ASTM D5477-18

(Practice)Standard Practice for Identification of Polymer Layers or Inclusions by Fourier Transform Infrared Microspectroscopy (FT-IR)

Standard Practice for Identification of Polymer Layers or Inclusions by Fourier Transform Infrared Microspectroscopy (FT-IR)

SIGNIFICANCE AND USE

4.1 A speck will ultimately cause a failure to occur by virtue of its appearance in a film or by the decrease in electrical or mechanical properties in the polymer substrate (see Specification D1248).

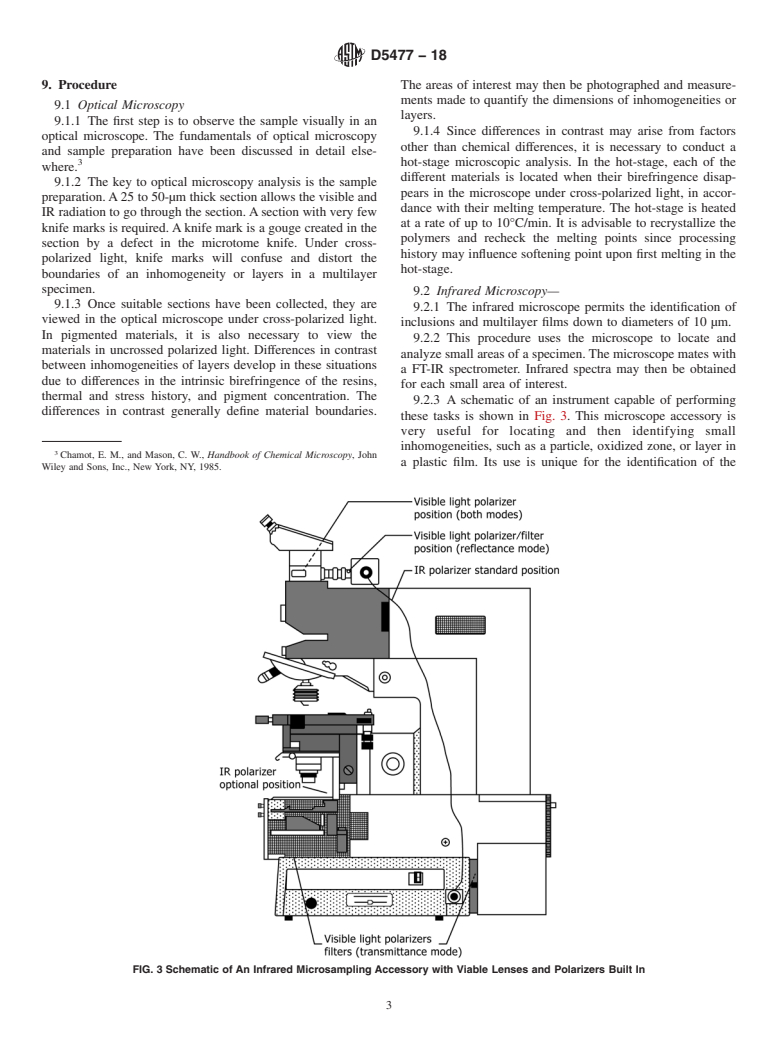

4.2 The analysis of composite layers for barrier purposes by microscopic Fourier transform infrared spectroscopy (FT-IR) can indicate the adequacy of the barrier tape or indicate why a barrier may be defective (a missing layer or hole in the layer or poor coextrusion practice). Fig. 1 represents a typical multilayer film.

FIG. 1 Position and Function of Materials in a Typical Multilayer Film

SCOPE

1.1 This practice describes the techniques used for detecting two different polymer entities such as:

1.1.1 Abnormal specks or spots on a surface or in the film that are objectionable as defects and

1.1.2 Layers of different polymeric sheets commonly used as barrier films made by coextrusion.

1.2 This practice utilizes through-transmittance optical and infrared techniques.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 7.

