ASTM D3917-15a

(Specification)Standard Specification for Dimensional Tolerance of Thermosetting Glass-Reinforced Plastic Pultruded Shapes

Standard Specification for Dimensional Tolerance of Thermosetting Glass-Reinforced Plastic Pultruded Shapes

ABSTRACT

This specification defines the dimensional tolerances of standard rods, bars, and shapes pultruded from thermosetting glass-reinforced plastics. Tolerances cover dimensional criteria for cross sections, width or diameter, straightness, twist, surface flatness, angularity, and camber.

SCOPE

1.1 This specification defines production tolerances applicable to standard rods, bars, shapes, and flat sheet pultruded from thermosetting glass-reinforced plastics.

1.2 These dimensional tolerances apply to all shapes specified as “standard” by the pultrusion industry.

1.3 Custom shapes and products designed for special applications may carry specific tolerances that vary from the standard.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The following safety hazards caveat pertains only to the test methods portion, Section 4, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D3917 −15a

Standard Specification for

Dimensional Tolerance of Thermosetting Glass-Reinforced

1

Plastic Pultruded Shapes

This standard is issued under the fixed designation D3917; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.5 The following safety hazards caveat pertains only to the

test methods portion, Section 4, of this specification: This

1.1 This specification defines production tolerances appli-

standard does not purport to address all of the safety concerns,

cable to standard rods, bars, shapes, and flat sheet pultruded

if any, associated with its use. It is the responsibility of the user

from thermosetting glass-reinforced plastics.

of this standard to establish appropriate safety and health

1.2 These dimensional tolerances apply to all shapes speci-

practices and determine the applicability of regulatory limita-

fied as “standard” by the pultrusion industry.

tions prior to use.

1.3 Custom shapes and products designed for special appli-

NOTE 1—There is no known ISO equivalent to this standard.

cations may carry specific tolerances that vary from the

2. Terminology

standard.

2.1 Definitions:

1.4 The values stated in inch-pound units are to be regarded

2.1.1 camber—the deviation of the edge or surface from a

as standard. The values given in parentheses are mathematical

reference straight line with the weight of the pultrusion not

conversions to SI units that are provided for information only

minimizing the measurement.

and are not considered standard.

2.1.2 flat sheet—a rectangular solid pultruded profile with a

width of 12 in. up to and including 78 inches.

2.1.3 mean wall thickness—the average of two or more wall

1

This specification is under the jurisdiction of ASTM Committee D20 on

thickness measurements taken at multiple locations.

Plastics and is the direct responsibility of Subcommittee D20.18 on Reinforced

Thermosetting Plastics.

2.1.4 straightness—the upward deviation of a pultruded

Current edition approved Oct. 1, 2015. Published October 2015. Originally

shape when resting on a flat surface measured in a manner that

approved in 1980. Last previous edition approved in 2015 as D3917 - 15. DOI:

10.1520/D3917-15A. the weight of the pultruded part minimizes the deviation.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3917−15a

3. Dimensional Criteria 3.1.3 For wall thickness and flatsheets of thickness over

0.125 in. (3.175 mm) dimensions, if the calculated tolerance as

3.1 Cross-sectional dimensions for standard rods, bars, and

per above table is more than 0.05 in. (1.27 mm), the thickness

shapes shall be prescribed in Table 1.

tolerance shall be 60.05 in. (1.27 mm).

3.1.1 For die struck dimension, if the calculated tolerance as

per above table is more than 0.094 in. (2.39 mm), then the die

3.2 Length tolerances for standard rods, bars, and shapes

struck dimension tolerance shall be 60.094 in. (2.39 mm).

shall be as prescribed in Table 2.

3.1.2 For wall thickness of open shapes and closed shapes

3.3 Straightness tolerances shall be as prescribed in Table 3

and flatsheets of thickness under 0.125 in. (3.175 mm)

dimensions, if the calculated tolerance as per above table is less (also see 4.2).

than 0.01 in. (0.25 mm), the thickness tolerance shall be 60.01

in. (0.25 mm).

