ASTM D5856-95(2002)

(Test Method)Standard Test Method for Measurement of Hydraulic Conductivity of Porous Material Using a Rigid-Wall, Compaction-Mold Permeameter

Standard Test Method for Measurement of Hydraulic Conductivity of Porous Material Using a Rigid-Wall, Compaction-Mold Permeameter

SCOPE

1.1 This test method covers laboratory measurement of the hydraulic conductivity (also referred to as ) of laboratory-compacted materials with a rigid-wall, compaction-mold permeameter.

1.2 This test method may be used with laboratory-compacted specimens that have a hydraulic conductivity less than or equal to 1 X 10 -5 m/s. The hydraulic conductivity of compacted materials that have hydraulic conductivities greater than 1 X 10 -5 m/s may be determined by Test Method D 2434.

1.3 The values stated in SI units are to be regarded as the standard, unless other units are specifically given. By tradition in U.S. practice, hydraulic conductivity is reported in centimetres per second, although the common SI units for hydraulic conductivity are metres per second.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5856 – 95 (Reapproved 2002)

Standard Test Method for

Measurement of Hydraulic Conductivity of Porous Material

Using a Rigid-Wall, Compaction-Mold Permeameter

This standard is issued under the fixed designation D 5856; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 4753 Specification for Evaluating, Selecting, and Speci-

fying Balances and Scales for Use in Soil, Rock, and

1.1 This test method covers laboratory measurement of the

Construction Materials

hydraulic conductivity (also referred to as coeffıcient of per-

D 5084 Test Method for Measurement of Hydraulic Con-

meability) of laboratory-compacted materials with a rigid-wall,

ductivity of Saturated Porous Materials Using a Flexible

compaction-mold permeameter.

Wall Permeameter

1.2 This test method may be used with laboratory-

E 145 Specification for Gravity-Convection and Forced-

compacted specimens that have a hydraulic conductivity less

−5

Ventilation Ovens

than or equal to 1 3 10 m/s. The hydraulic conductivity of

compacted materials that have hydraulic conductivities greater

3. Terminology

−5

than 1 3 10 m/s may be determined by Test Method D 2434.

3.1 Definitions of Terms Specific to This Standard:

1.3 The values stated in SI units are to be regarded as the

3.1.1 flux—quantity of flow per unit area per unit time.

standard, unless other units are specifically given. By tradition

3.1.2 hydraulic conductivity, k—the rate of discharge of

in U.S. practice, hydraulic conductivity is reported in centime-

water under laminar flow conditions through a unit cross-

tres per second, although the common SI units for hydraulic

sectional area of a porous medium under a unit hydraulic

conductivity are metres per second.

gradient and standard temperature conditions (20°C).

1.4 This standard does not purport to address all of the

3.1.2.1 Discussion—The term coeffıcient of permeability is

safety concerns, if any, associated with its use. It is the

often used instead of hydraulic conductivity, but hydraulic

responsibility of the user of this standard to establish appro-

conductivity is used exclusively in this test method. A more

priate safety and health practices and determine the applica-

complete discussion of the terminology associated with Dar-

bility of regulatory limitations prior to use.

cy’s law is given in the literature .

2. Referenced Documents 3.1.3 pore volume of flow—the cumulative quantity of

outflow from a test specimen divided by the volume of pore

2.1 ASTM Standards:

space in the specimen.

D 653 Terminology Relating to Soil, Rock, and Contained

3.1.4 For definitions of other terms used in this test method

Fluids

see Terminology D 653.

D 698 Test Method for Laboratory Compaction Character-

istics of Soil Using Standard Effort (12 400 ft-lbf/ft (600

4. Significance and Use

3 2

KN-m/m ))

4.1 This test method applies to one-dimensional, laminar

D 854 Test Method for Specific Gravity of Soils Solids by

2 flow of water within laboratory-compacted, porous materials

Water Pycnometer

such as soil.

