ASTM E1830-15(2019)

(Test Method)Standard Test Methods for Determining Mechanical Integrity of Photovoltaic Modules

Standard Test Methods for Determining Mechanical Integrity of Photovoltaic Modules

SIGNIFICANCE AND USE

4.1 The useful life of photovoltaic modules may depend on their ability to withstand periodic exposure to high wind forces, cyclic loads induced by specific site conditions or shipment methods, high loads caused by accumulated snow and ice on the module surface, and twisting deflections caused by mounting to non-planar surfaces or structures. The effects on the module may be physical or electrical, or both. Most importantly, the effects may compromise the safety of the module, particularly in high voltage applications, or where the public may be exposed to broken glass or other debris.

4.2 These test methods describe procedures for mounting the test specimen, conducting the prescribed mechanical tests, and reporting the effects of the testing.

4.2.1 The mounting and fastening method shall comply with the manufacturer's recommendations as closely as possible. If slots or multiple mounting holes are provided on the module frame for optional mounting point capability, the worst-case mounting positions shall be selected in order to subject the module to the maximum stresses.

4.2.2 If an unframed module is being tested, the module shall be mounted in strict accordance with the manufacturer's instructions using the recommended attachment clips, brackets, fasteners or other hardware, and tightened to the specified torque.

4.2.3 The test specimen is mounted on a test base in a planar manner (unless specified otherwise), simulating a field mounting arrangement in order to ensure that modules are tested in a configuration that is representative of their use in the field.

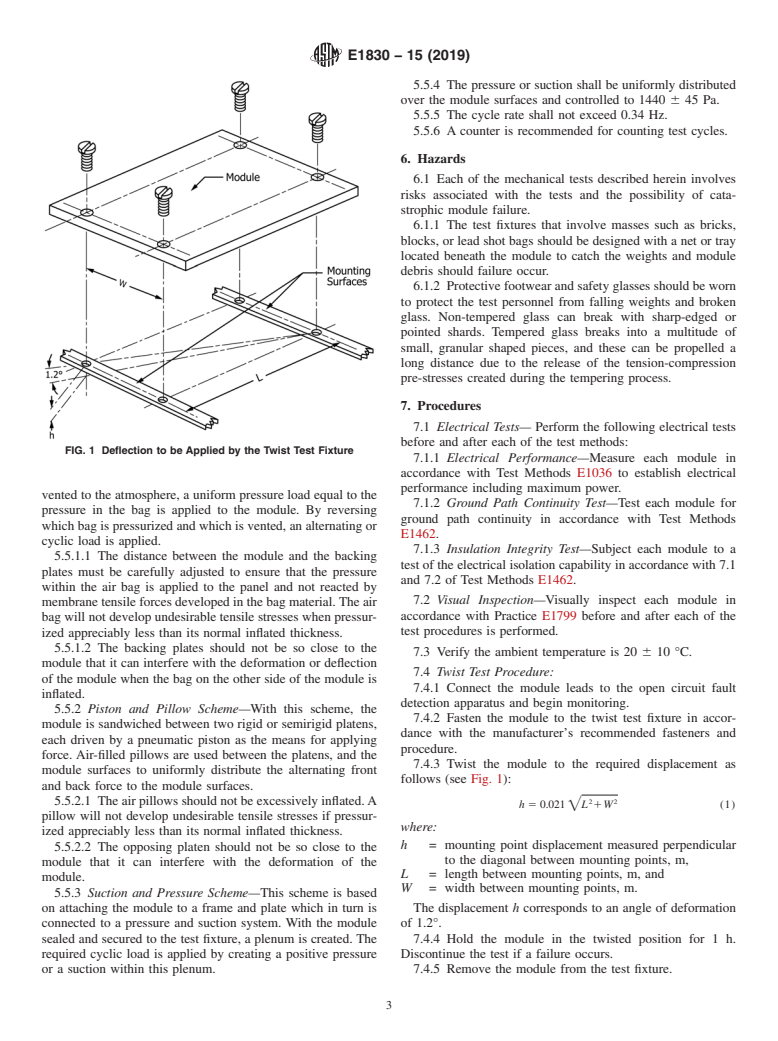

4.2.4 During the twist test, the module is mounted in a manner simulating a non-planar field mounting where one of the fastening points is displaced to create an intentional twist of 1.2°.

4.3 Data obtained during testing may be used to evaluate and compare the effects of the simulated environments on the test specimens. These test methods require analysis of both visible effects and electri...

SCOPE

1.1 These test methods cover procedures for determining the ability of photovoltaic modules to withstand the mechanical loads, stresses and deflections used to simulate, on an accelerated basis, high wind conditions, heavy snow and ice accumulation, and non-planar installation effects.

