ASTM C1642-14

(Practice)Standard Practice for Determining Air Leakage Rates of Aerosol Foam Sealants and Other Construction Joint Fill and Insulation Materials

Standard Practice for Determining Air Leakage Rates of Aerosol Foam Sealants and Other Construction Joint Fill and Insulation Materials

SIGNIFICANCE AND USE

5.1 This practice is intended to measure air flow through materials used to fill joints found in building construction.

5.2 This practice does not purport to establish all required criteria for the selection of an air barrier assembly. Therefore, the results should be used only for comparison purposes and should not be seen as the equivalent to field installed building systems.

SCOPE

1.1 This practice is intended to determine the air leakage rate of aerosol foam sealants as measured in a standardized jig. This practice provides a procedure for preparing the test apparatus and further describes the application of aerosol foam sealant and other joint fillers to the apparatus prior to conducting Test Method E283.

1.2 This practice allows testing laboratories to quantify the air leakage rate of aerosol foam sealants or joint filling products using Test Method E283 and reporting the data in L/(s · m2) according to Practice E29.

1.3 This practice is used in conjunction with Test Method E283. Although Test Method E283 is a laboratory test method used with fenestration products, individuals interested in performing field air leakage tests on installed units should reference Test Method E783 and AAMA 502.

1.4 Aerosol foam sealants are used for a variety of end use applications generally intended to reduce air leakage in the building envelope.

1.5 Insulating type materials also will be found suitable for evaluation with this practice.

1.6 There are no other known practices or test methods that specify the preparation of the assemblies used to determine the air leakage rate of gap filling sealants, dry preformed foams or insulations.

1.7 The values given in SI units are the standard. The inch-pound units in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1642 − 14

Standard Practice for

Determining Air Leakage Rates of Aerosol Foam Sealants

1

and Other Construction Joint Fill and Insulation Materials

This standard is issued under the fixed designation C1642; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This practice is intended to determine the air leakage

C717 Terminology of Building Seals and Sealants

rate of aerosol foam sealants as measured in a standardized jig.

C1330 Specification for Cylindrical Sealant Backing for Use

This practice provides a procedure for preparing the test

with Cold Liquid-Applied Sealants

apparatus and further describes the application of aerosol foam

C1536 Test Method for Measuring the Yield for Aerosol

sealant and other joint fillers to the apparatus prior to conduct-

Foam Sealants

ing Test Method E283.

C1620 Specification for Aerosol Polyurethane and Aerosol

1.2 This practice allows testing laboratories to quantify the

Latex Foam Sealants

air leakage rate of aerosol foam sealants or joint filling

E29 Practice for Using Significant Digits in Test Data to

products using Test Method E283 and reporting the data in

Determine Conformance with Specifications

2

L/(s · m ) according to Practice E29.

E283 Test Method for Determining Rate of Air Leakage

1.3 This practice is used in conjunction with Test Method Through Exterior Windows, Curtain Walls, and Doors

Under Specified Pressure Differences Across the Speci-

E283. Although Test Method E283 is a laboratory test method

used with fenestration products, individuals interested in per- men

E783 Test Method for Field Measurement of Air Leakage

forming field air leakage tests on installed units should

reference Test Method E783 and AAMA 502. Through Installed Exterior Windows and Doors

2.2 Other Standards:

1.4 Aerosol foam sealants are used for a variety of end use

AAMA 502 Voluntary Specification for Field Testing of

applications generally intended to reduce air leakage in the

3

Newly Installed Fenestration Products

building envelope.

ISO/IEC 17025 General requirements for the competence of

4

1.5 Insulating type materials also will be found suitable for

testing and calibration laboratories

evaluation with this practice.

3. Terminology

1.6 There are no other known practices or test methods that

specify the preparation of the assemblies used to determine the

3.1 Definitions:

air leakage rate of gap filling sealants, dry preformed foams or

3.1.1 air barrier—the assembly of material(s) used in build-

insulations.

ing construction to reduce or retard the uncontrolled passage of

air into and out of the building.

