ASTM F2178-02

(Test Method)Standard Test Method for Determining The Arc Rating Of Face Protective Products

Standard Test Method for Determining The Arc Rating Of Face Protective Products

SCOPE

1.1 This test method is used to measure the arc rating of products intended for use as face protection for workers exposed to electric arcs.

1.2 This test method will measure the arc rating of face protective products. The faceshield or other applicable portions of the complete product must meet ANSI Z87.1. This excludes the textile or non ANSI Z87.1 testable parts of the hood assemblies or other tested products. This standard does not measure optical and impact properties (See ANSI Z87.1).

1.3 The materials used in this method are in the form of faceshields attached to the head by protective helmets (hard hats), headgear, or hood assemblies.

1.3.1 Fabric layers used in hood assemblies or other items tested under this standard meet flammability requirements of Specification F 1506.

1.4 This standard shall be used to measure and describe the properties of materials, products, or assemblies in response to convective and radiant energy generated by an electric arc under controlled laboratory conditions and does not purport to predict damage from light other than the thermal aspects measured.

1.5 Units—The values stated in either SI units or in other units shall be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way.

1.6 This standard shall not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire assessment, which takes into account all of the factors, which are pertinent to an assessment of the fire hazard of a particular end use.

1.7 This standard does not purport to describe or appraise the effect of the electric arc fragmentation explosion and subsequent molten metal splatter, which involves the pressure wave containing molten metals and possible fragments of other materials except to the extent that heat energy transmission due to these arc explosion phenomena is reduced by test specimens.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautions, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2178–02

Standard Test Method for

Determining The Arc Rating Of Face Protective Products

This standard is issued under the fixed designation F2178; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope wavecontainingmoltenmetalsandpossiblefragmentsofother

materialsexcepttotheextentthatheatenergytransmissiondue

1.1 This test method is used to measure the arc rating of

tothesearcexplosionphenomenaisreducedbytestspecimens.

products intended for use as face protection for workers

1.8 This standard does not purport to address all of the

exposed to electric arcs.

safety concerns, if any, associated with its use. It is the

1.2 This test method will measure the arc rating of face

responsibility of the user of this standard to establish appro-

protectiveproducts.Thefaceshieldorotherapplicableportions

priate safety and health practices and determine the applica-

of the complete product must meetANSI Z87.1.This excludes

bility of regulatory limitations prior to use. For specific

the textile or non ANSI Z87.1 testable parts of the hood

precautions, see Section 7.

assemblies or other tested products. This standard does not

measure optical and impact properties (See ANSI Z87.1).

2. Referenced Documents

1.3 The materials used in this method are in the form of

2.1 ASTM Standards:

faceshields attached to the head by protective helmets (hard

C177 Test Method for Steady-State Heat Flux Measure-

hats), headgear, or hood assemblies.

ments and Thermal Transmission Properties by Means of

1.3.1 Fabric layers used in hood assemblies or other items

the Guarded-Hot-Plate Apparatus

tested under this standard meet flammability requirements of

D123 Terminology Relating to Textiles

Specification F1506.

D4391 Terminology Relating to the Burning Behavior of

1.4 This standard shall be used to measure and describe the

Textiles

properties of materials, products, or assemblies in response to

E457 TestMethodforMeasuringHeat-TransferRateUsing

convective and radiant energy generated by an electric arc

a Thermal Capacitance (Slug) Calorimeter

under controlled laboratory conditions and does not purport to

F1494 Terminology Relating to Protective Clothing

predict damage from light other than the thermal aspects

F1506 Specification for Flame Resistant Textile Materials

measured.

for Wearing Apparel for Use by Electrical Workers Ex-

1.5 Units—The values stated in either SI units or in other

posed to Momentary Electric Arc and Related Thermal

unitsshallberegardedseparatelyasstandard.Thevaluesstated

Hazards

in each system may not be exact equivalents; therefore, each

F1958 Test Method for Determining the Ignitability of

system must be used independently of the other, without

Non-Flame-Resistant Materials for Clothing by Electric

combining values in any way.

Arc Exposure Method Using Mannequins

1.6 This standard shall not be used to describe or appraise

F1959 Test Method for Determining the Arc Thermal

the fire hazard or fire risk of materials, products, or assemblies

Performance Value of Materials for Clothing

under actual fire conditions. However, results of this test may

2.2 ANSI/IEEE Standards:

be used as elements of a fire assessment, which takes into

IEEE Standard Dictionary of Electrical and Electronics

account all of the factors, which are pertinent to an assessment

Terms

of the fire hazard of a particular end use.

