ASTM A541/A541M-05(2020)

(Specification)Standard Specification for Quenched and Tempered Carbon and Alloy Steel Forgings for Pressure Vessel Components

Standard Specification for Quenched and Tempered Carbon and Alloy Steel Forgings for Pressure Vessel Components

ABSTRACT

This specification covers quenched and tempered carbon and alloy steel forgings for pressure vessel components. Heat and product analyses shall be performed to evaluate material conformance with chemical composition requirements. Tension and Charpy V-notch tests shall also be carried out to assess material conformance with mechanical property requirements such as, tensile strength, yield strength, elongation, reduction of area, and Charpy value. Sampling of test specimens for mechanical examination shall be done by either one of four methods specified by the purchaser. Repair welding may also be made at the option of the purchaser.

SCOPE

1.1 This specification2 covers requirements for quenched and tempered carbon and alloy steel forgings for pressure vessel components.

1.2 All grades are considered weldable under proper conditions. Welding technique is of fundamental importance, and it is presupposed that welding procedure and inspection will be in accordance with approved methods for the grade of material used.

Note 1: Grades 1 and 1A have different chemistries but the same mechanical requirements.

Note 2: Designations have been changed as follows:

Current

Formerly

Grade 1

Class 1

Grade 1A

Class 1A

Grade 1C

Class 4

Grade 2 Class 1

Class 2

Grade 2 Class 2

Class 2A

Grade 3 Class 1

Class 3

Grade 3 Class 2

Class 3A

Grade 4N Class 1

Class 7

Grade 4N Class 2

Class 7A

Grade 4N Class 3

Class 7B

Grade 5 Class 1

Class 8

Grade 5 Class 2

Class 8A

Grade 11 Class 4

Class 11C

Grade 22 Class 3

Class 22B

Grade 22 Class 4

Class 22C

Grade 22 Class 5

Class 22D

Grade 22V

Class 22V

Grade 3V

Class 3V

1.3 The values stated in either inch-pound units or SI (metric) units are to be regarded separately as standard. Within the text and tables, the SI units are shown in brackets. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4 Unless the order specifies the applicable “M” specification designation, the material shall be furnished to the inch-pound units.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A541/A541M −05 (Reapproved 2020)

Standard Specification for

Quenched and Tempered Carbon and Alloy Steel Forgings

for Pressure Vessel Components

This standard is issued under the fixed designationA541/A541M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 Unless the order specifies the applicable “M” specifica-

2 tion designation, the material shall be furnished to the inch-

1.1 This specification covers requirements for quenched

pound units.

and tempered carbon and alloy steel forgings for pressure

1.5 This international standard was developed in accor-

vessel components.

dance with internationally recognized principles on standard-

1.2 All grades are considered weldable under proper condi-

ization established in the Decision on Principles for the

tions. Welding technique is of fundamental importance, and it

Development of International Standards, Guides and Recom-

ispresupposedthatweldingprocedureandinspectionwillbein

mendations issued by the World Trade Organization Technical

accordance with approved methods for the grade of material

Barriers to Trade (TBT) Committee.

used.

NOTE 1—Grades 1 and 1A have different chemistries but the same

2. Referenced Documents

mechanical requirements.

2.1 ASTM Standards:

NOTE 2—Designations have been changed as follows:

