ASTM D3461-97(2002)

(Test Method)Standard Test Method for Softening Point of Asphalt and Pitch (Mettler Cup-and-Ball Method)

Standard Test Method for Softening Point of Asphalt and Pitch (Mettler Cup-and-Ball Method)

SCOPE

1.1 This test method covers the determination of the softening point of asphalt and pitch in the range from 50 to 180°C by the cup-and-ball apparatus, and gives results comparable to those obtained by Test Method D 36.

Note 1—If the softening point of asphalt by this Mettler cup-and-ball method fails to meet specified requirements, tests may be rerun using the Test Method D 36 (ring-and-ball) softening point apparatus as a referee method.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3461–97 (Reapproved 2002)

Standard Test Method for

Softening Point of Asphalt and Pitch (Mettler Cup-and-Ball

Method)

This standard is issued under the fixed designation D 3461; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of the soft- 4.1 Asphalt and pitch do not go through a solid-liquid phase

ening point of asphalt and pitch in the range from 50 to 180°C change when heated, and therefore do not have true melting

by the cup-and-ball apparatus, and gives results comparable to points. As the temperature is raised, they gradually soften or

those obtained by Test Method D 36. become less viscous. For this reason, the determination of the

softening point must be made by an arbitrary, but closely

NOTE 1—If the softening point of asphalt by this Mettler cup-and-ball

defined, method if the test values are to be reproducible.

method fails to meet specified requirements, tests may be rerun using the

4.2 This test method is useful in determining the consis-

Test Method D 36 (ring-and-ball) softening point apparatus as a referee

method. tency as one element in establishing the uniformity of ship-

ments or sources of supply.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Apparatus

responsibility of the user of this standard to establish appro-

5.1 AMettler dropping point cell can be used to determine

priate safety and health practices and determine the applica-

softening points by this test method. These commercially

bility of regulatory limitations prior to use.

available instruments consist of a control unit with a digital

temperature indicator, matched furnace, sample cartridges, and

2. Referenced Documents

accessories. The control unit automatically regulates the heat-

2.1 ASTM Standards:

ing rate of the furnace. The softening point is indicated on the

A 314 Specification for Stainless Steel Billets and Bars for

2 readout, and the heating program stopped, when the sample

Forgings

flow triggers a photocell detector. A general view of the

D 36 Test Method for Softening Point of Bitumen (Ring-

3 components of the Mettler apparatus is shown in Fig. 1.

and-Ball Apparatus)

5.1.1 Control Unit—This unit shall provide a continuous,

D 140 Practice for Sampling Bituminous Materials

5 linear temperature increase from 25 to 250°C at a rate of

D 4296 Practice for Sampling Pitch

2°C/min. A digital readout shall indicate the temperature to

3. Summary of Test Method 0.1°C throughout.

5.1.2 Furnace Unit—This unit shall be capable of heating a

3.1 In this test method the softening point is defined as the

specimen cup assembly, as described in 5.1.3, at a linear rate of

temperature at which the specimen, suspended in a cylindrical

2 6 0.3°C/min. It shall include a sensing system capable of

cup with a 6.5-mm hole in the bottom and with a lead ball,

detecting the softening point with a precision of 0.1°C.

