ASTM E1256-95(2007)

(Test Method)Standard Test Methods for Radiation Thermometers (Single Waveband Type)

Standard Test Methods for Radiation Thermometers (Single Waveband Type)

SCOPE

1.1 The test methods described in these test methods can be utilized to evaluate the following six basic operational parameters of a radiation thermometer (single waveband type):Calibration AccuracyRepeatabilityTarget SizeResponse TimeWarm-Up TimeLong-Term Drift

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1256–95 (Reapproved 2007)

Standard Test Methods for

Radiation Thermometers (Single Waveband Type)

This standard is issued under the fixed designation E1256; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Definitions of Terms Specific to This Standard:

2.2.1 reference temperature source, n—a source of thermal

1.1 The test methods described in these test methods can be

radiant power of known temperature or emissivity, or both,

utilized to evaluate the following six basic operational param-

used in the testing of radiation thermometers.

eters of a radiation thermometer (single waveband type):

2.2.2 target size, n—the diameter of a circle in the target

Section

plane of a radiation thermometer that is centered on its line of

Calibration Accuracy 7

Repeatability 8

sight and contains 99 % of the input radiant power received by

Target Size 9

that instrument.

Response Time 10

2.2.3 temperature resolution, n—the minimum simulated or

Warm-Up Time 11

Long-Term Drift 12

actual change in target temperature that gives a usable change

in output or indication, or both.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Significance and Use

responsibility of the user of this standard to establish appro-

3.1 The purpose of these test methods is to establish

priate safety and health practices and determine the applica-

consensus test methods by which both manufacturers and end

bility of regulatory limitations prior to use.

users may make tests to establish the validity of the readings of

2. Terminology

their radiation thermometers. The test results can also serve as

standard performance criteria for instrument evaluation or

2.1 Definitions:

selection, or both.

2.1.1 blackbody, n—the perfect or ideal source of thermal

3.2 The goal is to provide test methods that are reliable and

radiant power having a spectral distribution described by the

can be performed by a sufficiently skilled end user or manu-

Planck equation.

facturer in the hope that it will result in a better understanding

2.1.1.1 Discussion—The term blackbody is often used to

of the operation of radiation thermometers and also promote

describe a furnace or other source of radiant power which

improved communication between the manufacturers and the

approximates the ideal.

end users. A user without sufficient knowledge and experience

2.1.2 center wavelength, n—a wavelength, usually near the

should seek assistance from the equipment makers or other

middle of the band of radiant power over which a radiation

expert sources, such as those found at the National Institute of

thermometer responds, that is used to characterize its perfor-

Standards and Technology in Gaithersburg, Maryland.

mance.

3.3 Use these test methods with the awareness that there are

2.1.2.1 Discussion—The value of the center wavelength is

other parameters, particularly spectral response limits and

usually specified by the manufacturer of the instrument.

temperature resolution, which impact the use and characteriza-

2.1.3 radiation thermometer, n—a radiometer calibrated to

tion of radiation thermometers for which test methods have not

indicate the temperature of a blackbody.

yet been developed.

2.1.4 radiometer, n—a device for measuring radiant power

3.3.1 Temperature resolution is the minimum simulated or

that has an output proportional to the intensity of the input

actual change in target temperature that results in a usable

power.

change in output or indication, or both. It is usually expressed

2.1.5 target plane, n—the plane, perpendicular to the line of

as a temperature differential or a percent of full-scale value, or

sight of a radiation thermometer, that is in focus for that

both, and usually applies to value measured. The magnitude of

instrument.

the temperature resolution depends upon a combination of four

factors: detector noise equivalent power (NEP) or noise

These test methods are under the jurisdiction of ASTM Committee E20 on

equivalent temperature, electronic signal processing, signal-to-

TemperatureMeasurementandarethedirectresponsibilityofSubcommitteeE20.02

noise characteristics (including amplification noise), and

on Radiation Thermometry.

analog-to-digital conversion “granularity.”

Current edition approved Nov. 1, 2007. Published December 2007. Originally

approved in 1988. Last previous edition approved in 2001 as E1256 – 95 (2001).

