ASTM B655/B655M-10

(Specification)Standard Specification for Niobium-Hafnium Alloy Bar and Wire

Standard Specification for Niobium-Hafnium Alloy Bar and Wire

ABSTRACT

This specification covers hafnium alloyed niobium bar, rod, and wire. The material covered by this specification is R04295, a niobium-base alloy containing hafnium and titanium. The alloy shall conform to the required chemical composition for carbon, oxygen, nitrogen, hydrogen, hafnium, titanium, zirconium, tungsten, tantalum, and niobium. Materials in the annealed condition supplied under this specification shall conform to the required mechanical properties such as tensile strength, yield strength, and elongation. The alloy shall undergo the following test methods: room temperature tension test; elevated temperature tension test; and chemical test.

SIGNIFICANCE AND USE

The following applies to all specified limits in this standard for purposes of determining conformance with this specification. The observed value or a calculated value shall be rounded off to the nearest unit in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E29.

SCOPE

1.1 This specification covers hafnium alloyed niobium bar and wire.

1.2 The material covered by this specification is R04295, niobium-base alloy containing approximately 10 % hafnium and 1 % titanium.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 14, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B655/B655M −10

Standard Specification for

1

Niobium-Hafnium Alloy Bar and Wire

This standard is issued under the fixed designation B655/B655M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 lot, n—a lot is defined as that material produced from

one ingot and heat treated at the same conditions. Unless

1.1 This specification covers hafnium alloyed niobium bar

otherwise agreed between manufacturer and purchaser, a lot

and wire.

shall be limited to the product of an 8 h period for final

1.2 The material covered by this specification is R04295,

continuous anneal or to a single furnace load for a final batch

niobium-base alloy containing approximately 10 % hafnium

anneal.

and 1 % titanium.

3.1.2 bar, n—a hot rolled, forged, or cold worked semifin-

1.3 The values stated in either SI units or inch-pound units

ished solid section product whose cross sectional area is equal

are to be regarded separately as standard. The values stated in

to or less than 16 sq in. [10.323 sq mm]; rectangular bar must

each system may not be exact equivalents; therefore, each

be less than or equal to 10 in. [254 mm] in width and greater

system shall be used independently of the other. Combining

than 0.187 in. [4.8 mm] in thickness.

values from the two systems may result in non-conformance

3.1.3 wire, n—material 0.020 to 0.1875 in. [0.50 to 4.8 mm]

with the standard.

in diameter furnished in coils, spools, or on reels. Material less

1.4 The following safety hazards caveat pertains only to the

than 0.020 in. [0.50 mm] in diameter is not covered in this

test methods portion, Section 14, of this specification: This

specification.

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

4. Ordering Information

of this standard to establish appropriate safety and health

4.1 Orders for material under this specification should

practices and determine the applicability of regulatory limita-

include the following information as applicable:

tions prior to use.

4.1.1 General alloy description (see 1.2) and ASTM desig-

2. Referenced Documents

nation and year of issue,

2

4.1.2 Quantity in weight or pieces,

2.1 ASTM Standards:

4.1.3 Size, diameter, and length,

B652/B652M Specification for Niobium-Hafnium Alloy In-

4.1.4 Chemical Composition (Section 6),

gots

4.1.5 Temper (Section 7),

E8 Test Methods for Tension Testing of Metallic Materials

E21 TestMethodsforElevatedTemperatureTensionTestsof 4.1.6 Mechanical test temperature and limits (Sections 8

Metallic Materials and 14),

E29 Practice for Using Significant Digits in Test Data to

4.1.7 Permissible dimensional tolerances and weight or

Determine Conformance with Specifications quantity variations (see 9.2 and 9.4),

E2626 Guide for Spectrometric Analysis of Reactive and

4.1.8 Quality and finish (see 10.2),

Refractory Metals

4.1.9 Sampling (see 13.2),

4.1.10 Inspection witnessing (see 15.2),

3. Terminology

4.1.11 Certification requirements (Section 18), and

3.1 Definitions:

4.1.12 Packaging (Section 20),

1

This specification is under the jurisdiction of ASTM Committee B10 on

5. Materials and Manufacture

Reactive and Refractory Metals and Alloysand is the direct responsibility of

Subcommittee B10.03 on Niobium and Tantalum.

5.1 Materials covered by this specification shall be made

Current edition approved May 1, 2010. Published June 2010. Originally

from ingots in accordance with Specification B652/B652M.

approved in 1979. Last previous edition approved in 2004 as B655/B655M – 04.

DOI: 10.1520/B0655_B0655M-10.