A275/A275M Practice for Magnetic Particle Examination of

Current Formerly

Steel Forgings

Grade 1 Class 1

A370 Test Methods and Definitions for Mechanical Testing

Grade 1A Class 1A

of Steel Products

Grade 1C Class 4

Grade 2 Class 1 Class 2 A388/A388M Practice for Ultrasonic Examination of Steel

Grade 2 Class 2 Class 2A

Forgings

Grade 3 Class 1 Class 3

A788/A788M Specification for Steel Forgings, General Re-

Grade 3 Class 2 Class 3A

quirements

Grade 4N Class 1 Class 7

Grade 4N Class 2 Class 7A

E208 Test Method for Conducting Drop-Weight Test to

Grade 4N Class 3 Class 7B

Determine Nil-Ductility Transition Temperature of Fer-

Grade 5 Class 1 Class 8

Grade 5 Class 2 Class 8A ritic Steels

Grade 11 Class 4 Class 11C

2.2 ASME Code:

Grade 22 Class 3 Class 22B

Grade 22 Class 4 Class 22C ASME Boiler and Pressure Vessel Code

Grade 22 Class 5 Class 22D

Grade 22V Class 22V

3. Ordering Information and General Requirements

Grade 3V Class 3V

3.1 In addition to the ordering information required by

1.3 The values stated in either inch-pound units or SI

Specification A788/A788M, the purchaser shall include with

(metric) units are to be regarded separately as standard. Within

the inquiry and order a detailed drawing that locates areas of

the text and tables, the SI units are shown in brackets. The

significant loading in the forging (when required); the method

values stated in each system are not necessarily exact equiva-

of selecting test locations (see 6.2); purchase option (if any) in

lents; therefore, to ensure conformance with the standard, each

accordance with 9.1, and any supplementary requirements

system shall be used independently of the other, and values

desired.

from the two systems shall not be combined.

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and RelatedAlloys, and is the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

A01.06 on Steel Forgings and Billets. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved March 1, 2020. Published March 2020. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1965. Last previous edition approved in 2015 as A541/A541M – 05 the ASTM website.

(2015). DOI: 10.1520/A0541_A0541M–05R20. Available from American Society of Mechanical Engineers (ASME), ASME

For ASME Boiler and Pressure Vessel Code applications, see related Specifi- International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

cation SA-541/SA-541M in Section II of that Code. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A541/A541M−05 (2020)

3.2 Material supplied to this specification shall conform to

Grade °F [°C]

the requirements of Specification A788/A788M, which out-

1, 1A, 2 Class 2, 3 Class 2 1150 [620]

lines additional ordering information, manufacturing

2, 3 Class 1, 22 Class 3 1200 [650]

requirements, testing and retesting methods and procedures,

1C, 11 Class 4, 22 Class 4, 4N Class 1, 4N 1100 [595]

Class 2, 5 Class 1, 5 Class 2

marking, certification, product analysis variations, and addi-

22 Class 15 1050 [565]

tional supplementary requirements.

4N Class 3 1125 [605]

3V, 3VCb 1250 [675]

3.3 If the requirements of this specification are in conflict

22V 1250 [675]

with the requirements of Specification A788/A788M, the

5.2 For Classes 1, 1A, 2, 2A, 3, or 3A, a multiple stage

requirements of this specification shall prevail.

austenitizing procedure may be used whereby the forging is

first fully austenitized and liquid quenched, followed by

4. Chemical Composition

reheating within the intercritical temperature range to partially

4.1 Heat Analysis—The heat analysis obtained from sam-

reaustenitize, and again liquid quenched. On completion of the

pling in accordance with Specification A788/A788M shall

austenitizing/quenching cycles, the forgings shall be tempered

comply with Table 1 except that the additional features of

at a subcritical temperature as described in 5.1.

Supplementary Requirements S8, S9, S10, S12, and S15 shall

alsoapplyasindividuallyspecifiedintheorderinginformation. 6. Mechanical Properties

4.2 ProductAnalysis—The manufacturer shall use the prod- 6.1 General Requirements—The forgings shall conform to

uct analysis provision of Specification A788/A788M to obtain the requirements of Table 2.The forgings shall also conform to

a product analysis from a forging representing each heat or the requirements of Table 3 unless either Supplementary

multiple heat. The permissible variations of Table 1 of Speci- Requirement S6 or S13 is specified, in which case the

fication A788/A788M do not apply to carbon, phosphorus, requirements of those sections shall apply. The largest obtain-

silicon,andsulphurforallclasses,vanadiumforGrade1C,and able tension test specimen as specified in Fig. 4 of Test

columbium and calcium for Grades 22V and 3VCb. Boron is Methods and Definitions A370 shall be used. Impact speci-

not subject to product analysis. The purchaser may also make mens shall be Charpy V-notch, as shown in Fig. 10 of Test

this determination in accordance with Specification A788/ Methods and Definitions A370. The usage of subsize impact

A788M.

specimens due to material limitations must have prior pur-

chaser approval.