DOI: 10.1520/E1256-95R07.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1256–95 (2007)

4.1.5 Aperture Set—If an iris diaphragm is not available, an

aperture disc set of appropriate diameters can be used. Each

aperture should be blackened and also mounted and protected

from extraneous sources of radiation as discussed in 4.1.4.1.

4.1.6 Data Acquisition Systems—Of appropriate speed and

storage capacity to measure and record the output signal of the

radiation thermometer in the Response Time Test Method,

Section 9.

4.1.7 Power Supply—Capable of supplying the proper volt-

age and frequency, if necessary, to the radiation thermometer.

5. Calibration Accuracy Test Method

5.1 Summary—This test method outlines the procedure to

be used to evaluate the maximum deviation between the

temperature indicated by the radiation thermometer and the

FIG. 1 Spectral Response Limits

known temperature of a reference temperature source, includ-

ing the uncertainty of the reference temperature source relative

to the current International Temperature Scale.

3.3.2 Spectral response limits are the upper and lower limits

5.2 Test Conditions:

to the wavelength band of radiant energy to which the

5.2.1 Rated supply voltage and frequency.

instrument responds. These limits are generally expressed in

micrometers (µm) and include the effects of all elements in the 5.2.2 Prescribed warm-up period.

measuring optical path. At the spectral response limits, the

5.2.3 After execution of internal standardization check (if

transmission of the measuring optics is 5 % of peak transmis-

available).

sion (see Fig. 1).

5.2.4 Emissivity compensation set to one (1).

5.2.5 Minimumopeningofthereferencetemperaturesource

4. Apparatus

shallnotobstructthefieldofviewoftheradiationthermometer

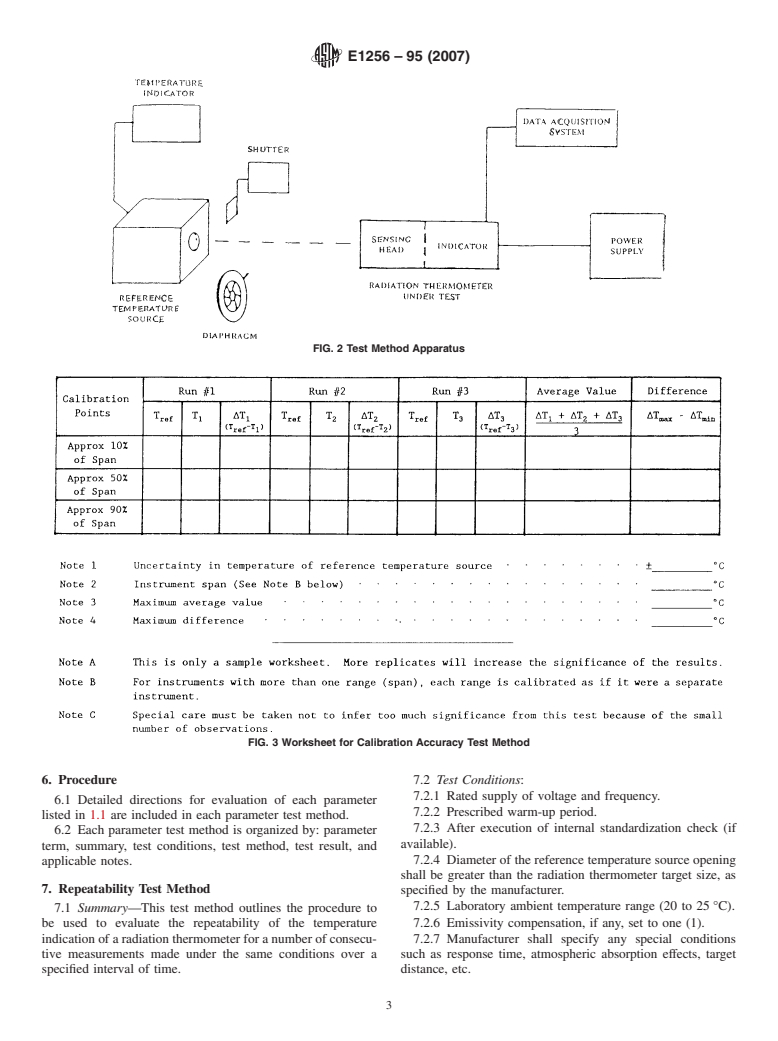

4.1 The following apparatus, set up as illustrated in Fig. 2,

with the test aperture as specified by the manufacturer.

can be used to perform the standard tests for all six parameters.