5.2 The various niobium-hafnium alloy products covered by

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

this specification are formed with the conventional extrusion,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

forging, swaging, rolling, and drawing equipment normally

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. available in metal working plants.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B655/B655M−10

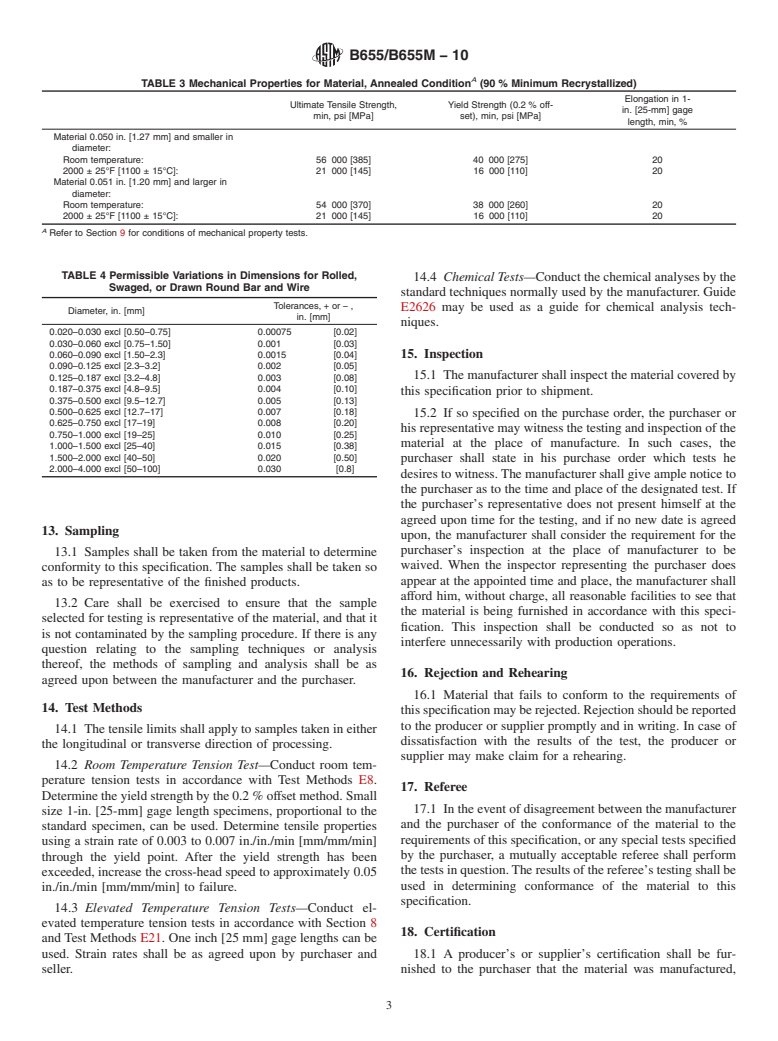

TABLE 2 Additional Chemical Requirements for Finished

6. Chemical Composition

Product (When Specified by Purchaser)

6.1 The chemical composition of niobium-hafnium alloy

Niobium-Hafnium Alloy Grade R04295

ingots and billets for conversion to finished products covered

Content, Maximum

Element

by this specification shall conform to the requirements pre-

Weight %

scribed in

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B655/B655M–04 Designation: B655/B655M – 10

Standard Specification for

Niobium-Hafnium Alloy Bar, Rod, and WireNiobium-Hafnium

1

Alloy Bar and Wire

This standard is issued under the fixed designation B655/B655M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers hafnium alloyed niobium bar, rod,bar and wire.

1.2 The material covered by this specification is R04295, niobium-base alloy containing approximately 10 % hafnium and 1 %

titanium.

1.3 The values stated in either inch-poundSI units or SIinch-pound units are to be regarded separately as standard. Within the

text, the SI units are shown in brackets. The values stated in each system aremay not be exact equivalents; therefore, each system

shall be used independently of the other. Combining values from the two systems may result in non-conformance with the

specification. standard.

1.4 Thefollowingsafetyhazardscaveatpertainsonlytothetestmethodsportion,Section14,ofthisspecification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B652/B652M Specification for Niobium-Hafnium Alloy Ingots

E8 Test Methods for Tension Testing of Metallic Materials

E21 Test Methods for Elevated Temperature Tension Tests of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications Practice for Using

Significant Digits in Test Data to Determine Conformance with Specifications

E2626 Guide for Spectrometric Analysis of Reactive and Refractory Metals

3. Terminology

3.1 Definitions:

3.1.1 barlot, n—material less than 6 in. [150 mm] in width and 0.187 in. [4.8 mm] or greater in thickness, with a rectangular

or square cross section, supplied in straight lengths. —a lot is defined as that material produced from one ingot and heat treated

at the same conditions. Unless otherwise agreed between manufacturer and purchaser, a lot shall be limited to the product of an

8 h period for final continuous anneal or to a single furnace load for a final batch anneal.

