ASTM C1303-00

(Test Method)Standard Test Method for Estimating the Long-Term Change in the Thermal Resistance of Unfaced Rigid Closed Cell Plastic Foams by Slicing and Scaling Under Controlled Laboratory Conditions

Standard Test Method for Estimating the Long-Term Change in the Thermal Resistance of Unfaced Rigid Closed Cell Plastic Foams by Slicing and Scaling Under Controlled Laboratory Conditions

SCOPE

1.1 This test method covers a procedure for estimating the long-term change in thermal resistance of unfaced rigid closed cell plastic foams by reducing the material thickness to accelerate aging under controlled laboratory conditions (1-3).

1.2 This test method is limited to unfaced, homogeneous materials (see 3.2.4). It may be applied to a wide range of rigid closed cell plastic foam types, including but not limited to, polystyrenes, polyurethanes, polyisocyanurates, and phenolics produced in board form, foamed-in-place, or spray-applied applications. No specific procedures are detailed in this test method to address the effects of permeable or impermeable facings or skins, manufactured thickness, orientation, manufacturing process, density, quality, the influence of structures or containments, or the end-use environmental conditions on internal cell gas composition. The user of this test method shall consider if these parameters limit the use of this test method for a specific application.

1.3 This test method utilizes standard test procedures for measuring the thermal resistance of insulation materials. Periodic measurements are performed on specimens to observe the effects of aging. Specimens of reduced thickness are used to shorten the time required for these observations. The results of these measurements are coupled with a scaling factor to estimate the thermal resistance of the material under evaluation for other thicknesses as a function of time.

1.4 This test method specifies methods of specimen preparation, procedures for determining the specimen effective diffusion thickness (see 3.2.3), and precautions for determining the thermal resistance of thin specimens.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This test method should be used to measure and describe the relative change in thermal resistance of rigid closed cell plastic foams under controlled laboratory conditions. It should not be used to describe or appraise the performance of these materials or products under actual use conditions. With continuing development, results from this test method may be used as an element in an assessment which takes into account all of the factors that are pertinent to an estimation of the thermal performance of these materials. Critical elements of this assessment are presently not available. See 1.2.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation:C1303–00

Standard Test Method for

Estimating the Long-Term Change in the Thermal

Resistance of Unfaced Rigid Closed-Cell Plastic Foams by

Slicing and Scaling Under Controlled Laboratory

,

1 2

Conditions

This standard is issued under the fixed designation C 1303; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

1.1 This test method covers a procedure for estimating the

only.

long-termchangeinthermalresistanceofunfacedrigidclosed-

1.6 Thistestmethodshouldbeusedtomeasureanddescribe

cell plastic foams by reducing the material thickness to

the relative change in thermal resistance of rigid closed-cell

accelerate aging under controlled laboratory conditions (1-3).

plastic foams under controlled laboratory conditions. It should

1.2 This test method is limited to unfaced, homogeneous

not be used to describe or appraise the performance of these

materials (see 3.2.4). It may be applied to a wide range of rigid

materials or products under actual use conditions. With con-

closed cell plastic foam types, including but not limited to,

tinuingdevelopment,resultsfromthistestmethodmaybeused

polystyrenes, polyurethanes, polyisocyanurates, and phenolics

as an element in an assessment which takes into account all of

produced in board form, foamed-in-place, or spray-applied

the factors that are pertinent to an estimation of the thermal

applications. No specific procedures are detailed in this test

performance of these materials. Critical elements of this

method to address the effects of permeable or impermeable

assessment are presently not available. See 1.2.

facings or skins, manufactured thickness, orientation, manu-

1.7 This standard does not purport to address all of the

facturingprocess,density,quality,theinfluenceofstructuresor

safety concerns, if any, associated with its use. It is the

containments, or the end-use environmental conditions on

responsibility of the user of this standard to establish appro-

internal cell gas composition.The user of this test method shall

priate safety and health practices and determine the applica-

consideriftheseparameterslimittheuseofthistestmethodfor

bility of regulatory limitations prior to use.

a specific application.

1.3 This test method utilizes standard test procedures for

2. Referenced Documents

measuring thermal resistance. Periodic measurements are per-

2.1 ASTM Standards:

formed on specimens to observe the effects of aging. Speci-

C 168 Terminology Relating to Thermal Insulating Materi-

mensofreducedthicknessareusedtoshortenthetimerequired

als

for these observations. The results of these measurements are

C 177 Test Method for Steady-State Heat Flux Measure-

coupled with a scaling factor to estimate the thermal resistance

ments and Thermal Transmission Properties by Means of

of the material under evaluation for other thicknesses as a

the Guarded-Hot-Plate Apparatus

function of time.

