ASTM C773-88(2020)

(Test Method)Standard Test Method for Compressive (Crushing) Strength of Fired Whiteware Materials

Standard Test Method for Compressive (Crushing) Strength of Fired Whiteware Materials

SIGNIFICANCE AND USE

3.1 Resistance to compression is the measure of the greatest strength of a ceramic material. Ideally, ceramics should be stressed this way in use. This test is a measure of the potential load-bearing usefulness of a ceramic.

SCOPE

1.1 This test method covers two test procedures (A and B) for the determination of the compressive strength of fired whiteware materials.

1.2 Procedure A is generally applicable to whiteware products of low- to moderately high-strength levels (up to 150 000 psi or 1030 MPa).

1.3 Procedure B is specifically devised for testing of high-strength ceramics (over 100 000 psi or 690 MPa).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C773 − 88 (Reapproved 2020)

Standard Test Method for

Compressive (Crushing) Strength of Fired Whiteware

Materials

This standard is issued under the fixed designation C773; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope stressed this way in use. This test is a measure of the potential

load-bearing usefulness of a ceramic.

1.1 This test method covers two test procedures (A and B)

for the determination of the compressive strength of fired

PROCEDURE A

whiteware materials.

1.2 Procedure A is generally applicable to whiteware prod-

4. Apparatus

ucts of low- to moderately high-strength levels (up to

4.1 Testing Machine—Any testing machine conforming to

150 000 psi or 1030 MPa).

Practices E4 and to the requirements for speed of testing

1.3 Procedure B is specifically devised for testing of high-

prescribed in Sections 5 and 12 of this test method, may be

strength ceramics (over 100 000 psi or 690 MPa).

used.

1.4 This standard does not purport to address all of the

4.2 Spherical Bearing Block—In vertical testing machines,

safety concerns, if any, associated with its use. It is the

the spherical bearing block shall be spring suspended from the

responsibility of the user of this standard to establish appro-

upper head of the machine in such a manner that the upper

priate safety, health, and environmental practices and deter-

platen of the machine (lower face of the spherical bearing

mine the applicability of regulatory limitations prior to use.

block) remains in a central position (spherical surfaces in full

1.5 This international standard was developed in accor-

contact) when not loaded. The spherical surfaces shall be well

dance with internationally recognized principles on standard-

lubricated, and the center of curvature shall lie on the lower

ization established in the Decision on Principles for the

face of the platen. The diagonal or diameter of the platen shall

Development of International Standards, Guides and Recom-

be only slightly greater than the diagonal of the 1 ⁄2-in.

mendations issued by the World Trade Organization Technical

(38.1 mm)squarecontactblockstofacilitateaccuratecentering

Barriers to Trade (TBT) Committee.

of the specimens.

2. Referenced Documents

4.3 Contact Blocks—Cold-rolled steel contact blocks shall

2.1 ASTM Standards:

be used between the test specimen and the platens of the

E4 Practices for Force Verification of Testing Machines 1 5

machine. These blocks shall be 1 ⁄2 in. (38.1 mm) square by ⁄8

E6 Terminology Relating to Methods of Mechanical Testing

to ⁄4 in. (15.9 to 19.1 mm) thick, and the contact faces shall be

E165/E165M Practice for Liquid Penetrant Testing for Gen-

surface ground until plane and parallel. The contact blocks

eral Industry

shall be resurfaced, if necessary, after each strength test, and

may be reused only so long as the thickness remains over ⁄2 in.

3. Significance and Use

(12.7 mm). If the contact block is cracked during testing, it

3.1 Resistance to compression is the measure of the greatest

shall be replaced.

strength of a ceramic material. Ideally, ceramics should be

4.4 Cushion Pads—Cushion pads shall be used between the

test specimens and the contact blocks to aid in distributing the

load. New cushion pads shall be used for each specimen.

ThistestmethodisunderthejurisdictionofASTMCommitteeC21onCeramic

Suitable materials for cushion pads, selected in accordance

Whitewares and Related Products and is the direct responsibility of Subcommittee

C21.03 on Methods for Whitewares and Environmental Concerns.

with the compressive strength range of the material being

Current edition approved Nov. 1, 2020. Published December 2020. Originally

tested, are shown in the following below:

approvedin1974toreplaceC407andC528.Lastpreviouseditionapprovedin2016

Compressive Strength Range, psi Cushion Pad

as C773 – 88 (2016). DOI: 10.1520/C0773-88R20.

