ASTM D5436-03(2008)

(Specification)Standard Specification for Cast Poly(Methyl Methacrylate) Plastic Rods, Tubes, and Shapes

Standard Specification for Cast Poly(Methyl Methacrylate) Plastic Rods, Tubes, and Shapes

ABSTRACT

This specification covers poly(methyl mathacrylate) plastic rods, tubes, and other shapes produced by casting or machining cast blanks. It does not however apply to heat-formed and molded or extruded parts and shapes, or sections that are made by assembling or joining two or more pieces. The plastics may be of two types according to the material's ultraviolet light absorbing properties while the castings may be specified according to the surface finishing which may be a smooth surface finish obtained either in the casting process or by surface polishing or a rough, unfinished surface which may be frosted, abraded, sanded, machined, or as-cast. Tests shall be conducted in the standard laboratory atmosphere to determine the physical and optical properties of the materials. The specimens shall conform to the index of refraction, specific gravity, water absorption, deflection temperature under flexural load, tensile strength, elongation at break, spectral transmittance, luminous transmittance, and haze requirements.

SCOPE

1.1 This specification covers poly(methyl methacrylate) rods, tubes, and other shapes produced by casting or machining cast blanks. This specification does not apply to heat-formed and molded or extruded parts and shapes, or sections that are made by assembling or joining two or more pieces.

Note 1—The properties included in this specification are those required to identify the types and grades of materials covered. There may be other requirements necessary to identify particular characteristics.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 2—There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5436 −03(Reapproved 2008)

Standard Specification for

Cast Poly(Methyl Methacrylate) Plastic Rods, Tubes, and

Shapes

This standard is issued under the fixed designation D5436; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* D1600 Terminology forAbbreviatedTerms Relating to Plas-

tics

1.1 This specification covers poly(methyl methacrylate)

D3892 Practice for Packaging/Packing of Plastics

rods,tubes,andothershapesproducedbycastingormachining

E29 Practice for Using Significant Digits in Test Data to

cast blanks. This specification does not apply to heat-formed

Determine Conformance with Specifications

and molded or extruded parts and shapes, or sections that are

made by assembling or joining two or more pieces.

3. Terminology

NOTE1—Thepropertiesincludedinthisspecificationarethoserequired

3.1 The terminology used in this specification is in accor-

to identify the types and grades of materials covered. There may be other

dance with Terminology D883 and Terminology D1600.

requirements necessary to identify particular characteristics.

1.2 This standard does not purport to address all of the

4. Classification

safety concerns, if any, associated with its use. It is the

4.1 Types—This specification covers two types of cast

responsibility of the user of this standard to establish appro-

methacrylate plastics:

priate safety and health practices and determine the applica-

4.1.1 Type UVA—Material having ultraviolet-lightabsorbing

bility of regulatory limitations prior to use.

properties as shown in Table 1.

NOTE 2—There is no known ISO equivalent to this standard. 4.1.2 Type UVT—Material not subject to the light-absorbing

properties shown in Table 1.

2. Referenced Documents

4.2 Finish—Castings may be specified with the following

2.1 ASTM Standards:

finishes:

D542 Test Method for Index of Refraction of Transparent

4.2.1 Finish 1—Rods, tubes, and shapes having a smooth

Organic Plastics

surface finish obtained either in the casting process or by

D570 Test Method for Water Absorption of Plastics

highly polishing the surface.

D618 Practice for Conditioning Plastics for Testing

4.2.2 Finish 2—Rods, tubes, and shapes having a rough,

D638 Test Method for Tensile Properties of Plastics

unfinished surface which may be frosted, abraded, sanded,

D648 Test Method for Deflection Temperature of Plastics

machined, or as-cast.

