ASTM D7110-14

(Test Method)Standard Test Method for Determining the Viscosity-Temperature Relationship of Used and Soot-Containing Engine Oils at Low Temperatures

Standard Test Method for Determining the Viscosity-Temperature Relationship of Used and Soot-Containing Engine Oils at Low Temperatures

SIGNIFICANCE AND USE

5.1 Significance of Low Temperature, Low Shear Rate, Engine Oil Rheology—The low-temperature, low-shear viscometric behavior of an engine oil, whether new, used, or sooted, determines whether the oil will flow to the sump inlet screen, then to the oil pump, then to the sites in the engine requiring lubrication in sufficient quantity to prevent engine damage immediately or ultimately after cold temperature starting. Two forms of flow problems have been identified,3 flow-limited and air-binding behavior. The first form of flow restriction, flow-limited behavior, is associated with the oil's viscosity; the second, air-binding behavior, is associated with gelation.

5.2 Significance of the Test Method—The temperature-scanning technique employed by this test method was designed to determine the susceptibility of the engine oil to flow-limited and air-binding response to slow cooling conditions by providing continuous information on the rheological condition of the oil over the temperature range of use.3,4,5 In this way, both viscometric and gelation response are obtained in one test.

Note 1: This test method is one of three related to pumpability related problems. Measurement of low-temperature viscosity by the two other pumpability test methods, D3829 and D4684, hold the sample in a quiescent state and generate the apparent viscosity of the sample at shear rates ranging up to 15 s-1 and shear stresses up to 525 Pa at a previously selected temperature. Such difference in test parameters (shear rate, shear stress, sample motion, temperature scanning, and so forth) can lead to differences in the measured apparent viscosity among these methods with some test oils, particularly when other rheological factors associated with gelation are present. In addition, the three methods differ considerably in cooling rates.

5.3 Gelation Index and Gelation Index Temperature—This test method has been further developed to yield parameters called the Gelation Index and Gelation Ind...

SCOPE

1.1 This test method covers how to measure the apparent viscosity of used and soot-containing engine oils at low temperatures.

1.2 A shear rate of approximately 0.2 s-1 is produced at shear stresses below 200 Pa. Apparent viscosity is measured continuously as the sample is cooled at a rate of 3°C per hour over the range of −5 °C to −40 °C.

1.3 The measurements resulting from this test method are viscosity, the maximum rate of viscosity increase (Gelation Index) and the temperature at which the Gelation Index occurs.

1.4 Applicability to petroleum products other than engine oils has not been determined in preparing this test method.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7110 − 14

StandardTest Method for

Determining the Viscosity-Temperature Relationship of Used

and Soot-Containing Engine Oils at Low Temperatures

This standard is issued under the fixed designation D7110; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 This test method covers how to measure the apparent 3.1 Definitions:

viscosity of used and soot-containing engine oils at low

3.1.1 apparent viscosity, n—theviscosityobtainedbyuseof

temperatures.

this test method.

-1

3.1.1.1 Discussion—See3.1.7fordefinitionofviscosityand

1.2 A shear rate of approximately 0.2 s is produced at

units.

shear stresses below 200 Pa. Apparent viscosity is measured

continuously as the sample is cooled at a rate of 3°C per hour

3.1.2 digital contact thermometer (DCT), n—an electronic

over the range of −5°C to −40°C.

device consisting of a digital display and associated tempera-

ture sensing probe.

1.3 The measurements resulting from this test method are

viscosity, the maximum rate of viscosity increase (Gelation

3.1.2.1 Discussion—This device consists of a temperature

Index)andthetemperatureatwhichtheGelationIndexoccurs.

sensor connected to a measuring instrument; this instrument

1.4 Applicability to petroleum products other than engine

measures the temperature-dependent quantity of the sensor,

oils has not been determined in preparing this test method.

computes the temperature from the measured quantity, and

providesadigitaloutput,ordisplayofthetemperature,orboth.