1.7 This standard does not purport to describe or appraise

the effect of the electric arc fragmentation explosion and

Annual Book of ASTM Standards, Vol 04.06.

subsequent molten metal splatter, which involves the pressure

Annual Book of ASTM Standards, Vol 07.01.

Annual Book of ASTM Standards, Vol 07.02.

Annual Book of ASTM Standards, Vol 15.03.

1 6

This test method is under the jurisdiction of ASTM Committee F18 on Annual Book of ASTM Standards, Vol 11.03.

Electrical Protective Equipment for Workers and is the direct responsibility of Annual Book of ASTM Standards, Vol 10.03.

Subcommittee F18.65 on Wearing Apparel. AvailablefromInstituteofElectricalandElectronicsEngineers,Inc.,445Hoes

Current edition approved April 10, 2002. Published June 2002. Ln., P.O. Box 1331, Piscataway, NJ 05584-1331.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2178

ANSI Z87.1-1999 Practice for Occupational and Educa- 3.2.13 calorimeter, n—a device used in which the heat

tional Eye and Face Protection measured causes a change in state.

3.2.13.1 Discussion—Thedeterminationofheatenergy,asa

3. Terminology consequence of an electrical arc exposure, is made in this

standardbymeasuringthechangeintemperatureofanexposed

3.1 Definitions—For definitions of other textile terms used

copper slug of specific geometry and mass during finite time

in this method, refer to terminology in Terminology D123,

intervals.

D4391 and F1494.

3.2.14 closure,n—pointonsupplycurrentwaveformwhere

3.2 Definitions of Terms Specific to This Standard:

arc is initiated.

3.2.1 afterflame, n—persistent flaming of a material after

3.2.15 deformation, n—for electric arc testing of face pro-

the ignition source has been removed.

tective products, the sagging of material greater than 3 in. or

3.2.2 afterflame time, n—the length of time for which a

melting in any manner that the faceshield/window touches any

material continues to flame after the ignition source has been

part of the body.

removed.

3.2.16 delta peak temperature, n—difference between the

3.2.3 arc duration, n—time duration of the arc, s.

maximumtemperatureandtheinitialtemperatureofthesensor

3.2.4 arc energy, vi dt, n—sum of the instantaneous arc

during the test, °C.

voltage values multiplied by the instantaneous arc current

values multiplied by the incremental time values during the 3.2.17 dripping, n—in electric arc testing, a material re-

sponse evidenced by flowing of the fiber polymer or the

arc, J.

faceshield window polymer.

3.2.5 arc gap, n—distance between the arc electrodes, in.

3.2.6 arc rating, n—a value which indicates the arc perfor- 3.2.18 electricarcignition,n—inelectricarctestingofface

manceofamaterialorsystemofmaterials;eitherATPVorE . protective products, the initiation of combustion as related to

BT

electric arc exposure, a response that causes the ignition of

3.2.6.1 Discussion—When the arc rating represents the

ATPV, it shall be reported as Arc Rating (ATPV). When Arc textile test specimen material which is accompanied by heat

and light, and then subsequent burning for at least 5 s, and

Rating represents the E , it shall be designated asArc Rating

BT

(E ).E isdeterminedwhentheATPVcannotbedetermined. consumption of at least 25% of the test specimen area.

BT BT

3.2.7 arc thermal performance value (ATPV), n—in arc 3.2.18.1 Discussion—For multilayer specimens, consump-

testingfaceprotectiveproducts,theincidentenergyonafabric tion of the innermost FR layer must be at least 25%.

or material that results in sufficient heat transfer through the

3.2.19 faceshield, n—a protective device commonly in-

fabric or material to cause the 50% probability of the onset of

tended to shield the wearer’s face, or portions thereof, in

a second-degree burn based on the Stoll curve. addition to the eyes, from certain hazards.

3.2.8 arc voltage, n—voltage across the gap caused by the

3.2.20 heat attenuation factor, HAF, n—in electric arc

current flowing through the resistance created by the arc gap

testing,theaverageofthepercentoftheincidentenergywhich

(V).

is blocked by a material.

3.2.9 asymmetrical arc current, n—the total arc current

3.2.20.1 Discussion—In Arc Testing of Face Protective

produced during closure; it includes a direct component and a

Products, HAF (face) is based on the highest sensor reading

symmetrical component, A.

among the four head sensors for each head exposure.

3.2.10 blowout, n—the extinguishing of the arc caused by a

3.2.21 heat flux, n—the thermal intensity indicated by the

magnetic field.

amountofenergytransmittedperunitareaandtime(cal/cm s).