Under Flexural Load in the Edgewise Position

NOTE 3—The sawed ends of Finish 1 and Finish 2 rods, tubes, and

D792 Test Methods for Density and Specific Gravity (Rela-

shapes are not polished.

tive Density) of Plastics by Displacement

D883 Terminology Relating to Plastics 5. General Requirements

D1003 Test Method for Haze and Luminous Transmittance

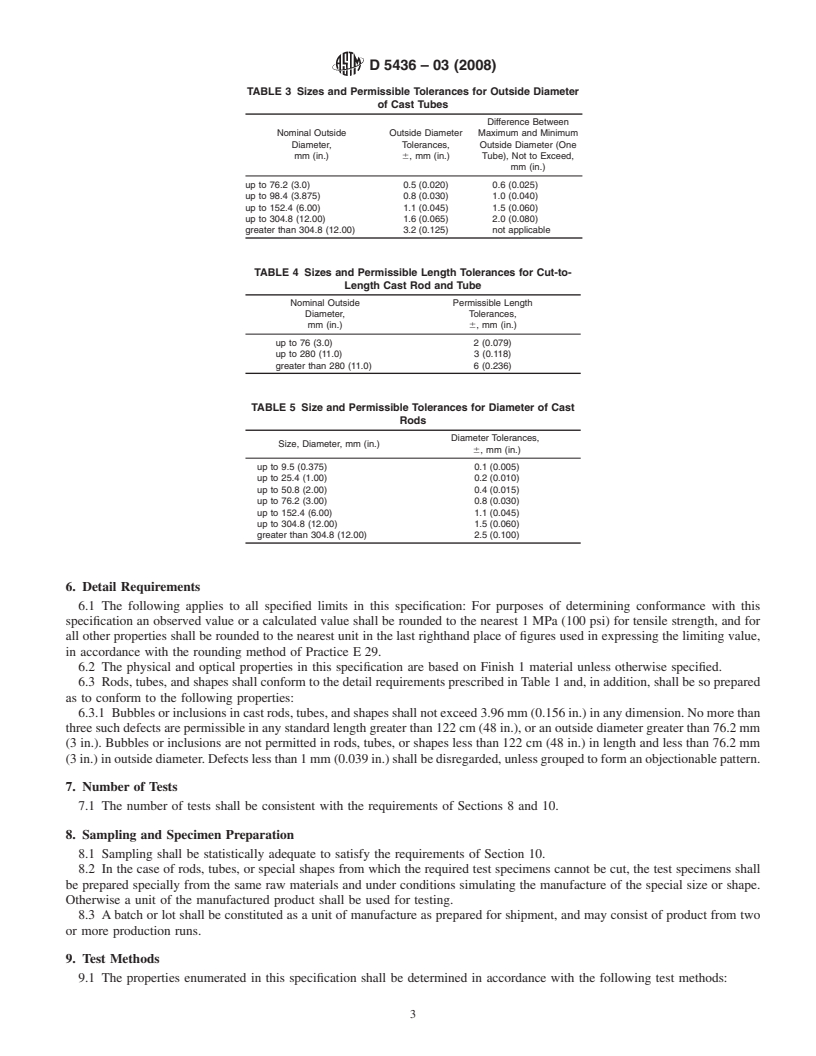

5.1 Finish 1 and Finish 2 cast tubes are subject to the

of Transparent Plastics

following permissible variations from the specified dimen-

sions:

5.1.1 CasttubesmaybespecifiedwitheitherTypeAorType

This specification is under the jurisdiction of ASTM Committee D20 on

B wall thickness tolerances as listed in Table 2. Type A

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

tolerancesarespecifiedforapplicationswherewallthicknessis

Materials.

critical to performance, otherwise Type B is generally speci-

Current edition approved Nov. 1, 2008. Published December 2008. Originally

fied.

approved in 1993. Last previous edition approved in 2003 as D5436 – 03. DOI:

10.1520/D5436-03R08.

5.1.2 Cast tubes are subject to the outside-diameter toler-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ances listed in Table 3.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.3 Cut-to-size lengths of cast tube are subject to the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. length tolerances listed in Table 4.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5436−03 (2008)

TABLE 1 Detail Requirements for Cast Methacrylate Rods, Tubes, TABLE 4 Sizes and Permissible Length Tolerances for Cut-to-

and Shapes Length Cast Rod and Tube

Type UVA Type UVT Nominal Outside Permissible Length

Diameter, Tolerances,

Index of refraction, n , 23°C

D

mm (in.) ±, mm (in.)

min: 1.48 1.48

max: 1.50 1.50 up to 76 (3.0) 2 (0.079)

up to 280 (11.0) 3 (0.118)

Specific gravity, 23/23°C (73.4/73.4°F)

min: 1.18 1.18 greater than 280 (11.0) 6 (0.236)

max: 1.20 1.20

Spectral transmittance, %, max

270 nm: 5 .