5. Heat Treatment for Mechanical Properties

6.2 Sampling—The longitudinal axis and mid-length of

5.1 After complete austenitization, the forgings shall be tension and impact test specimens shall be positioned in

quenched in a suitable liquid medium by spraying or immer- accordance with one of the following methods as specified by

sion. For Grade 22V forgings, the minimum austenitizing the purchaser:

temperature shall be 1650 °F [900 °C]. Quenching shall be 6.2.1 Method 1—This method shall always be used when

followed by tempering at a subcritical temperature and holding the maximum quenched thickness does not exceed 2 in. [50

at this temperature for a minimum time of ⁄2 h/in. [25 mm] of mm]. Specimens shall be located in the production forging or

maximumsectionthickness.Minimumtemperingtemperatures test forging (as described in Method 4) at mid-thickness and at

shall be: least 2 in. from other quenched surfaces.

TABLE 1 Chemical Requirements Composition, %

Grade 1 Grade 1A Grade 2 Grade 3 Grade 1C Grade 11 Grade 22 Grade 4N Grade 5 Grade 3V Grade 22 Grade 22V Grade

Class 4 Classes 4 Class 3 3VCb

and 5

Carbon 0.35 max 0.30 max 0.27 max 0.25 max 0.18 max 0.10–0.20 0.05–0.15 0.23 max 0.23 max 0.10–0.15 0.11–0.15 0.11–0.15 0.10-0.15

Manganese 0.40–0.90 0.70–1.35 0.50–0.90 1.20–1.50 1.30 max 0.30–0.80 0.30–0.60 0.20–0.40 0.20–0.40 0.30–0.60 0.30–0.60 0.30–0.60 0.30-0.60

Phosphorus 0.025 max 0.025 max 0.025 max 0.025 max 0.025 max 0.025 max 0.025 max 0.025 max 0.025 max 0.020 max 0.015 max 0.015 max 0.020 max

Sulfur 0.025 max 0.025 max 0.025 max 0.025 max 0.025 max 0.025 max 0.025 max 0.025 max 0.025 max 0.020 max 0.015 max 0.010 max 0.010 max

A

Silicon 0.35 max 0.40 max 0.35 max 0.35 max 0.35 max 0.50–1.00 0.50 max 0.30 max 0.30 max 0.10 max 0.50 max 0.10 max 0.10 max

Nickel 0.40 max 0.40 max 0.50–1.00 0.40–1.00 0.25 max 0.50 max 0.50 max 2.8–3.9 2.8–3.9 . . . 0.25 max 0.25 max 0.25 max

Chromium 0.25 max 0.25 max 0.25–0.45 0.25 max 0.15 max 1.00–1.50 2.00–2.50 1.25–2.00 1.25–2.00 2.8–3.3 2.00–2.50 2.00–2.50 2.7-3.3

Molybdenum 0.10 max 0.10 max 0.55–0.70 0.45–0.60 0.05 max 0.45–0.65 0.90–1.10 0.40–0.60 0.40–0.60 0.90–1.10 0.90–1.10 0.90–1.10 0.90-1.10

Vanadium 0.05 max 0.05 max 0.05 max 0.05 max 0.02–0.12 0.05 max 0.05 max 0.03 max 0.08 max 0.20–0.30 0.02 max 0.25–0.35 0.20-0.30

Titanium . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.015–0.035 . . . 0.030 max 0.015 max

Boron . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.001–0.003 . . . 0.0020 max . . .

Copper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 max 0.25 max

Columbium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.07 max 0.015-0.070

B

Calcium . . . . . . . . . . . 0.015 max 0.0005-

0.0150

A

When vacuum carbon-deoxidation is required for the classes included in Supplementary Requirement S10, the silicon content shall be 0.10 % max.