1.5 The values stated in SI units are to be regarded as

This device is sometimes referred to a digital thermometer.

standard. No other units of measurement are included in this

standard.

3.1.3 Newtonian oil, n—an oil that, at a given temperature,

exhibits a constant viscosity at all shear rates or shear stresses.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1.4 non-Newtonian oil, n—an oil that, at a given

responsibility of the user of this standard to establish appro-

temperature,exhibitsaviscositythatvarieswithshearstressor

priate safety and health practices and determine the applica-

shear rate.

bility of regulatory limitations prior to use.

3.1.5 shear rate, n—velocity gradient perpendicular to the

2. Referenced Documents direction of flow.

3.1.5.1 Discussion—The SI unit for shear rate is the recip-

2.1 ASTM Standards:

-1

rocal second (1/s; also s ).

D341Practice for Viscosity-Temperature Charts for Liquid

Petroleum Products

3.1.6 shear stress, n—force per unit area in the direction of

D3829Test Method for Predicting the Borderline Pumping

flow.

Temperature of Engine Oil

3.1.6.1 Discussion—TheSIunitforshearstressisthepascal

D4684Test Method for Determination of Yield Stress and

(Pa).

Apparent Viscosity of Engine Oils at Low Temperature

3.1.7 viscosity, n—thatpropertyofafluidwhichresistsflow.

D4057Practice for Manual Sampling of Petroleum and

3.1.7.1 Discussion—Viscosity is defined as the ratio of the

Petroleum Products

applied shear stress (force causing flow) and the shear rate

(resultant velocity of flow per unit distance from a stationary

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

surface wet by the fluid). Mathematically expressed:

Subcommittee D02.07 on Flow Properties.

viscosity 5 shearstress/shearrateor, symbolically, η 5 τ/γ˙ (1)

Current edition approved Dec. 1, 2014. Published January 2015. Originally

approved in 2005. Last previous edition approved in 2011 as D7110–05a (2011).

in which the symbols in the second portion of Eq 1 are

DOI: 10.1520/D7110-14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or defined by 3.1.5 and 3.1.6. The SI unit for viscosity used

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

herein is millipascal seconds (mPa·s).

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 3.2 Definitions of Terms Specific to This Standard:

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7110 − 14

3.2.1 air-binding oils, n—those engine oils whose border- 3.2.10 Gelation Index reference oils, n—non-Newtonian

linepumpingtemperaturesaredeterminedbyacombinationof oils chosen to give certain levels of Gelation Index as a check

gelation and viscous flow. on instrument performance.

3.2.2 borderline pumping temperature, n—that temperature 3.2.11 Gelation Index Temperature, n—the temperature in

at which an engine oil may have such poor flow characteristics degrees Celsius at which the Gelation Index occurs.

that the engine oil pump may not be capable of supplying

3.2.12 pre-treatment sample heating bath, n—a water or air

sufficient lubricant to the engine.

bath to heat the samples for 1.5 h at 90°C 6 2°C before

3.2.3 calibration oil, n—Newtonianoilsdevelopedandused testing.

to calibrate the viscometer drive module over the viscosity

3.2.13 programmable liquid cold bath, n—a liquid bath

range required for this test method.

having a temperature controller capable of being programmed

3.2.3.1 Discussion—These calibration oils are specially

to run the calibration and the analysis portions of the test

blended to give sufficient sensitivity and range for the special

method.

viscometer head used.

3.2.14 temperature controller, n—a programmable device

3.2.4 computer-programmed automated analysis, n—use of

which, when properly programmed, ramps the temperature

techniques for acquiring analog data, converting these to

upward or downward at a chosen rate or series of steps while

digital values and using this information to automatically

simultaneously controlling temperature excursions.

record and analyze torque output from the viscometer drive

3.2.14.1 calibration program, n—a program to run the

module and to render this information into tabular data and

required series of temperatures at which the torque values

plotted relationships.

necessary to calibrate the viscometer drive module are col-

3.2.4.1 analog-to-digital (A-D) converter, n—a device for

lected and analyzed.

converting continuously produced electrical signals into dis-

3.2.14.2 test program, n—a program to run the test oil

crete numerical values capable of being analyzed by computer

analysis at 1°C/h temperature decrease.

technology.