5.2.6 Laboratory ambient temperature range (20 to 25 °C).

4.1.1 Reference Temperature Source—A blackbody (or

5.2.7 Manufacturer shall specify any special conditions

other stable isothermal radiant source of high and known

such as atmospheric absorption effects, target distance, etc.

emissivity) with an opening diameter at least as large as that

5.2.8 Manufacturer shall specify the output for determining

specified in these test methods.

the indicated temperature.

NOTE 1—Typical examples include nearly isothermal furnaces with

5.3 Test Method:

internal geometries, such as a sphere with an opening small relative to its

5.3.1 The radiation thermometer is sighted at the reference

radius, or a right circular cylinder with one end closed having a radius

temperature source whose temperature is sequentially stabi-

small relative to its length. Consult footnote for greater detail.

lized at three calibration points distributed uniformly over the

4.1.2 Temperature Indicator—Either contact or radiometric,

measurement range of the instrument.

which accurately displays the temperature of the reference

5.3.2 The temperature of the reference temperature source

temperature source.

and the temperature indicated by the radiation thermometer are

4.1.3 Shutter Mechanism—Of sufficient size so as to com-

recorded, then the difference between the two values is

pletely block the opening of the reference temperature source

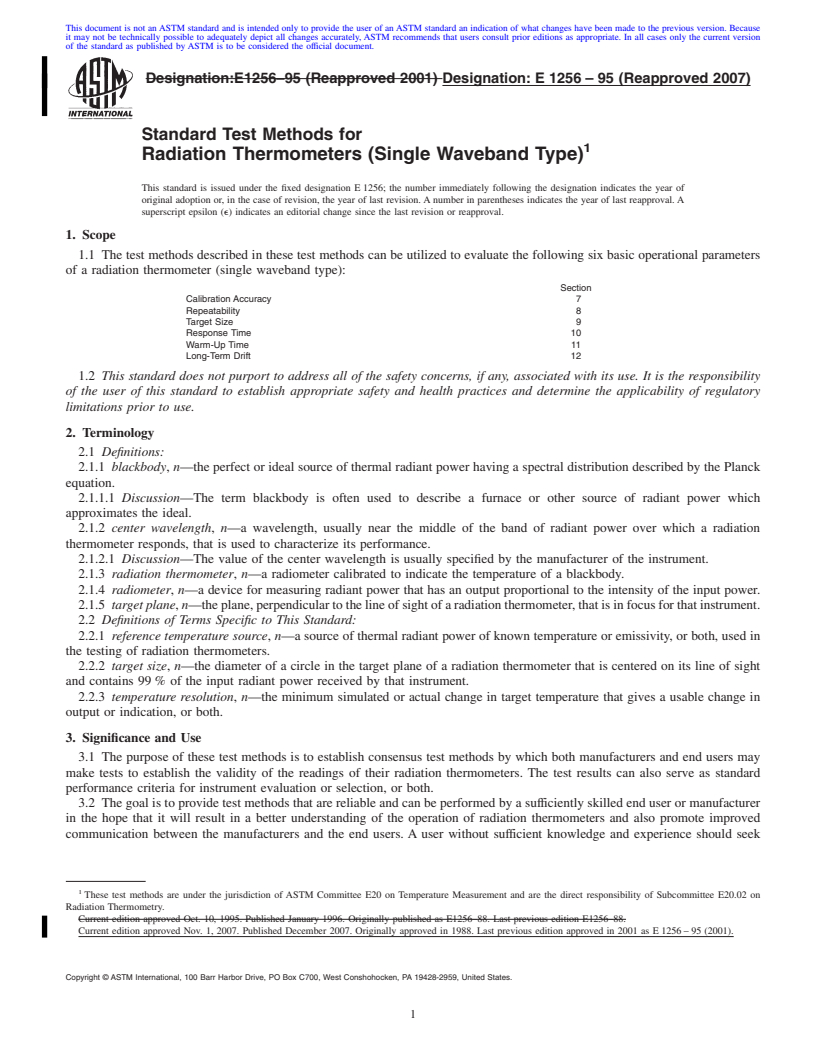

calculated and recorded (see Fig. 3).

from the field of view of the test instrument. The shutter

5.3.3 The test sequence is repeated twice for the same three

mechanism shall activate in a time interval that is short when

calibration points, and an average temperature difference is

compared with the response time of the test instrument.

calculated and recorded for each calibration point.