TABLE 5 Size and Permissible Tolerances for Diameter of Cast

280 nm: 5 .

Rods

290 nm: 5 .

310 nm: 5 .

Diameter Tolerances,

Size, Diameter, mm (in.)

340 nm: 5 .

±, mm (in.)

Luminous transmittance, %, min

up to 9.5 (0.375) 0.1 (0.005)

up to 4.7 mm (0.187 in.) thickness: 91 91

up to 25.4 (1.00) 0.2 (0.010)

25.4 mm (1.00 in.) thickness: 89 89

up to 50.8 (2.00) 0.4 (0.015)

greater than 25.4 mm (1.00 in.) thickness: 87 87

up to 76.2 (3.00) 0.8 (0.030)

Haze, %, max 3.0 3.0

up to 152.4 (6.00) 1.1 (0.045)

Deflection temperature under load at 1820

up to 304.8 (12.00) 1.5 (0.060)

kPa (264 psi), °C (°F) min.

greater than 304.8 (12.00) 2.5 (0.100)

<12.0 mm (0.472 in.) 87 (188.6) 87 (188.6)

>12.0 mm (0.472 in.)–24.0 mm (0.944 in.) 88 (190.4) 88 (190.4)

>24.0 mm (0.944 in.)–100 mm (3.937 in.) 93 (199.4) 93 (199.4)

Water absorption at 23°C

Gain in weight, 3.2 mm (0.125 in.) thick, %, 0.8 0.8

6. Detail Requirements

max

Tensile strength at 23°C (73.4°F), min, MPa 55 (8000) 55 (8000)

6.1 The following applies to all specified limits in this

(psi)