C 236 Test Method for Steady-State Thermal Performance

1.4 This test method specifies methods of specimen prepa-

of Building Assemblies by Means of a Guarded Hot Box

ration, procedures for determining the specimen effective

C 518 Test Method for Steady-State Heat Flux Measure-

diffusion thickness (see 3.2.3), and precautions for determining

ments and Thermal Transmission Properties by Means of

the thermal resistance of thin specimens.

the Heat Flow Meter Apparatus

C 578 SpecificationforRigid,CellularPolystyreneThermal

Insulation

This test method is under the jurisdiction of ASTM Committee C-16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.30 on C 591 Specification for Unfaced Preformed Rigid Cellular

Thermal Measurement.

Polyisocyanurate Thermal Insulation

Current edition approved March 10, 2000. Published May 2000.

C 976 Test Method for Thermal Performance of Building

Originally published as C 1303-95. Last previous edition C 1303-95.

Assemblies by Means of a Calibrated Hot Box

ISO/TC163/SC2/WG7 is also developing a standard to address the aging of

unfacedrigidclosed-cellplasticfoams.Thisdocumentisentitled,“Determinationof

C 1029 Specification for Spray-Applied Rigid Cellular

the Long-Term Thermal Resistance of Closed-Cell Cellular Plastic Thermal

Insulation.”

The boldface numbers in parentheses refer to the list of references at the end of

this standard. Annual Book of ASTM Standards, Vol 04.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

C1303–00

Polyurethane Thermal Insulation sample. See 7.1.1 and 7.1.2. As more data becomes available,

C 1045 Practice for Calculating Thermal Transmission this description will be refined.

Properties from Steady-State Heat Flux Measurements

3.2.5 normalized thermal resistance—thermal resistance di-

C 1114 TestMethodforSteady-StateThermalTransmission

vided by the intial thermal resistance.

Properties by Means of the Thin-Heater Apparatus

3.2.6 primary stage—that portion of the aging process

C 1126 Specification for Faced or Unfaced Rigid Cellular

where changes in thermophysical properties are primarily

Phenolic Thermal Insulation

influenced by the diffusion of air components into the rigid

C 1289 Specification for Faced Rigid Cellular Polyisocya-

closed-cell plastic foam.

nurate Thermal Insulation Board

3.2.7 scaled time—time divided by the square of the speci-

D 2856 Test Method for Open-Cell Content of Rigid Cel-

men thickness.

lular Plastics by the Air Pycnometer

3.2.8 scaling factor, n—the square of the material thickness

E 122 Practice for Choice of Sample Size to Estimate a

Measure of Quality for a Lot or Process dividedbythesquareofthetestspecimenthickness(see5.2.4).

This ratio represents the acceleration rate that is being applied

3. Terminology

to the aging process of a rigid closed-cell plastic foam because

ofthicknessdifferences.SeeRef(1)foradetailedderivationof

3.1 Definitions—For definitions of terms and symbols used

scaling factor.

in this test method, refer to Terminology C 168C 168.

3.2 Definitions of Terms Specific to This Standard: 3.2.9 secondary stage, n—that portion of the aging process

3.2.1 aging, v—the change in thermophysical properties of

where changes in thermophysical properties are primarily

rigid closed– cell plastic foam with time primarily due to

influenced by the diffusion of blowing agent(s) from the rigid

changes in the composition of the gas contained within the

closed–cell plastic foam.

closed cells.

3.2.10 service life, n—theanticipatedperiodoftimethatthe

3.2.2 effective diffusion coeffıcient, n—a material property

material is expected to maintain claimed thermophysical prop-

that relates the rate of gas transport to the gas partial pressure

erties. The service life may be dependent on the specific

gradients across the material of a given thickness at a given

end-use application.

temperature. The term “effective” is used to describe mass

3.2.11 thickness of damaged surface layer (TDSL), n—the

transport by several mechanisms.

average thickness of surface cells, on one surface, that are

3.2.3 effective diffusion thickness, n—the geometric thick-

either destroyed (ruptured or opened) during the preparation of

ness minus two times the thickness of damaged surface layer

test specimens or were originally open due to the manufactur-

(TDSL). See thickness of damaged surface layer (TDSL).

ing process.

