ASTM F2977-13

(Test Method)Standard Test Method for Small Punch Testing of Polymeric Biomaterials Used in Surgical Implants

Standard Test Method for Small Punch Testing of Polymeric Biomaterials Used in Surgical Implants

SIGNIFICANCE AND USE

4.1 Miniature specimen testing techniques are used to characterize the mechanical behavior of polymer stock materials and surgical implants after manufacture, sterilization, shelf aging, radiation crosslinking, thermal treatment, filler incorporation, and implantation (1-3). Furthermore, experimental materials can be evaluated after accelerated aging, fatigue testing, and hip, knee, or spine wear simulation. Consequently, the small punch test makes it possible to examine relationships between wear performance and mechanical behavior. This test method can also be used to rank the mechanical behavior relative to a reference control material.

4.2 Small punch testing results may vary with specimen preparation and with the speed and environment of testing. Consequently, where precise comparative results are desired, these factors must be carefully controlled.

SCOPE

1.1 This test method covers the determination of mechanical behavior of polymeric biomaterials by small punch testing of miniature disk specimens (0.5 mm in thickness and 6.4 mm in diameter). The test method has been established for characterizing surgical materials after ram extrusion or compression molding (1-3)2; for evaluating as-manufactured implants and sterilization method effects (4, 5); as well as for testing of implants that have been retrieved (explanted) from the human body (6, 7).

1.2 The results of the small punch test, namely the peak load, ultimate displacement, ultimate load, and work to failure, provide metrics of the yielding, ultimate strength, ductility, and toughness under multiaxial loading conditions. Because the mechanical behavior can be different when loaded under uniaxial and multiaxial loading conditions (8), the small punch test provides a complementary mechanical testing technique to the uniaxial tensile test. However, it should be noted that the small punch test results may not correlate with uniaxial tensile test results.

1.3 In addition to its use as a research tool in implant retrieval analysis, the small punch test can be used as a laboratory screening test to evaluate new materials with minimal material waste (1).

1.4 The small punch test has been applied to other polymers, including polymethyl methacrylate (PMMA) bone cement, polyacetal, and high density polyethylene (HDPE), ultra high molecular weight polyethylene (UHMWPE), and polyetheretherketone (PEEK) (2, 3, 5, 10, 11). This standard outlines general guidelines for the small punch testing of implantable polymers.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2977 − 13

Standard Test Method for

Small Punch Testing of Polymeric Biomaterials Used in

1

Surgical Implants

This standard is issued under the fixed designation F2977; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 Thistestmethodcoversthedeterminationofmechanical

behavior of polymeric biomaterials by small punch testing of

2. Referenced Documents

miniature disk specimens (0.5 mm in thickness and 6.4 mm in

3

2.1 ASTM Standards:

diameter). The test method has been established for character-

D695 Test Method for Compressive Properties of Rigid

izing surgical materials after ram extrusion or compression

2

Plastics

molding (1-3) ; for evaluating as-manufactured implants and

D883 Terminology Relating to Plastics

sterilization method effects (4, 5); as well as for testing of

E4 Practices for Force Verification of Testing Machines

implants that have been retrieved (explanted) from the human

E83 Practice for Verification and Classification of Exten-

body (6, 7).

someter Systems

1.2 The results of the small punch test, namely the peak

F1714 Guide for GravimetricWearAssessment of Prosthetic

load, ultimate displacement, ultimate load, and work to failure,

Hip Designs in Simulator Devices

providemetricsoftheyielding,ultimatestrength,ductility,and

F1715 Guide for Wear Assessment of Prosthetic Knee De-

toughness under multiaxial loading conditions. Because the 4

signs in Simulator Devices (Withdrawn 2006)

mechanical behavior can be different when loaded under

F2003 Practice for Accelerated Aging of Ultra-High Mo-

uniaxial and multiaxial loading conditions (8), the small punch

lecular Weight Polyethylene after Gamma Irradiation in

test provides a complementary mechanical testing technique to

Air

the uniaxial tensile test. However, it should be noted that the

F2102 Guide for Evaluating the Extent of Oxidation in

small punch test results may not correlate with uniaxial tensile

Polyethylene Fabricated Forms Intended for Surgical

test results.

Implants

1.3 In addition to its use as a research tool in implant

3. Terminology

retrieval analysis, the small punch test can be used as a

laboratory screening test to evaluate new materials with

3.1 Definitions:

minimal material waste (1).