1.7 The values given in SI units are the standard. The

3.1.2 exfiltration—air flow direction from building interior

inch-pound units in parentheses are for information only.

toward exterior.

1.8 This standard does not purport to address all of the

3.1.3 infiltration—air flow direction from building exterior

safety concerns, if any, associated with its use. It is the

toward interior.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This practice is under the jurisdiction of ASTM Committee C24 on Building the ASTM website.

3

Seals and Sealants and is the direct responsibility of Subcommittee C24.61 on Available from American Architectural Manufacturers Association (AAMA),

Aerosol Foam Sealants. 1827 Walden Office Square, Suite 550, Schaumburg, IL 60173-4268, http://

Current edition approved Sept. 15, 2014. Published November 2014. Originally www.aamanet.org.

4

approved in 2007. Last previous edition approved in 2007 as C1642-07. DOI: Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/C1642-14. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1642 − 14

3.1.4 preformed dry foam material—any cellular product

designed for filling construction joints to resist air leakage.

3.1.5 preformed pre-compressed tapes—any cellular tape

supplied compressed from its fully expanded shape and de-

signed for filling co

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

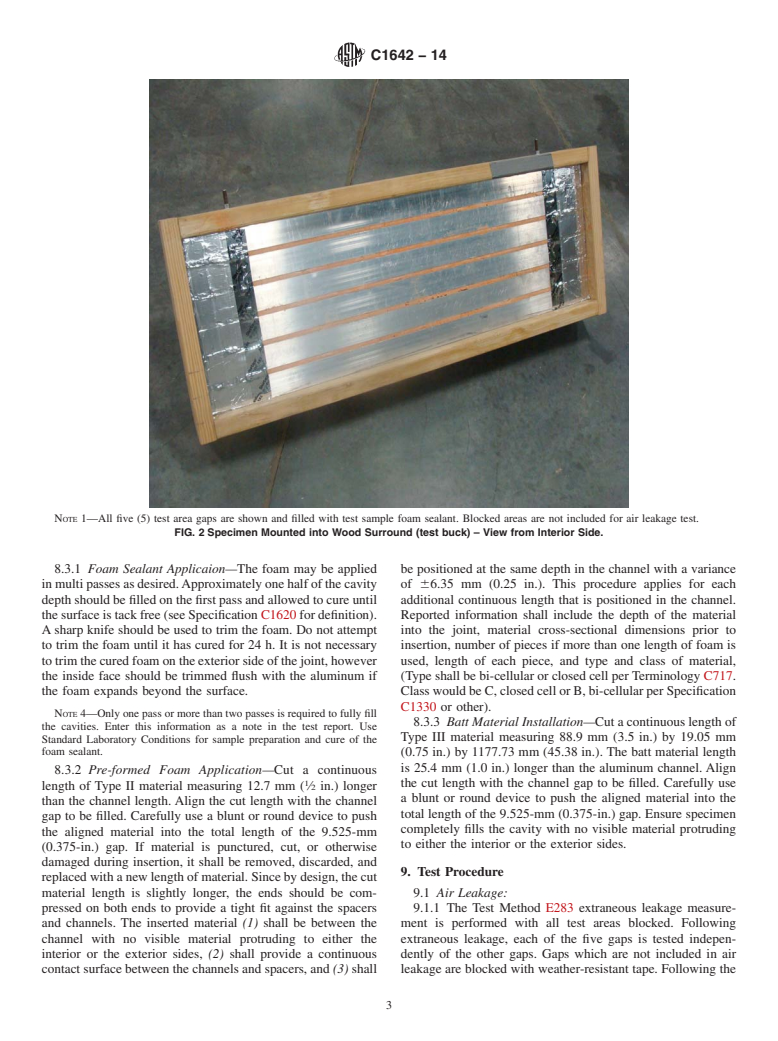

Designation: C1642 − 07 C1642 − 14

Standard Practice for

Determining Air Leakage Rates of Aerosol Foam Sealants

1

and Other Construction Joint Fill and Insulation Materials

This standard is issued under the fixed designation C1642; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice is intended to determine the air leakage rate of aerosol foam sealants as measured in a standardized jig. This

practice provides a procedure for preparing the test apparatus and further describes the application of aerosol foam sealant and

other joint fillers to the apparatus prior to conducting Test Method E283.