3.2.11 breakopen, n—in electric arc testing, a material

3.2.22 i t, n—sum of the instantaneous arc current values

response evidenced by the formation of one or more holes in

squared multiplied by the incremental time values during the

the material which may allow thermal energy to pass through

arc, A /s.

material.

3.2.23 incident energy monitoring sensors, n—sensors

3.2.11.1 Discussion—Thespecimenisconsideredtoexhibit

mounted on each side of each head, using calorimeters, not

breakopen when any hole in the material or fabric is at least

covered by specimens, used to measure incident energy.

one-half square inch in area or at least one inch in any

3.2.24 incident exposure energy (E), n—in arc testing, the

i

dimension. For textile materials, single threads across the

total incident energy delivered to monitor calorimeter sensors

opening or hole does not reduce the size of the hole for the 2

as a result of the arc exposure, cal/cm .

purposesofthisstandard. In multiple layer specimensofflame

3.2.24.1 Discussion—In an arc test exposure, incident ex-

resistant material, all the layers must breakopen to meet the

posure energy for a specimen is determined from the average

definition.

of the measured incident energy from the respective two

3.2.12 breakopen threshold energy (E ), n—in arc testing

BT

monitor sensors adjacent to the test specimen.

face protective products, the incident energy on a fabric or

3.2.25 material response, n—material response to an elec-

material that represents the 50% probability that a breakopen

tricarcisindicatedbythefollowingterms:breakopen,melting,

response will occur.

dripping, deformation, afterflame time, shrinkage, and electric

arc ignition.

3.2.26 melting, n—in testing face protective products, a

material response evidenced by softening of the fiber polymer

Available from American National Standards Institute, 25 W. 43rd St., 4th

Floor, New York, NY 10036. or the faceshield window polymer.

F2178

3.2.27 peak arc current, n—maximum value of the AC arc 4.1.2 The thermal energy exposure and heat transport re-

current, A. sponse of the test specimen(s) are measured with copper slug

3.2.28 RMS arc current, n—root mean square of theAC arc calorimeters. The change in temperature versus time is used,

current, A. along with the known thermo-physical properties of copper to

3.2.29 shrinkage, n—in testing face protective products, a determinetherespectiveheatenergiesdeliveredtoandthrough

material response evidenced by reduction in specimen size of the specimen(s).

the fabric or the faceshield window. 4.2 This procedure incorporates incident energy monitoring

3.2.30 Stoll curve, n—curve produced from data on human sensors.

tissue tolerance to heat and used to predict the onset of 4.3 Productandmaterialperformanceforthisprocedureare

second-degree burn injury (See Table 1). determined by comparing the amount of heat energy generated

3.2.31 time to delta peak temperature, n—the time from by the arc flash on monitor sensors with the energy transferred

beginning of the initiation of the arc to the time the delta peak byorthroughthetestspecimen(s)andmeasuredbysensorson

temperature is reached, s. the mannequin head.

3.2.32 X/R ratio, n—the ratio of system inductive reactance 4.4 Product and material responses shall be further de-

to resistance. scribed by recording the observed effects of the electric arc

3.2.32.1 Discussion—It is proportional to the L/R ratio of exposure on the specimens using the terms in the Report

time constant, and is, therefore, indicative of the rate of decay section.

of any DC offset.Alarge X/R ratio corresponds to a large time

5. Significance and Use

constant and a slow rate of decay.

5.1 Thistestmethodisintendedforthedeterminationofthe

4. Summary of Test Method

arc rating of a product/design, intended for use as face

4.1 This test method determines the heat transport response protection for workers exposed to electric arcs.

5.1.1 Because of the variability of the arc exposure, differ-

across a material, fabric, or fabric system when exposed to the

heatenergyfromanelectricarc.Thisheattransportresponseis ent heat transmission values may result for individual sensors.

The results of each sensor are evaluated in accordance with

assessed versus the Stoll curve, an approximate human tissue

tolerance predictive model that projects the onset of a second- Section 12.

5.2 This test method maintains the specimen in a static,

degree burn injury (found in Table 1).

4.1.1 Productsaremountedonthestandardmannequinhead vertical position and does not involve movement except that

resulting from the exposure.

containing copper slug calorimeters inserted in the eyes,

mouth, and chin positions. During this procedure, the amount 5.3 This test method specifies a standard set of exposure

conditions. Different exposure conditions may produce differ-

of heat energy transferred by the specimen face protective

products is measured during and after exposure to an electric ent results.

arc.