8 mm in diameter, centered on top of the sample in the cup,

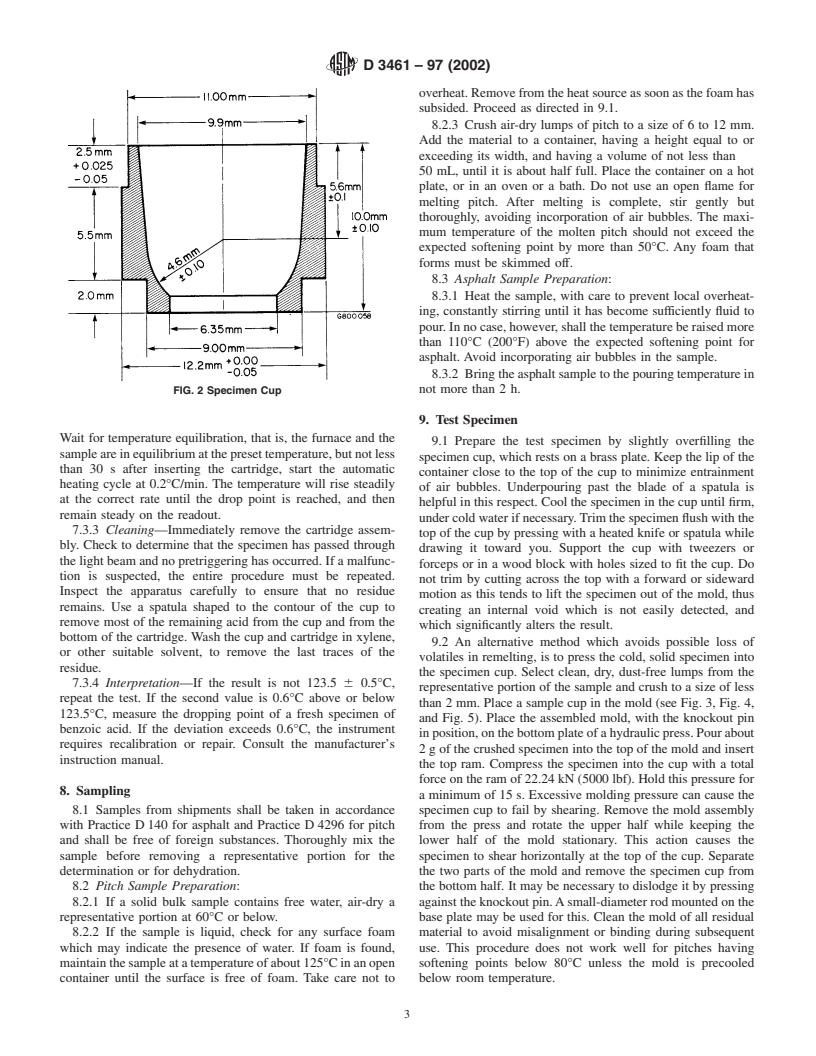

5.1.3 Specimen Cup Assembly—A cup of chromium-plated

flows downward a distance of 19 mm to interrupt a light beam,

brass, or stainless steel conforming to the requirements for

as the sample is heated at a linear rate in air.

Type 303 (UNS 530300) as prescribed in Specification A 314,

with dimensions shown in Fig. 2. It shall be placed in the

This test method is under the jurisdiction of ASTM Committee D02 on assembly so that the test specimen will flow down a distance of

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

19 mm before interrupting a light beam and stopping the

D02.05.OF on Industrial Pitches.

heating program as the softening point is reached.

Current edition approved July 10, 1997. Published October 1997. Originally

e2

published as D 3461 – 76. Last previous edition D 3461 – 85 (1994) .

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 04.04.

4 6

Annual Book of ASTM Standards, Vol 04.03. Available from the Mettler Toledo, Inc., Balances and Instruments, 69

Annual Book of ASTM Standards, Vol 05.02. Princeton-Hightstown Rd., Hightstown, NJ 08520-0071.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3461–97 (2002)

FIG. 1 General View of the Mettler FP-5/53

5.1.4 Lead Ball—A lead ball weighing 3.20 6 0.10 g. hygroscopic, it must be stored in a tightly sealed container, and

A32-caliber lead shot is suitable for this purpose. replaced with fresh material from a newly opened supply if

hydration or other contamination is suspected.

6. Reagents

7.3 Procedure:

6.1 Xylene, industrial grade. 7.3.1 Filling the Specimen Cup—Place the cup on a clean,

flat surface. Add a small amount of benzoic acid crystals and

7. Calibration of Mettler Apparatus

press down with a rod (4.5 mm in diameter). Check that the

bottom orifice is completely filled. Refill and repeat the

7.1 This step, required only occasionally, is designed to

pressing step until the cup is filled with benzoic acid. Remove

establish that the temperature indicated by the instrument is in

any crystals from the exterior of the cup.

agreement with a known standard.Aspecial cup with a bottom

orifice of 2.8 mm is used instead of the one prescribed for the 7.3.2 Heating—Preheat the Mettler furnace to 121°C, and

specimen testing. maintain it at that temperature. Place the cartridge assembly

7.2 Reagent—Use either analytical reagent or primary stan- containing the benzoic acid in position in the furnace, taking

dard grade benzoic acid for this calibration.As this material is care that the slits for the light beam are properly positioned.

D3461–97 (2002)

overheat.Removefromtheheatsourceassoonasthefoamhas

subsided. Proceed as directed in 9.1.

8.2.3 Crush air-dry lumps of pitch to a size of 6 to 12 mm.

Add the material to a container, having a height equal to or

exceeding its width, and having a volume of not less than

50 mL, until it is about half full. Place the container on a hot

plate, or in an oven or a bath. Do not use an open flame for

melting pitch. After melting is complete, stir gently but

thoroughly, avoiding incorporation of air bubbles. The maxi-

mum temperature of the molten pitch should not exceed the

expected softening point by more than 50°C. Any foam that

forms must be skimmed off.

8.3 Asphalt Sample Preparation:

8.3.1 Heat the sample, with care to prevent local overheat-

ing, constantly stirring until it has become sufficiently fluid to

pour. In no case, however, shall the temperature be raised more

than 110°C (200°F) above the expected softening point for

asphalt. Avoid incorporating air bubbles in the sample.

8.3.2 Bring the asphalt sample to the pouring temperature in

not more than 2 h.

FIG. 2 Specimen Cup

9. Test Specimen

Wait for temperature equilibration, that is, the furnace and the

9.1 Prepare the test specimen by slightly overfilling the

sampleareinequilibriumatthepresettemperature,butnotless

specimen cup, which rests on a brass plate. Keep the lip of the

than 30 s after inserting the cartridge, start the automatic

container close to the top of the cup to minimize entrainment

heating cycle at 0.2°C/min. The temperature will rise steadily

of air bubbles. Underpouring past the blade of a spatula is

at the correct rate until the drop point is reached, and then

helpful in this respect. Cool the specimen in the cup until firm,

remain steady on the readout.

under cold water if necessary.Trim the specimen flush with the

7.3.3 Cleaning—Immediately remove the cartridge assem-

top of the cup by pressing with a heated knife or spatula while

bly. Check to determine that the specimen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.