4.1.4 Iris Diaphragm—Of sufficient size so that when fully

5.4 Test Result—The value for the calibration accuracy of

open the iris diameter is greater than the opening of the

the temperature indication of the radiation thermometer is

reference temperature source. It shall be located with its

taken to be the largest of the three average temperature

opening concentric with and perpendicular to the line of sight

differencesdeterminedin5.3.2plusorminustheuncertaintyof

of the radiation thermometer.

the temperature of the reference temperature source relative to

4.1.4.1 The side of the diaphragm facing the radiation

the current International Temperature Scale.

thermometer should be blackened (nearly nonreflective) so as

to minimize the effect of radiation reflected from the surround-

NOTE 2—The calibration accuracy is generally expressed as a tempera-

ture difference or a percent of full-scale value, or both.

ing environment. In addition the iris should be shaded from

sources of intense extraneous radiation. (See Note 9). NOTE 3—The value applies across the entire measurement range.

NOTE 4—If the reference temperature source is measured with other

than a calibrated reference or secondary standard radiation thermometer,

then the emissivity of the source enters into the calibration of the test

DeWitt, D. P., and Nutter, G. D., eds., “Theory and Practice of Radiation

Thermometry,” John Wiley and Sons, New York, NY. radiation thermometer.

E1256–95 (2007)

FIG. 2 Test Method Apparatus

FIG. 3 Worksheet for Calibration Accuracy Test Method

6. Procedure 7.2 Test Conditions:

7.2.1 Rated supply of voltage and frequency.

6.1 Detailed directions for evaluation of each parameter

7.2.2 Prescribed warm-up period.

listed in 1.1 are included in each parameter test method.

7.2.3 After execution of internal standardization check (if

6.2 Each parameter test method is organized by: parameter

available).

term, summary, test conditions, test method, test result, and

7.2.4 Diameter of the reference temperature source opening

applicable notes.

shall be greater than the radiation thermometer target size, as

7. Repeatability Test Method

specified by the manufacturer.

7.2.5 Laboratory ambient temperature range (20 to 25 °C).

7.1 Summary—This test method outlines the procedure to

7.2.6 Emissivity compensation, if any, set to one (1).

be used to evaluate the repeatability of the temperature

indication of a radiation thermometer for a number of consecu- 7.2.7 Manufacturer shall specify any special conditions

tive measurements made under the same conditions over a such as response time, atmospheric absorption effects, target

specified interval of time. distance, etc.

E1256–95 (2007)

FIG. 4 Target Diameter versus Target Distance from Instrument

7.3 Test Method: 8.2.5 Minimumopeningofthereferencetemperaturesource

7.3.1 Once a day for twelve consecutive working days, the shall be large enough so as to not obstruct the optical path of

radiation thermometer is sighted at the reference temperature the radiation thermometer, as specified by the manufacturer,

source whose temperature is stabilized at the approximate whenitissightedthroughanaperturethatistwicethediameter

midpoint of the radiation thermometer calibration range. of the instrument’s target size at the plane of the aperture.

NOTE 5—The selected reference temperature source temperature shall

NOTE 8—Some radiation thermometers have a target size so large that

be reproduced for each of the twelve consecutive tests.

a commercially available reference temperature source cannot be used; a

separate test method is under preparation for use in such cases.

7.3.2 The temperature of the reference temperature source

and the temperature(s) indicated by the radiation thermometer

8.2.6 Manufacturer shall specify any special conditions

during each day’s test are recorded.

such as atmospheric absorption effects, distance, how and

7.3.3 The radiation thermometer shall be switched off after

when to clean the radiation thermometer lens, etc.

each series of measurements.

8.3 Test Method:

7.4 Test Result—The value for the repeatability of the

8.3.1 Thetemperatureofthereferencetemperaturesourceis

readings of the radiation thermometer is taken to be the

stabilized at a value near the top of the calibration range of the

standard deviation of the twelve recorded readings.

radiation thermometer.