3.2.4 homogeneous material, n—a material with a variation

3.2.12 time-averaged thermal resistance, n—the thermal

of less than 10 % in the slope of the primary stage thermal

*

resistance of a material of given thickness averaged over a

resistivity versus t results, for specimens within a specific

specified time period.

3.2.13 transition point , n—the estimated age of a rigid

closed-cell plastic foam when the aging process switches from

Annual Book of ASTM Standards, Vol 08.02.

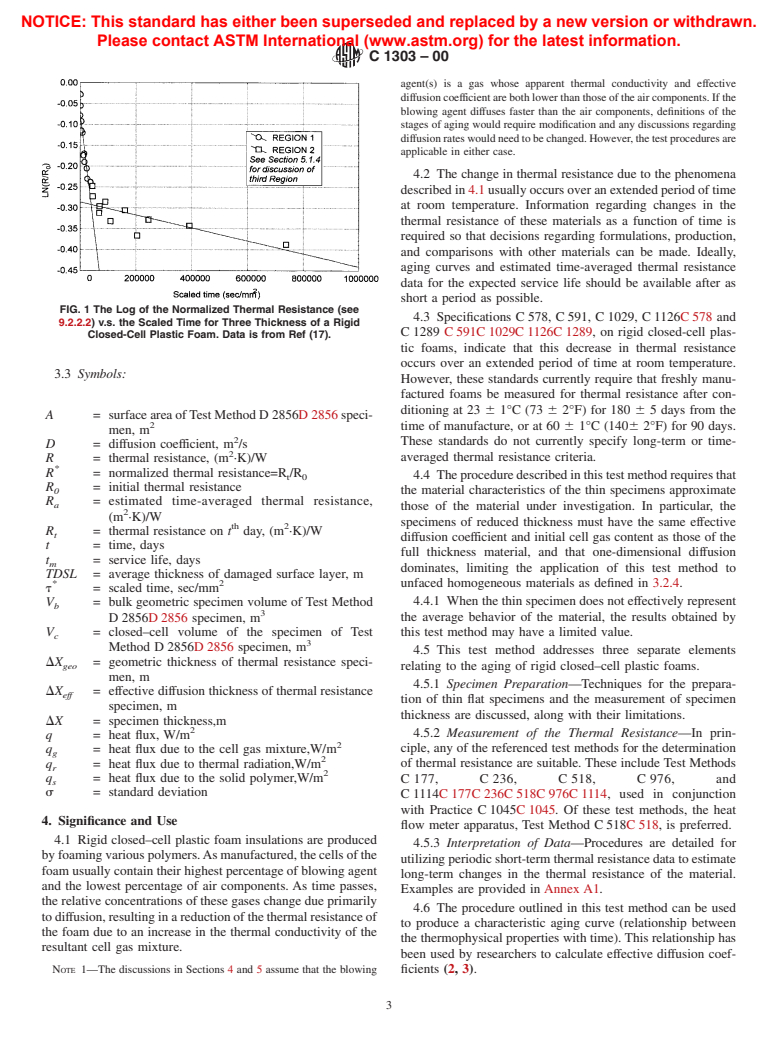

Annual Book of ASTM Standards, Vol 14.02. the primary to secondary stage (see Fig. 1).

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

C1303–00

agent(s) is a gas whose apparent thermal conductivity and effective

diffusioncoefficientarebothlowerthanthoseoftheaircomponents.Ifthe

blowing agent diffuses faster than the air components, definitions of the

stages of aging would require modification and any discussions regarding

diffusionrateswouldneedtobechanged.However,thetestproceduresare

applicable in either case.

4.2 The change in thermal resistance due to the phenomena

describedin4.1usuallyoccursoveranextendedperiodoftime

at room temperature. Information regarding changes in the

thermal resistance of these materials as a function of time is

required so that decisions regarding formulations, production,

and comparisons with other materials can be made. Ideally,

aging curves and estimated time-averaged thermal resistance

data for the expected service life should be available after as

short a period as possible.

FIG. 1 The Log of the Normalized Thermal Resistance (see

4.3 Specifications C 578, C 591, C 1029, C 1126C 578 and

9.2.2.2) v.s. the Scaled Time for Three Thickness of a Rigid

C 1289 C 591C 1029C 1126C 1289, on rigid closed-cell plas-

Closed-Cell Plastic Foam. Data is from Ref (17).

tic foams, indicate that this decrease in thermal resistance

occurs over an extended period of time at room temperature.

