ASTM F1930-11

(Test Method)Standard Test Method for Evaluation of Flame Resistant Clothing for Protection Against Flash Fire Simulations Using an Instrumented Manikin

Standard Test Method for Evaluation of Flame Resistant Clothing for Protection Against Flash Fire Simulations Using an Instrumented Manikin

SIGNIFICANCE AND USE

Use this test method to measure the thermal protection provided by different materials, garments, clothing ensembles, and systems to a specified fire exposure (see 3.2.2, 4.1, 10.1.3, and 10.1.4).

This test method does not simulate high radiant exposures, for example, those found in electric arc flash exposures, some types of fire exposures where liquid or solid fuels are involved, nor exposure to nuclear explosions.

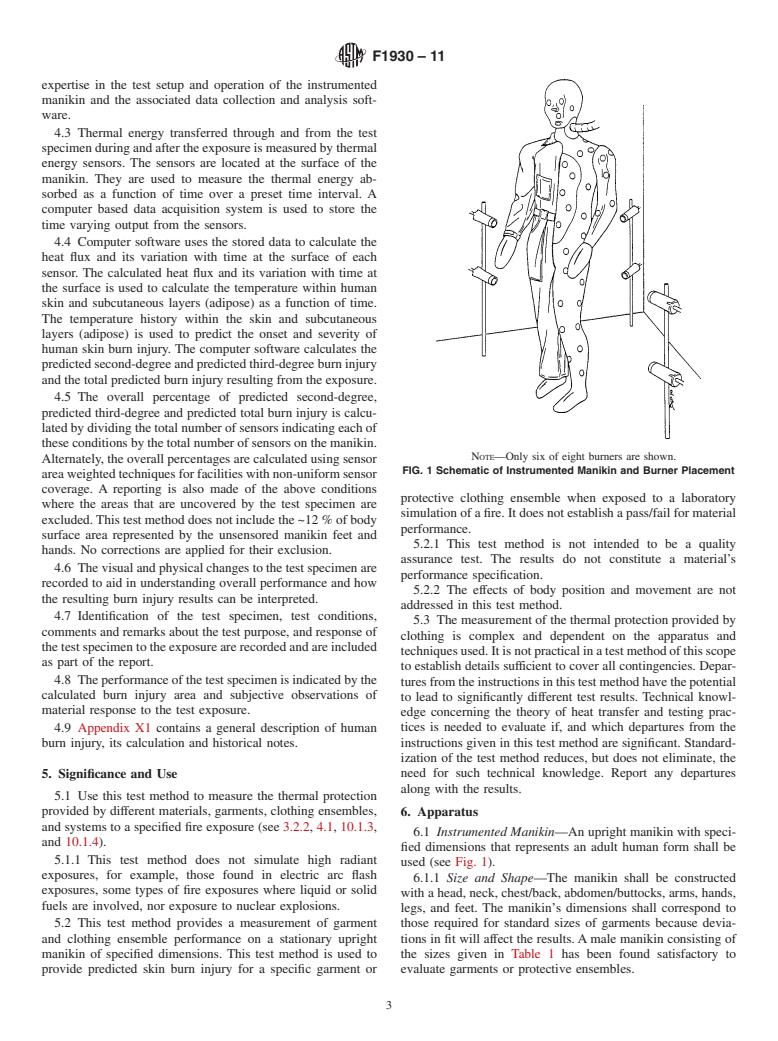

This test method provides a measurement of garment and clothing ensemble performance on a stationary upright manikin of specified dimensions. This test method is used to provide predicted skin burn injury for a specific garment or protective clothing ensemble when exposed to a laboratory simulation of a fire. It does not establish a pass/fail for material performance.

This test method is not intended to be a quality assurance test. The results do not constitute a material’s performance specification.

The effects of body position and movement are not addressed in this test method.

The measurement of the thermal protection provided by clothing is complex and dependent on the apparatus and techniques used. It is not practical in a test method of this scope to establish details sufficient to cover all contingencies. Departures from the instructions in this test method have the potential to lead to significantly different test results. Technical knowledge concerning the theory of heat transfer and testing practices is needed to evaluate if, and which departures from the instructions given in this test method are significant. Standardization of the test method reduces, but does not eliminate, the need for such technical knowledge. Report any departures along with the results.