N

8.3.2 The iris is positioned in the front of and concentric

X !

~

N N ( i

i 5 1 with the opening of the reference temperature source (as

2 2

¯

~X 2 X! X 2

( (

i i

N

i 5 1 i 5 1 illustrated in Fig. 2). The iris is then adjusted to a diameter

Œ

S.D. 5 5!

N 2 1 N 2 1

slightly smaller (typically 10 %) than the expected target

diameter.

where:

S.D. = standard deviation,

NOTE 9—The iris should be kept cool enough so that its thermal

N = number of measurements,

emissiondoesnotcontributesignificantlytotheoutputsignal.Uncovering

X = value of the ith measurement, and the iris quickly can minimize heating, but this requires care. Evaluation of

i

N

¯

X = the error from this source requires computational procedures beyond the

X

( i scope of this test method; a discussion of such procedures can be found in

i 5 1

footnote 2. In most cases, however, the error is insignificant if the iris is

average of the twelve measurements = .

N

maintained near room temperature (20 °C) and the reference temperature

NOTE 6—The repeatability of the temperature indication is generally

source temperature is at or above 200 °C.

expressed as a temperature difference or a percent of full-scale value, or

8.3.3 The position of the radiation thermometer is then

both.

NOTE 7—Thevaluefortherepeatabilitycanbeappliedacrosstheentire adjusted vertically and horizontally and focused to produce

measurement range, or, the same test can be performed at other selected

maximum output while also maintaining the line of sight

temperatures across the measurement range in order to assess the

perpendicular to the iris.

repeatability of the radiation thermometer at those temperatures.

8.3.4 The iris is then opened to the point where the

temperature indicated by the radiation thermometer stops

8. Target Size

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E1256–95 (Reapproved 2001) Designation:E1256–95 (Reapproved 2007)

Standard Test Methods for

Radiation Thermometers (Single Waveband Type)

This standard is issued under the fixed designation E 1256; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 The test methods described in these test methods can be utilized to evaluate the following six basic operational parameters

of a radiation thermometer (single waveband type):

Section

Calibration Accuracy 7

Repeatability 8

Target Size 9

Response Time 10

Warm-Up Time 11

Long-Term Drift 12

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Terminology

2.1 Definitions:

2.1.1 blackbody, n—the perfect or ideal source of thermal radiant power having a spectral distribution described by the Planck

equation.

2.1.1.1 Discussion—The term blackbody is often used to describe a furnace or other source of radiant power which

approximates the ideal.

2.1.2 center wavelength, n—a wavelength, usually near the middle of the band of radiant power over which a radiation

thermometer responds, that is used to characterize its performance.

2.1.2.1 Discussion—The value of the center wavelength is usually specified by the manufacturer of the instrument.

2.1.3 radiation thermometer, n—a radiometer calibrated to indicate the temperature of a blackbody.

2.1.4 radiometer, n—a device for measuring radiant power that has an output proportional to the intensity of the input power.

2.1.5 target plane, n—theplane,perpendiculartothelineofsightofaradiationthermometer,thatisinfocusforthatinstrument.

2.2 Definitions of Terms Specific to This Standard:

2.2.1 reference temperature source, n—a source of thermal radiant power of known temperature or emissivity, or both, used in

the testing of radiation thermometers.

2.2.2 target size, n—the diameter of a circle in the target plane of a radiation thermometer that is centered on its line of sight

and contains 99 % of the input radiant power received by that instrument.

2.2.3 temperature resolution, n—the minimum simulated or actual change in target temperature that gives a usable change in

output or indication, or both.

3. Significance and Use

3.1 The purpose of these test methods is to establish consensus test methods by which both manufacturers and end users may

make tests to establish the validity of the readings of their radiation thermometers. The test results can also serve as standard

performance criteria for instrument evaluation or selection, or both.

3.2 The goal is to provide test methods that are reliable and can be performed by a sufficiently skilled end user or manufacturer

in the hope that it will result in a better understanding of the operation of radiation thermometers and also promote improved

communication between the manufacturers and the end users. A user without sufficient knowledge and experience should seek

These test methods are under the jurisdiction of ASTM Committee E20 on Temperature Measurement and are the direct responsibility of Subcommittee E20.02 on

Radiation Thermometry.