specification: For purposes of determining conformance with

Elongation at break, %, min 2 2

this specification an observed value or a calculated value shall

be rounded to the nearest 1 MPa (100 psi) for tensile strength,

and for all other properties shall be rounded to the nearest unit

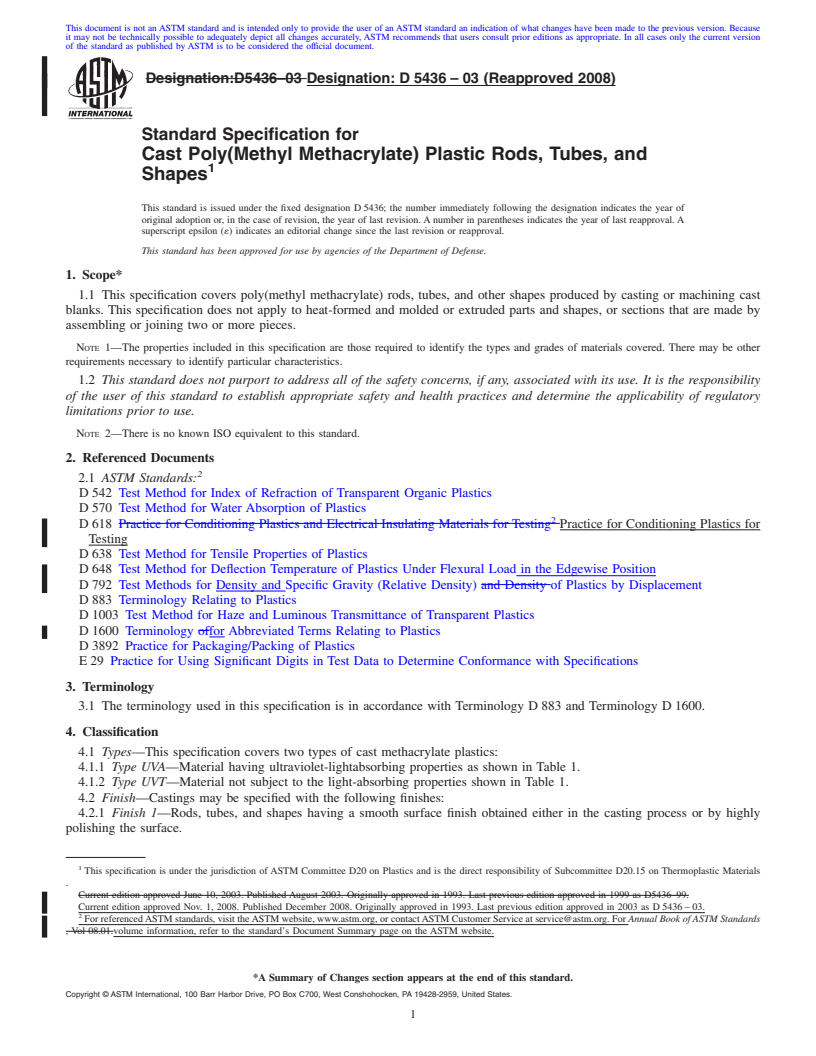

TABLE 2 Sizes and Permissible Tolerances for Wall Thickness of

Cast Tube in the last righthand place of figures used in expressing the

limiting value, in accordance with the rounding method of

Permissible Wall Thickness Tolerances,

Nominal Wall Thickness,

±, mm (in.)

Practice E29.

mm (in.)

Type A Type B

6.2 The physical and optical properties in this specification

up to 4.7 (0.187) 0.5 (0.020) not applicable

are based on Finish 1 material unless otherwise specified.

up to 6.4 (0.250) 0.6 (0.025) 1.1 (0.045)

up to 9.5 (0.375) 0.9 (0.035) 1.4 (0.055)

6.3 Rods, tubes, and shapes shall conform to the detail

up to 12.7 (0.550) 1.1 (0.045) 1.5 (0.060)

requirements prescribed in Table 1 and, in addition, shall be so

up to 19.0 (0.750) 1.5 (0.060) 2.3 (0.090)

up to 25.4 (1.00) 3.8 (0.150) not applicable prepared as to conform to the following properties:

greater than 25.4 (1.00) 6.4 (0.250) not applicable

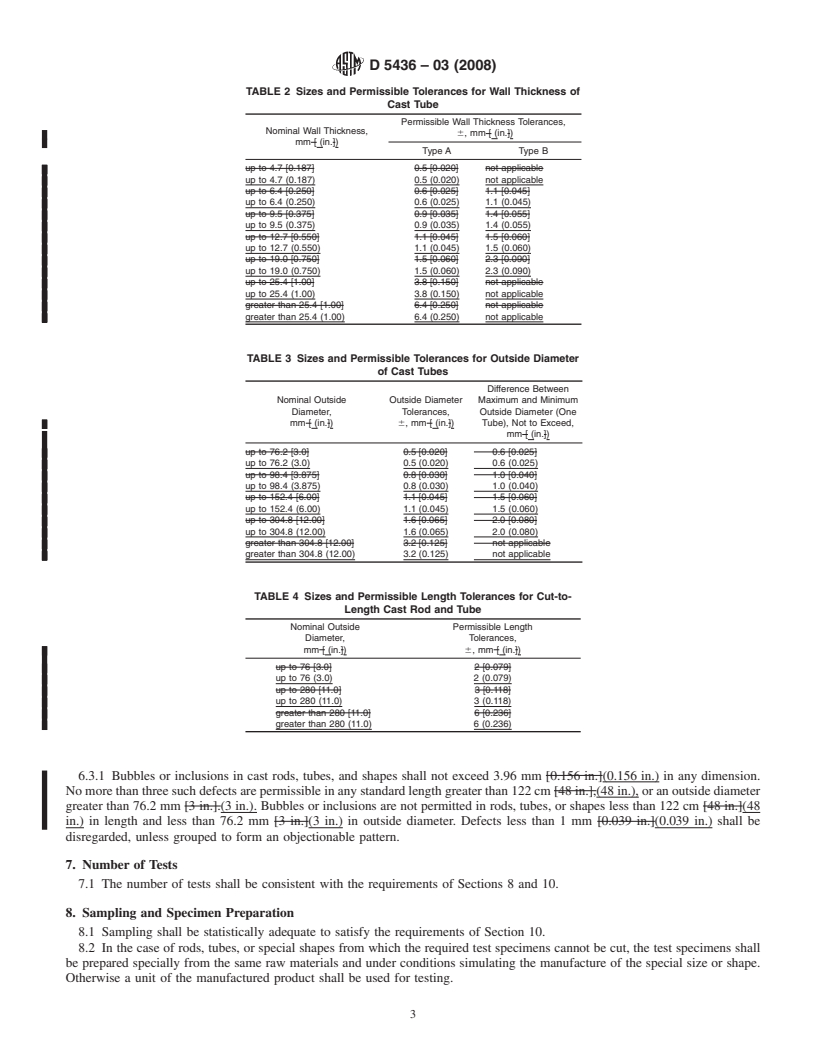

6.3.1 Bubbles or inclusions in cast rods, tubes, and shapes

shall not exceed 3.96 mm (0.156 in.) in any dimension. No

more than three such defects are permissible in any standard

TABLE 3 Sizes and Permissible Tolerances for Outside Diameter

length greater than 122 cm (48 in.), or an outside diameter

of Cast Tubes

g

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5436–99 Designation: D 5436 – 03 (Reapproved 2008)

Standard Specification for

Cast Poly(Methyl Methacrylate) Plastic Rods, Tubes, and

Shapes

This standard is issued under the fixed designation D 5436; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers poly(methyl methacrylate) rods, tubes, and other shapes produced by casting or machining cast

blanks. This specification does not apply to heat-formed and molded or extruded parts and shapes, or sections that are made by

assembling or joining two or more pieces.

NOTE 1—The properties included in this specification are those required to identify the types and grades of materials covered. There may be other

requirements necessary to identify particular characteristics.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 2—There is no known ISO equivalent to this standard.

2. Referenced Documents

2.1 ASTM Standards:

D 542 Test Method for Index of Refraction of Transparent Organic Plastics

D 570 Test Method for Water Absorption of Plastics

D 618 Practice for Conditioning Plastics and Electrical Insulating Materials for Testing Practice for Conditioning Plastics for

Testing

D 638 Test Method for Tensile Properties of Plastics

D 648 Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position

D 792 Test Methods for Density and Specific Gravity (Relative Density) and Density of Plastics by Displacement

D 883 Terminology Relating to Plastics

D 1003 Test Method for Haze and Luminous Transmittance of Transparent Plastics

D 1600 Terminology offor Abbreviated Terms Relating to Plastics

D 3892 Practice for Packaging/Packing of Plastics

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3. Terminology

3.1 The terminology used in this specification is in accordance with Terminology D 883 and Terminology D 1600.

4. Classification

4.1 Types—This specification covers two types of cast methacrylate plastics:

4.1.1 Type UVA—Material having ultraviolet-lightabsorbing properties as shown in Table 1.

4.1.2 Type UVT—Material not subject to the light-absorbing properties shown in Table 1.

4.2 Finish—Castings may be specified with the following finishes:

This specification is under the jurisdiction of ASTM Committee D-20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials.

Current edition approved Nov. 10, 1999. Published February 2000. Originally published as D5436–93. Last previous edition D5436–93.

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials

.

Current edition approved Nov. 1, 2008. Published December 2008. Originally approved in 1993. Last previous edition approved in 2003 as D 5436 – 03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 08.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5436 – 03 (2008)

TABLE 1 Detail Requirements for Cast Methacrylate Rods,

Tubes, and Shapes

Type UVA Type UVT

Index of refraction, n , 23°C

D

min: 1.48 1.48

max: 1.50 1.50

Specific gravity, 23/23°C (73.4/73.4°F)

min: 1.18 1.18

max: 1.20 1.20

Spectral transmittance, %, max

270 nm: 5 .

280 nm: 5 .

290 nm: 5 .

310 nm: 5 .

340 nm: 5 .

