ASTM F1359/F1359M-22

(Test Method)Standard Test Method for Liquid Penetration Resistance of Protective Clothing or Protective Ensembles Under a Shower Spray While on a Manikin

Standard Test Method for Liquid Penetration Resistance of Protective Clothing or Protective Ensembles Under a Shower Spray While on a Manikin

SIGNIFICANCE AND USE

5.1 This test method evaluates the ability of the construction and configuration of protective clothing or protective ensembles to resist liquid penetration. In most cases, the conditions used in this test method will not represent actual end-use conditions.

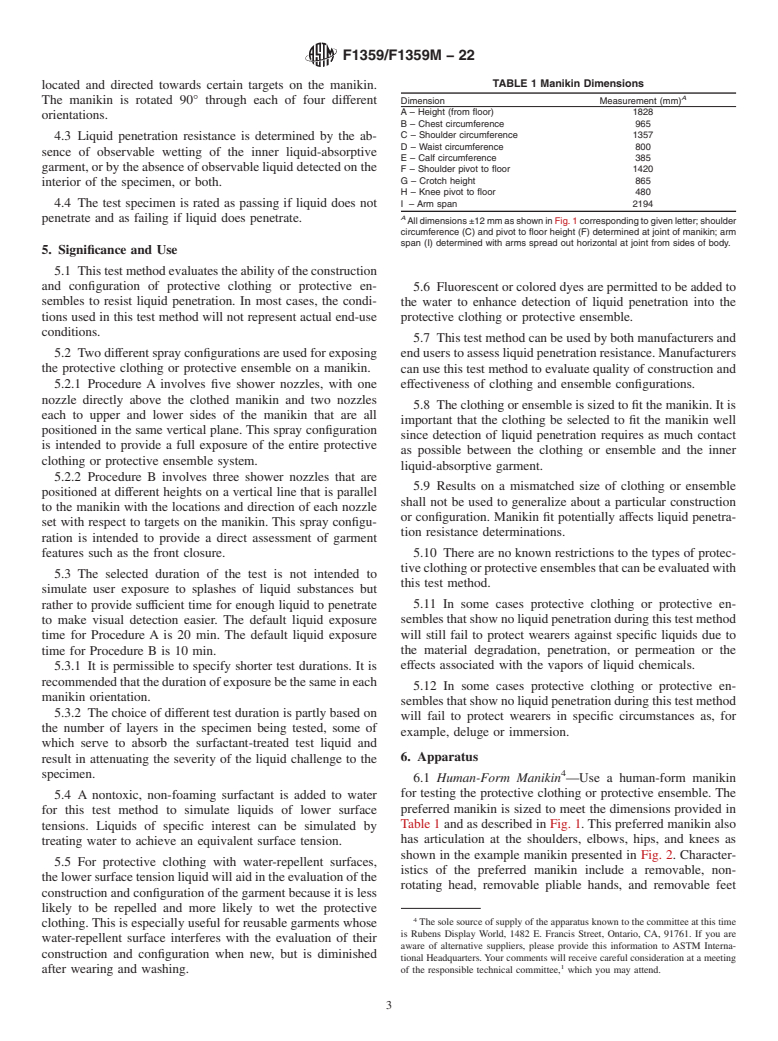

5.2 Two different spray configurations are used for exposing the protective clothing or protective ensemble on a manikin.

5.2.1 Procedure A involves five shower nozzles, with one nozzle directly above the clothed manikin and two nozzles each to upper and lower sides of the manikin that are all positioned in the same vertical plane. This spray configuration is intended to provide a full exposure of the entire protective clothing or protective ensemble system.

5.2.2 Procedure B involves three shower nozzles that are positioned at different heights on a vertical line that is parallel to the manikin with the locations and direction of each nozzle set with respect to targets on the manikin. This spray configuration is intended to provide a direct assessment of garment features such as the front closure.

5.3 The selected duration of the test is not intended to simulate user exposure to splashes of liquid substances but rather to provide sufficient time for enough liquid to penetrate to make visual detection easier. The default liquid exposure time for Procedure A is 20 min. The default liquid exposure time for Procedure B is 10 min.

5.3.1 It is permissible to specify shorter test durations. It is recommended that the duration of exposure be the same in each manikin orientation.