3.2.14.3 hold program, n—a program to reach and hold the

3.2.5 critical pumpability temperature, n—the temperature

programmable liquid cold bath at −5°C.

at which an oil reaches a viscosity believed to be critical to

3.2.15 test cell, n—the combination of the rotor and stator.

limiting pumpability of the oil (see 3.2.6).

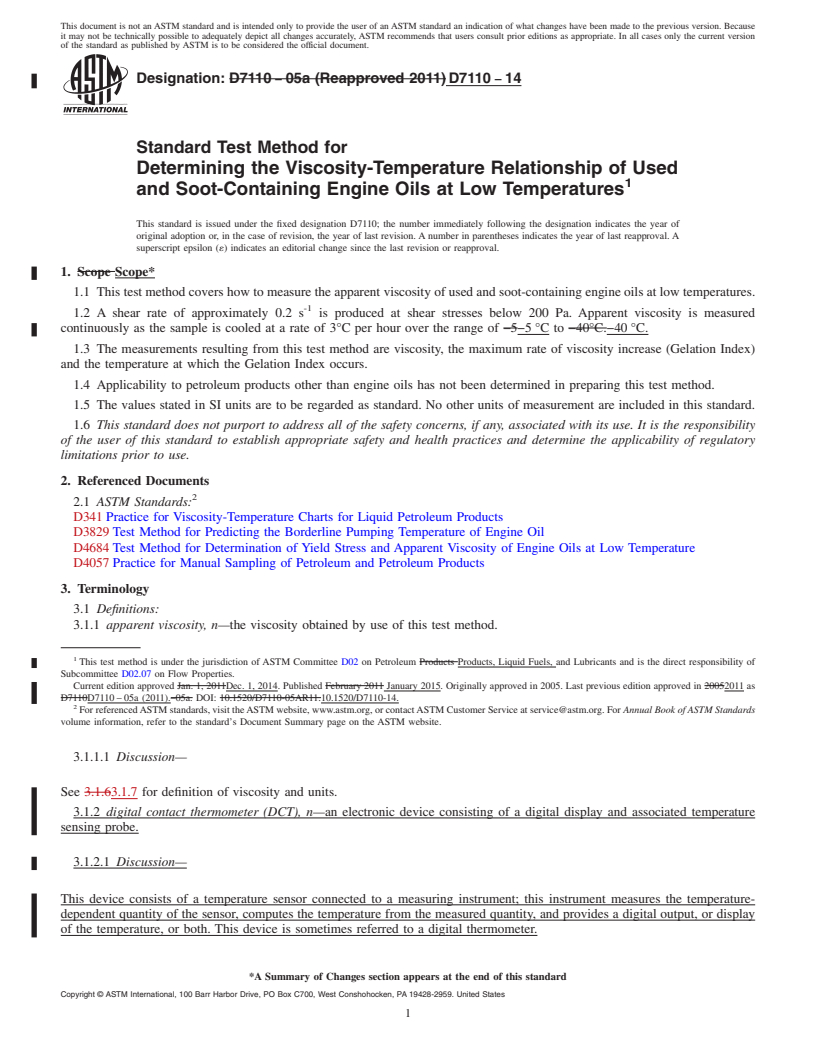

Critical elements of the test cell are sketched in Fig. 1.

3.2.6 critical pumpability viscosity, n—thatapparentviscos-

ity believed to cause pumpability problems in an engine.

3.2.7 flow-limited oils, n—those oils whose borderline

pumping temperatures are determined by viscous flow.

