ASTM F1057-10

(Practice)Standard Practice for Estimating the Quality of Extruded Poly (Vinyl Chloride) (PVC) Pipe by the Heat Reversion Technique

Standard Practice for Estimating the Quality of Extruded Poly (Vinyl Chloride) (PVC) Pipe by the Heat Reversion Technique

SIGNIFICANCE AND USE

This practice is applicable to distinguish between properly and improperly extruded PVC plastic pipe. It can be used to:

Reveal incomplete exsiccation of compound before or during extrusion (Note 1),

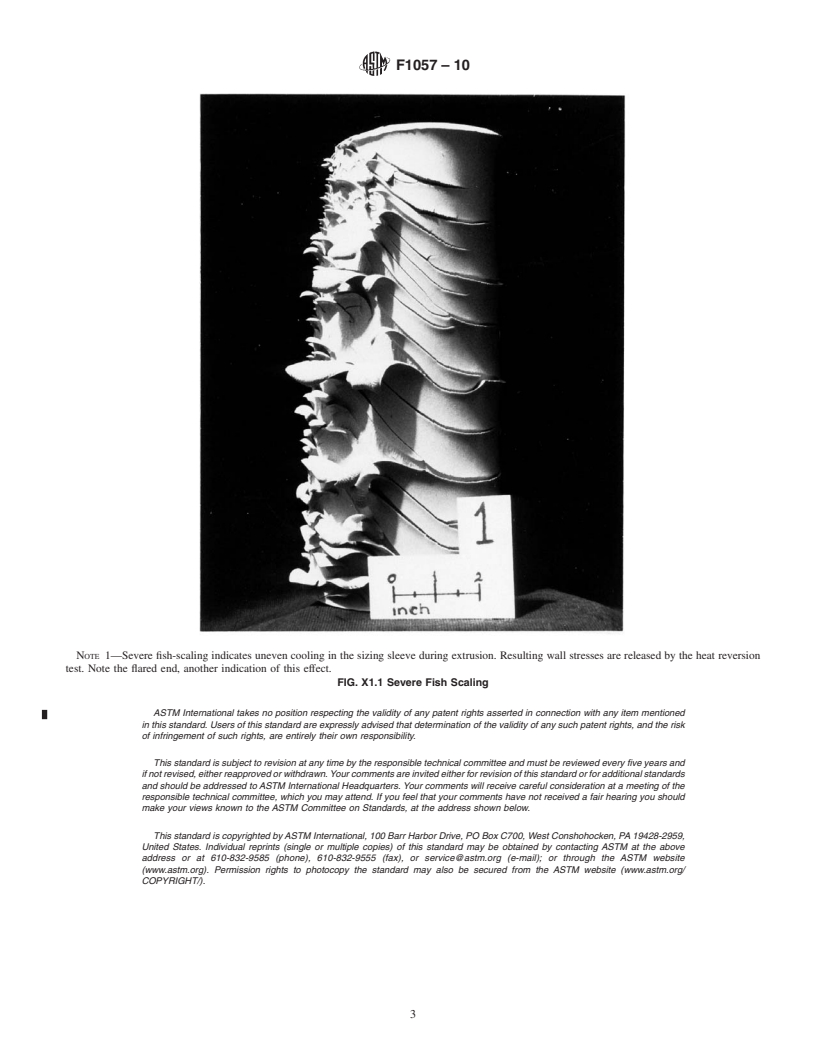

Determine the presence of stress in the pipe wall produced by the extrusion process (Note 2),

Determine whether infused areas are present, and

Reveal contamination.

Note 1—Residual moisture in the compound vaporizes at extrusion temperatures and is normally evacuated as it forms vapor. Pockets of moisture trapped in the pipe wall result from incomplete exsiccation of the compound, and may reduce the physical properties of the pipe.

Note 2—Minor residual stress in the pipe will not impair field performance and handleability. High-residual stress has no proven effect on performance, but may impair handleability during installation.

SCOPE

1.1 This practice covers a procedure for estimating the quality of extruded poly (vinyl chloride) (PVC) plastic pipes by observing the reaction of pipe specimens after exposure to hot air in the oven at 180 ± 5°C for 30 min duration.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1057 − 10

Standard Practice for

Estimating the Quality of Extruded Poly (Vinyl Chloride)

1

(PVC) Pipe by the Heat Reversion Technique

This standard is issued under the fixed designation F1057; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope within 3 in. from the outer edge of the test specimen; make

assurances that the temperature does not contact the test

1.1 This practice covers a procedure for estimating the

specimen.

qualityofextrudedpoly(vinylchloride)(PVC)plasticpipesby

observing the reaction of pipe specimens after exposure to hot

NOTE 3—The oven should be vented to the outside of the building.

air in the oven at 180 6 5°C for 30 min duration. NOTE 4—Monitoring of the test temperature within the oven may

require a secondary temperature monitoring device in addition to the

1.2 This standard does not purport to address all of the

temperature monitoring device within the oven control system.

safety problems, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Procedure

priate safety and health practices and determine the applica-

4.1 Preparespecimensofpipe150mm(6in.)longorlonger

bility of regulatory limitations prior to use.

with ends cut square so that they stand perpendicular on end

2. Significance and Use when placed in the oven.

4.1.1 Cut staves from pipes whose size prevents insertion of

2.1 This practice is applicable to distinguish between prop-

full round specimens in the oven. Prepare large-diameter pipe

erly and improperly extruded PVC plastic pipe. It can be used

staves so that their lengths parallel to the pipe axis are 150 mm

to:

(6 in.) or longer.