1.2 This practice allows testing laboratories to quantify the air leakage rate of aerosol foam sealants or joint filling products

2

using Test Method E283 and reporting the data in L/(s · mL/(s · m ) according to Practice E29.

1.3 This practice is used in conjunction with Test Method E283. Although Test Method E283 is a laboratory test method used

with fenestration products, individuals interested in performing field air leakage tests on installed units should reference Test

Method E783 and AAMA 502.

1.4 Aerosol foam sealants are used for a variety of end use applications generally intended to reduce air leakage in the building

envelope.

1.5 Insulating type materials also will be found suitable for evaluation with this practice.

1.6 There are no other known practices or test methods that specify the preparation of the assemblies used to determine the air

leakage rate of gap filling sealants, dry preformed foams or insulations.

1.7 The values given in SI units are the standard. The inch-pound units in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C717 Terminology of Building Seals and Sealants

C1330 Specification for Cylindrical Sealant Backing for Use with Cold Liquid-Applied Sealants

C1536 Test Method for Measuring the Yield for Aerosol Foam Sealants

C1620 Specification for Aerosol Polyurethane and Aerosol Latex Foam Sealants

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E283 Test Method for Determining Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified

Pressure Differences Across the Specimen

E783 Test Method for Field Measurement of Air Leakage Through Installed Exterior Windows and Doors

2.2 Other Standards:

3

AAMA 502 Voluntary Specification for Field Testing of Newly Installed Fenestration Products

4

ISO/IEC 17025 General requirements for the competence of testing and calibration laboratories

1

This practice is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.61 on Aerosol Foam

Sealants.

Current edition approved July 1, 2007Sept. 15, 2014. Published August 2007November 2014. Originally approved in 2007. Last previous edition approved in 2007 as

C1642-07. DOI: 10.1520/C1642-07.10.1520/C1642-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Architectural Manufacturers Association (AAMA), 1827 Walden Office Square, Suite 550, Schaumburg, IL 60173-4268, http://