TABLE 1 Cross-Sectional Dimensions—Standard Rods, Bars, and Shapes

Solid Dimensions, ±in. (mm)

A B B C

B B

Die Struck Wall Thickness Thickness (Flat Sheets) Wall Thickness

A, B

(Open Shape) (Closed Shape)

Dimension Thickness Thickness

0.125 (3.175) and under over 0.125 (3.175)

±4 % ±10 % ±15 % ±10 % ±20 %

0.094 (2.39) max ±0.010 (0.25) min ±0.010 (0.25) min ±0.050 (1.27) max ±0.010 (0.25) min

A

The outside dimension of a part.

B

Standard pultruded section with dimension up to 36-in. (914-mm) diameter.

TABLE 2 Length—Standard Rods, Bars, Shapes, and Flat Sheet

Allowable Deviation from Specified Length, +, – in. (+, – mm), except as noted

Length up to 8 ft (2.44 m) Length over 8 to 24 ft (2.44 to

Length over 24 ft (7.32 m)

inclusive 7.32 m) inclusive

All Rods, Bars, and Shapes +0.25, –0 (+6.35, –0) +0.5, –0 (+12.7, –0) +3, –0 (+76.2, –0)

A

TABLE 3 Straightness —Standard Bars, Rods, Shapes, and Flat Sheet

Allowable Deviation (D) from Straight, in. (mm)

Specified Thick

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D3917 − 15 D3917 − 15a

Standard Specification for

Dimensional Tolerance of Thermosetting Glass-Reinforced

1

Plastic Pultruded Shapes

This standard is issued under the fixed designation D3917; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorial corrections were made in July 2015.

1. Scope*

1.1 This specification defines production tolerances applicable to standard rods, bars, shapes, and flat sheet pultruded from

thermosetting glass-reinforced plastics.

1.2 These dimensional tolerances apply to all shapes specified as “standard” by the pultrusion industry.

1.3 Custom shapes and products designed for special applications may carry specific tolerances that vary from the standard.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 The following safety hazards caveat pertains only to the test methods portion, Section 4, of this specification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

2. Terminology

2.1 Definitions:

2.1.1 camber—the deviation of the edge or surface from a reference straight line with the weight of the pultrusion not

minimizing the measurement.

2.1.2 flat sheet—a rectangular solid pultruded profile with a width of 12 in. up to and including 78 inches.

2.1.3 mean wall thickness—the average of two or more wall thickness measurements taken at multiple locations.

2.1.4 straightness—the upward deviation of a pultruded shape when resting on a flat surface measured in a manner that the

weight of the pultruded part minimizes the deviation.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermosetting

Plastics.

Current edition approved April 1, 2015Oct. 1, 2015. Published April 2015October 2015. Originally approved in 1980. Last previous edition approved in 20122015 as

D3917 - 12.D3917 - 15. DOI: 10.1520/D3917-15E01.10.1520/D3917-15A.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3917 − 15a

3. Dimensional Criteria

3.1 Cross-sectional dimensions for standard rods, bars, and shapes shall be prescribed in Table 1.

3.1.1 For die struck dimension, if the calculated tolerance as per above table is more than 0.094 in. (2.39 mm), then the die

struck dimension tolerance shall be 60.094 in. (2.39 mm).

3.1.2 For wall thickness of open shapes and closed shapes and flatsheets of thickness under 0.125 in. (3.175 mm) dimensions,

if the calculated tolerance as per above table is less than 0.01 in. (0.25 mm), the thickness tolerance shall be 60.01 in. (0.25 mm).

3.1.3 For wall thickness and flatsheets of thickness over 0.125 in. (3.175 mm) dimensions, if the calculated tolerance as per

above table is more than 0.05 in. (1.27 mm), the thickness tolerance shall be 60.05 in. (1.27 mm).