2.1.1 Reveal incomplete exsiccation of compound before or

during extrusion (Note 1),

4.2 Examine the specimens and note any unusual features

2.1.2 Determine the presence of stress in the pipe wall

such as discoloration, inclusions, or pinholes in the cut edge.

produced by the extrusion process (Note 2),

4.3 Place the specimens of whole pipe in the preheated oven

2.1.3 Determine whether infused areas are present, and

so that each specimen stands on end with sufficient separation

2.1.4 Reveal contamination.

between them so that hot air can flow freely between the pipes.

NOTE 1—Residual moisture in the compound vaporizes at extrusion

Place specimens of pipe staves on the floor of the preheated

temperatures and is normally evacuated as it forms vapor. Pockets of

ovensothattheyrestontheirlongitudinaledgesandsothathot

moisturetrappedinthepipewallresultfromincompleteexsiccationofthe

air can flow freely around them. Record the time when the air

compound, and may reduce the physical properties of the pipe.

in the oven directly adjacent to the test specimen recovers to

NOTE 2—Minor residual stress in the pipe will not impair field

performance and handleability. High-residual stress has no proven effect 180°C (356°F). Recovery must occur within 15 min or less.

on performance, but may impair handleability during installation.

After an additional 30 min of exposure within the test

temperature tolerance of 180 6 5°C, remove the specimens,

3. Apparatus

taking care not to alter any heat effects.

3.1 Air Oven, thermostatically controlled, capable of oper-

4.4 Examine the specimens within 3 min after removal from

ating at 180 6 5°C (356 6 9°F) and capable of meeting the

the oven, while still hot. With a sharp knife, cut whole pipe

recovery requirement of 4.3. Additionally, the oven must have

specimens lengthwise at approximately 60° circumferential

heat generation (power) capacity such that the recovery

intervals, resulting in six pipe staves of approximately equal

achievedwhileataconstantovensetpoint.Theairtemperature

widths. Cut specimens being tested in the form of staves into

with the oven (that is, the test temperature) is to be monitored

three roughly equal segments. Note the following for the

report:

1 4.4.1 The shape of the pipe ends and the pipe barrel,

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test

4.4.2 The condition and appearance of both the inner and

Methods.

outer surfaces of the material, and

Current edition approved May 1, 2010. Published June 2010. Originally

4.4.3 The condition and appearance of the cut edges of the

approved in 1987. Last previous edition approved in 2005 as F1057–87(2005). DOI:

10.1520/F1057-10. material.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

-----------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F1057–87 (Reapproved 2005) Designation:F1057–10

Standard Practice for

Estimating the Quality of Extruded Poly (Vinyl Chloride)

1

(PVC) Pipe by the Heat Reversion Technique

This standard is issued under the fixed designation F1057; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This practice covers a procedure for estimating the quality of extruded poly (vinyl chloride) (PVC) plastic pipes by observing

the reaction of pipe specimens after exposure to heat.

1.1 This practice covers a procedure for estimating the quality of extruded poly (vinyl chloride) (PVC) plastic pipes by

observing the reaction of pipe specimens after exposure to hot air in the oven at 180 6 5°C for 30 min duration.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Significance and Use

2.1 This practice is applicable to distinguish between properly and improperly extruded PVC plastic pipe. It can be used to:

2.1.1 Reveal incomplete exsiccation of compound before or during extrusion (Note 1),

2.1.2 Determine the presence of stress in the pipe wall produced by the extrusion process (Note 2),

2.1.3 Determine whether infused areas are present, and

2.1.4 Reveal contamination.

NOTE 1—Residual moisture in the compound vaporizes at extrusion temperatures and is normally evacuated as it forms vapor. Pockets of moisture

trapped in the pipe wall result from incomplete exsiccation of the compound, and may reduce the physical properties of the pipe.

NOTE 2—Minor residual stress in the pipe will not impair field performance and handleability. High-residual stress has no proven effect on

performance, but may impair handleability during installation.

3. Apparatus

3.1 Air Oven, thermostatically controlled, capable of operating at 180 6 5°C (356 6 9°F) such that after insertion of the

specimen to be tested the test temperature is regained within 15 min or less. , thermostatically controlled, capable of operating at

180 6 5°C (356 6 9°F) and capable of meeting the recovery requirement of 4.3.Additionally, the oven must have heat generation

(power) capacity such that the recovery achieved while at a constant oven set point. The air temperature with the oven (that is,

the test temperature) is to be monitored within 3 in. from the outer edge of the test specimen; make assurances that the temperature

does not contact the test specimen.

NOTE 3—The oven should be vented to the outside of the building.

NOTE 4—Monitoring of the test temperature within the oven may require a secondary temperature monitoring device in addition to the temperature

monitoring device within the oven control system.

4. Procedure

4.1 Prepare specimens of pipe 150 mm (6 in.) long or longer with ends cut square so that they stand perpendicular on end when

placed in the oven.

4.1.1 Cut staves from pipes whose size prevents insertion of full round specimens in the oven. Prepare large-diameter pipe

staves so that their lengths parallel to the pipe axis are 150 mm (6 in.) or longer.

4.2 Examine the specimens and note any unusual features such as discoloration, inclusions, or pinholes in the cut edge.

4.3 Place the specimens of whole pipe in the preheated oven so that each specimen stands on end with sufficient separation

between them so that hot air can flow freely between the pipes. Place specimens of pipe staves on the floor of the preheated oven

so that they rest on their longitudinal edges and so that hot air can flow freely around them. Record the time when the air in the

oven directly adjacent to the test specimen recovers to 180°C (356°F). Recovery must occur within 15 min or less. After an

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test Methods.

Current edition approved AugustMay 1, 2005.2010. Published August 2005.June 2010. Originally approved in 1987. Last previous edition approved in 20002005 as

F1057–87(20005). DOI: 10.1520/F1057-87R05.10.1520/F1057-10.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Bo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.