B

For Grade 22V, rare earth metals (REM) may be added in place of calcium, subject to agreement between the producer and the purchaser. In that case the total amount

of REM shall be determined and reported.

A541/A541M−05 (2020)

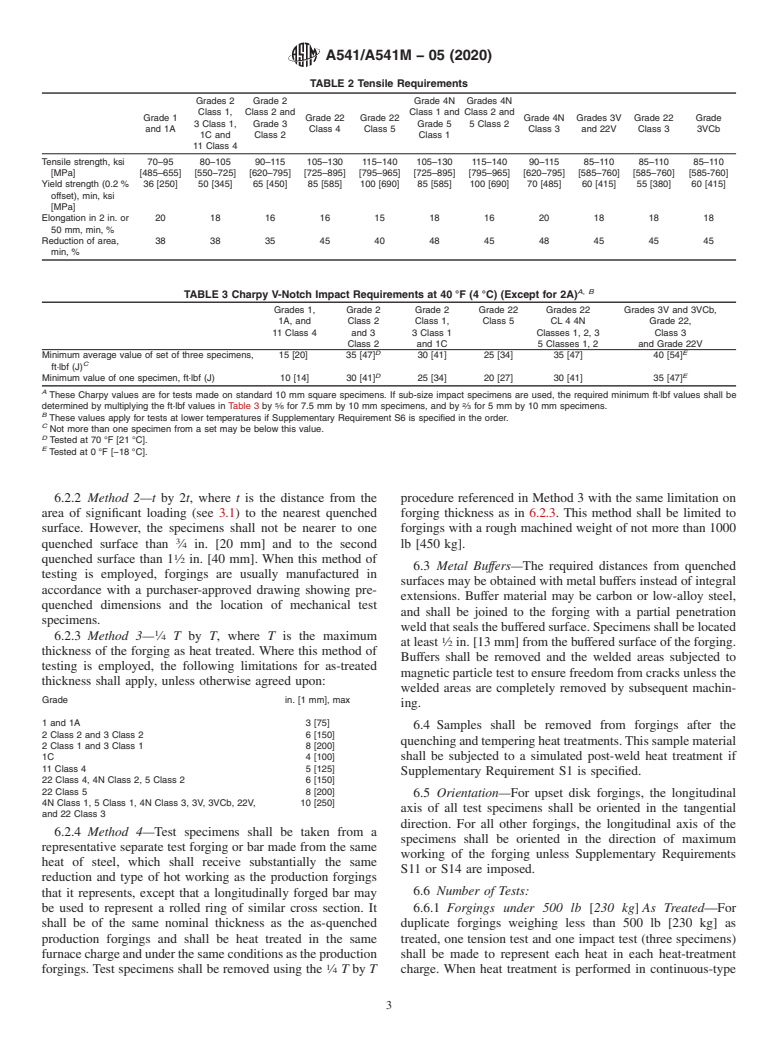

TABLE 2 Tensile Requirements

Grades 2 Grade 2 Grade 4N Grades 4N

Class 1, Class 2 and Class 1 and Class 2 and

Grade 1 Grade 22 Grade 22 Grade 4N Grades 3V Grade 22 Grade

3 Class 1, Grade 3 Grade 5 5 Class 2

and 1A Class 4 Class 5 Class 3 and 22V Class 3 3VCb

1C and Class 2 Class 1

11 Class 4

Tensile strength, ksi 70–95 80–105 90–115 105–130 115–140 105–130 115–140 90–115 85–110 85–110 85–110

[MPa] [485–655] [550–725] [620–795] [725–895] [795–965] [725–895] [795–965] [620–795] [585–760] [585–760] [585-760]

Yield strength (0.2 % 36 [250] 50 [345] 65 [450] 85 [585] 100 [690] 85 [585] 100 [690] 70 [485] 60 [415] 55 [380] 60 [415]

offset), min, ksi

[MPa]

Elongation in 2 in. or 20 18 16 16 15 18 16 20 18 18 18

50 mm, min, %

Reduction of area, 38 38 35 45 40 48 45 48 45 45 45

min, %

A, B

TABLE 3 Charpy V-Notch Impact Requirements at 40 °F (4 °C) (Except for 2A)

