ASTM D4510-05(2009)

(Test Method)Standard Test Method for Counting Partial Cleavages in Wool and Other Animal Fibers (Withdrawn 2018)

Standard Test Method for Counting Partial Cleavages in Wool and Other Animal Fibers (Withdrawn 2018)

SIGNIFICANCE AND USE

Test Method D4510 for the counting of partial cleavages, may be used for the acceptance testing of commercial shipments of wool and other animal fibers, but caution is advised, since information on between-laboratory precision is limited. Comparative tests as directed in 5.1.1 may be advisable.

In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type in question. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using Students t-test for unpaired data and an acceptable probability level chosen by the two parties before the testing is begun. If a bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results in the light of the known bias.

Chemically damaged or tendered fibers are recognizable microscopically by qualified operators and should not be counted as partial cleavages. Such fibers exhibit total loss of cuticle, severe surface erosion, tenderizing cracks, longitudinal fibrillation, or a combination of these features (see Figs. 1 and 2). In a study of deliberately over-carbonized wool at one laboratory, it was found that when more than 24 tendered fibers were seen in 1 m, partial cleavage counts were significantly higher than on similar fibers that were not overcarbonized.

FIG. 1 (A) Partial Cleavage—But do not count if it is at the end of a fiber. The split may have been caused by other means

FIG. 1(B–D) Split ...

SCOPE

1.1 This test method covers a procedure, using the microprojector, for the counting of partial cleavages in wool and other animal fibers.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers a procedure, using the microprojector, for the counting of partial cleavages in wool and other animal fibers.

Formerly under the jurisdiction of Committee D13 on Textiles, this test method was withdrawn in January 2018 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4510 − 05 (Reapproved 2009)

Standard Test Method for

Counting Partial Cleavages in Wool and Other Animal

Fibers

This standard is issued under the fixed designation D4510; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers a procedure, using the

4.1 This test method describes a procedure:

microprojector, for the counting of partial cleavages in wool

4.1.1 The segmenting of various test specimens in prepara-

and other animal fibers.

tion for testing,

1.2 The values stated in SI units are to be regarded as 4.1.2 The projection on a screen of magnified images of the

standard. No other units of measurement are included in this

randomly sampled short segments of fiber from the small test

standard. specimens, and

4.1.3 The measurement of the number of partially cleaved

1.3 This standard does not purport to address all of the

fibers.

safety problems, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5.1 Test Method D4510 for the counting of partial

cleavages, may be used for the acceptance testing of commer-

2. Referenced Documents

cial shipments of wool and other animal fibers, but caution is

2.1 ASTM Standards:

advised, since information on between-laboratory precision is

D123Terminology Relating to Textiles

limited. Comparative tests as directed in 5.1.1 may be advis-

D2258Practice for Sampling Yarn for Testing

able.

D2525Practice for Sampling Wool for Moisture

5.1.1 In case of a dispute arising from differences in

D4845Terminology Relating to Wool

reportedtestresultswhenusingthistestmethodforacceptance

2.2 Other Document: testing of commercial shipments, the purchaser and the sup-

Wool Products Labeling Act of 1983 plier should conduct comparative tests to determine if there is

a statistical bias between their laboratories. Competent statis-

3. Terminology

tical assistance is recommended for the investigation of bias.

As a minimum, the two parties should take a group of test

3.1 For all terminology relating to D13.13, Wool and Wool

specimens that are as homogeneous as possible and that are

Felt, refer to Terminology D4845.

from a lot of material of the type in question. The test

3.1.1 The following terms are relevant to this standard:

specimensshouldthenberandomlyassignedinequalnumbers

cashmere, coarse hair, cashmere coarse hair content, cashmere

toeachlaboratoryfortesting.Theaverageresultsfromthetwo

down, cashmere hair.

laboratories should be compared using Students t-test for

3.2 For all other terminology related to textiles, see Termi-

unpaireddataandanacceptableprobabilitylevelchosenbythe

nology D123.

twopartiesbeforethetestingisbegun.Ifabiasisfound,either

its cause must be found and corrected or the purchaser and the

suppliermustagreetointerpretfuturetestresultsinthelightof

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextiles

the known bias.

and is the direct responsibility of Subcommittee D13.13 on Wool and Felt.

Current edition approved July 1, 2009. Published January 2010. Originally

5.2 Chemicallydamagedortenderedfibersarerecognizable

approved in 1991. Last previous edition approved in 2005 as D4510–05. DOI:

microscopically by qualified operators and should not be

10.1520/D4510-05R09.

counted as partial cleavages. Such fibers exhibit total loss of

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

cuticle,severesurfaceerosion,tenderizingcracks,longitudinal

Standards volume information, refer to the standard’s Document Summary page on

fibrillation, or a combination of these features (see Figs. 1 and

the ASTM website.