Luminous transmittance, %, min

up to 4.7 mm (0.187 in.) thickness: 91 91

25.4 mm (1.00 in.) thickness: 89 89

greater than 25.4 mm (1.00 in.) thickness: 87 87

Haze, %, max 3.0 3.0

Deflection temperature under load at 1820 see Fig. 1 see F

kPa (264 psi), °C

Deflection temperature under load at 1820

kPa (264 psi), °C (°F) min.

ig.) 87 (188.6) 87 (188.6)

<12.0 mm (0.472 in.) 87 (188.6) 87 (188.6)

>12.0 mm (0.472 in.)–24.0 mm (0.944 in.) 88 (190.4) 88 (190.4)

>24.0 mm (0.944 in.)–100 mm (3.937 in.) 93 (199.4) 93 (199.4)

Water absorption at 23°C

Gain in weight, 3.2 mm (0.125 in.) thick, %, 0.8 0.8

max

Tensile strength at 23°C (73.4°F), min, MPa 55 (8000) 55 (8000)

(psi)

Elongation at break, %, min 2 2

4.2.1 Finish 1—Rods, tubes, and shapes having a smooth surface finish obtained either in the casting process or by highly

polishing the surface.

4.2.2 Finish 2—Rods, tubes, and shapes having a rough, unfinished surface which may be frosted, abraded, sanded, machined,

or as-cast.

NOTE 3—The sawed ends of Finish 1 and Finish 2 rods, tubes, and shapes are not polished.

5. General Requirements

5.1 Finish 1 and Finish 2 cast tubes are subject to the following permissible variations from the specified dimensions:

5.1.1 Cast tubes may be specified with either TypeAor Type B wall thickness tolerances as listed in Table 2. TypeAtolerances

are specified for applications where wall thickness is critical to performance, otherwise Type B is generally specified.

5.1.2 Cast tubes are subject to the outside-diameter tolerances listed in Table 3.

5.1.3 Cut-to-size lengths of cast tube are subject to the length tolerances listed in Table 4.

5.2 Finish 1 and Finish 2 cast rods are subject to the following dimensions and tolerances.

5.2.1 Cast rods are subject to the diameter tolerances listed in Table 5.

5.2.2 Cut-to-size lengths of cast rod are subject to the length tolerances listed in Table 4.

5.3 Tolerances for shapes other than simple rods and tubes depend upon the shapes themselves.Tolerances for these cast shapes

are to be specified independently.

TABLE 2 Sizes and Permissible Tolerances for Wall Thickness of

Cast Tube

Permissible Wall Thickness Tolerances,

Nominal Wall Thickness,

6, mm (in.)

mm (in.)

Type A Type B

up to 4.7 (0.187) 0.5 (0.020) not applicable

up to 6.4 (0.250) 0.6 (0.025) 1.1 (0.045)

up to 9.5 (0.375) 0.9 (0.035) 1.4 (0.055)

up to 12.7 (0.550) 1.1 (0.045) 1.5 (0.060)

up to 19.0 (0.750) 1.5 (0.060) 2.3 (0.090)

up to 25.4 (1.00) 3.8 (0.150) not applicable

greater than 25.4 (1.00) 6.4 (0.250) not applicable

D 5436 – 03 (2008)

TABLE 3 Sizes and Permissible Tolerances for Outside Diameter

of Cast Tubes

Difference Between

Nominal Outside Outside Diameter Maximum and Minimum

Diameter, Tolerances, Outside Diameter (One

mm (in.) 6, mm (in.) Tube), Not to Exceed,

mm (in.)

up to 76.2 (3.0) 0.5 (0.020) 0.6 (0.025)

up to 98.4 (3.875) 0.8 (0.030) 1.0 (0.040)

up to 152.4 (6.00) 1.1 (0.045) 1.5 (0.060)

up to 304.8 (12.00) 1.6 (0.065) 2.0 (0.080)

greater than 304.8 (12.00) 3.2 (0.125) not applicable

TABLE 4 Sizes and Permissible Length Tolerances for Cut-to-

Length Cast Rod and Tube

Nominal Outside Permissible Length

Diameter, Tolerances,

mm (in.) 6, mm (in.)