Grades 1, Grade 2 Grade 2 Grade 22 Grades 22 Grades 3V and 3VCb,

1A, and Class 2 Class 1, Class 5 CL 4 4N Grade 22,

11 Class 4 and 3 3 Class 1 Classes 1, 2, 3 Class 3

Class 2 and 1C 5 Classes 1, 2 and Grade 22V

D E

Minimum average value of set of three specimens, 15 [20] 35 [47] 30 [41] 25 [34] 35 [47] 40 [54]

C

ft·lbf (J)

D E

Minimum value of one specimen, ft·lbf (J) 10 [14] 30 [41] 25 [34] 20 [27] 30 [41] 35 [47]

A

These Charpy values are for tests made on standard 10 mm square specimens. If sub-size impact specimens are used, the required minimum ft·lbf values shall be

5 2

determined by multiplying the ft·lbf values in Table 3 by ⁄6 for 7.5 mm by 10 mm specimens, and by ⁄3 for 5 mm by 10 mm specimens.

B

These values apply for tests at lower temperatures if Supplementary Requirement S6 is specified in the order.

C

Not more than one specimen from a set may be below this value.

D

Tested at 70 °F [21 °C].

E

Tested at 0 °F [−18 °C].

6.2.2 Method 2—t by 2t, where t is the distance from the procedure referenced in Method 3 with the same limitation on

area of significant loading (see 3.1) to the nearest quenched forging thickness as in 6.2.3. This method shall be limited to

surface. However, the specimens shall not be nearer to one forgings with a rough machined weight of not more than 1000

quenched surface than ⁄4 in. [20 mm] and to the second lb [450 kg].

quenched surface than 1 ⁄2 in. [40 mm]. When this method of

6.3 Metal Buffers—The required distances from quenched

testing is employed, forgings are usually manufactured in

surfaces may be obtained with metal buffers instead of integral

accordance with a purchaser-approved drawing showing pre-

extensions. Buffer material may be carbon or low-alloy steel,

quenched dimensions and the location of mechanical test

and shall be joined to the forging with a partial penetration

specimens.

weldthatsealsthebufferedsurface.Specimensshallbelocated

6.2.3 Method 3— ⁄4 T by T, where T is the maximum

at least ⁄2 in. [13 mm] from the buffered surface of the forging.

thickness of the forging as heat treated. Where this method of

Buffers shall be removed and the welded areas subjected to

testing is employed, the following limitations for as-treated

magnetic particle test to ensure freedom from cracks unless the

thickness shall apply, unless otherwise agreed upon:

welded areas are completely removed by subsequent machin-

Grade in. [1 mm], max

ing.

1 and 1A 3 [75]

6.4 Samples shall be removed from forgings after the

2 Class 2 and 3 Class 2 6 [150]

quenchingandtemperingheattreatments.Thissamplematerial

2 Class 1 and 3 Class 1 8 [200]

1C 4 [100] shall be subjected to a simulated post-weld heat treatment if

11 Class 4 5 [125]

Supplementary Requirement S1 is specified.

22 Class 4, 4N Class 2, 5 Class 2 6 [150]

22 Class 5 8 [200]

6.5 Orientation—For upset disk forgings, the longitudinal

4N Class 1, 5 Class 1, 4N Class 3, 3V, 3VCb, 22V, 10 [250]

axis of all test specimens shall be oriented in the tangential

and 22 Class 3

direction. For all other forgings, the longitudinal axis of the

6.2.4 Method 4—Test specimens shall be taken from a

specimens shall be oriented in the direction of maximum

representative separate test forging or bar made from the same

working of the forging unless Supplementary Requirements

heat of steel, which shall receive substantially the same

S11 or S14 are imposed.

reduction and type of hot working as the production forgings

6.6 Number of Tests:

that it represents, except that a longitudinally forged bar may

be used to represent a rolled ring of similar cross section. It

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.