2). In a study of deliberately over-carbonized wool at one

Act of Congress, “Wool Products LabelingAct of 1939,” 76th Congress,Third

Session, approved October 14, 1939. laboratory,itwasfoundthatwhenmorethan24tenderedfibers

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4510 − 05 (2009)

FIG. 1 (A) Partial Cleavage—But do not count if it is at the end

of a fiber. The split may have been caused by other means

were seen in 1 m, partial cleavage counts were significantly

higher than on similar fibers that were not overcarbonized.

6. Apparatus and Material

6.1 Microprojector —The microscope shall be equipped

with a fixed body tube, a focusable stage responsive to coarse

and fine adjustments, a focusable substage with condenser and

iris diaphragm, and a vertically installed adequate light source

to give a precise magnification of 500×, that is, a 12.5×eye-

piece and a 21×0.50 numerical aperture objective.

FIG. 1 (B–D) Split Fiber (continued)

6.2 Stage Micrometer —calibrated in intervals of 0.01 mm

for accurate setting and control of the magnification.

6.3 Fiber-Sectioning Apparatus:

6,7

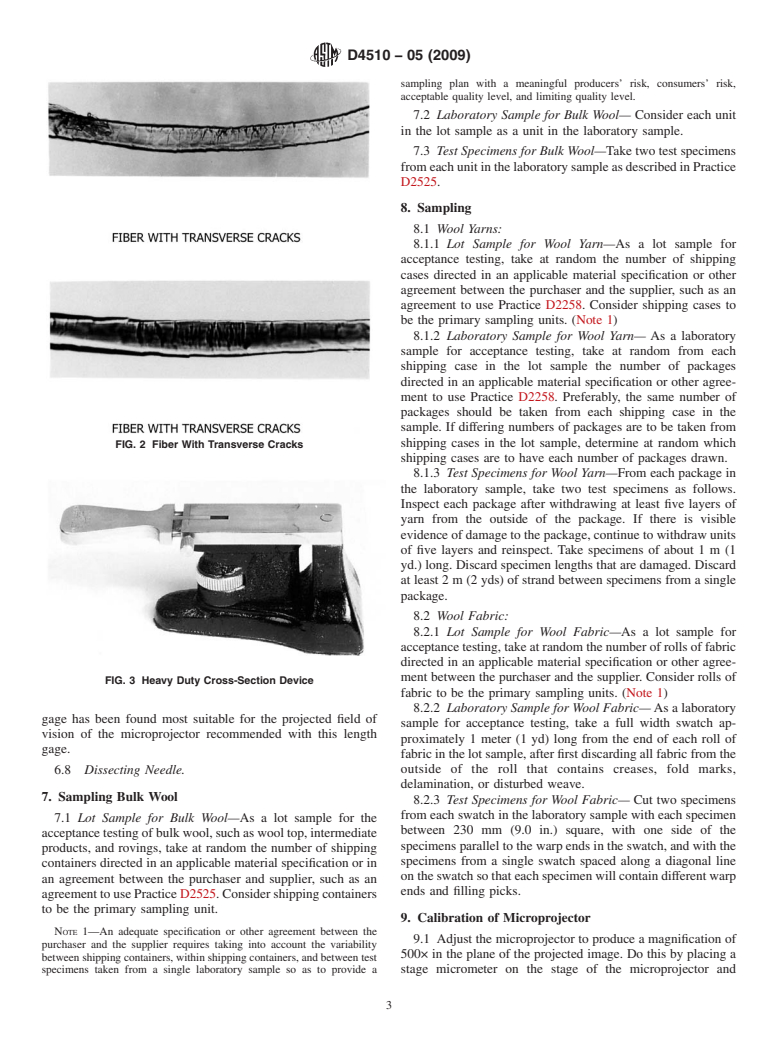

6.3.1 Heavy-Duty Sectioning Device — An instrument applying pressure vertically downward, cuts fibers approxi-

comprisedofametalplatewithaslotandcompressingkeyand mately 250 µm in length (Fig. 3).

equipped with a propulsion mechanism by which the fiber

6.4 Microscope Slides, 25 by 75 mm (1 by 3 in.).

bundle may be extruded for sectioning. The instrument is

6.5 Cover Glasses, No. 1 thickness, 22 by 50 mm ( ⁄8 by 2

designed to hold a sliver of top or equivalent bulk of fibers, or

in.).

yarn. (Fig. 3)

6.3.2 Safety Razor Blades—Single-edge or double-edge

6.6 Mounting Medium —Colorless immersion oil with a

blades (if used with blade holder). refractive index of 1.480 6 0.005 at 20°C (68°F), and a