3.2.8 gelation, n—a rheological condition of an oil charac-

terized by a marked increase in flow resistance over and above

the normal exponential increase of viscosity with decreasing

temperature, particularly at lower shear stresses and tempera-

tures.

3.2.8.1 Discussion—Gelation has been attributed to a pro-

cessofnucleationandcrystallizationofoilcomponentsandthe

consequent formation of a gel-like mass.

3.2.9 Gelation Index, n—the maximum value of the incre-

mental ratio:

2@ log log η 2 log log η #/ log T 2 log T (2)

~ ! ~ ! ~ !

1 2 1 2

in which η is dynamic viscosity and T is temperature in

Kelvin over the temperature range scanned when the incre-

mental decrease in temperature is 1°K.

3.2.9.1 Discussion—The technique of deriving Gelation In-

dex was first developed and practiced by collecting informa-

tion from a strip-chart recording and applying the empirical

MacCoull-Walther-Wright equation. For further information,

see Appendix1 of Viscosity-Temperature Charts D341.

Symposium on Low Temperature Lubricant Rheology Measurement and Rel-

evance to Engine Operation,ASTMSTP1143,Ed.RobertB.Rhodes,ASTM,1992.

Selby, T. W., “The Use of the Scanning Brookfield Technique to Study the

Critical Degree of Gelation of Lubricants at Low Temperatures,” SAE Paper

910746, Society of Automotive Engineers, 1991. FIG. 1 Test Cell

D7110 − 14

3.2.15.1 rotor, n—a titanium rotor sized to give a compro- andair-bindingresponsetoslowcoolingconditionsbyprovid-

mise of sensitivity and range to the determination of viscosity ing continuous information on the rheological condition of the

3,4,5

and gelation using this test method. oil over the temperature range of use. In this way, both

viscometric and gelation response are obtained in one test.

3.2.15.2 stator, n—a precision-bore borosilicate glass tube,

NOTE1—Thistestmethodisoneofthreerelatedtopumpabilityrelated

to which a measured amount of oil is added for the test and

problems. Measurement of low-temperature viscosity by the two other

within which the specially-made rotor turns.

pumpability test methods, D3829 and D4684, hold the sample in a

3.2.15.2.1 stator collar, n—aclampforthestatorwhichalso

quiescent state and generate the apparent viscosity of the sample at shear

-1

rates ranging up to 15 s and shear stresses up to 525Pa at a previously

positions it on the test cell alignment device.

selected temperature. Such difference in test parameters (shear rate, shear

3.2.15.3 test cell alignment device, n—a special device used

stress, sample motion, temperature scanning, and so forth) can lead to

to support the viscometer drive module while maintaining the

differences in the measured apparent viscosity among these methods with

stator and the rotor coaxial and vertical in regard to the some test oils, particularly when other rheological factors associated with

gelation are present. In addition, the three methods differ considerably in

viscometerdriveshaft.Laterdesignsadmitdrygasintothecell

cooling rates.

to prevent moisture and frost buildup.

5.3 Gelation Index and Gelation Index Temperature—This

3.2.16 test oil, n—any oil for which apparent viscosity is to

test method has been further developed to yield parameters

be determined using the procedure described by this test

calledtheGelationIndexandGelationIndexTemperature.The

method.

first parameter is a measure of the maximum rate of torque

3.2.17 viscometer drive module, n—the rotor drive and

increasecausedbytherheologicalresponseoftheoilastheoil

torque-sensing component of a rotational viscometer.

is cooled slowly. The second parameter is the temperature at

3.2.18 viscometer module support, n—a part of the test cell

which the Gelation Index occurs.

alignment device supporting the viscometer drive module.