Note 1: There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5477 −18

Standard Practice for

Identification of Polymer Layers or Inclusions by Fourier

1

Transform Infrared Microspectroscopy (FT-IR)

This standard is issued under the fixed designation D5477; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

tics

1.1 Thispracticedescribesthetechniquesusedfordetecting

E131Terminology Relating to Molecular Spectroscopy

two different polymer entities such as:

E168Practices for General Techniques of Infrared Quanti-

1.1.1 Abnormal specks or spots on a surface or in the film

tative Analysis

that are objectionable as defects and

E2015Guide for Preparation of Plastics and Polymeric

1.1.2 Layers of different polymeric sheets commonly used

Specimens for Microstructural Examination

as barrier films made by coextrusion.

IEEE/ASTM SI-10Standard for Use of the International

1.2 This practice utilizes through-transmittance optical and

System of Units (SI):The Modern Metric System

infrared techniques.

3. Terminology

1.3 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information 3.1 Definitions:

only. 3.1.1 For definitions of the terms used in this practice, refer

to Terminologies D883 and D1600.

1.4 This standard does not purport to address all of the

3.1.2 For units, symbols, and abbreviations used in this

safety concerns, if any, associated with its use. It is the

practice, refer to Terminology E131 or IEEE/ASTM SI-10.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

4. Significance and Use

mine the applicability of regulatory limitations prior to use.

4.1 Aspeckwillultimatelycauseafailuretooccurbyvirtue

Specific hazard statements are given in Section 7.

of its appearance in a film or by the decrease in electrical or

NOTE 1—There is no known ISO equivalent to this standard.

mechanical properties in the polymer substrate (see Specifica-

1.5 This international standard was developed in accor-

tion D1248).

dance with internationally recognized principles on standard-

4.2 Theanalysisofcompositelayersforbarrierpurposesby

ization established in the Decision on Principles for the

microscopic Fourier transform infrared spectroscopy (FT-IR)

Development of International Standards, Guides and Recom-

can indicate the adequacy of the barrier tape or indicate why a

mendations issued by the World Trade Organization Technical

barriermaybedefective(amissinglayerorholeinthelayeror

Barriers to Trade (TBT) Committee.

poor coextrusion practice). Fig. 1 represents a typical multi-

layer film.

2. Referenced Documents

2

5. Apparatus

2.1 ASTM Standards:

−1

D883Terminology Relating to Plastics

5.1 FT-IR Spectrophotometer, with nominal 4-cm resolu-

D1248Specification for Polyethylene Plastics Extrusion

tion (see Practices E168).