1.1.1 A static load test to 2400 Pa is used to simulate wind loads on both module surfaces.

1.1.2 A static load test to 5400 Pa is used to simulate heavy snow and ice accumulation on the module front surface.

1.1.3 A twist test is used to simulate the non-planar mounting of a photovoltaic module by subjecting it to a twist angle of 1.2°.

1.1.4 A cyclic load test of 10 000 cycles duration and peak loading to 1440 Pa is used to simulate dynamic wind or other flexural loading. Such loading might occur during shipment or after installation at a particular location.

1.2 These test methods define photovoltaic test specimens and mounting methods, and specify parameters that must be recorded and reported.

1.3 Any individual mechanical test may be performed singly, or may be combined into a test sequence with other mechanical or nonmechanical tests, or both. Certain preconditioning test methods such as annealing or light soaking may also be necessary or desirable as a part of such a sequence. However, the determination of such test sequencing and preconditioning is beyond the scope of these test methods.

1.4 These test methods do not establish pass or fail levels. The determination of acceptable or unacceptable results is beyond the scope of these test methods.

1.5 These test methods do not apply to concentrator modules.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 The following precautionary caveat pertains only to the hazards portion, Section 6, and the warning statements, 7.5.3.2 and 7.6.3.2, of these test methods.This standard doe...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1830 − 15 (Reapproved 2019)

Standard Test Methods for

Determining Mechanical Integrity of Photovoltaic Modules

This standard is issued under the fixed designation E1830; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 The following precautionary caveat pertains only to the

hazards portion, Section 6, and the warning statements, 7.5.3.2

1.1 These test methods cover procedures for determining

and 7.6.3.2, of these test methods.This standard does not

theabilityofphotovoltaicmodulestowithstandthemechanical

purport to address all of the safety concerns, if any, associated

loads, stresses and deflections used to simulate, on an acceler-

with its use. It is the responsibility of the user of this standard

ated basis, high wind conditions, heavy snow and ice

to establish appropriate safety, health, and environmental

accumulation, and non-planar installation effects.

practices and determine the applicability of regulatory limita-

1.1.1 A static load test to 2400 Pa is used to simulate wind

tions prior to use.

loads on both module surfaces.

1.8 This international standard was developed in accor-

1.1.2 Astatic load test to 5400 Pa is used to simulate heavy

dance with internationally recognized principles on standard-

snow and ice accumulation on the module front surface.

ization established in the Decision on Principles for the

1.1.3 A twist test is used to simulate the non-planar mount-

Development of International Standards, Guides and Recom-

ing of a photovoltaic module by subjecting it to a twist angle

mendations issued by the World Trade Organization Technical

of 1.2°.

Barriers to Trade (TBT) Committee.

1.1.4 A cyclic load test of 10 000 cycles duration and peak

loading to 1440 Pa is used to simulate dynamic wind or other

2. Referenced Documents

flexural loading. Such loading might occur during shipment or

2.1 ASTM Standards:

after installation at a particular location.

E772 Terminology of Solar Energy Conversion

1.2 These test methods define photovoltaic test specimens

E1036 Test Methods for Electrical Performance of Noncon-

and mounting methods, and specify parameters that must be

centrator Terrestrial Photovoltaic Modules and Arrays

recorded and reported.

Using Reference Cells

1.3 Any individual mechanical test may be performed E1462 Test Methods for Insulation Integrity and Ground

singly, or may be combined into a test sequence with other

Path Continuity of Photovoltaic Modules

mechanical or nonmechanical tests, or both. Certain precondi-

E1799 Practice for Visual Inspections of Photovoltaic Mod-

tioning test methods such as annealing or light soaking may

ules

also be necessary or desirable as a part of such a sequence.

3. Terminology

However, the determination of such test sequencing and

preconditioning is beyond the scope of these test methods.

3.1 Definitions—Definitions of terms used in these test

methods may be found in Terminology E772.

1.4 These test methods do not establish pass or fail levels.

The determination of acceptable or unacceptable results is

4. Significance and Use

beyond the scope of these test methods.