3.2 Length tolerances for standard rods, bars, and shapes shall be as prescribed in Table 2.

3.3 Straightness tolerances shall be as prescribed in Table 3 (also see 4.2).

TABLE 1 Cross-Sectional Dimensions—Standard Rods, Bars, and Shapes

Solid Dimensions, ±in. (mm)

A B B C

B B

Die Struck Wall Thickness Thickness (Flat Sheets) Wall Thickness

A, B

(Open Shape) (Closed Shape)

Dimension Thickness Thickness

0.125 (3.175) and under over 0.125 (3.175)

±4 % ±10 % ±15 % ±10 % ±20 %

0.094 (2.39) max ±0.010 (0.25) min ±0.010 (0.25) min ±0.050 (1.27) max ±0.010 (0.25) min

A

The outside dimension of a part.

B

Standard pultruded section with dimension up to 36-in. (914-mm) diameter.

TABLE 2 Length—Standard Rods, Bars, Shapes, and Flat Sheet

Allowable Deviation from Specified Length, +, – in. (+, – mm), except as noted

Length up to 8 ft (2.44 m) Length over 8 to 24 ft (2.44 to

Length over 24 ft (7.32 m)

inc

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3917 − 15a

Standard Specification for

Dimensional Tolerance of Thermosetting Glass-Reinforced

1

Plastic Pultruded Shapes

This standard is issued under the fixed designation D3917; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.5 The following safety hazards caveat pertains only to the

test methods portion, Section 4, of this specification: This

1.1 This specification defines production tolerances appli-

standard does not purport to address all of the safety concerns,

cable to standard rods, bars, shapes, and flat sheet pultruded

if any, associated with its use. It is the responsibility of the user

from thermosetting glass-reinforced plastics.

of this standard to establish appropriate safety and health

1.2 These dimensional tolerances apply to all shapes speci-

practices and determine the applicability of regulatory limita-

fied as “standard” by the pultrusion industry.

tions prior to use.

1.3 Custom shapes and products designed for special appli-

NOTE 1—There is no known ISO equivalent to this standard.

cations may carry specific tolerances that vary from the

2. Terminology

standard.

2.1 Definitions:

1.4 The values stated in inch-pound units are to be regarded

2.1.1 camber—the deviation of the edge or surface from a

as standard. The values given in parentheses are mathematical

reference straight line with the weight of the pultrusion not

conversions to SI units that are provided for information only

minimizing the measurement.

and are not considered standard.

2.1.2 flat sheet—a rectangular solid pultruded profile with a

width of 12 in. up to and including 78 inches.

1 2.1.3 mean wall thickness—the average of two or more wall

This specification is under the jurisdiction of ASTM Committee D20 on

thickness measurements taken at multiple locations.

Plastics and is the direct responsibility of Subcommittee D20.18 on Reinforced

Thermosetting Plastics.

2.1.4 straightness—the upward deviation of a pultruded

Current edition approved Oct. 1, 2015. Published October 2015. Originally

shape when resting on a flat surface measured in a manner that

approved in 1980. Last previous edition approved in 2015 as D3917 - 15. DOI:

10.1520/D3917-15A. the weight of the pultruded part minimizes the deviation.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3917 − 15a

3. Dimensional Criteria 3.1.3 For wall thickness and flatsheets of thickness over

0.125 in. (3.175 mm) dimensions, if the calculated tolerance as

3.1 Cross-sectional dimensions for standard rods, bars, and

per above table is more than 0.05 in. (1.27 mm), the thickness

shapes shall be prescribed in Table 1.

tolerance shall be 60.05 in. (1.27 mm).

3.1.1 For die struck dimension, if the calculated tolerance as

per above table is more than 0.094 in. (2.39 mm), then the die

3.2 Length tolerances for standard rods, bars, and shapes

struck dimension tolerance shall be 60.094 in. (2.39 mm).

shall be as prescribed in Table 2.

3.1.2 For wall thickness of open shapes and closed shapes

and flatsheets of thickness under 0.125 in. (3.175 mm) 3.3 Straightness tolerances shall be as prescribed in Table 3

dimensions, if the calculated tolerance as per above table is less (also see 4.2).

than 0.01 in. (0.25 mm), the thickness tolerance shall be 60.01

in. (0.25 mm).