Current edition approved Oct. 10, 1995. Published January 1996. Originally published as E1256–88. Last previous edition E1256–88.

Current edition approved Nov. 1, 2007. Published December 2007. Originally approved in 1988. Last previous edition approved in 2001 as E 1256 – 95 (2001).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1256–95 (2007)

assistance from the equipment makers or other expert sources, such as those found at the National Institute of Standards and

Technology in Gaithersburg, Maryland.

3.3 Use these test methods with the awareness that there are other parameters, particularly spectral response limits and

temperature resolution, which impact the use and characterization of radiation thermometers for which test methods have not yet

been developed.

3.3.1 Temperature resolution is the minimum simulated or actual change in target temperature that results in a usable change

in output or indication, or both. It is usually expressed as a temperature differential or a percent of full-scale value, or both, and

usually applies to value measured. The magnitude of the temperature resolution depends upon a combination of four factors:

detectornoiseequivalentpower(NEP)ornoiseequivalenttemperature,electronicsignalprocessing,signal-to-noisecharacteristics

(including amplification noise), and analog-to-digital conversion “granularity.”

3.3.2 Spectral response limits are the upper and lower limits to the wavelength band of radiant energy to which the instrument

responds.These limits are generally expressed in micrometers (µm) and include the effects of all elements in the measuring optical

path. At the spectral response limits, the transmission of the measuring optics is 5 % of peak transmission (see Fig. 1).

4. Apparatus

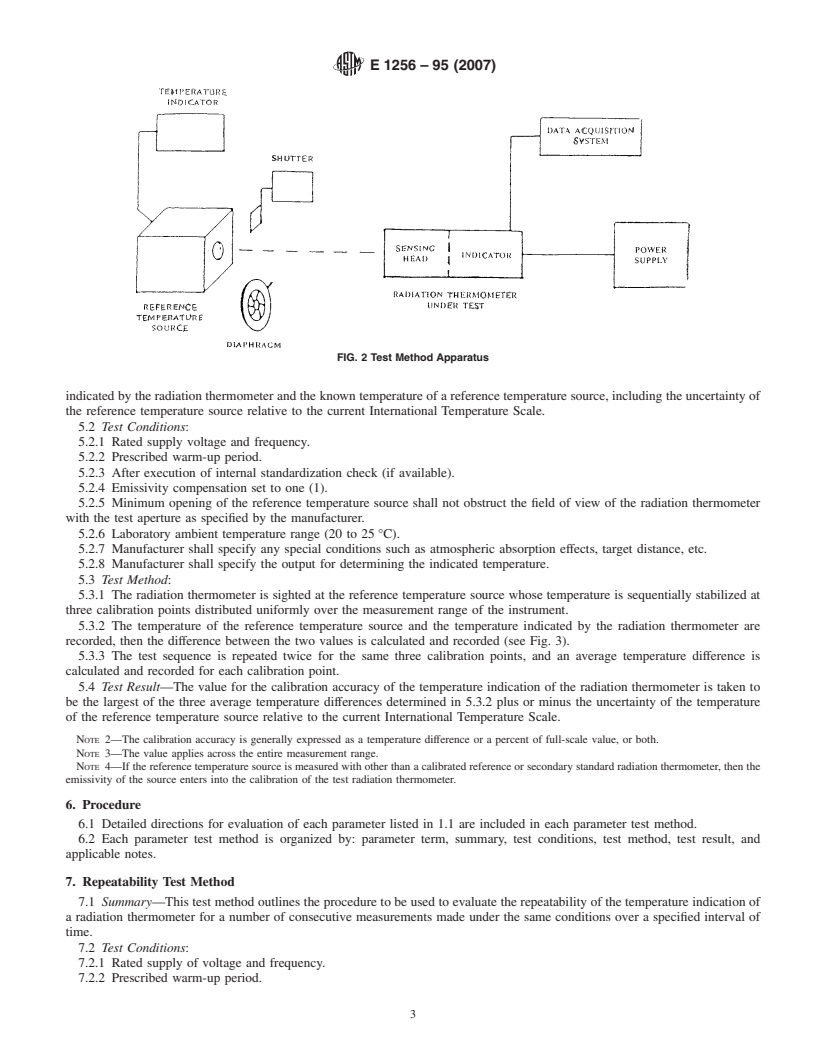

4.1 The following apparatus, set up as illustrated in Fig. 2, can be used to perform the standard tests for all six parameters.