6. Apparatus

4. Summary of Test Method

6.1 Test Cell—Shown in Fig. 1, consisting of a matched

4.1 Usedandsootedengineoilsareanalyzedusingaspecial

rotor and a stator of the following critical dimensions:

rotational viscometer with analog or digital output to a com-

6.1.1 Rotor Dimensions—Critical length is 65.5mm 6

puter program.Aspecially made glass stator/metal rotor cell is

0.1mm and critical diameter is 18.40mm 6 0.02mm.

attached to the viscometer and subjected to a programmed

6.1.2 Stator Dimensions—Critical diameter is 22.05mm

temperature change for both calibration and sample analysis.

(60.02mm) at whatever length will satisfy the immersion

Following calibration of the rotor-stator set, an approximately

depth when the upper oil level is a minimum of 15mm below

20mL test sample of a test lubricating oil is poured into the

the cooling liquid level over the entire temperature range.

stator and preheated for 1.5h to 2.0h at 90°C in an oven or

6.2 Viscometer Drive Modules—Rotational viscometer

water bath. Shortly after completing the preheating step, the

drive modules capable of producing an analog signal to an

room-temperature rotor is put into the stator containing the

analog-to-digital converter or other analog signal data proces-

heated oil and coupled to a torque-sensing viscometer head

sor such as a strip-chart recorder.

using an adapter to automatically center the rotor in the stator

6.2.1 With the rotor and stator described in 6.1.1 and 6.1.2,

during test. A programmable low-temperature bath is used to

the viscometer drive module must be capable of measuring to

cool the cell at a specified rate of 3°C⁄h from −5°C to the

at least 90000mPa·s (cP).

temperature at which the maximum torque recordable is

6.3 Test Cell Alignment Device—Simultaneously maintains

exceeded when using a speed of 0.3r⁄min for the rotor. After

averticalaxialalignmentandreasonablyconsistentpositioning

the desired information has been collected, the computer

of the rotor in the stator to give repeatable torque readout from

program generates the desired viscometric and rheological

test to test when setting up the apparatus for analysis.

values from the recorded data.

6.3.1 Viscometer Support—Supports the viscometer drive

5. Significance and Use

module and aligns it vertically.

6.3.2 Stator Collar—Clampsthestatorandsupportsitwhen

5.1 Significance of Low Temperature, Low Shear Rate,

the stator collar is attached to the viscometer support.

Engine Oil Rheology—The low-temperature, low-shear visco-

metricbehaviorofanengineoil,whethernew,used,orsooted,

6.4 Ameansofprovidingadrygasatmosphereoverthetop

determines whether the oil will flow to the sump inlet screen,

of the test sample is necessary to prevent condensation and

then to the oil pump, then to the sites in the engine requiring

freezing of water on the oil surface.

lubrication in sufficient quantity to prevent engine damage

6.5 Programmable Liquid Cooling Bath—Liquid bath ca-

immediately or ultimately after cold temperature starting. Two

pable of running either the calibration or the testing program

formsofflowproblemshavebeenidentified, flow-limitedand

with temperature control of 60.1°C over the temperature

air-binding behavior. The first form of flow restriction, flow-

range desired at 1°C⁄h.

limited behavior, is associated with the oil’s viscosity; the

second, air-binding behavior, is associated with gelation.

Shaub,H.,“AHistoryofASTMAccomplishmentsinLowTemperatureEngine

5.2 Significance of the Test Method—The temperature-

Oil Rheology,” Symposium on Low Temperature Lubricant Rheology Measurement

scanningtechniqueemployedbythis

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7110 − 05a (Reapproved 2011) D7110 − 14

Standard Test Method for

Determining the Viscosity-Temperature Relationship of Used

and Soot-Containing Engine Oils at Low Temperatures

This standard is issued under the fixed designation D7110; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers how to measure the apparent viscosity of used and soot-containing engine oils at low temperatures.

-1

1.2 A shear rate of approximately 0.2 s is produced at shear stresses below 200 Pa. Apparent viscosity is measured

continuously as the sample is cooled at a rate of 3°C per hour over the range of −5−5 °C to −40°C.−40 °C.