Materials for Wire and Cable

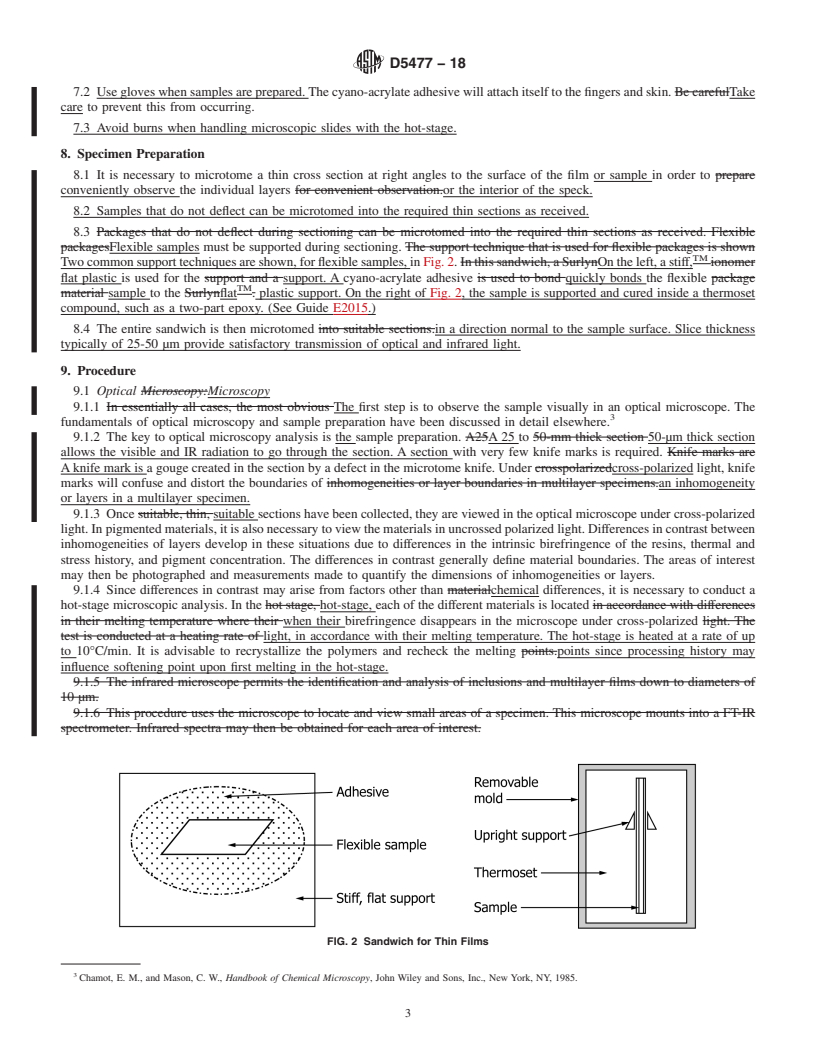

5.2 Microsampling Accessory, accommodated into the

FT-IRformicroscopicinfraredanalysis,withnominal6.25-µm

resolution in the infrared mode.

1

ThispracticeisunderthejurisdictionofASTMCommitteeD20onPlasticsand

5.3 Optical Microscope,equippedwithcross-polarizedlight

is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

Current edition approved Aug. 1, 2018. Published August 2018. Originally and phase contrast accessories. May be incorporated into the

published as D5477–93. Last previous edition approved in 2011 as D5477–11.

infrared microsampling accessory.

DOI: 10.1520/D5477-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5.4 Hot-Stage, with temperature readout, is accommodated

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

into the optical microscope or microsampling accessory.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5.5 Microtome, capable of <25 µm slices 62.5 µm.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5477 − 18