6.3.3 FRL Fiber Cutter —Adevice comprised of two razor

viscosity of 78.81 SUS at 37.8°C (100°F).

blades, a threaded pin and an assemblage that will hold the

6.7 Length Gage, made of stiff, white paper 155 mm long,

blades rigidly in position. The device, which is operated by

and having thin transverse lines inscribed on it 10 mm from

each end, so that the distance between the lines shall be 135.0

6 2.5 mm. The length gage shall be of convenient width (for

Available from R&B Instruments, Leeds Wortly Low Mills, 318 Whitehall

example, 30 mm). A satisfactory length gage may also be

Road, Leeds L512 4RJ England.

constructed of cardboard by inscribing thereon concentric

Available from most scientific laboratory instrument supply companies.

Available from Joe Opherkens, 426 Adams, Ogden, UT 84403.

circles having diameters of 135 mm and 155 mm. This length

Shirley Fibre Microtome available from Crosroe, Inc., P.O. Box 6408, Tower

Drive, Greenville, SC 29606.

Available from Albany International Research Co., 777 West St., P.O. Box

9114, Mansfield, MA 02048-9114. Available from Yocom-McColl Testing Laboratories, Inc.

D4510 − 05 (2009)

sampling plan with a meaningful producers’ risk, consumers’ risk,

acceptable quality level, and limiting quality level.

7.2 Laboratory Sample for Bulk Wool— Consider each unit

in the lot sample as a unit in the laboratory sample.

7.3 Test Specimens for Bulk Wool—Take two test specimens

fromeachunitinthelaboratorysampleasdescribedinPractice

D2525.

8. Sampling

8.1 Wool Yarns:

8.1.1 Lot Sample for Wool Yarn—As a lot sample for

acceptance testing, take at random the number of shipping

cases directed in an applicable material specification or other

agreement between the purchaser and the supplier, such as an

agreement to use Practice D2258. Consider shipping cases to

be the primary sampling units. (Note 1)

8.1.2 Laboratory Sample for Wool Yarn— As a laboratory

sample for acceptance testing, take at random from each

shipping case in the lot sample the number of packages

directed in an applicable material specification or other agree-

ment to use Practice D2258. Preferably, the same number of

packages should be taken from each shipping case in the

sample. If differing numbers of packages are to be taken from

shipping cases in the lot sample, determine at random which

FIG. 2 Fiber With Transverse Cracks

shipping cases are to have each number of packages drawn.

8.1.3 Test Specimens for Wool Yarn—From each package in

the laboratory sample, take two test specimens as follows.

Inspect each package after withdrawing at least five layers of

yarn from the outside of the package. If there is visible

evidenceofdamagetothepackage,continuetowithdrawunits

of five layers and reinspect. Take specimens of about 1 m (1

yd.) long. Discard specimen lengths that are damaged. Discard

at least 2 m (2 yds) of strand between specimens from a single

package.

8.2 Wool Fabric:

8.2.1 Lot Sample for Wool Fabric—As a lot sample for

acceptancetesting,takeatrandomthenumberofrollsoffabric

directed in an applicable material specification or other agree-

ment between the purchaser and the supplier. Consider rolls of

FIG. 3 Heavy Duty Cross-Section Device

fabric to be the primary sampling units. (Note 1)

8.2.2 Laboratory Sample for Wool Fabric—As a laboratory

gage has been found most suitable for the projected field of

sample for acceptance testing, take a full width swatch ap-

vision of the microprojector recommended with this length

proximately 1 meter (1 yd) long from the end of each roll of

gage.

fabricinthelotsample,afterfirstdiscardingallfabricfromthe

outside of the roll that contains creases, fold marks,

6.8 Dissecting Needle.

delamination, or disturbed weave.

7. Sampling Bulk Wool

8.2.3 Test Specimens for Wool Fabric— Cut two specimens

from each swatch in the laboratory sample with each specimen

7.1 Lot Sample for Bulk Wool—As a lot sample for the

between 230 mm (9.0 in.) square, with one side of the

acceptancetestingofbulkwool,suchaswooltop,intermediate

specimensparalleltothewarpendsintheswatch,andwiththe

products, and rovings, take at random the number of shipping

specimens from a single swatch spaced along a diagonal line

containers directed in an applicable material specification or in

ontheswatchsothateachspecimenwillcontaindifferentwarp

an agreement between the purchaser and supplier, such as an

ends and filling picks.

agreementtousePracticeD2525.Considershippingcontainers

to be the primary sampling unit.

9. Calibration of Microprojector

NOTE 1—An adeq

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.