D 1557 Test Method for Laboratory Compaction Character-

3 4.2 The hydraulic conductivity of porous materials gener-

istics of Soil Using Modified Effort (56 000 ft-lbf/ft (2700

3 2

ally decreases with an increasing amount of air in the pores of

KN-m/m ))

the material. This test method applies to porous materials

D 2216 Method for Laboratory Determination of Water

2 containing little or no air. The test method is designed to

(Moisture) Content of Soil and Rock by Mass

minimize the amount of air in the test specimen. However, this

D 2434 Test Method for Permeability of Granular Soils

2 test method does not ensure complete saturation of the test

(Constant Head)

specimen with water. In cases where it is essential to saturate

This test method is under the jurisdiction of ASTM Committee D18 on Soil and

Rock and is the direct responsibility of Subcommittee D18.04 on Hydrologic Annual Book of ASTM Standards, Vol 04.02.

Properties of Soil and Rock. Olson, R. E., and Daniel, D. E., “Measurement of the Hydraulic Conductivity

Current edition approved Nov. 10, 1995. Published January 1996. of Fine-Grained Soils,” Symposium on Permeability and Groundwater Contaminant

Annual Book of ASTM Standards, Vol 04.08. Transport, ASTM STP 746, ASTM, 1981, pp. 18–64.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5856 – 95 (2002)

the test specimen fully with water, the compacted specimen initial head loss divided by final head loss over an interval of

may be tested using Test Method D 5084. time shall be measured such that this computed ratio is accurate

4.3 This test method applies to permeation of porous mate- to within 6 5 %. The head loss shall be measured with a

rials with water. Permeation with other liquids, such as pressure gage, electronic pressure transducer, engineer’s scale,

chemical wastes, can be accomplished using procedures simi- graduated pipette, or any other device of suitable accuracy.

lar to those described in this test method. However, this test Falling head tests may be performed with either a constant

method is only intended to be used when water is the permeant tailwater elevation (Test Method B), rising tailwater elevation

liquid. (Test Method C), or increasing tailwater elevation (Test

4.4 It is assumed that Darcy’s law is valid and that the Method D).

hydraulic conductivity is essentially unaffected by hydraulic

5.1.3 Constant Rate of Flow—The system must be capable

gradient. The validity of Darcy’s law may be evaluated by

of maintaining a constant rate of flow through the specimen to

measuring the hydraulic conductivity of the specimen at three

within 6 5 % or better. Flow measurement or control shall be

hydraulic gradients; if all measured values are similar (within

by calibrated syringe, graduated pipette, or other device of

25 %), then Darcy’s law may be taken as valid. However, when

suitable accuracy. The head loss across the specimen shall be

the hydraulic gradient acting on a test specimen is changed, the

measured to an accuracy of 6 5 % or better using an electronic

state of stress will also change, and, if the specimen or pore

pressure transducer or other device of suitable accuracy. A

fluid is compressible, the volume of the test specimen or pore

means to ensure that the head being measured is not affected by

fluid will change. Thus, some change in hydraulic conductivity

sidewall leakage should be included. More information on

may occur when the hydraulic gradient is altered, even in cases

testing with a constant rate of flow is given in the literature .

where Darcy’s law is valid.

5.2 Flow Measurement System—Both inflow and outflow

4.5 One potential problem with this method of testing is the

volumes shall be measured or controlled. Flow volumes shall

possibility that water will flow along the interface between the

be measured by a graduated accumulator, graduated pipette,

test specimen and the compaction/permeameter ring. The

graduated cylinder, vertical standpipe in conjunction with an

problem tends to be of minimal significance for materials that

electronic pressure transducer, marriotte bottle, or other

swell when exposed to water (for example, compacted, clayey

volume-measuring device of suitable accuracy. For long-term

soils) but can be a very serious problem for materials that

tests, evaporative losses may be significant and should be

might tend to shrink and pull away from the walls of the

accounted for using a suitable correction procedure.

permeameter. Test Method D 5084 is recommended for any

5.2.1 Flow Accuracy—Required accuracy for the quantity

material that tends to shrink when exposed to the permeant

of flow measured over an interval of time is 6 5 % or better.

liquid.

