ASTM D494-11(2019)

(Test Method)Standard Test Method for Acetone Extraction of Phenolic Molded or Laminated Products

Standard Test Method for Acetone Extraction of Phenolic Molded or Laminated Products

SIGNIFICANCE AND USE

4.1 For molded phenolic products, acetone extraction shall be considered solely as a quantitative expression of a property normally associated with degree of cure. There is no demonstrably rigorous relation between the optimum mechanical and electrical properties of a well-cured piece and the numerical value of the acetone test. The amount of acetone-soluble matter is affected by: (1) nature of resin and filler, (2) lubricant, (3) molding temperature, (4) length of cure, (5) thickness of the section from which sample is taken, (6) nature of molded piece, (7) technique used in molding, (8) distribution of fines in the material to be extracted, and (9) method of grinding the specimen. These variations under some conditions will cause a difference of 3 to 4 % in acetone-extractable matter. For this reason, the test method shall be used only as a comparative test for measuring undercure.

4.2 For laminated phenolic products, acetone extraction indicates change in stage of cure, change in resin content, change in type of resin used, presence of plasticizers or other acetone-extractable addition agents, and is affected in general by the same factors as stated in 6.1

SCOPE

1.1 This test method covers the determination of the amount of acetone-soluble matter in molded or laminated phenolic products.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: This test method is similar to ISO 308.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D494 − 11 (Reapproved 2019)

Standard Test Method for

Acetone Extraction of Phenolic Molded or Laminated

Products

This standard is issued under the fixed designation D494; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope content of material in the unmoulded state)

1.1 This test method covers the determination of the amount

3. Terminology

of acetone-soluble matter in molded or laminated phenolic

products.

3.1 All definitions are in accordance with Terminology

D883.

1.2 The values stated in SI units are to be regarded as

standard. The values given in parentheses are mathematical

4. Significance and Use

conversions to inch-pound units that are provided for informa-

tion only and are not considered standard.

4.1 For molded phenolic products, acetone extraction shall

1.3 This standard does not purport to address all of the

be considered solely as a quantitative expression of a property

safety concerns, if any, associated with its use. It is the

normally associated with degree of cure. There is no demon-

responsibility of the user of this standard to establish appro-

strably rigorous relation between the optimum mechanical and

priate safety, health, and environmental practices and deter-

electrical properties of a well-cured piece and the numerical

mine the applicability of regulatory limitations prior to use.

valueoftheacetonetest.Theamountofacetone-solublematter

is affected by: (1) nature of resin and filler, (2) lubricant, (3)

NOTE 1—This test method is similar to ISO 308.

molding temperature, (4) length of cure, (5) thickness of the

1.4 This international standard was developed in accor-

sectionfromwhichsampleistaken,(6)natureofmoldedpiece,

dance with internationally recognized principles on standard-

(7) technique used in molding, (8) distribution of fines in the

ization established in the Decision on Principles for the

material to be extracted, and (9) method of grinding the

Development of International Standards, Guides and Recom-

specimen. These variations under some conditions will cause a

mendations issued by the World Trade Organization Technical

difference of 3 to 4 % in acetone-extractable matter. For this

Barriers to Trade (TBT) Committee.

reason, the test method shall be used only as a comparative test

for measuring undercure.

2. Referenced Documents

2.1 ASTM Standards: 4.2 For laminated phenolic products, acetone extraction

D618 Practice for Conditioning Plastics for Testing

indicates change in stage of cure, change in resin content,

D883 Terminology Relating to Plastics

change in type of resin used, presence of plasticizers or other

E11 Specification for Woven Wire Test Sieve Cloth and Test

acetone-extractable addition agents, and is affected in general

Sieves

by the same factors as stated in 6.1

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

5. Apparatus

2.2 ISO Standards:

5.1 Sieves—The set of sieves used shall consist of sieves

ISO 308 Plastics—Phenolic moulding materials—

Nos. 40 (425-µm) and 140 (106-µm), with a cover and

Determination of acetone-soluble matter (apparent resin

receiving pan, conforming to the requirements of Specification

E11.