up to 76 (3.0) 2 (0.079)

up to 280 (11.0) 3 (0.118)

greater than 280 (11.0) 6 (0.236)

TABLE 5 Size and Permissibl

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5436–03 Designation: D 5436 – 03 (Reapproved 2008)

Standard Specification for

Cast Poly(Methyl Methacrylate) Plastic Rods, Tubes, and

Shapes

This standard is issued under the fixed designation D 5436; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers poly(methyl methacrylate) rods, tubes, and other shapes produced by casting or machining cast

blanks. This specification does not apply to heat-formed and molded or extruded parts and shapes, or sections that are made by

assembling or joining two or more pieces.

NOTE 1—The properties included in this specification are those required to identify the types and grades of materials covered. There may be other

requirements necessary to identify particular characteristics.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 2—There is no known ISO equivalent to this standard.

2. Referenced Documents

2.1 ASTM Standards:

D 542 Test Method for Index of Refraction of Transparent Organic Plastics

D 570 Test Method for Water Absorption of Plastics

D 618 Practice for Conditioning Plastics and Electrical Insulating Materials for Testing Practice for Conditioning Plastics for

Testing

D 638 Test Method for Tensile Properties of Plastics

D 648 Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position

D 792 Test Methods for Density and Specific Gravity (Relative Density) and Density of Plastics by Displacement

D 883 Terminology Relating to Plastics

D 1003 Test Method for Haze and Luminous Transmittance of Transparent Plastics

D 1600 Terminology offor Abbreviated Terms Relating to Plastics

D 3892 Practice for Packaging/Packing of Plastics

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3. Terminology

3.1 The terminology used in this specification is in accordance with Terminology D 883 and Terminology D 1600.

4. Classification

4.1 Types—This specification covers two types of cast methacrylate plastics:

4.1.1 Type UVA—Material having ultraviolet-lightabsorbing properties as shown in Table 1.

4.1.2 Type UVT—Material not subject to the light-absorbing properties shown in Table 1.

4.2 Finish—Castings may be specified with the following finishes:

4.2.1 Finish 1—Rods, tubes, and shapes having a smooth surface finish obtained either in the casting process or by highly

polishing the surface.

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials

.

Current edition approved June 10, 2003. Published August 2003. Originally approved in 1993. Last previous edition approved in 1999 as D5436–99.

Current edition approved Nov. 1, 2008. Published December 2008. Originally approved in 1993. Last previous edition approved in 2003 as D 5436 – 03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 08.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5436 – 03 (2008)

TABLE 1 Detail Requirements for Cast Methacrylate Rods,

Tubes, and Shapes

Type UVA Type UVT

Index of refraction, n , 23°C

D

min: 1.48 1.48

max: 1.50 1.50

Specific gravity, 23/23°C [73.4/73.4°F]

Specific gravity, 23/23°C (73.4/73.4°F)

min: 1.18 1.18

max: 1.20 1.20

Spectral transmittance, %, max

270 nm: 5 .

280 nm: 5 .

290 nm: 5 .

310 nm: 5 .

340 nm: 5 .

Luminous transmittance, %, min

up to 4.7 mm [0.187 in.] thickness: 91 91

up to 4.7 mm (0.187 in.) thickness: 91 91

25.4 mm [1.00 in.] thickness: 89 89

25.4 mm (1.00 in.) thickness: 89 89

greater than 25.4 mm [1.00 in.] thickness: 87 87

greater than 25.4 mm (1.00 in.) thickness: 87 87

Haze, %, max 3.0 3.0

Deflection temperature under load at 1820

kPa [264 psi], °C [°F] min.

Deflection temperature under load at 1820

kPa (264 psi), °C (°F) min.