1.3 The measurements resulting from this test method are viscosity, the maximum rate of viscosity increase (Gelation Index)

and the temperature at which the Gelation Index occurs.

1.4 Applicability to petroleum products other than engine oils has not been determined in preparing this test method.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D341 Practice for Viscosity-Temperature Charts for Liquid Petroleum Products

D3829 Test Method for Predicting the Borderline Pumping Temperature of Engine Oil

D4684 Test Method for Determination of Yield Stress and Apparent Viscosity of Engine Oils at Low Temperature

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

3. Terminology

3.1 Definitions:

3.1.1 apparent viscosity, n—the viscosity obtained by use of this test method.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.07 on Flow Properties.

Current edition approved Jan. 1, 2011Dec. 1, 2014. Published February 2011 January 2015. Originally approved in 2005. Last previous edition approved in 20052011 as

D7110D7110 – 05a (2011).–05a. DOI: 10.1520/D7110-05AR11.10.1520/D7110-14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.1.1 Discussion—

See 3.1.63.1.7 for definition of viscosity and units.

3.1.2 digital contact thermometer (DCT), n—an electronic device consisting of a digital display and associated temperature

sensing probe.

3.1.2.1 Discussion—

This device consists of a temperature sensor connected to a measuring instrument; this instrument measures the temperature-

dependent quantity of the sensor, computes the temperature from the measured quantity, and provides a digital output, or display

of the temperature, or both. This device is sometimes referred to a digital thermometer.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7110 − 14

3.1.3 Newtonian oil, n—an oil that, at a given temperature, exhibits a constant viscosity at all shear rates or shear stresses.

3.1.4 non-Newtonian oil, n—an oil that, at a given temperature, exhibits a viscosity that varies with shear stress or shear rate.

3.1.5 shear rate, n—velocity gradient perpendicular to the direction of flow.

3.1.5.1 Discussion—

-1

The SI unit for shear rate is the reciprocal second (1/s; also s ).

3.1.6 shear stress, n—force per unit area in the direction of flow.

3.1.6.1 Discussion—

The SI unit for shear stress is the pascal (Pa).

3.1.7 viscosity, n—that property of a fluid which resists flow.

3.1.7.1 Discussion—

Viscosity is defined as the ratio of the applied shear stress (force causing flow) and the shear rate (resultant velocity of flow per

unit distance from a stationary surface wet by the fluid). Mathematically expressed:

viscosity 5 shear stress/shear rate or, symbolically, η5 τ/G (1)

viscosity5shear stress/shear rate or,symbolically,η5τ/γ˙ (1)

in which the symbols in the second portion of Eq 1 are defined by 3.1.43.1.5 and 3.1.53.1.6. The SI unit for viscosity used

herein is millipascal seconds (mPa·s).

3.2 Definitions of Terms Specific to This Standard:

3.2.1 air-binding oils, n—those engine oils whose borderline pumping temperatures are determined by a combination of gelation

and viscous flow.

3.2.2 borderline pumping temperature, n—that temperature at which an engine oil may have such poor flow characteristics that

the engine oil pump may not be capable of supplying sufficient lubricant to the engine.

3.2.3 calibration oil, n—Newtonian oils developed and used to calibrate the viscometer drive module over the viscosity range

required for this test method.

3.2.3.1 Discussion—

These calibration oils are specially blended to give sufficient sensitivity and range for the special viscometer head used.

3.2.4 computer-programmed automated analysis, n—use of techniques for acquiring analog data, converting these to digital

values and using this information to automatically record and analyze torque output from the viscometer drive module and to

render this information into tabular data and plotted relationships.

3.2.4.1 analog-to-digital (A-D) converter, n—a device for converting continuously produced electrical signals into discrete

numerical values capable of being analyzed by computer technology.

3.2.5 critical pumpability temperature, n—the temperature at which an oil reaches a viscosity believed to be critical to limiting

pumpability of the oil (see 3.2.6).