5.2.2 Head Losses—Head losses in the tubes, valves, po-

4.6 The correlation between results obtained with this test

rous end pieces, and filter paper may lead to error. To guard

method and the hydraulic conductivities of in-place, com-

against such errors, the permeameter shall be assembled with

pacted materials has not been fully investigated. Experience

no specimen inside (but with any porous end pieces or sheets

has sometimes shown that flow patterns in small, laboratory-

of filter paper that will be used) and then the hydraulic system

prepared test specimens do not necessarily follow the same

filled. If a constant or falling head test is to be used, the

patterns on large field scales and that hydraulic conductivities

hydraulic pressures or heads that will be used in testing a

measured on small test specimens are not necessarily the same

specimen shall be applied, and the rate of flow measured with

as larger-scale values. Therefore, the results should be applied

an accuracy of 6 5 % or better. This rate of flow shall be at

to field situations with caution and by qualified personnel.

least ten times greater than the rate of flow that is measured

when a specimen has been compacted inside the permeameter

5. Apparatus

and the same hydraulic pressures or heads are applied. If a

5.1 Hydraulic System—Constant head (Test Method A),

constant rate of flow test is to be used, the rate of flow to be

falling head (Test Methods B, C, and D), or constant rate of

used in testing a specimen shall be supplied to the permeameter

flow (Test Method E) systems may be used provided they meet

and the head loss measured. The head loss without a specimen

the criteria outlined as follows:

shall be less than 0.1 times the head loss when a specimen is

5.1.1 Constant Head—The system must be capable of

present.

maintaining a constant hydraulic pressure or head to within 6

5.3 Permeameter Cell—The permeameter cell shall consist

5 % and shall include means to measure hydraulic pressures or

of a rigid-wall compaction mold into which the material to be

heads to within the prescribed tolerance. In addition, the head

tested is compacted and in which the compacted material is

loss across the test specimen must be held constant to within 6

permeated; and two end plates to control flow into and out of

5 % and shall be measured with the same accuracy or better.

the test specimen. A swell ring may be provided as discussed in

Pressures shall be measured by a pressure gage, electronic

5.3.2. The permeameter shall be designed and operated so that

pressure transducer, or any other device of suitable accuracy.

permeant water flows downward through the test specimen,

Head of liquid in a standpipe may be measured with a

graduated pipette, ruler, scale, or other device of suitable

accuracy.

5.1.2 Falling Head—The system shall allow for measure-

Olsen, H. W., Gill, J. D., Willden, A. T., and Nelson, N. R.,“ Innovations in

ment of the applied head loss, thus hydraulic gradient, to

Hydraulic Conductivity Measurements,” Transportation Research Record No. 1309,

within6 5 % or better at any time. In addition, the ratio of Transportation Research Board, National Research Council, Washington, DC, 1991.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5856 – 95 (2002)

although upward flow may be used if the top of the specimen

is protected from upward movement by a rigid porous element.

5.3.1 Compaction Mold/Permeameter Ring—The compac-

tion mold/permeameter ring shall be constructed of a rigid

material that will not be damaged during compaction of the test

specimen and that will not undergo adverse chemical reactions

with the test material or permeant water. Materials such as

steel, aluminum, brass, plastic, and glass have been used. The

mold shall be sufficiently rigid so that its expansion when the

permeameter is pressurized is negligibly small. The mold can

be any cylindrical shape so long as: the cross-sectional area

along the direction of flow does not vary by more than 6 2%;

height and diameter are each $ 25 mm; height does not vary

by more than 6 1 %, and the largest particle and clod size in

the compacted specimen is # ⁄6 the lesser of the height or

diameter.

