ASTM C408-88(2020)

(Test Method)Standard Test Method for Thermal Conductivity of Whiteware Ceramics

Standard Test Method for Thermal Conductivity of Whiteware Ceramics

SIGNIFICANCE AND USE

2.1 This test method provides information useful in understanding and quantifying such parameters as thermal shock resistance and ability to conduct or dissipate heat.

SCOPE

1.1 This test method covers a general procedure2 for determining the thermal conductivity of whiteware ceramics over the temperature range from 100 to 300 °F (40 to 150 °C).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C408 − 88 (Reapproved 2020)

Standard Test Method for

Thermal Conductivity of Whiteware Ceramics

This standard is issued under the fixed designation C408; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope (305 mm) long, which is sealed to the base with a rubber

2 gasket. With the exception of the copper thermodes and the

1.1 This test method covers a general procedure for deter-

coppercoolingjackets,theinstrumentshallbemadeentirelyof

mining the thermal conductivity of whiteware ceramics over

brass with all joints silver soldered. During operation, the

the temperature range from 100 to 300 °F (40 to 150 °C).

system shall be evacuated to a pressure of approximately 1 µm

1.2 The values stated in inch-pound units are to be regarded

of mercury with an oil-diffusion pump which is backed up with

as standard. The values given in parentheses are mathematical

a mechanical vacuum pump.

conversions to SI units that are provided for information only

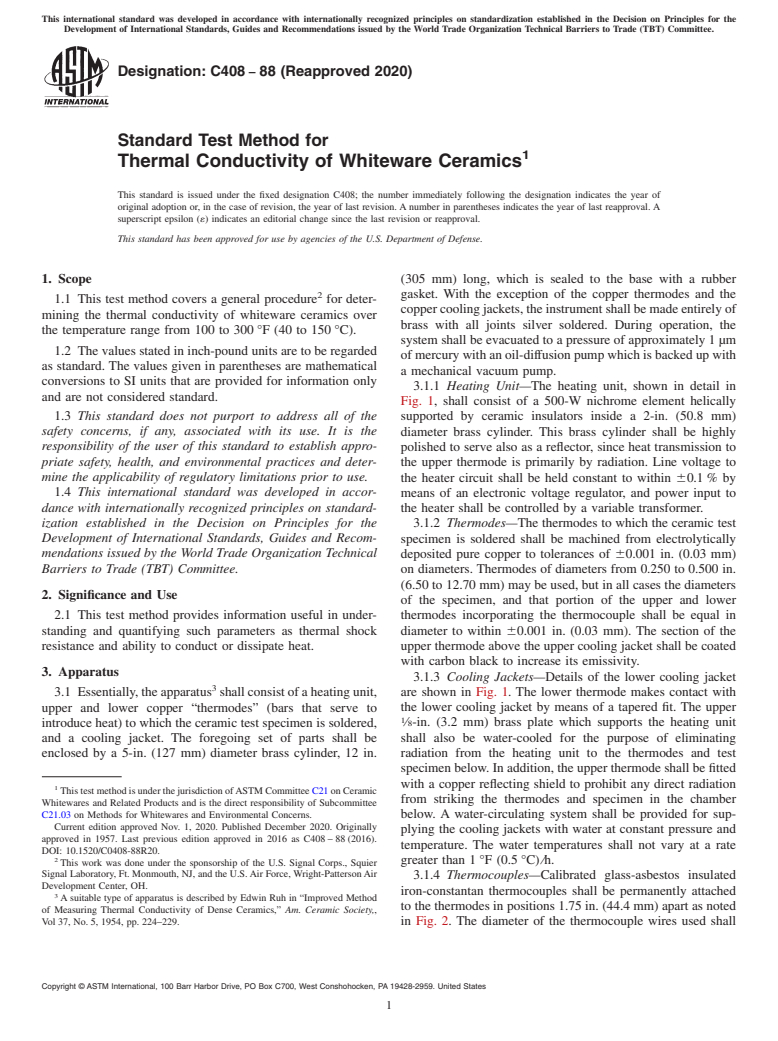

3.1.1 Heating Unit—The heating unit, shown in detail in

and are not considered standard.

Fig. 1, shall consist of a 500-W nichrome element helically

1.3 This standard does not purport to address all of the supported by ceramic insulators inside a 2-in. (50.8 mm)

safety concerns, if any, associated with its use. It is the

diameter brass cylinder. This brass cylinder shall be highly

responsibility of the user of this standard to establish appro- polished to serve also as a reflector, since heat transmission to

priate safety, health, and environmental practices and deter-

the upper thermode is primarily by radiation. Line voltage to

mine the applicability of regulatory limitations prior to use. the heater circuit shall be held constant to within 60.1 % by

1.4 This international standard was developed in accor-

means of an electronic voltage regulator, and power input to

dance with internationally recognized principles on standard- the heater shall be controlled by a variable transformer.

ization established in the Decision on Principles for the

3.1.2 Thermodes—The thermodes to which the ceramic test

Development of International Standards, Guides and Recom- specimen is soldered shall be machined from electrolytically

mendations issued by the World Trade Organization Technical

deposited pure copper to tolerances of 60.001 in. (0.03 mm)

Barriers to Trade (TBT) Committee. on diameters. Thermodes of diameters from 0.250 to 0.500 in.

(6.50 to 12.70 mm) may be used, but in all cases the diameters

2. Significance and Use

of the specimen, and that portion of the upper and lower

2.1 This test method provides information useful in under- thermodes incorporating the thermocouple shall be equal in

standing and quantifying such parameters as thermal shock diameter to within 60.001 in. (0.03 mm). The section of the

resistance and ability to conduct or dissipate heat. upper thermode above the upper cooling jacket shall be coated

with carbon black to increase its emissivity.