3.1.2 lotbar, n—a lot is defined as that material produced from one ingot and heat treated at the same conditions. —a hot rolled,

forged, or cold worked semifinished solid section product whose cross sectional area is equal to or less than 16 sq in. [10.323 sq

mm]; rectangular bar must be less than or equal to 10 in. [254 mm] in width and greater than 0.187 in. [4.8 mm] in thickness.

1

3.1.3 rod, n—material 0.125 to 2 ⁄2 in. [3.2 to 64 mm] in diameter in round, hexagonal, or octagonal cross section supplied in

straight lengths.

3.1.4wire, n—material 0.020 to 0.1240.1875 in. [0.50 to 3.24.8 mm] in diameter furnished in coils, spools, or on reels. Material

less than 0.020 in. [0.50 mm] in diameter is not covered in this specification.

4. Ordering Information

4.1 Orders for material under this specification should include the following information as applicable:

4.1.1 General alloy description (see 1.2) and ASTM designation and year of issue,

1

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.03 on Niobium and Tantalum.

Current edition approved May 1, 2004.2010. Published May 2004.June 2010. Originally approved in 1979. Last previous edition approved in 19962004 as

B655/B655M–96(1999).B655/B655M – 04. DOI: 10.1520/B0655_B0655M-104.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

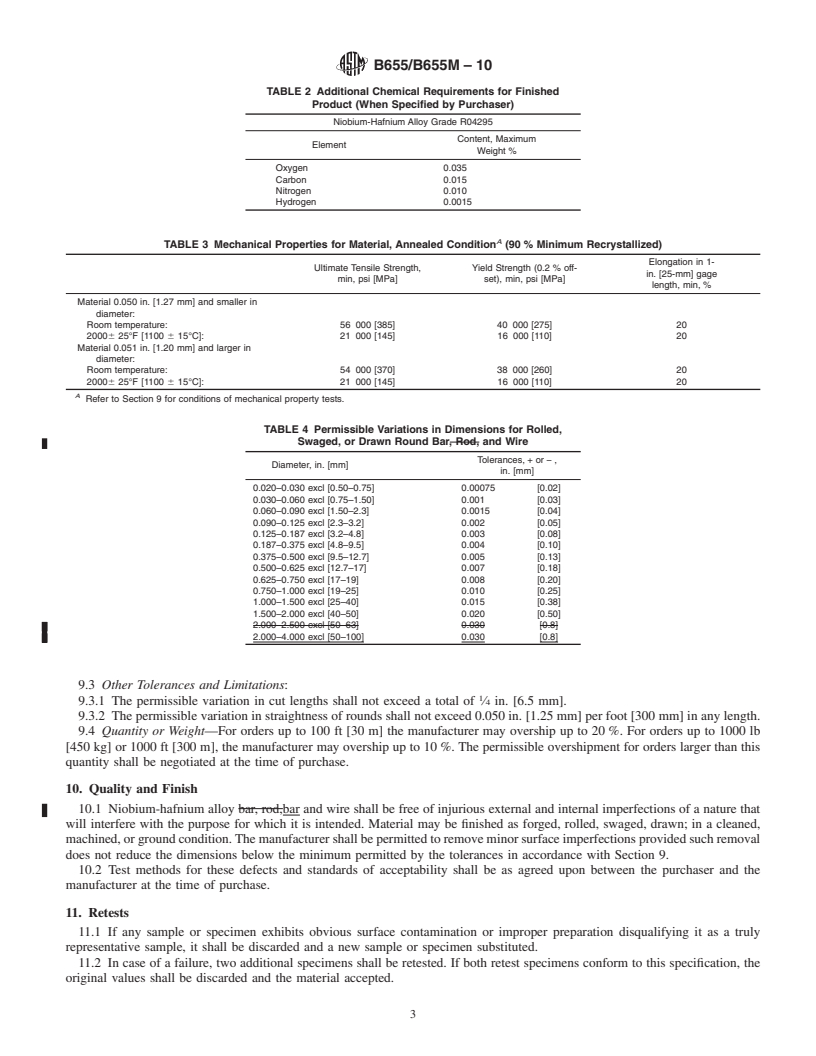

B655/B655M – 10

4.1.2 Quantity in weight or pieces,

4.1.3 Size, diameter, and length,

4.1.4 Chemical Composition (Section 6),

4.1.5 Temper (Section 7),

4.1.6 Mechanical test temperature and limits (Sections 8 and 14),

4.1.7 Permissible dimensi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.