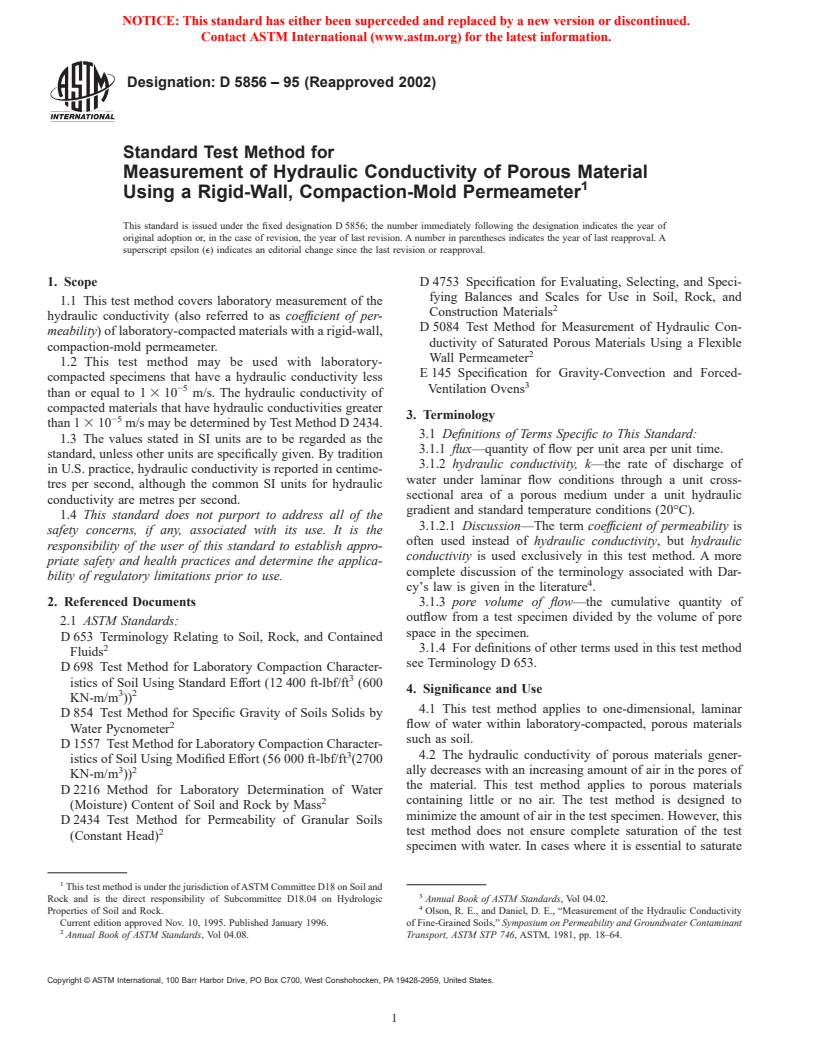

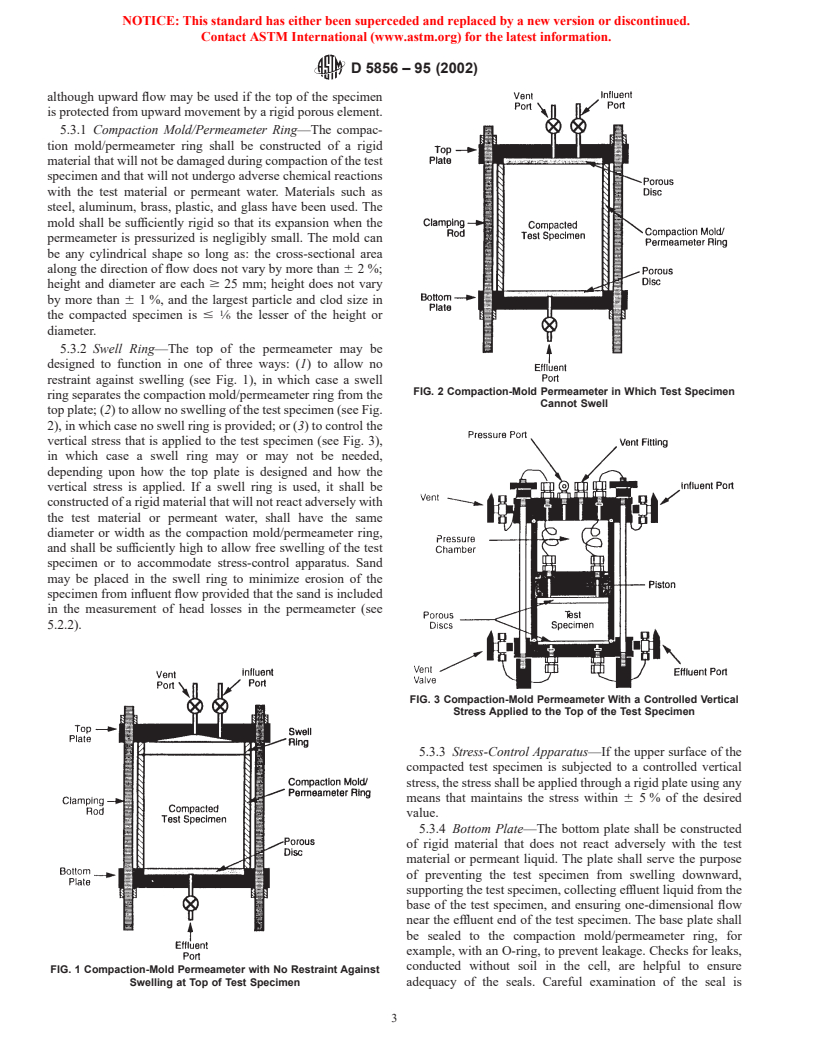

5.3.2 Swell Ring—The top of the permeameter may be

designed to function in one of three ways: (1) to allow no

restraint against swelling (see Fig. 1), in which case a swell

FIG. 2 Compaction-Mold Permeameter in Which Test Specimen

ring separates the compaction mold/permeameter ring from the

Cannot Swell

top plate; (2) to allow no swelling of the test specimen (see Fig.

2), in which case no swell ring is provided; or (3) to control the

vertical stress that is applied to the test specimen (see Fig. 3),

in which case a swell ring may or may not be needed,

depending upon how the top plate is designed and how the

vertical stress is applied. If a swell ring is used, it shall be

constructed of a rigid material that will not react adversely with

the test material or permeant water, shall have the same

diameter or width as the compaction mold/permeameter ring,

and shall be sufficiently high to allow free swelling of the test

specimen or to accommodate stress-control apparatus. Sand

may be placed in the swell ring to minimize erosion of the

specimen from influent flow provided that the sand is included

in the measurement of head losses in the permeameter (see

5.2.2).

FIG. 3 Compaction-Mold Permeameter With a Controlled Vertical

Stress Applied to the Top of the Test Specimen

5.3.3 Stress-Control Apparatus—If the upper surface of the

compacted test specimen is subjected to a controlled vertical

stress, the stress shall be applied through a rigid plate using any

means that maintains the stress within 6 5 % of the desired

value.

5.3.4 Bottom Plate—The bottom plate shall be constructed

of rigid material that does not react adversely with the test

material or permeant liquid. The plate shall serve the purpose

of preventing the test specimen from swelling downward,

supporting the test specimen, collecting effluent liquid from the

base of the test specimen, and ensuring one-dimensional flow

near the effluent end of the test specimen. The base plate shall

be sealed to the compaction mold/permeameter ring, for

example, with an O-ring, to prevent leakage. Checks for leaks,

conducted without soil in the cell, are helpful to ensure

FIG. 1 Compaction-Mold Permeameter with No Restraint Against

Swell

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.