4.1 The useful life of photovoltaic modules may depend on

1.5 These test methods do not apply to concentrator mod-

theirabilitytowithstandperiodicexposuretohighwindforces,

ules.

cyclic loads induced by specific site conditions or shipment

1.6 The values stated in SI units are to be regarded as

methods, high loads caused by accumulated snow and ice on

standard. No other units of measurement are included in this

the module surface, and twisting deflections caused by mount-

standard.

ing to non-planar surfaces or structures. The effects on the

module may be physical or electrical, or both. Most

importantly, the effects may compromise the safety of the

These test methods are under the jurisdiction of ASTM Committee E44 on

Solar, Geothermal and Other Alternative Energy Sources and are the direct

responsibility of Subcommittee E44.09 on Photovoltaic Electric Power Conversion. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2019. Published April 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1996. Last previous edition approved in 2015 as E1830 - 15. DOI: Standardsvolume information, refer to the standard’s Document Summary page on

10.1520/E1830-15R19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1830 − 15 (2019)

module, particularly in high voltage applications, or where the 5.3.1 Test Base—A rigid test base shall be provided that

public may be exposed to broken glass or other debris. enables the module to be mounted front-side up or front-side

downinaccordancewiththerequirementsof4.2.1–4.2.3.The

4.2 These test methods describe procedures for mounting

test base shall enable the module to deflect freely during load

the test specimen, conducting the prescribed mechanical tests,

application to preclude any inadvertent interference or limiting

and reporting the effects of the testing.

of the normal deflections.

4.2.1 Themountingandfasteningmethodshallcomplywith

5.3.2 Load Measurement Equipment—Means shall be pro-

the manufacturer’s recommendations as closely as possible. If

vided for measuring the applied load to within the prescribed

slots or multiple mounting holes are provided on the module

tolerances.

frame for optional mounting point capability, the worst-case

5.3.3 Loads—Suitable masses or means of applying pres-

mounting positions shall be selected in order to subject the

sure shall be provided that enable the load to be applied in a

module to the maximum stresses.

gradual, uniform manner. Some examples of loads that can be

4.2.2 If an unframed module is being tested, the module

used are:

shall be mounted in strict accordance with the manufacturer’s

5.3.3.1 Stacks of paper or small canvas or plastic bags filled

instructionsusingtherecommendedattachmentclips,brackets,

with several kilograms of sand, loose stones, or lead shot in a

fasteners or other hardware, and tightened to the specified

sufficient quantity to meet the total load requirement,

torque.

5.3.3.2 A water bag that can be progressively filled to

4.2.3 Thetestspecimenismountedonatestbaseinaplanar

increase the load,

manner (unless specified otherwise), simulating a field mount-

5.3.3.3 Apneumatic bag that can be inflated to a controlled

ing arrangement in order to ensure that modules are tested in a

pressure and that is located between the module and a fixed

configuration that is representative of their use in the field.

surface (see 5.5, Cyclic Load Test Apparatus),

4.2.4 During the twist test, the module is mounted in a

5.3.3.4 Loose sand can be used provided that a perimeter

manner simulating a non-planar field mounting where one of

retaining skirt of cardboard or thin plywood, for example, is

thefasteningpointsisdisplacedtocreateanintentionaltwistof

employed around the module perimeter to retain the sand and

1.2°.

maintain load uniformity to the module edges, or

4.3 Data obtained during testing may be used to evaluate

5.3.3.5 Bricks or cement blocks may be used, but a pad

and compare the effects of the simulated environments on the

should first be placed on the module to prevent scratch or

test specimens. These test methods require analysis of both

particle damage. With such rigid load elements, care should be

visible effects and electrical performance effects.

exercised to minimize load concentration points.

4.3.1 Effects on modules may vary from no changes to

5.3.3.6 If the applied load is comprised of discrete load

significant changes. Some physical changes in the module may

elements such as bags, bricks, or blocks, the individual units

be visible even though there are no apparent electrical perfor-

shall weigh within 5 % of one another to ensure the application

mance changes. Conversely, electrical performance changes

of a uniform load on the module.

may occur with no visible change in the module.

5.3.3.7 The applied load may be measured by pre-weighing

4.3.2 All conditions of measurement, effects of the test

the load elements, or the load may be measured in situ during

exposure, and any deviations from these test methods must be

the test by the use of load scales incorporated into the test

described in the report so that an assessment of their signifi-

apparatus.Ifapneumaticbagisused,theloadcanbemeasured

cance can be made.

withapressuregagebecausetheloadisprovidedbypneumatic

pressure.

4.4 If these test methods are being performed as part of a

combined sequence with other mechanical or nonmechanical

5.4 Twist Test Apparatus:

tests, the results of the final electrical test (7.2) and visual

5.4.1 A rigid test fixture shall be provided that allows the

inspection (7.3) from one test may be used as the initial

module to be installed in a flat, planar configuration, and that

electrical test and visual inspection for the next test; duplica-

permits the displacement of one of the attachment points such

tion of these tests is unnecessary unless so specified.

that a twist is induced in the module (see Fig. 1). The test

fixture must meet the requirements of 4.2.1 – 4.2.4.