(MPa)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5000 to 50 000 incl (34.5 to 345) blotting paper, ⁄64 in. (0.4 mm) thick

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Over 50 000 to 150 000 incl (345 to mild steel, ⁄32 in. (0.8 mm) thick

Standards volume information, refer to the standard’s Document Summary page on

1030.0) (65 HRB max)

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

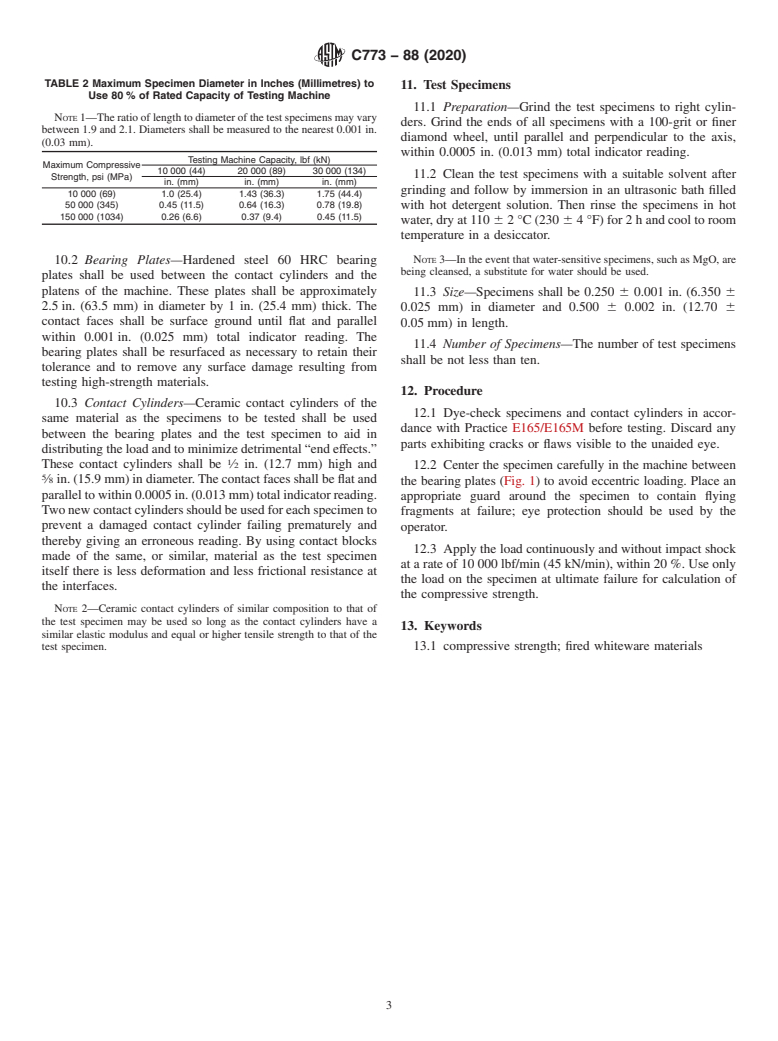

C773 − 88 (2020)

TABLE 1 Typical Loading Rates to Cause Failure in 1 min NOTE 1—It is desirable to include details of the origin of the specimen

and subsequent treatment.

NOTE 1—The loading rate of 16 000 lbf/min (70 kN/min) shall be used

for the first three tests of an unknown material to determine the general

8. Precision and Bias

strength classification group. Some specimens crack before ultimate

8.1 Interlaboratory Test Data—An interlaboratory test was

failure; the load at which the first audible crack occurs shall be noted, but

run in 1979 in which randomly drawn samples of six materials

only the load on the specimen at ultimate failure shall be used for

calculation of compressive strength.

were tested in each of five laboratories. One operator in each

Compressive Strength, Specimen Diameter, Loading Rate, laboratory tested ten specimens of each material. The compo-

psi (MPa) in. (mm) lbf/min (kN/min)

nents of variance for compressive strength results expressed as

10 000 (69) 1.00 (25.4) 8000 (35)

coefficients of variation were calculated as follows:

50 000 (345) 0.64 (16.3) 16 000 (70)

single-operator component 1.50 % of the average

150 000 (1034) 0.45 (11.5) 24 000 (105)

between-laboratory component 8.80 % of the average

8.2 Critical Differences—For the components of variance

reported in 8.1, two averages of observed values should be

5. Procedure

considered significantly different at the 95 % probability level

5.1 Dye-checkspecimensinaccordancewithPracticeE165/

if the difference equals or exceeds the following critical

E165M before testing. Discard any pieces exhibiting cracks or

differences listed below:

flaws visible to the unaided eye.

A

Critical Difference, % of Grand Average

5.2 Clean the test specimens with a suitable solvent after Number of Observa- Single-operator Between-laboratory

tions in Each Average Precision Precision

grinding and immerse in an ultrasonic bath filled with hot

10 4.16 24.40

detergent solution. Then rinse specimens in hot water, dry at

110 6 2 °C (230 6 4 °F) for 2 h and cool to room temperature A

The critical differences were calculated using t = 1.960 which is based on infinite

in a desiccator. degrees of freedom.

5.3 Carefully center the specimen in the machine between

8.3 Confidence Limits—For the components of variance

the contact blocks. Place an appropriate guard around the

noted in 8.1, single averages of observed values have the

specimen to contain flying fragments at failure; eye protection

following 95 % confidence limits:

should be used by the operator.

Width of 95 % Confidence Limits,

A

5.4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.