. Acceptance criteria are not part of this

used in all tests. Unless otherwise indicated, it is intended that

test method and if needed are to be negotiated by the user and

all reagents shall conform to the specifications of the Commit-

the producer.

tee onAnalytical Reagents of theAmerican Chemical Society,

where such specifications are available. Other grades may be

6. Apparatus

used provided it is first ascertained that the reagent is of

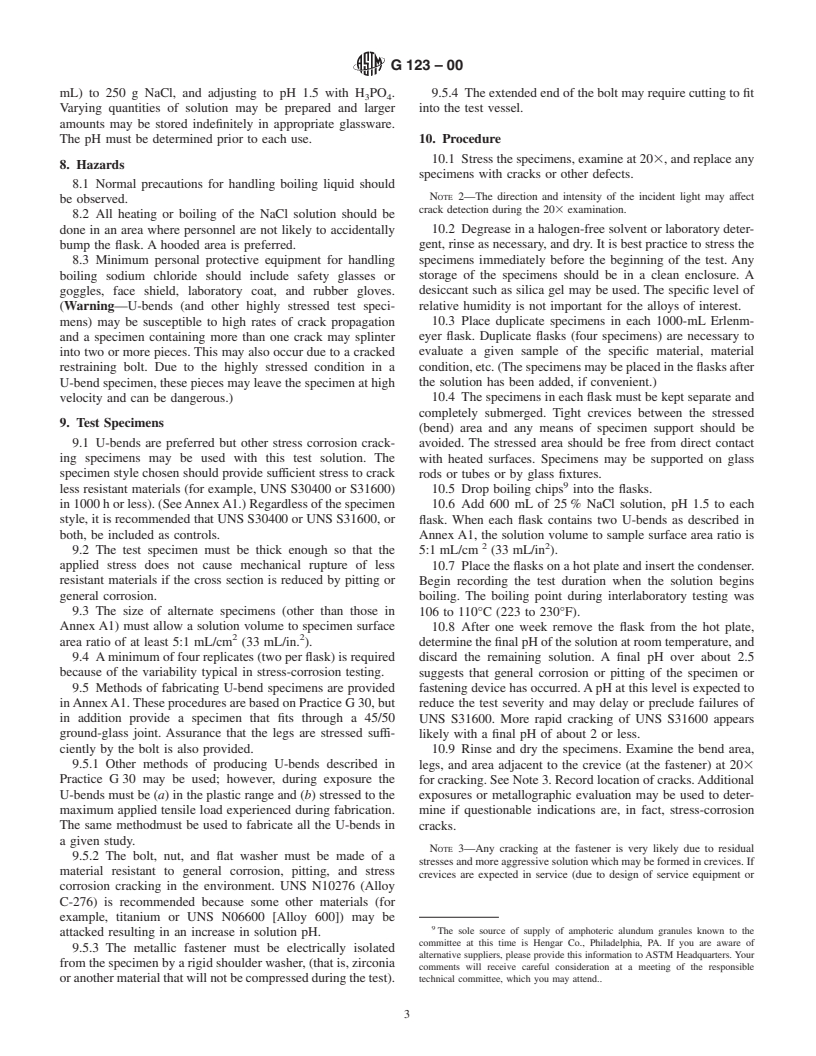

6.1 TheglasswareusedforthistestmethodisshowninFig.

sufficiently high purity to permit its use without affecting

1 and is as follows:

results.

6.1.1 Flask—1000-mL Erlenmeyer flask with a 45/50

7.2 Purity of Water—Solutions shall be made with water of

ground-glass joint.

purityconformingtoatleastTypeIVreagentwaterasspecified

6.1.2 Condenser, a four-bulbAllihn condenser with a 45/50

in Specification D1193 (except that for this method limits for

ground glass joint (water-cooled joint suggested), a water

chlorides and sodium may be ignored).

jacket at least 20 cm (8 in.) long anda1to2.5cm (0.4 to 0.95

7.3 Sodium Chloride (NaCl)—Asolution of 25% NaCl (by

in.) long drip tip is used. (ModifiedAllihn condensers with no

mass) acidified to pH 1.5 with phosphoric acid (H PO)is

3 4

drip tip and condensers with longer drip tips may produce

used.Thesolutionmaybepreparedbyadding750gH O(750

different results.These alternateAllihn condenser designs may

be used if control samples of susceptible (for example, UNS

S31600) and resistant (for example, UNS N08020) materials

Reagent Chemicals, American Chemical Society Specifications, American

are included in the study.)

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

20Cb-3 is a registered trademark of CarpenterTechnology Corp., Reading, PA. MD.

G123–00

mL) to 250 g NaCl, and adjusting to pH 1.5 with H PO . 9.5.4 Theextendedendoftheboltmayrequirecuttingtofit

3 4

Varying quantities of solution may be prepared and larger into the test vessel.

amounts may be stored indefinitely in appropriate glassware.

The pH must be determined prior to each use. 10. Procedure

10.1 Stressthespecimens,examineat203,andreplaceany

8. Hazards

specimens with cracks or other defects.