4.5 Some module designs may not use any external metallic

5.4.2 Acceptable test fixtures capable of meeting this re-

components and thus lack a ground point designation by the

quirement include a simple table and shim arrangement, or a

module manufacturer. In these cases, the ground path continu-

more complicated rack structure with a special screw adjust-

ity test is not applicable.

ment for imposing the twist-inducing displacement.

5. Apparatus

5.5 Cyclic Load TestApparatus—Severalschemesareavail-

able for conducting the cyclic load test. Whichever scheme is

5.1 In addition to the apparatus required for Test Methods

selected must adhere to the requirements of 4.2.1 – 4.2.3.

E1036 and E1462, the following apparatus is required.

Schemes that have been found acceptable are:

5.2 Open Circuit Fault Detection—Instrumentation for

5.5.1 Air Bag Scheme—With this scheme, pressure is ap-

monitoring the module under test for open circuit conditions

pliedbyinflatableairbags.Themoduleissandwichedbetween

during the mechanical integrity tests. An acceptable apparatus

two inflatable air bags which in turn are sandwiched between

is described in Annex A1.

rigid or semirigid backing plates. By pressurizing the bag on

5.3 Static Load Test Apparatus: one side of the module while the bag on the opposite side is

E1830 − 15 (2019)

5.5.4 The pressure or suction shall be uniformly distributed

over the module surfaces and controlled to 1440 6 45 Pa.

5.5.5 The cycle rate shall not exceed 0.34 Hz.

5.5.6 A counter is recommended for counting test cycles.

6. Hazards

6.1 Each of the mechanical tests described herein involves

risks associated with the tests and the possibility of cata-

strophic module failure.

6.1.1 The test fixtures that involve masses such as bricks,

blocks, or lead shot bags should be designed with a net or tray

located beneath the module to catch the weights and module

debris should failure occur.

6.1.2 Protective footwear and safety glasses should be worn

to protect the test personnel from falling weights and broken

glass. Non-tempered glass can break with sharp-edged or

pointed shards. Tempered glass breaks into a multitude of

small, granular shaped pieces, and these can be propelled a

long distance due to the release of the tension-compression

pre-stresses created during the tempering process.

7. Procedures

7.1 Electrical Tests— Perform the following electrical tests

before and after each of the test methods:

FIG. 1 Deflection to be Applied by the Twist Test Fixture

7.1.1 Electrical Performance—Measure each module in

accordance with Test Methods E1036 to establish electrical

performance including maximum power.

vented to the atmosphere, a uniform pressure load equal to the

7.1.2 Ground Path Continuity Test—Test each module for

pressure in the bag is applied to the module. By reversing

ground path continuity in accordance with Test Methods

which bag is pressurized and which is vented, an alternating or

E1462.

cyclic load is applied.

7.1.3 Insulation Integrity Test—Subject each module to a

5.5.1.1 The distance between the module and the backing

test of the electrical isolation capability in accordance with 7.1

plates must be carefully adjusted to ensure that the pressure

and 7.2 of Test Methods E1462.

within the air bag is applied to the panel and not reacted by

7.2 Visual Inspection—Visually inspect each module in

membrane tensile forces developed in the bag material.The air

accordance with Practice E1799 before and after each of the

bag will not develop undesirable tensile stresses when pressur-

test procedures is performed.

ized appreciably less than its normal inflated thickness.

5.5.1.2 The backing plates should not be so close to the

7.3 Verify the ambient temperature is 20 6 10 °C.

module that it can interfere with the deformation or deflection

7.4 Twist Test Procedure:

of the module when the bag on the other side of the module is

7.4.1 Connect the module leads to the open circuit fault

inflated.

detection apparatus and begin monitoring.

5.5.2 Piston and Pillow Scheme—With this scheme, the

7.4.2 Fasten the module to the twist test fixture in accor-

module is sandwiched between two rigid or semirigid platens,

dance with the manufacturer’s recommended fasteners and

each driven by a pneumatic piston as the means for applying

procedure.

force. Air-filled pillows are used between the platens, and the

7.4.3 Twist the module to the required displacement as

module surfaces to uniformly distribute the alternating front

follows (see Fig. 1):

and back force to the module surfaces.

2 2

5.5.2.1 The air pillows should not be excessively inflated.A

h 5 0.021 =L 1W (1)

pillow will not develop undesirable tensile stresses if pressur-

where:

ized appreciably less than its normal inflated thickness.

h = mounting point displacement measured perpendicular

5.5.2.2 The opposing platen should not be so close to the

to the diagonal between mounting points, m,

module that it can interfere with the deformation of the

L = length between mounting points, m, and

module.

W = width between mounting points, m.

5.5.3 Suction and Pressu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.