4.1.1 Reference Temperature Source—A blackbody (or other stable isothermal radiant source of high and known emissivity)

with an opening diameter at least as large as that specified in these test methods.

NOTE 1—Typical examples include nearly isothermal furnaces with internal geometries, such as a sphere with an opening small relative to its radius,

or a right circular cylinder with one end closed having a radius small relative to its length. Consult footnote for greater detail.

4.1.2 Temperature Indicator—Either contact or radiometric, which accurately displays the temperature of the reference

temperature source.

4.1.3 Shutter Mechanism—Of sufficient size so as to completely block the opening of the reference temperature source from

the field of view of the test instrument. The shutter mechanism shall activate in a time interval that is short when compared with

the response time of the test instrument.

4.1.4 Iris Diaphragm—Of sufficient size so that when fully open the iris diameter is greater than the opening of the reference

temperature source. It shall be located with its opening concentric with and perpendicular to the line of sight of the radiation

thermometer.

4.1.4.1 Thesideofthediaphragmfacingtheradiationthermometershouldbeblackened(nearlynonreflective)soastominimize

the effect of radiation reflected from the surrounding environment. In addition the iris should be shaded from sources of intense

extraneous radiation. (See Note 9).

4.1.5 Aperture Set—If an iris diaphragm is not available, an aperture disc set of appropriate diameters can be used. Each

aperture should be blackened and also mounted and protected from extraneous sources of radiation as discussed in 4.1.4.1.

4.1.6 Data Acquisition Systems—Of appropriate speed and storage capacity to measure and record the output signal of the

radiation thermometer in the Response Time Test Method, Section 9.

4.1.7 Power Supply—Capable of supplying the proper voltage and frequency, if necessary, to the radiation thermometer.

5. Calibration Accuracy Test Method

5.1 Summary—This test method outlines the procedure to be used to evaluate the maximum deviation between the temperature

DeWitt, D. P., and Nutter, G. D., eds., “Theory and Practice of Radiation Thermometry,” John Wiley and Sons, New York, NY.

FIG. 1 Spectral Response Limits

E1256–95 (2007)

FIG. 2 Test Method Apparatus

indicated by the radiation thermometer and the known temperature of a reference temperature source, including the uncertainty of

the reference temperature source relative to the current International Temperature Scale.

5.2 Test Conditions:

5.2.1 Rated supply voltage and frequency.

5.2.2 Prescribed warm-up period.

5.2.3 After execution of internal standardization check (if available).

5.2.4 Emissivity compensation set to one (1).

5.2.5 Minimum opening of the reference temperature source shall not obstruct the field of view of the radiation thermometer

with the test aperture as specified by the manufacturer.

5.2.6 Laboratory ambient temperature range (20 to 25 °C).

5.2.7 Manufacturer shall specify any special conditions such as atmospheric absorption effects, target distance, etc.

5.2.8 Manufacturer shall specify the output for determining the indicated temperature.

5.3 Test Method:

5.3.1 The radiation thermometer is sighted at the reference temperature source whose temperature is sequentially stabilized at

three calibration points distributed uniformly over the measurement range of the instrument.

5.3.2 The temperature of the reference temperature source and the temperature indicated by the radiation thermometer are

recorded, then the difference between the two values is calculated and recorded (see Fig. 3).

5.3.3 The test sequence is repeated twice for the same three calibration points, and an average temperature difference is

calculated and recorded for each calibration point.

5.4 Test Result—The value for the calibration accuracy of the temperature indication of the radiation thermometer is taken to

be the largest of the three average temperature differences determined in 5.3.2 plus or minus the uncertainty of the temperature

of the reference temperature source relative to the current International Temperature Scale.

NOTE 2—The calibration accuracy is generally expressed as a temperature difference or a percent of full-scale value, or both.

NOTE 3—The value applies across the entire measurement range.