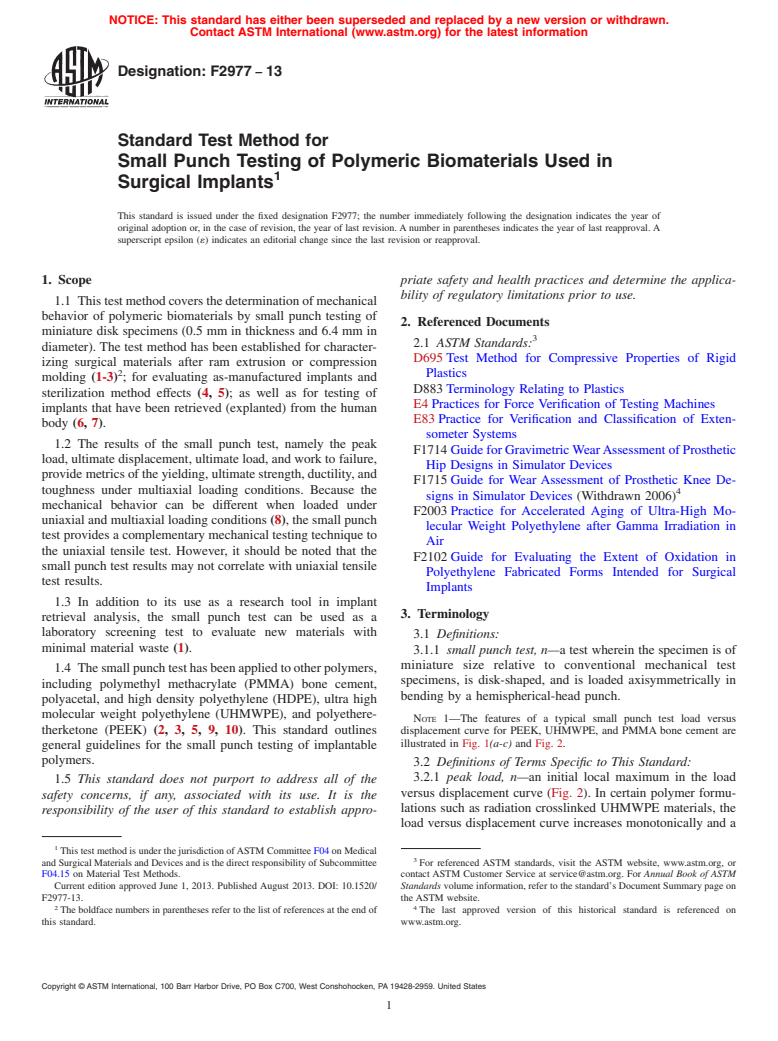

3.1.1 small punch test, n—a test wherein the specimen is of

miniature size relative to conventional mechanical test

1.4 Thesmallpunchtesthasbeenappliedtootherpolymers,

specimens, is disk-shaped, and is loaded axisymmetrically in

including polymethyl methacrylate (PMMA) bone cement,

bending by a hemispherical-head punch.

polyacetal, and high density polyethylene (HDPE), ultra high

molecular weight polyethylene (UHMWPE), and polyethere-

NOTE 1—The features of a typical small punch test load versus

therketone (PEEK) (2, 3, 5, 9, 10). This standard outlines

displacement curve for PEEK, UHMWPE, and PMMA bone cement are

illustrated in Fig. 1(a-c) and Fig. 2.

general guidelines for the small punch testing of implantable

polymers.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 peak load, n—an initial local maximum in the load

1.5 This standard does not purport to address all of the

versus displacement curve (Fig. 2). In certain polymer formu-

safety concerns, if any, associated with its use. It is the

lations such as radiation crosslinked UHMWPE materials, the

responsibility of the user of this standard to establish appro-

load versus displacement curve increases monotonically and a

1

This test method is under the jurisdiction ofASTM Committee F04 on Medical

3

and Surgical Materials and Devices and is the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

F04.15 on Material Test Methods. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved June 1, 2013. Published August 2013. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F2977-13. the ASTM website.

2 4

The boldface numbers in parentheses refer to the list of references at the end of The last approved version of this historical standard is referenced on

this standard. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2977 − 13

FIG. 1 Representative load versus displacement curves for (a) PEEK, (b) UHMWPE, and (c) PMMA bone cement. Note that the vertical

axis is different fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.