3.3 Symbols:

However, these standards currently require that freshly manu-

factured foams be measured for thermal resistance after con-

ditioning at 23 6 1°C (73 6 2°F) for 180 6 5 days from the

A = surfaceareaofTestMethodD 2856D 2856speci-

time of manufacture, or at 60 6 1°C (1406 2°F) for 90 days.

men, m

These standards do not currently specify long-term or time-

D = diffusion coefficient, m /s

averaged thermal resistance criteria.

R = thermal resistance, (m ·K)/W

*

R = normalized thermal resistance=R/R

4.4 Theproceduredescribedinthistestmethodrequiresthat

t 0

R = initial thermal resistance

0 the material characteristics of the thin specimens approximate

R = estimated time-averaged thermal resistance,

a

those of the material under investigation. In particular, the

(m ·K)/W

specimens of reduced thickness must have the same effective

th 2

R = thermal resistance on t day, (m ·K)/W

t

diffusion coefficient and initial cell gas content as those of the

t = time, days

full thickness material, and that one-dimensional diffusion

t = service life, days

m

dominates, limiting the application of this test method to

TDSL = average thickness of damaged surface layer, m

* 2 unfaced homogeneous materials as defined in 3.2.4.

t = scaled time, sec/mm

4.4.1 When the thin specimen does not effectively represent

V = bulk geometric specimen volume of Test Method

b

D 2856D 2856 specimen, m the average behavior of the material, the results obtained by

V = closed–cell volume of the specimen of Test this test method may have a limited value.

c

Method D 2856D 2856 specimen, m

4.5 This test method addresses three separate elements

DX = geometric thickness of thermal resistance speci-

geo

relating to the aging of rigid closed–cell plastic foams.

men, m

4.5.1 Specimen Preparation—Techniques for the prepara-

DX = effective diffusion thickness of thermal resistance

eff

tion of thin flat specimens and the measurement of specimen

specimen, m

thickness are discussed, along with their limitations.

DX = specimen thickness,m

4.5.2 Measurement of the Thermal Resistance—In prin-

q = heat flux, W/m

ciple, any of the referenced test methods for the determination

q = heat flux due to the cell gas mixture,W/m

g

q = heat flux due to thermal radiation,W/m of thermal resistance are suitable. These include Test Methods

r

q = heat flux due to the solid polymer,W/m C 177, C 236, C 518, C 976, and

s

s = standard deviation

C 1114C 177C 236C 518C 976C 1114, used in conjunction

with Practice C 1045C 1045. Of these test methods, the heat

4. Significance and Use

flow meter apparatus, Test Method C 518C 518, is preferred.

4.1 Rigid closed–cell plastic foam insulations are produced

4.5.3 Interpretation of Data—Procedures are detailed for

byfoamingvariouspolymers.Asmanufactured,thecellsofthe

utilizingperiodicshort-termthermalresistancedatatoestimate

foam usually contain their highest percentage of blowing agent

long-term changes in the thermal resistance of the material.

and the lowest percentage of air components. As time passes,

Examples are provided in Annex A1.

the relative concentrations of these gases change due primarily

4.6 The procedure outlined in this test method can be used

todiffusion,resultinginareductionofthethermalresistanceof

to produce a characteristic aging curve (relationship between

the foam due to an increase in the thermal conductivity of the

the thermophysical properties with time). This relationship has

resultant cell gas mixture.

been used by researchers to calculate effective diffusion coef-

NOTE 1—The discussions in Sections 4 and 5 assume that the blowing ficients (2, 3).

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

C1303–00

5. Background and Theory

5.1 The Aging Process:

5.1.1 During the service life of a rigid closed-cell plastic

foam, air components diffuse into the cells, and the blowing

agent diffuses out of the cells or partially dissolves into the

polymer matrix. Each process occurs at a rate that depends on

the type of polymer, the foam structure, the temperature, the

gas type, and its pressure (1).

5.1.2 In general, as the inward diffusion of air components

is much faster than the outward diffusion of the captive

blowing agent, the aging process comprises two stages. During

the primary stage, the cell gas composition changes at a

significantratebecauseoftherapiddiffusionofaircomponents

into the cell and the outward diffusion of all diffuse blowing

agents, if present; so too does the thermal resistance of the

FIG. 2 The Normalized Thermal Resistance (see 9.2.2.2)ofTwo

material.

Thicknesses of a Rigid Closed Cell Plastic Foam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.