3.2.6 critical pumpability viscosity, n—that apparent viscosity believed to cause pumpability problems in an engine.

3.2.7 flow-limited oils, n—those oils whose borderline pumping temperatures are determined by viscous flow.

3.2.8 gelation, n—a rheological condition of an oil characterized by a marked increase in flow resistance over and above the

normal exponential increase of viscosity with decreasing temperature, particularly at lower shear stresses and temperatures.

3.2.8.1 Discussion—

Gelation has been attributed to a process of nucleation and crystallization of oil components and the consequent formation of a

gel-like mass.

3.2.9 Gelation Index, n—the maximum value of the incremental ratio:

Symposium on Low Temperature Lubricant Rheology Measurement and Relevance to Engine Operation, ASTM STP 1143, Ed. Robert B. Rhodes, ASTM, 1992.

D7110 − 14

2 log log η 2 log log η / log T 2 log T (2)

@~ ! ~ ! ~ !#

1 2 1 2

2@ log log η ! 2 ~log log η !#/~log T 2 log T ! (2)

~

1 2 1 2

in which η is dynamic viscosity and T is temperature in Kelvin over the temperature range scanned when the incremental

decrease in temperature is 1°K.1 °K.

3.2.9.1 Discussion—

The technique of deriving Gelation Index was first developed and practiced by collecting information from a strip-chart recording

and applying the empirical MacCoull-Walther-Wright equation. For further information, see Appendix 1 of Viscosity-Temperature

Charts D341.

3.2.10 Gelation Index reference oils, n—non-Newtonian oils chosen to give certain levels of Gelation Index as a check on

instrument performance.

3.2.11 Gelation Index Temperature, n—the temperature in degrees Celsius at which the Gelation Index occurs.

3.2.12 pre-treatment sample heating bath, n—a water or air bath to heat the samples for 1.5 h at 9090 °C 6 2°C2 °C before

testing.

3.2.13 programmable liquid cold bath, n—a liquid bath having a temperature controller capable of being programmed to run

the calibration and the analysis portions of the test method.

3.2.14 temperature controller, n—a programmable device which, when properly programmed, ramps the temperature upward

or downward at a chosen rate or series of steps while simultaneously controlling temperature excursions.

3.2.14.1 calibration program, n—a program to run the required series of temperatures at which the torque values necessary to

calibrate the viscometer drive module are collected and analyzed.

3.2.14.2 test program, n—a program to run the test oil analysis at 1°C/h temperature decrease.

3.2.14.3 hold program, n—a program to reach and hold the programmable liquid cold bath at −5°C.−5 °C.

3.2.15 test cell, n—the combination of the rotor and stator. Critical elements of the test cell are sketched in Fig. 1.

3.2.15.1 rotor, n—a titanium rotor sized to give a compromise of sensitivity and range to the determination of viscosity and

gelation using this test method.

3.2.15.2 stator, n—a precision-bore borosilicate glass tube, to which a measured amount of oil is added for the test and within

which the specially-made rotor turns.

3.2.15.2.1 stator collar, n—a clamp for the stator which also positions it on the test cell alignment device.

3.2.15.3 test cell alignment device, n—a special device used to support the viscometer drive module while maintaining the stator

and the rotor coaxial and vertical in regard to the viscometer driveshaft. Later designs admit dry gas into the cell to prevent

moisture and frost buildup.

3.2.16 test oil, n—any oil for which apparent viscosity is to be determined using the procedure described by this test method.

3.2.17 viscometer drive module, n—the rotor drive and torque-sensing component of a rotational viscometer.

3.2.18 viscometer module support, n—a part of the test cell alignment device supporting the viscometer drive module.