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

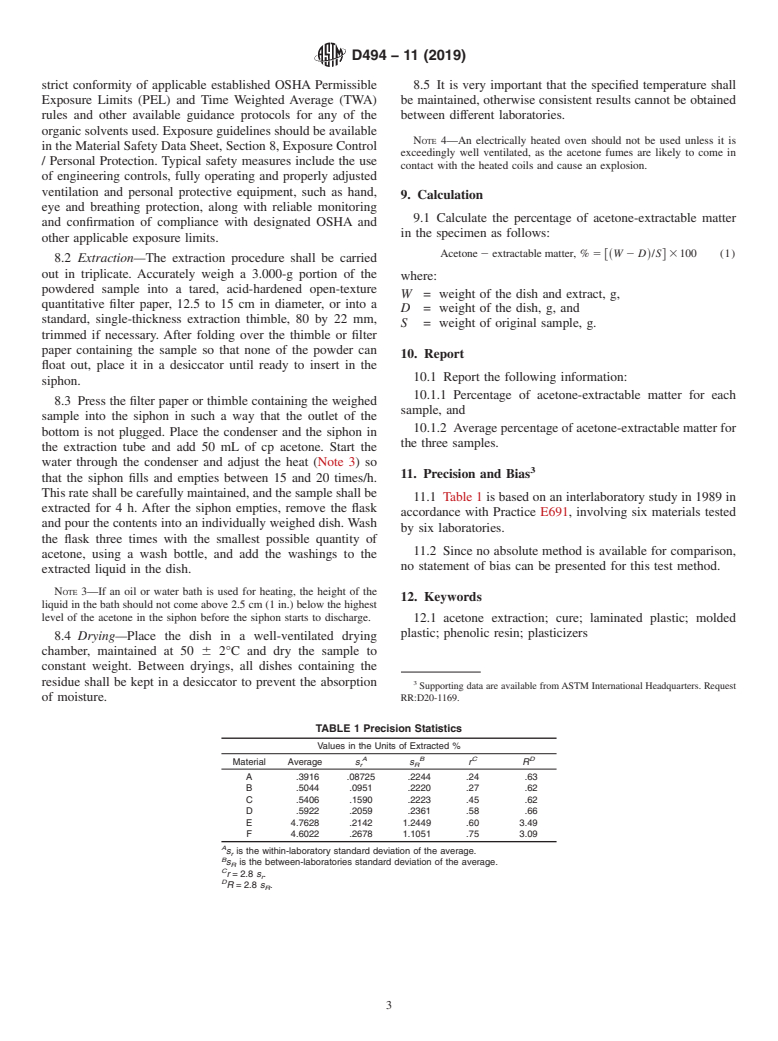

5.2 Extraction Apparatus—The apparatus may be of the

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

type shown in Fig. 1, or a Wiley-Richardson type, as shown in

Current edition approved Nov. 1, 2019. Published November 2019. Originally

Fig. 2. The former type is more suitable for use with small

approved in 1946. Last previous edition approved in 2011 as D494 - 11. DOI:

10.1520/D0494-11R19.

electric hot plates, while the latter is more suitable for use with

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

oil or water baths. In either case, it shall be possible to control

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the temperature so that the rate of extraction can be regulated

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. accurately.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D494 − 11 (2019)

5.3 Drying Dishes—The drying dishes shall be lightweight

dishes, approximately 63.5 mm (2 ⁄2 in.) in diameter and 38.1

mm (1 ⁄2 in.) in height.

6. Preparation of Sample

6.1 Precautions—It is of utmost importance that extreme

care shall be taken during the preparation of the sample for

extraction. The sample shall be drillings if possible; however,

if not possible, other suitable means of producing particles

equivalent to drillings shall be used. Drillings taken from a

large molded product shall be truly representative of all

sections of the part in proper proportions. The drills for

sampling shall be kept sharp and so operated that no undue

heating of the material shall occur which will tend to precure

the material.

NOTE 2—If it is impracticable to obtain samples by drilling, the parts

may be broken up with a lathe, planer, milling machine, or a suitable

grinder. A mortar and pestle or a pebble mill is considered suitable as a

grinder, provided no perceptible heating occurs during the grinding

procedure. A sharp file or rasp may be used for procuring the sample

where the size or shape of the part is such that no other method is suitable.

6.2 In any case, the particles of the sample shall be of the

smallest size practicable, so that they will pass through the No.

40 sieve with the minimum of reworking or grinding. It is

important in preparing the sample that the smallest possible

volume shall be obtained for a unit weight of the material.

6.3 The sample shall be sieved through a No. 40 sieve and

that part which will not pass through shall be reground and

blended with the original material passing the sieve. After

assembling the Nos. 40 and 140 sieves and the receiving pan,

the sample shall be placed in the top sieve, the cover placed on,

and the entire sample shall be resieved either by a mechanical

FIG. 1 Extraction Apparatus

sieve shaker or hand sieving. If the hand-sieving method is

used, the sieve shall be rotated with slight tapping, the period

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.