SCOPE

1.1 This test method is used to provide predicted human skin burn injury for single layer garments or protective clothing ensembles mounted on a stationary instrumented manikin which are then exposed in a laboratory to a simulated fire environment having controlled heat flux, flame distribution, and duration. The average exposure heat flux is 84 kW/m2 (2 cal/s•cm2), with durations up to 20 seconds.

1.2 The visual and physical changes to the single layer garment or protective clothing ensemble are recorded to aid in understanding the overall performance of the garment or protective ensemble and how the predicted human skin burn injury results can be interpreted.

1.3 The skin burn injury prediction is based on a limited number of experiments where the forearms of human subjects were exposed to elevated thermal conditions. This forearm information for skin burn injury is applied uniformly to the entire body except for the hands and feet. The hands and feet are not included in the skin burn injury prediction.

1.4 The measurements obtained and observations noted can only apply to the particular garment(s) or ensemble(s) tested using the specified heat flux, flame distribution, and duration.

1.5 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire-hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.6 This method is not a fire-test-response test method.

1.7 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units or other units commonly used for thermal testing. If appropriate, round the non-SI units for convenience.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.9 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be emplo...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1930–11

Standard Test Method for

Evaluation of Flame Resistant Clothing for Protection

Against Flash Fire Simulations Using an Instrumented

1

Manikin

This standard is issued under the fixed designation F1930; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This test method is used to provide predicted human

bility of regulatory limitations prior to use.

skinburninjuryforsinglelayergarmentsorprotectiveclothing

1.9 Fire testing is inherently hazardous. Adequate safe-

ensembles mounted on a stationary instrumented manikin

guards for personnel and property shall be employed in

which are then exposed in a laboratory to a simulated fire

conducting these tests.

environment having controlled heat flux, flame distribution,

2

and duration. The average exposure heat flux is 84 kW/m (2

2. Referenced Documents

2

cal/s•cm ), with durations up to 20 seconds.

2

2.1 ASTM Standards:

1.2 The visual and physical changes to the single layer

D123 Terminology Relating to Textiles

garment or protective clothing ensemble are recorded to aid in

D1835 Specification for Liquefied Petroleum (LP) Gases

understanding the overall performance of the garment or

D5219 Terminology Relating to Body Dimensions for Ap-

protective ensemble and how the predicted human skin burn

parel Sizing

injury results can be interpreted.

E511 Test Method for Measuring Heat Flux Using a

1.3 The skin burn injury prediction is based on a limited

Copper-Constantan Circular Foil, Heat-Flux Transducer

number of experiments where the forearms of human subjects

F1494 Terminology Relating to Protective Clothing

were exposed to elevated thermal conditions. This forearm

3

2.2 AATCC Standards:

information for skin burn injury is applied uniformly to the

Test Method 135 Dimensional Changes of Fabrics after

entire body except for the hands and feet. The hands and feet

Home Laundering

are not included in the skin burn injury prediction.

Test Method 158 Dimensional Changes on Dry-Cleaning in

1.4 The measurements obtained and observations noted can

Perchloroethylene: Machine Method

only apply to the particular garment(s) or ensemble(s) tested

4

2.3 Canadian Standards:

using the specified heat flux, flame distribution, and duration.

CAN/CGSB-4.2 No. 58-M90 Textile Test Methods Color-

1.5 This standard is used to measure and describe the

fastness and Dimensional Change in Domestic Launder-

responseofmaterials,products,orassembliestoheatandflame

ing of Textiles

under controlled conditions, but does not by itself incorporate

CAN/CGSB-3.14 M88 Liquefied Petroleum Gas (Propane)

all factors required for fire-hazard or fire risk assessment of the

5

2.4 NFPA Standards:

materials, products, or assemblies under actual fire conditions.

NFPA 54 National Fuel Gas Code, 2009 Edition

1.6 This method is not a fire-test-response test method.

NFPA 58 Liquefied Petroleum Gas Code 2008 Edition

1.7 The values stated in SI units are to be regarded as

NFPA 85 Boiler and Combustion Systems Hazards Code,

standard. The values given in parentheses are mathematical

2007 Edition

conversions to inch-pound units or other units commonly used

NFPA 86 Standard for Ovens and Furnaces, 2007 Edition

for thermal testing. If appropriate, round the non-SI units for

convenience.