TABLE 1 Cross-Sectional Dimensions—Standard Rods, Bars, and Shapes

Solid Dimensions, ±in. (mm)

A B B C

B B

Die Struck Wall Thickness Thickness (Flat Sheets) Wall Thickness

A, B

(Open Shape) (Closed Shape)

Dimension Thickness Thickness

0.125 (3.175) and under over 0.125 (3.175)

±4 % ±10 % ±15 % ±10 % ±20 %

0.094 (2.39) max ±0.010 (0.25) min ±0.010 (0.25) min ±0.050 (1.27) max ±0.010 (0.25) min

A

The outside dimension of a part.

B

Standard pultruded section with dimension up to 36-in. (914-mm) diameter.

TABLE 2 Length—Standard Rods, Bars, Shapes, and Flat Sheet

Allowable Deviation from Specified Length, +, – in. (+, – mm), except as noted

Length up to 8 ft (2.44 m) Length over 8 to 24 ft (2.44 to

Length over 24 ft (7.32 m)

inclusive 7.32 m) inclusive

All Rods, Bars, and Shapes +0.25, –0 (+6.35, –0) +0.5, –0 (+12.7, –0) +3, –0 (+76.2, –0)

A

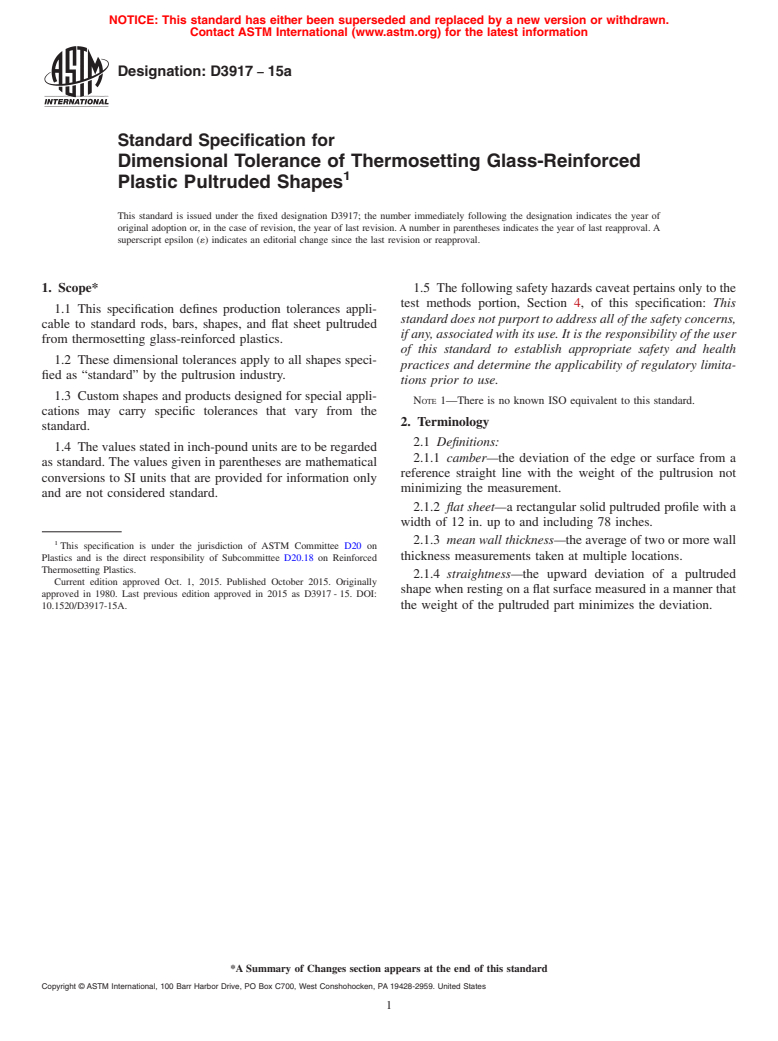

TABLE 3 Straightness —Standard Bars, Rods, Shapes, and Flat Sheet

Allowable Deviation (D) from Straight, in. (mm)

Specified Thickness

Specified Diameter (Rods)

(Rectangles)

Product

Specified Width (Bars)

Minimum Thickness

(Shapes)

Max Dimension (Shapes)

in. (mm) in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.