NOTE 1—In addition to the standard set of exposure conditions, other

conditionsrepresentativeoftheexpectedhazardmaybeusedandshallbe

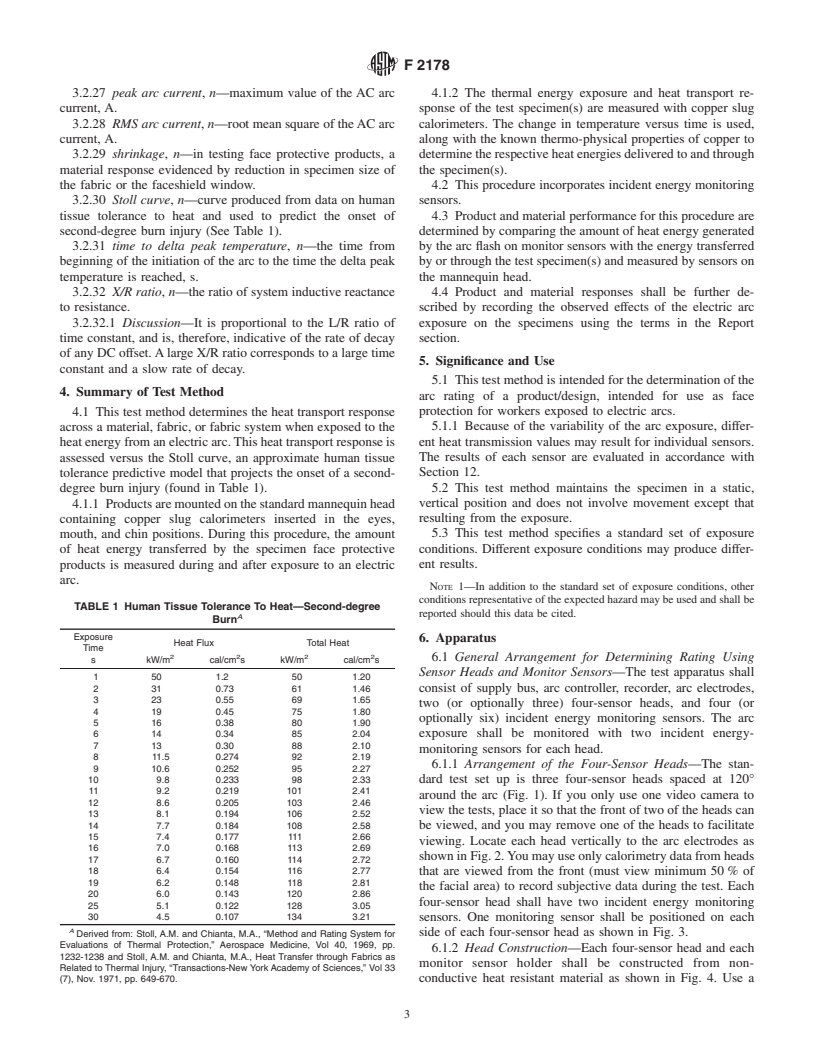

TABLE 1 Human Tissue Tolerance To Heat—Second-degree

reported should this data be cited.

A

Burn

Exposure

6. Apparatus

Heat Flux Total Heat

Time

2 2 2 2

6.1 General Arrangement for Determining Rating Using

s kW/m cal/cm s kW/m cal/cm s

Sensor Heads and Monitor Sensors—The test apparatus shall

1 50 1.2 50 1.20

2 31 0.73 61 1.46 consist of supply bus, arc controller, recorder, arc electrodes,

3 23 0.55 69 1.65

two (or optionally three) four-sensor heads, and four (or

4 19 0.45 75 1.80

optionally six) incident energy monitoring sensors. The arc

5 16 0.38 80 1.90

6 14 0.34 85 2.04 exposure shall be monitored with two incident energy-

7 13 0.30 88 2.10

monitoring sensors for each head.

8 11.5 0.274 92 2.19

6.1.1 Arrangement of the Four-Sensor Heads—The stan-

9 10.6 0.252 95 2.27

10 9.8 0.233 98 2.33 dard test set up is three four-sensor heads spaced at 120°

11 9.2 0.219 101 2.41

around the arc (Fig. 1). If you only use one video camera to

12 8.6 0.205 103 2.46

view the tests, place it so that the front of two of the heads can

13 8.1 0.194 106 2.52

14 7.7 0.184 108 2.58 be viewed, and you may remove one of the heads to facilitate

15 7.4 0.177 111 2.66

viewing. Locate each head vertically to the arc electrodes as

16 7.0 0.168 113 2.69

showninFig.2.Youmayuseonlycalorimetrydatafromheads

17 6.7 0.160 114 2.72

18 6.4 0.154 116 2.77

that are viewed from the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.