2

1.8 This standard does not purport to address all of the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

safety concerns, if any, associated with its use. It is the contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

Available from American Association of Textile Chemists and Colorists

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF23onPersonal (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://

Protective Clothing and Equipment and is the direct responsibility of Subcommittee www.aatcc.org.

4

F23.80 on Flame and Thermal. Available from Standards Council of Canada, Suite 1200, 45 O’Conor St.,

Current edition approved Feb. 1, 2011. Published March 2011. Originally Ottawa, Ontario, K1P 6N7.

5

approved in 1999. Last previous edition approved in 2008 as F1930 - 00(2008). Available from National Fire Protection Association (NFPA), 1 Batterymarch

DOI:10.1520/F1930–11. Park, Quincy, MA 02169-7471, http://www.nfpa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F1930–00 (Reapproved 2008) Designation:F1930–11

Standard Test Method for

Evaluation of Flame Resistant Clothing for Protection

Against Flash Fire Simulations Using an Instrumented

1

Manikin

This standard is issued under the fixed designation F1930; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This test method covers quantitative measurements and subjective observations that characterize the performance of single

layer garments or protective clothing ensembles in a simulated flash fire environment having controlled heat flux, flame

distribution, and duration. This test method is extremely complex and requires a high degree of technical expertise in both the test

setup and operation.

1.1.1Heat transmitted to each sensor location on the surface of an instrumented manikin is converted to show the corresponding

predicted degree of burn injury to human tissue.

1.1.2The sum of these values can then be converted to a percentage to show the total area of predicted burn injury.

1.1.2.1Use of the predicted burn injury to evaluate the heat transferred to the manikin does not constitute a material’s

performance specification.

1.1.3The visual and physical changes to the single layer garment or protective clothing ensemble are recorded to aid in

understanding how the burn injury results can be interpreted.

1.2The measurements obtained and observations noted can only apply to the particular garment(s) or ensemble(s) tested using

the specified heat flux, duration, and flame distribution.

1.3This standard should be used to measure and describe the response of materials, products, or assemblies to heat and flame

under controlled conditions and should not be used to describe or appraise the fire-hazard or fire-risk of materials, products, or

assemblies under actual fire conditions. However, results of this test may be used as elements of a fire-hazard assessment or a

fire-risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard or fire risk

of a particular end use.

1.4This test method is a fire-test-response test method.

1.5The values stated in customary units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units.

1.6This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations

prior to use.

1.1 This test method is used to provide predicted human skin burn injury for single layer garments or protective clothing

ensembles mounted on a stationary instrumented manikin which are then exposed in a laboratory to a simulated fire environment

2 2

having controlled heat flux, flame distribution, and duration. The average exposure heat flux is 84 kW/m (2 cal/s•cm ), with

durations up to 20 seconds.

1.2 The visual and physical changes to the single layer garment or protective clothing ensemble are recorded to aid in

understandingtheoverallperformanceofthegarmentorprotectiveensembleandhowthepredictedhumanskinburninjuryresults

can be interpreted.

1.3 The skin burn injury prediction is based on a limited number of experiments where the forearms of human subjects were

exposed to elevated thermal conditions. This forearm information for skin burn injury is applied uniformly to the entire body

except for the hands and feet. The hands and feet are not included in the skin burn injury prediction.

1.4 The measurements obtained and observations noted can only apply to the particular garment(s) or ensemble(s) tested using

the specified heat flux, flame distribution, and duration.

1

This test method is under the jurisdiction of ASTM Committee F23 on Personal Protective Clothing and Equipment and is the direct responsibility of Subcommittee

F23.80 on Flame and Thermal.

Current edition approved Dec. 15, 2008. Published March 2009. Originally approved in 1999. Last previous edition approved in 2000 as F1930-00. DOI:

10.1520/F1930-00R08.

Current edition approved Feb. 1, 2011. Published March 2011. Originally approved in 1999. Last previous edition approved in 2008 as F1930 - 00(2008).

DOI:10.1520/F1930–11.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.