4. Summary of Test Method

4.1 Used and sooted engine oils are analyzed using a special rotational viscometer with analog or digital output to a computer

program. A specially made glass stator/metal rotor cell is attached to the viscometer and subjected to a programmed temperature

change for both calibration and sample analysis. Following calibration of the rotor-stator set, an approximately 20-mL20 mL test

sample of a test lubricating oil is poured into the stator and preheated for 1.51.5 h to 2.0 h 2.0 h at 90°C90 °C in an oven or water

bath. Shortly after completing the preheating step, the room-temperature rotor is put into the stator containing the heated oil and

coupled to a torque-sensing viscometer head using an adapter to automatically center the rotor in the stator during test. A

programmable low-temperature bath is used to cool the cell at a specified rate of 3°C/h3 °C ⁄h from −5°C−5 °C to the temperature

at which the maximum torque recordable is exceeded when using a speed of 0.30.3 r ⁄ rpm min for the rotor. After the desired

information has been collected, the computer program generates the desired viscometric and rheological values from the recorded

data.

5. Significance and Use

5.1 Significance of Low Temperature, Low Shear Rate, Engine Oil Rheology—The low-temperature, low-shear viscometric

behavior of an engine oil, whether new, used, or sooted, determines whether the oil will flow to the sump inlet screen, then to the

Selby, T. W., “The Use of the Scanning Brookfield Technique to Study the Critical Degree of Gelation of Lubricants at Low Temperatures,” SAE Paper 910746, Society

of Automotive Engineers, 1991.

D7110 − 14

FIG. 1 Test Cell

oil pump, then to the sites in the engine requiring lubrication in sufficient quantity to prevent engine damage immediately or

ultimately after cold temperature starting. Two forms of flow problems have been identified, flow-limited and air-binding

behavior. The first form of flow restriction, flow-limited behavior, is associated with the oil’s viscosity; the second, air-binding

behavior, is associated with gelation.

5.2 Significance of the Test Method—The temperature-scanning technique employed by this test method was designed to

determine the susceptibility of the engine oil to flow-limited and air-binding response to slow cooling conditions by providing

3,4,5

continuous information on the rheological condition of the oil over the temperature range of use. In this way, both viscometric

and gelation response are obtained in one test.

NOTE 1—This test method is one of three related to pumpability related problems. Measurement of low-temperature viscosity by the two other

pumpability test methods, D3829 and D4684, hold the sample in a quiescent state and generate the apparent viscosity of the sample at shear rates ranging

-1

up to 15 s and shear stresses up to 525 Pa 525 Pa at a previously selected temperature. Such difference in test parameters (shear rate, shear stress, sample

motion, temperature scanning, and so forth) can lead to differences in the measured apparent viscosity among these methods with some test oils,

particularly when other rheological factors associated with gelation are present. In addition, the three methods differ considerably in cooling rates.

5.3 Gelation Index and Gelation Index Temperature—This test method has been further developed to yield parameters called

the Gelation Index and Gelation Index Temperature. The first parameter is a measure of the maximum rate of torque increase

caused by the rheological response of the oil as the oil is cooled slowly. The second parameter is the temperature at which the

Gelation Index occurs.

6. Apparatus

6.1 Test Cell—Shown in Fig. 1, consisting of a matched rotor and a stator of the following critical dimensions:

6.1.1 Rotor Dimensions—Critical length is 65.565.5 mm 6 0.1 mm 0.1 mm and critical diameter is 18.4018.40 mm 6 0.02

mm.0.02 mm.

6.1.2 Stator Dimensions—Critical diameter is 22.05 mm (60.02 mm) 22.05 mm (60.02 mm) at whatever length will satisfy the

immersion depth when the upper oil level is a minimum of 15 mm 15 mm below the cooling liquid level over the entire temperature

range.

Shaub, H., “A History of ASTM Accomplishments in Low Temperature Engine Oil Rheology,” Symposium on Low Temperature Lubricant Rheology Measurement and

Relevance to Engine Operation, ASTM STP 1143, Rhodes, R. B., ed., ASTM, 1992, pp. 1-19.

D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.