ASTM D3013-99

(Specification)Standard Specification for Epoxy Molding Compounds

Standard Specification for Epoxy Molding Compounds

SCOPE

1.1 This specification covers requirements for epoxy thermosetting molding compounds. It provides for their identification, quality control, and purchase in such a manner that the purchaser and the seller can agree on the substantial similarity of different commercial lots or shipments.

1.2 The compounds covered under this specification consist of mixtures or blends of epoxy resins and curing agents intimately combined, in an unreacted or partially reacted condition, with fillers, reinforcements, colorants, and other chemical agents.

Note 1-The properties included in this specification are those required to identify the kinds of molding compounds covered. There may be other requirements necessary to define particular characteristics. These will be added to the specification as their inclusion becomes generally desirable and the necessary test data and methods become available. Note 2-There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3013 – 99

Standard Specification for

Epoxy Molding Compounds

This standard is issued under the fixed designation D 3013; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* Insulating Materials for Testing

D 638 Test Method for Tensile Properties of Plastics

1.1 This specification covers requirements for epoxy ther-

D 648 Test Method for Deflection Temperature of Plastics

mosetting molding compounds. It provides for their identifica-

Under Flexural Load

tion, quality control, and purchase in such a manner that the

D 790 TestMethodsforFlexuralPropertiesofUnreinforced

purchaser and the seller can agree on the substantial similarity

and Reinforced Plastics and Electrical Insulating Materials

of different commercial lots or shipments.

D 883 Terminology Relating to Plastics

1.2 The compounds covered under this specification consist

D 1896 Practice for Transfer Molding Specimens of Ther-

of mixtures or blends of epoxy resins and curing agents

mosetting Compounds

intimately combined, in an unreacted or partially reacted

D 2863 Test Method for Measuring the Minimum Oxygen

condition, with fillers, reinforcements, colorants, and other

Concentration to Support Candle-Like Combustion of

chemical agents.

Plastics (Oxygen Index)

1.3 The values stated in SI units are to be regarded as the

D 3892 Practice for Packaging/Packing of Plastics

standard.

2.2 Military Standard:

NOTE 1—The properties included in this specification are those re-

MIL-STD-105 Sampling Procedures and Tables for Inspec-

quired to identify the kinds of molding compounds covered.There may be

tion by Attributes

other requirements necessary to define particular characteristics. These

will be added to the specification as their inclusion becomes generally

3. Terminology

desirable and the necessary test data and methods become available.

3.1 Definitions—Definitions of terms used in this specifica-

NOTE 2—There is no similar or equivalent ISO standard.

tion are in accordance with Terminology D 883.