3. Apparatus

3.1.3 Cooling Jackets—Details of the lower cooling jacket

3.1 Essentially,theapparatus shallconsistofaheatingunit, are shown in Fig. 1. The lower thermode makes contact with

the lower cooling jacket by means of a tapered fit. The upper

upper and lower copper “thermodes” (bars that serve to

introduce heat) to which the ceramic test specimen is soldered, ⁄8-in. (3.2 mm) brass plate which supports the heating unit

shall also be water-cooled for the purpose of eliminating

and a cooling jacket. The foregoing set of parts shall be

enclosed by a 5-in. (127 mm) diameter brass cylinder, 12 in. radiation from the heating unit to the thermodes and test

specimen below. In addition, the upper thermode shall be fitted

with a copper reflecting shield to prohibit any direct radiation

This test method is under the jurisdiction ofASTM CommitteeC21 on Ceramic

from striking the thermodes and specimen in the chamber

Whitewares and Related Products and is the direct responsibility of Subcommittee

C21.03 on Methods for Whitewares and Environmental Concerns.

below. A water-circulating system shall be provided for sup-

Current edition approved Nov. 1, 2020. Published December 2020. Originally

plying the cooling jackets with water at constant pressure and

approved in 1957. Last previous edition approved in 2016 as C408 – 88 (2016).

temperature. The water temperatures shall not vary at a rate

DOI: 10.1520/C0408-88R20.

greater than 1 °F (0.5 °C)⁄h.

This work was done under the sponsorship of the U.S. Signal Corps., Squier

Signal Laboratory, Ft. Monmouth, NJ, and the U.S.Air Force, Wright-PattersonAir

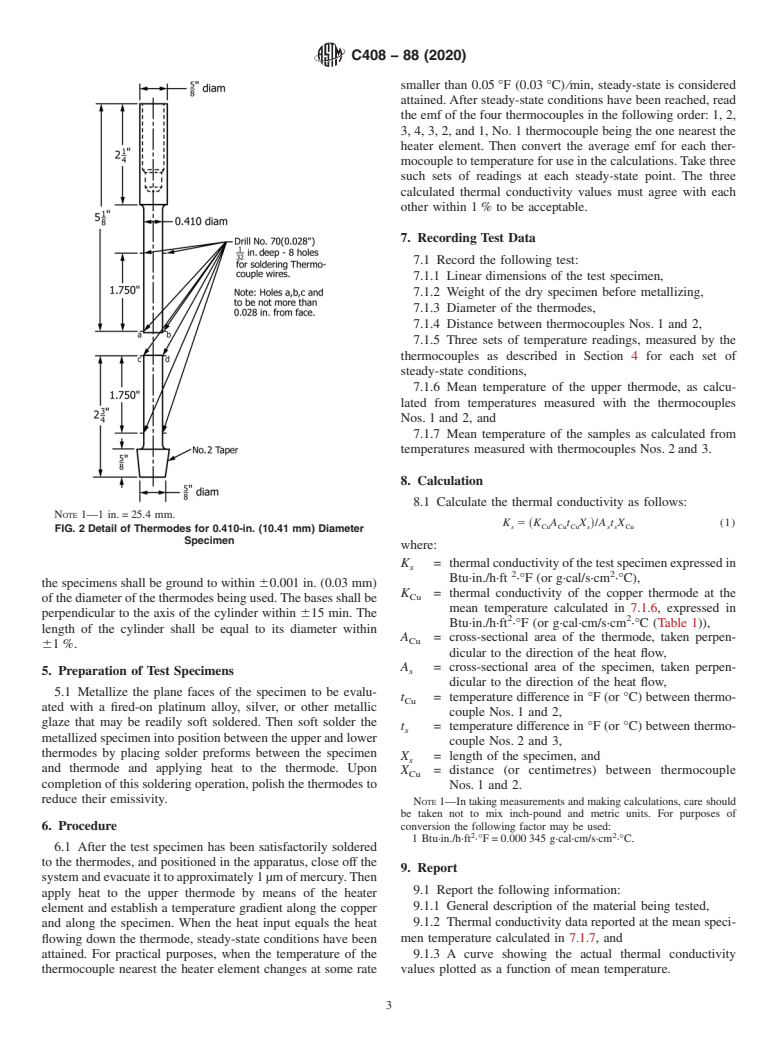

3.1.4 Thermocouples—Calibrated glass-asbestos insulated

Development Center, OH.

iron-constantan thermocouples shall be permanently attached

A suitable type of apparatus is described by Edwin Ruh in “Improved Method

to the thermodes in positions 1.75 in. (44.4 mm) apart as noted

of Measuring Thermal Conductivity of Dense Ceramics,” Am. Ceramic Society,,

Vol 37, No. 5, 1954, pp. 224–229. in Fig. 2. The diameter of the thermocouple wires used shall

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C408 − 88 (2020)

FIG. 1 Thermal Conductivity Apparatus

not exceed the diameter of No. 28 AWG (0.321 mm). The instrument for measuring emf shall not have an instrument

thermocouple wires shall be permanently attached to the error greater than 60.001 mV.

thermode by silver-soldering each wire of the thermocouple

4. Test Specimens

into No. 70 (0.028-in. diameter) (0.71 mm) holes drilled in the

thermode to a depth of ⁄32 in. (0.8 mm) on opposite ends of a 4.1 The ceramic test specimens used in the thermal conduc-

diameter. All thermocouple wires shall be taken through the tivity instrument shall be accurately ground cylinders. The

base plate without any break in the continuity of the wire. An specimens may b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.