5.3.2 The choice of different test duration is partly based on the number of layers in the specimen being tested, some of which serve to absorb the surfactant-treated test liquid and result in attenuating the severity of the liquid challenge to the specimen.

5.4 A nontoxic, non-foaming surfactant is added to water for this test method to simulate liquids of lower surface tensions. Liquids of specific interest can be simulat...

SCOPE

1.1 This test method measures the ability of protective clothing or protective ensembles to resist liquid penetration in the form of a shower spray with surfactant-treated water.

1.2 This test method measures the liquid penetration resistance of the construction and configuration of the overall protective clothing or protective ensemble, but especially of seams, closures, and interfaces with other components such as gloves, boots, hoods, and respiratory protective equipment. It is intended that this test method be used to assess the liquid penetration resistance of protective clothing and protective ensembles as received from the manufacturer and worn in accordance with their instructions.

1.3 Resistance of materials used in protective clothing to permeation or penetration can be determined in accordance with Test Method F739 (or Test Method F1383 or F1407) and Test Method F903, respectively. Alternatively, resistance of materials used in protective clothing to penetration by synthetic blood or liquids containing virus can be determined in accordance with Test Methods F1670/F1670M and F1671/F1671M.

1.4 The integrity of vapor protective ensembles is measured by its ability to maintain positive internal pressure with Test Method F1052.

1.5 The values in SI units or in other units shall be regarded separately as standard. The values stated in each system must be used independently of the other, without combining values in any way.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Developmen...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1359/F1359M − 22

Standard Test Method for

Liquid Penetration Resistance of Protective Clothing or

Protective Ensembles Under a Shower Spray While on a

1

Manikin

ThisstandardisissuedunderthefixeddesignationF1359/F1359M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Personnel in industry and emergency response can be exposed to numerous liquids capable of

causing harm upon contact with the human body. These liquids may include chemicals, contaminated

blood or body fluids, and other hazardous liquids. The deleterious effects of different chemicals can

range from acute trauma such as skin irritation and burn, to chronic degenerative disease such as

cancer. Biological-based hazard liquids may include various liquid-borne pathogens capable of

causing infection directly or with non-intact skin. Since engineering controls cannot eliminate all

possible exposures, attention is often placed on reducing the potential for direct skin contact through

the use of protective clothing.

Protective clothing is available in a variety of constructions, configurations, and materials, and is

designed to provide various levels of protection against many hazards. Protective clothing offering the

highest level of chemical protection is constructed to prevent any contact of solid, liquid, or gaseous

chemicals with the wearer. Test Method F1052 evaluates the integrity and construction of the vapor

protective ensembles by way of an internal pressure test. In some applications, protective clothing

need only isolate the wearer from splashes of liquids. This test method evaluates the integrity of the

construction and configuration of liquid-penetration-resistant protective clothing or protective

ensembles with a shower spray test.

Resistance of materials used in protective clothing to chemical permeation should be evaluated by

Test Method F739 for continuous contact and Test Method F1383 for intermittent contact (that is,

splash), or by Test Method F1407 using the permeation cup method. Resistance of protective clothing

materials to liquid penetration should be determined by Test Method F903. Resistance of protective

clothingmaterialsspecificallytobloodandotherpotentiallyinfectiousmaterialsshouldbedetermined

by Test Methods F1670/F1670M and F1671/F1671M.

1. Scope seams, closures, and interfaces with other components such as

gloves,boots,hoods,andrespiratoryprotectiveequipment.Itis

1.1 This test method measures the ability of protective

intended that this test method be used to assess the liquid

clothing or protective ensembles to resist liquid penetration in

penetration resistance of protective clothing and protective

the form of a shower spray with surfactant-treated water.

ensembles as received from the manufacturer and worn in

1.2 This test method measures the liquid penetration resis-

accordance with their instructions.

tance of the construction and configuration of the overall

protective clothing or protective ensemble, but especially of 1.3 Resistance of materials used in protective clothing to

permeation or penetration can be determined in accordance

1 with Test Method F739 (or Test Method F1383 or F1407) and

ThistestmethodisunderthejurisdictionofASTMCommitteeF23onPersonal

Protective Clothing and Equipment and is the direct responsibility of Subcommittee Test Method F903, respectively. Alternatively, resistance of

F23.30 on Chemicals.

materialsusedinprotectiveclothingtopenetrationbysynthetic

Current edition approved Jan. 1, 2022. Published January 2022. Originally

blood or liquids containing virus can be determined in accor-

approved in 1991. Last previous edition approved in 2016 as F1359/F1359M – 16a.