FIG. 1 Position and Function of Materials in a Typical Multilayer Film

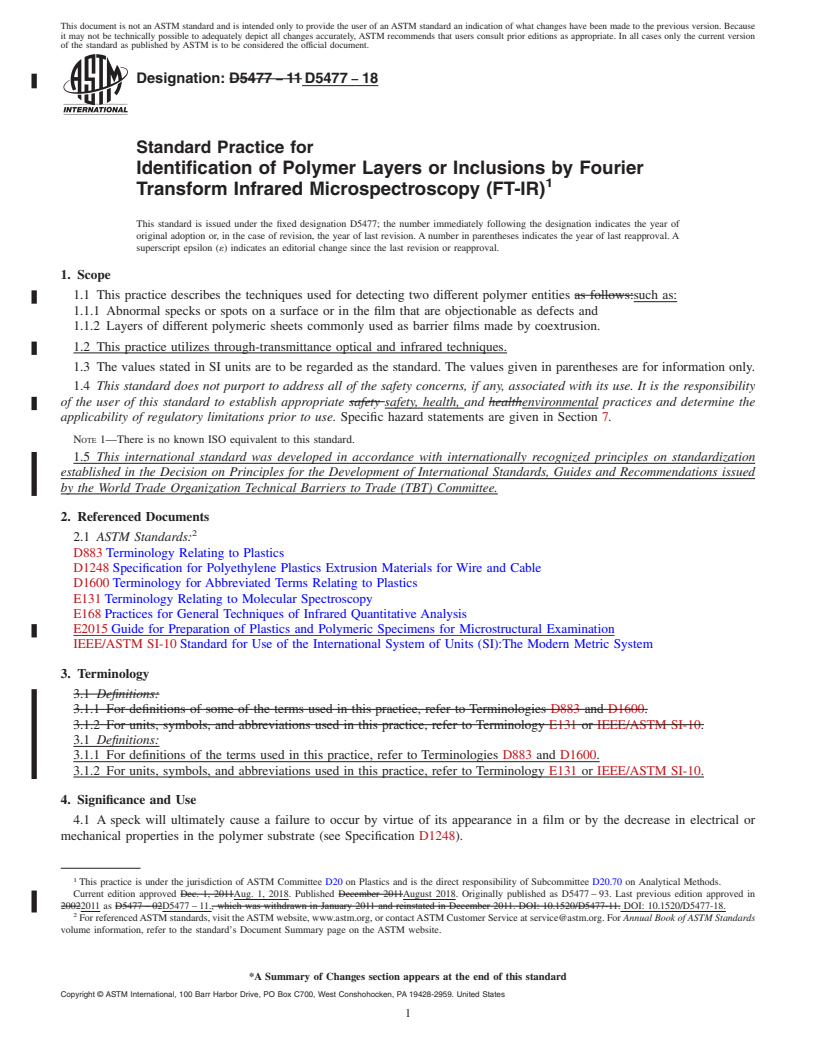

6. Material 8. Specimen Preparation

6.1 Stiff plastic at 25°C, 1.25 mm thick and large enough to 8.1 It is necessary to microtome a thin cross section at right

angles to the surface of the film

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5477 − 11 D5477 − 18

Standard Practice for

Identification of Polymer Layers or Inclusions by Fourier

1

Transform Infrared Microspectroscopy (FT-IR)

This standard is issued under the fixed designation D5477; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes the techniques used for detecting two different polymer entities as follows:such as:

1.1.1 Abnormal specks or spots on a surface or in the film that are objectionable as defects and

1.1.2 Layers of different polymeric sheets commonly used as barrier films made by coextrusion.

1.2 This practice utilizes through-transmittance optical and infrared techniques.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 7.

NOTE 1—There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D1248 Specification for Polyethylene Plastics Extrusion Materials for Wire and Cable

D1600 Terminology for Abbreviated Terms Relating to Plastics

E131 Terminology Relating to Molecular Spectroscopy

E168 Practices for General Techniques of Infrared Quantitative Analysis

E2015 Guide for Preparation of Plastics and Polymeric Specimens for Microstructural Examination

IEEE/ASTM SI-10 Standard for Use of the International System of Units (SI):The Modern Metric System

3. Terminology

3.1 Definitions:

3.1.1 For definitions of some of the terms used in this practice, refer to Terminologies D883 and D1600.

3.1.2 For units, symbols, and abbreviations used in this practice, refer to Terminology E131 or IEEE/ASTM SI-10.

3.1 Definitions:

3.1.1 For definitions of the terms used in this practice, refer to Terminologies D883 and D1600.

3.1.2 For units, symbols, and abbreviations used in this practice, refer to Terminology E131 or IEEE/ASTM SI-10.

4. Significance and Use

4.1 A speck will ultimately cause a failure to occur by virtue of its appearance in a film or by the decrease in electrical or

mechanical properties in the polymer substrate (see Specification D1248).

1

This practice is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

Current edition approved Dec. 1, 2011Aug. 1, 2018. Published December 2011August 2018. Originally published as D5477 – 93. Last previous edition approved in

20022011 as D5477 – 02D5477 – 11., which was withdrawn in January 2011 and reinstated in December 2011. DOI: 10.1520/D5477-11. DOI: 10.1520/D5477-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5477 − 18

4.2 The analysis of composite layers for barrier purposes by microscopic Fourier transform infrared spectroscopy (FT-IR) can

indicate the adequacy of the barrier tape or indicate why a barrier may be defective (a missing layer or hole in the layer or poor

coextrusion practice). Fig. 1 represents a typical multilayer film.

5. Apparatus

−1

5.1 FT-IR Spectrophotometer, with nominal 4-cm resolution (see Practices E168).

5.2 Microsampling Accessory, accommodated into the FT-IR for microscopic infrared and visible light analysis, with nominal

6.25-μm resolution on

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.