2. Referenced Documents

2 4. Classification

2.1 ASTM Standards:

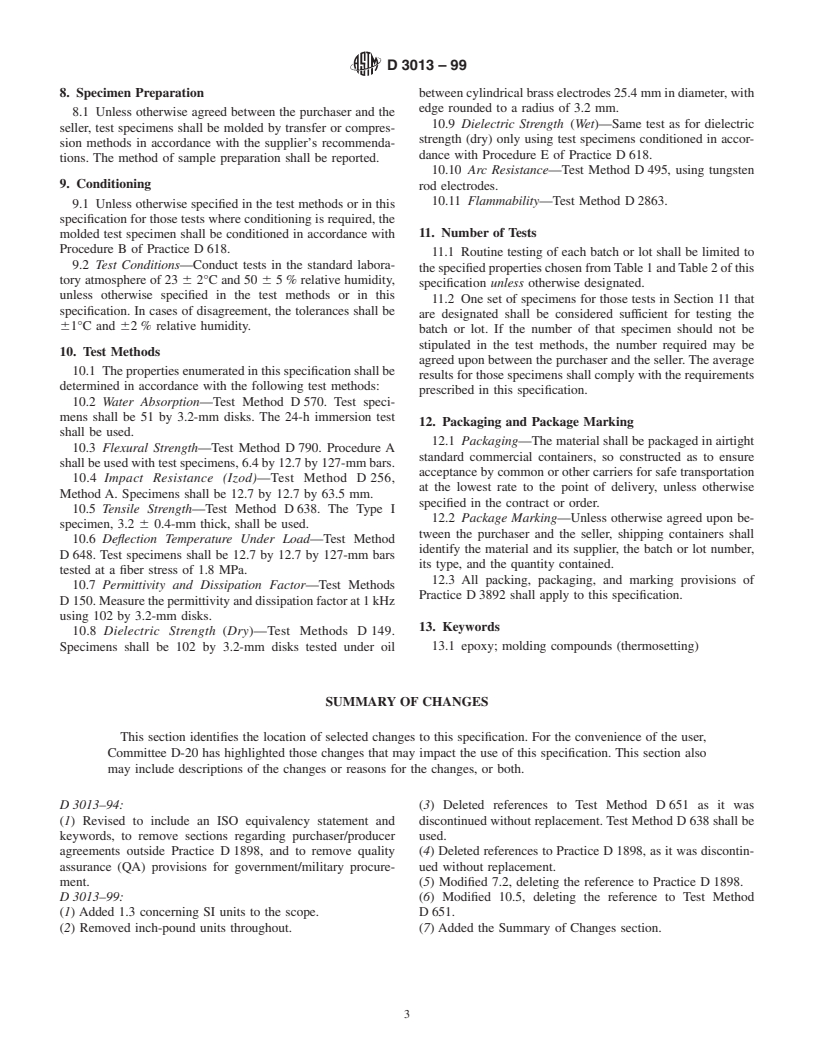

4.1 Grades—This specification is subdivided into various

D 149 Test Method for Dielectric Breakdown Voltage and

Dielectric Strength of Solid Electrical Insulating Materials grades of epoxy molding compounds based on physical prop-

erties. This specification provides for a system of characteriza-

at Commercial Power Frequencies

D 150 Test Methods for A-C Loss Characteristics and tion and identification which enables coverage for all commer-

ciallyavailablegradeshavingpropertieswithintherangeofthe

Permittivity (Dielectric Constant) of Solid Electrical Insu-

lating Materials possible combinations as may be selected from Table 1. A

gradeisdesignatedbythecellnumbersforeachpropertyinthe

D 256 Test Method for Determining the Pendulum Impact

Resistance of Notched Specimens of Plastics orderinwhichtheyarelistedinTable1.Whenapropertyisnot

specified, a “0” is entered as the cell number.

D 495 Test Method for High-Voltage, Low-Current, Dry

Arc Resistance of Solid Electrical Insulation 4.2 Classes—Each of the grades of epoxy molding com-

pound may be further subdivided into classes according to

D 570 Test Method for Water Absorption of Plastics

D 618 Practice for Conditioning Plastics and Electrical special requirements. A class is designated by a capital letter

followedbycelldesignationcorrespondingtotherequirements

detailed in Table 2. Where no special requirements, in addition

to grade properties, are needed, no class designation is shown.

This specification is under the jurisdiction of ASTM Committee D-20 on

Plastics and is the direct responsibility of Subcommittee D20.16 on Thermosetting

NOTE 3—An example of this classification system would be grade

Materials.

12324-D-00200-F-3 an epoxy molding compound having the following

Current edition approved Nov. 10, 1999. Published February 2000. Originally

requirements (see Table 1 and Table 2):

published as D 3013 – 72. Last previous edition D 3013 – 94.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3013–99

TABLE 1 Detail Grade Requirements for Epoxy Molding Compounds

Desig-

Grades (Cell Limits)

nation

Property and Unit

Order

01 2 3 4 5

No.

1 Water absorption, % in 24 h unspecified <0.16 0.16 to 0.30 0.31 to 1.0 1.1 to 3.0 >3.0

2 Flexural strength, MPa unspecified <42 42 to 69 70 to 103 104 to 207 >207

3 Impact resistance, unspecified

J/m of notch <22 22 to 53 54 to 267 268 to 534 >534

4 Tensile strength, unspecified

MPa <35 35 to 55 56 to 103 104 to 138 >138

5 Deflection temperature unspecified

under load,

°C 70 to 100 101 to 150 151 to 200 201 to 250 >250

TABLE 2 Detail Class Requirements for Epoxy Molding Compounds

Designa-

Classes (Cell Limits)

Class

Class tion Order Property and Unit

Designation

01 2 3 4 5

No.

Dielectric D 1 permittivity unspecified <3.81 3.81 to 4.50 4.51 to 5.00 5.01 to 6.00 >6.00

2 dissipation factor unspecified <0.016 0.016 to 0.03 0.04 to 0.10 0.11 to 0.20 >0.20

dielectric strength, V/mil

(short-time):

3 dry unspecified <301 301 to 325 326 to 350 351 to 400 >400

4 wet unspecified min 80 % of dry value using same test

5 arc resistance, s unspecified <61 61 to 110 111 to 140 141 to 180 >180

Flame-retardant F 1 flammability unspecified <25 25 to 40 >40 . .

5. General Requirements

5.1 The molding compounds shall be of uniform composi-

tionandsoformulatedastoconformtotherequirementsofthis

specification.

5.2 The apparent density, bulk factor, flow, particle size, and

color of the compounds shall be as agreed upon between the

purchaser and the seller in the order or contract. Properties

other than those specified in this specification may also be

agree

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.