<12.0 mm [0.472 in.] 87 [188.6] 87 [188.6]

<12.0 mm (0.472 in.) 87 (188.6) 87 (188.6)

>12.0 mm [0.472 in.]–24.0 mm [0.944 in.] 88 [190.4] 88 [190.4]

>12.0 mm (0.472 in.)–24.0 mm (0.944 in.) 88 (190.4) 88 (190.4)

>24.0 mm [0.944 in.]–100 mm [3.937 in.] 93 [199.4] 93 [199.4]

>24.0 mm (0.944 in.)–100 mm (3.937 in.) 93 (199.4) 93 (199.4)

Water absorption at 23°C

Gain in weight, 3.2 mm [0.125 in.] thick, %, 0.8 0.8

max

Gain in weight, 3.2 mm (0.125 in.) thick, %, 0.8 0.8

max

Tensile strength at 23°C [73.4°F], min, MPa 55 [8000] 55 [8000]

[psi]

Tensile strength at 23°C (73.4°F), min, MPa 55 (8000) 55 (8000)

(psi)

Elongation at break, %, min 2 2

4.2.2 Finish 2—Rods, tubes, and shapes having a rough, unfinished surface which may be frosted, abraded, sanded, machined,

or as-cast.

NOTE 3—The sawed ends of Finish 1 and Finish 2 rods, tubes, and shapes are not polished.

5. General Requirements

5.1 Finish 1 and Finish 2 cast tubes are subject to the following permissible variations from the specified dimensions:

5.1.1 Cast tubes may be specified with either TypeAor Type B wall thickness tolerances as listed in Table 2. TypeAtolerances

are specified for applications where wall thickness is critical to performance, otherwise Type B is generally specified.

5.1.2 Cast tubes are subject to the outside-diameter tolerances listed in Table 3.

5.1.3 Cut-to-size lengths of cast tube are subject to the length tolerances listed in Table 4.

5.2 Finish 1 and Finish 2 cast rods are subject to the following dimensions and tolerances.

5.2.1 Cast rods are subject to the diameter tolerances listed in Table 5.

5.2.2 Cut-to-size lengths of cast rod are subject to the length tolerances listed in Table 4.

5.3 Tolerances for shapes other than simple rods and tubes depend upon the shapes themselves.Tolerances for these cast shapes

are to be specified independently.

6. Detail Requirements

6.1 The following applies to all specified limits in this specification: For purposes of determining conformance with this

specification an observed value or a calculated value shall be rounded to the nearest 1 MPa [100 psi](100 psi) for tensile strength,

and for all other properties shall be rounded to the nearest unit in the last righthand place of figures used in expressing the limiting

value, in accordance with the rounding method of Practice E 29.

6.2 The physical and optical properties in this specification are based on Finish 1 material unless otherwise specified.

6.3 Rods, tubes, and shapes shall conform to the detail requirements prescribed in Table 1 and, in addition, shall be so prepared

as to conform to the following properties:

D 5436 – 03 (2008)

TABLE 2 Sizes and Permissible Tolerances for Wall Thickness of

Cast Tube

Permissible Wall Thickness Tolerances,

Nominal Wall Thickness,

6, mm [ (in.])

mm [ (in.])

Type A Type B

up to 4.7 [0.187] 0.5 [0.020] not applicable

up to 4.7 (0.187) 0.5 (0.020) not applicable

up to 6.4 [0.250] 0.6 [0.025] 1.1 [0.045]

up to 6.4 (0.250) 0.6 (0.025) 1.1 (0.045)

up to 9.5 [0.375] 0.9 [0.035] 1.4 [0.055]

up to 9.5 (0.375) 0.9 (0.035) 1.4 (0.055)

up to 12.7 [0.550] 1.1 [0.045] 1.5 [0.060]

up to 12.7 (0.550) 1.1 (0.045) 1.5 (0.060)

up to 19.0 [0.750] 1.5 [0.060] 2.3 [0.090]

up to 19.0 (0.750) 1.5 (0.060) 2.3 (0.090)

up to 25.4 [1.00] 3.8 [0.150] not applicable

up to 25.4 (1.00) 3.8 (0.150) not applicable

greater than 25.4 [1.00] 6.4 [0.250] not applicable

greater than 25.4 (1.00) 6.4 (0.250) not applicable

TABLE 3 Sizes and Permissible Tolerances for Outside Diameter

of Cast Tubes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.