NOTE 4—If the reference temperature source is measured with other than a calibrated reference or secondary standard radiation thermometer, then the

emissivity of the source enters into the calibration of the test radiation thermometer.

6. Procedure

6.1 Detailed directions for evaluation of each parameter listed in 1.1 are included in each parameter test method.

6.2 Each parameter test method is organized by: parameter term, summary, test conditions, test method, test result, and

applicable notes.

7. Repeatability Test Method

7.1 Summary—This test method outlines the procedure to be used to evaluate the repeatability of the temperature indication of

a radiation thermometer for a number of consecutive measurements made under the same conditions over a specified interval of

time.

7.2 Test Conditions:

7.2.1 Rated supply of voltage and frequency.

7.2.2 Prescribed warm-up period.

E1256–95 (2007)

FIG. 3 Worksheet for Calibration Accuracy Test Method

7.2.3 After execution of internal standardization check (if available).

7.2.4 Diameter of the reference temperature source opening shall be greater than the radiation thermometer target size, as

specified by the manufacturer.

7.2.5 Laboratory ambient temperature range (20 to 25 °C).

7.2.6 Emissivity compensation, if any, set to one (1).

7.2.7 Manufacturer shall specify any special conditions such as response time, atmospheric absorption effects, target distance,

etc.

7.3 Test Method:

7.3.1 Once a day for twelve consecutive working days, the radiation thermometer is sighted at the reference temperature source

whose temperature is stabilized at the approximate midpoint of the radiation thermometer calibration range.

NOTE 5—The selected reference temperature source temperature shall be reproduced for each of the twelve consecutive tests.

7.3.2 The temperature of the reference temperature source and the temperature(s) indicated by the radiation thermometer during

each day’s test are recorded.

7.3.3 The radiation thermometer shall be switched off after each series of measurements.

7.4 Test Result—Thevaluefortherepeatabilityofthereadingsoftheradiationthermometeristakentobethestandarddeviation

of the twelve recorded readings.

N

~ X !

N N (

i

i 5 1

2 2

¯

~X 2X! X 2

( (

i i

N

i 5 1 i 5 1

Œ

S.D. 5 5!

N 2 1 N 2 1

N

~ X !

(

N N i

i 5 1

2 2

~X 2¯X! X 2

( i ( i

N

i 5 1 i 5 1

Œ

!

S.D. 5 5

N 2 1 N 2 1

where:

S.D. = standard deviation,

N = number of measurements,

X = value of the ith measurement, and

i

E1256–95 (2007)

N

¯

X =

X

(

i

i 5 1

average of the twelve measurements = .

N

NOTE 6—The repeatability of the temperature indication is generally expressed as a temperature difference or a percent of full-scale value, or both.

NOTE 7—The value for the repeatability can be applied across the entire measurement range, or, the same test can be performed at other selected

temperatures across the measurement range in order to assess the repeatability of the radiation thermometer at those temperatures.

8. Target Size Test Method

8.1 Summary—This test method outlines the procedure to be used to evaluate the diameter of the circle located in the target

plane of the reference temperature source, at a known distance along and perpendicular to a radiation thermometer’s line of sight,

and from which 99 % of the radiant power received by the radiation thermometer is collected (see Figs. 3 and 4).

8.2 Test Conditions:

8.2.1 Rated supply voltage and frequency.

8.2.2 Prescribed warm-up period.

8.2.3 After execution of internal standardization check (if applicable).

8.2.4 Laboratory ambient temperature range (20 to 25 °C).

8.2.5 Minimum opening of the reference temperature source shall be large enough so as to not obstruct the optical path of the

radiation thermometer, as specified by the manufacturer, when it is sighted through an aperture that is twice the diameter of the

instrument’s target size at the plane of the aperture.

NOTE 8—Someradiationthermometershaveatargetsizesolargethatacommerciallyavailablereferencetemperaturesourcecannotbeused;aseparate

test method is under preparation for use in such cases.

8.2.6 Manufacturer shall specify any special conditions such as atmospheric absorption effects, distance, how and when to clean

the radiation thermometer lens, etc.

8.3 Test Method:

8.3.1 The temperature of the reference temperature source is stabilized at a value near the top of the calibration range of the

radiation thermometer.

8.3.2 The iris is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.