www.aamanet.org.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

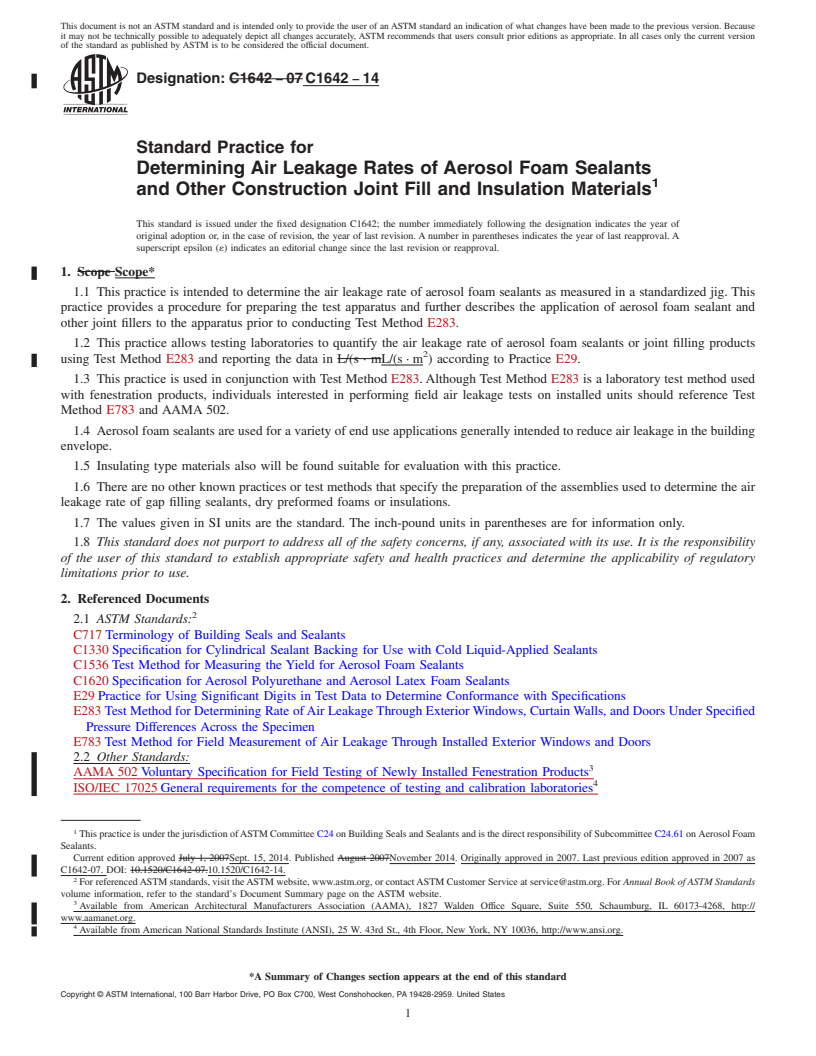

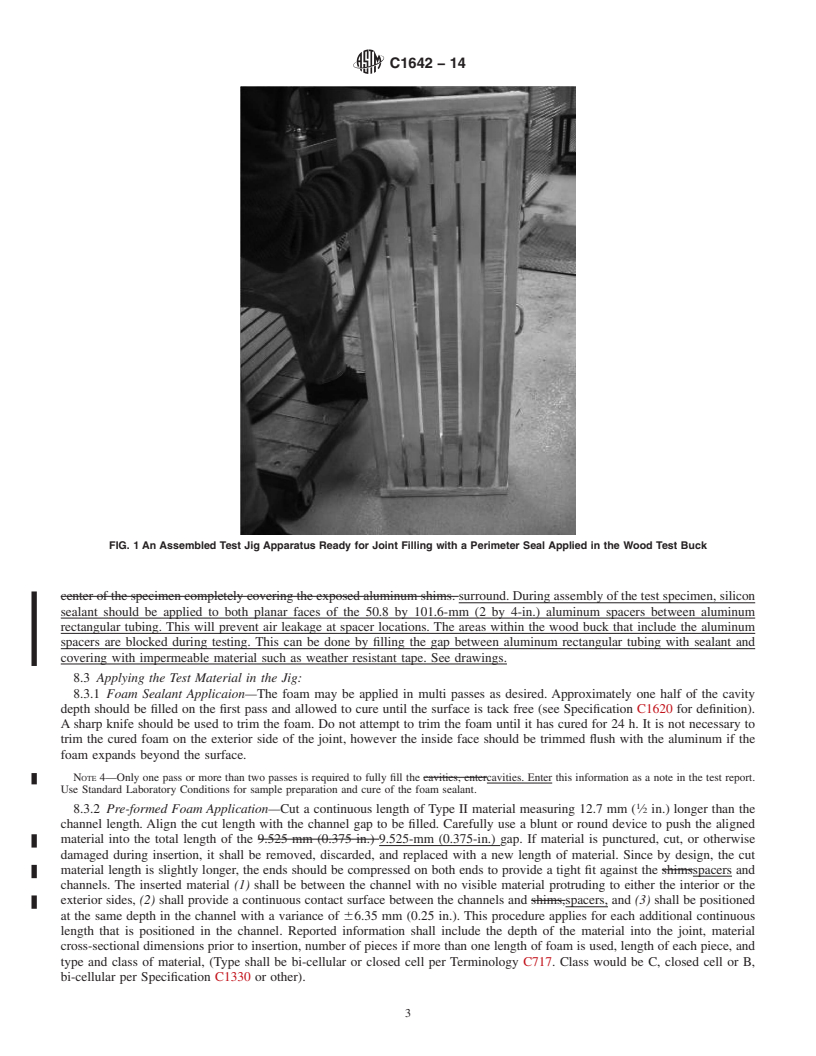

C1642 − 14

3. Terminology

3.1 Definitions:

3.1.1 air barrier—the assembly of material(s) used in building construction to reduce or retard the uncontrolled passage of air

into and out of the building.

3.1.2 rough opening gap—exfiltration—the open space between the building

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.