8.1 Normal precautions for handling boiling liquid should

NOTE 2—The direction and intensity of the incident light may affect

be observed.

crack detection during the 203 examination.

8.2 All heating or boiling of the NaCl solution should be

10.2 Degrease in a halogen-free solvent or laboratory deter-

done in an area where personnel are not likely to accidentally

bump the flask. A hooded area is preferred. gent, rinse as necessary, and dry. It is best practice to stress the

specimens immediately before the beginning of the test. Any

8.3 Minimum personal protective equipment for handling

boiling sodium chloride should include safety glasses or storage of the specimens should be in a clean enclosure. A

desiccant such as silica gel may be used. The specific level of

goggles, face shield, laboratory coat, and rubber gloves.

(Warning—U-bends (and other highly stressed test speci- relative humidity is not important for the alloys of interest.

10.3 Place duplicate specimens in each 1000-mL Erlenm-

mens) may be susceptible to high rates of crack propagation

and a specimen containing more than one crack may splinter eyer flask. Duplicate flasks (four specimens) are necessary to

evaluate a given sample of the specific material, material

into two or more pieces. This may also occur due to a cracked

restraining bolt. Due to the highly stressed condition in a condition,etc.(Thespecimensmaybeplacedintheflasksafter

the solution has been added, if convenient.)

U-bendspecimen,thesepiecesmayleavethespecimenathigh

velocity and can be dangerous.) 10.4 The specimens in each flask must be kept separate and

completely submerged. Tight crevices between the stressed

9. Test Specimens

(bend) area and any means of specimen support should be

9.1 U-bends are preferred but other stress corrosion crack- avoided. The stressed area should be free from direct contact

ing specimens may be used with this test solution. The with heated surfaces. Specimens may be supported on glass

specimen style chosen should provide sufficient stress to crack rods or tubes or by glass fixtures.

less resistant materials (for example, UNS S30400 or S31600) 10.5 Drop boiling chips into the flasks.

in1000horless).(SeeAnnexA1.)Regardlessofthespecimen

10.6 Add 600 mL of 25% NaCl solution, pH 1.5 to each

style, it is recommended that UNS S30400 or UNS S31600, or flask. When each flask contains two U-bends as described in

both, be included as controls.

AnnexA1, the solution volume to sample surface area ratio is

2 2

9.2 The test specimen must be thick enough so that the 5:1 mL/cm (33 mL/in ).

applied stress does not cause mechanical rupture of less

10.7 Placetheflasksonahotplateandinsertthecondenser.

resistant materials if the cross section is reduced by pitting or Begin recording the test duration when the solution begins

general corrosion.

boiling. The boiling point during interlaboratory testing was

9.3 The size of alternate specimens (other than those in 106 to 110°C (223 to 230°F).

AnnexA1) must allow a solution volume to specimen surface

10.8 After one week remove the flask from the hot plate,

2 2

area ratio of at least 5:1 mL/cm (33 mL/in. ). determinethefinalpHofthesolutionatroomtemperature,and

9.4 Aminimumoffourreplicates(twoperflask)isrequired

discard the remaining solution. A final pH over about 2.5

because of the variability typical in stress-corrosion testing. suggests that general corrosion or pitting of the specimen or

9.5 Methods of fabricating U-bend specimens are provided

fastening device has occurred.ApH at this level is expected to

inAnnexA1.TheseproceduresarebasedonPracticeG30,but reduce the test severity and may delay or preclude failures of

in addition provide a specimen that fits through a 45/50 UNS S31600. More rapid cracking of UNS S31600 appears

ground-glass joint. Assurance that the legs are stressed suffi- likely with a final pH of about 2 or less.

ciently by the bolt is also provided. 10.9 Rinse and dry the specimens. Examine the bend area,

9.5.1 Other methods of producing U-bends described in legs, and area adjacent to the crevice (at the fastener) at 203

Practice G30 may be used; however, during exposure the forcracking.SeeNote3.Recordlocationofcracks.Additional

U-bends must be (a) in the plastic range and (b) stressed to the

exposures or metallographic evaluation may be used to deter-

maximum applied tensile load experienced during fabrication. mine if questionable indications are, in fact, stress-corrosion

The same methodmust be used to fabricate all the U-bends in

cracks.

a given study.

NOTE 3—Any cracking at the fastener is very likely due to residual

9.5.2 The bolt, nut, and flat washer must be made of a

stressesandmoreaggressivesolutionwhichmaybeformedincrevices.If

material resistant to general corrosion, pitting, and stress

crevices are expected in service (due to design of service equipment or

corrosion cracking in the environment. UNS N10276 (Alloy

C-276) is recommended because some other materials (for

example, titanium or UNS N06600 [Alloy 600]) may be

The sole source of supply of amphoteric alundum granules known to the

attacked resulting in an increase in solution pH.

committee at this time is Hengar Co., Philadelphia, PA. If you are aware of

9.5.3 The metallic fastener must be electrically isolated

alternative suppliers, please provide this information toASTM Headquarters. Your

fromthespecimenbyarigidshoulderwasher,(thatis,zirconia

comments will receive careful consideration at a meeting of the responsible

oranothermaterialthatwillnotbecompressedduringthetest).

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.