DOI: 10.1520/F1359_F1359M-22. dance with Test Methods F1670/F1670M and F1671/F1671M.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1359/F1359M − 22

1.4 The integrity of vapor protective ensembles is measured 3.1.1 liquid splash protective clothing, n—protective cloth-

by its ability to maintain positive internal pressure with Test ing used to protect the wearer from liquid splashes and other

Method F1052. forms of incidental liquid contact.

3.1.2 liquid splash protective ensemble, n—protective en-

1.5 The values in SI units or in other units shall be regarded

semble used to protect the wearer from liquid splashes and

separately

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1359/F1359M − 16a F1359/F1359M − 22

Standard Test Method for

Liquid Penetration Resistance of Protective Clothing or

Protective Ensembles Under a Shower Spray While on a

1

Manikin

This standard is issued under the fixed designation F1359/F1359M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Personnel in industry and emergency response can be exposed to numerous liquids capable of

causing harm upon contact with the human body. These liquids may include chemicals, contaminated

blood or body fluids, and other hazardous liquids. The deleterious effects of different chemicals can

range from acute trauma such as skin irritation and burn, to chronic degenerative disease such as

cancer. Biological-based hazard liquids may include various liquidborneliquid-borne pathogens

capable of causing infection directly or with non-intact skin. Since engineering controls cannot

eliminate all possible exposures, attention is often placed on reducing the potential for direct skin

contact through the use of protective clothing.

Protective clothing is available in a variety of constructions, configurations, and materials, and is

designed to provide various levels of protection against many hazards. Protective clothing offering the

highest level of chemical protection is constructed to prevent any contact of solid, liquid, or gaseous

chemicals with the wearer. Test Method F1052 evaluates the integrity and construction of the vapor

protective ensembles by way of an internal pressure test. In some applications, protective clothing

need only isolate the wearer from splashes of liquids. This test method evaluates the integrity of the

construction and configuration of liquid-penetration-resistant protective clothing or protective

ensembles with a shower spray test.

Resistance of materials used in protective clothing to chemical permeation should be evaluated by

Test Method F739 for continuous contact and Test Method F1383 for intermittent contact (that is,

splash), or by Test Method F1407 using the permeation cup method. Resistance of protective clothing

materials to liquid penetration should be determined by Test Method F903. Resistance of protective

clothing materials specifically to blood and other potentially infectious materials should be determined

by Test MethodMethods F1670F1670/F1670M and Test Method F1671F1671/F1671M.

1. Scope

1.1 This test method measures the ability of protective clothing or protective ensembles to resist liquid penetration in the form of

a shower spray with surfactant-treated water.

1.2 This test method measures the liquid penetration resistance of the construction and configuration of the overall protective

clothing or protective ensemble, but especially of seams, closures, and interfaces with other components such as gloves, boots,

1

This test method is under the jurisdiction of ASTM Committee F23 on Personal Protective Clothing and Equipment and is the direct responsibility of Subcommittee

F23.30 on Chemicals.

Current edition approved July 1, 2016Jan. 1, 2022. Published October 2016January 2022. Originally approved in 1991. Last previous edition approved in 2016 as

F1359/F1359M - 16.F1359/F1359M – 16a. DOI: 10.1520/F1359_F1359M-16A.10.1520/F1359_F1359M-22.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1359/F1359M − 22

hoods, and respiratory protective equipment. It is intended that this test method be used to assess the liquid penetration resistance

of protective clothing and protective ensembles as received from the manufacturer and worn in accordance with their instructions.

1.3 Resistance of materials used in protective clothing to permeation or penetration can be determined in accordance with Test

Method F739 (or Test Method F1383 or Test Method F1407) and Test Method F903, respectively. Alternatively, resistance of

materials used in protective clothing to penetration by synthetic blood or liquids containing virus can be determined in accordance

with Test MethodMethods F1670F1670/F1670M and Test Method F1671F1671/F1671M.

1.4 The integrity of vapor protective ensembles is measured by its ability to maintain positive internal pressure with Test Method

F1052.

1.5 The v

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.