ASTM D5500-98(2014)

(Test Method)Standard Test Method for Vehicle Evaluation of Unleaded Automotive Spark-Ignition Engine Fuel for Intake Valve Deposit Formation

Standard Test Method for Vehicle Evaluation of Unleaded Automotive Spark-Ignition Engine Fuel for Intake Valve Deposit Formation

SIGNIFICANCE AND USE

5.1 Test Method—It was determined through field testing that intake valve deposits could adversely affect the driveability of certain automobiles.7 Southwest Research Institute and BMW of North America (BMW NA) jointly conducted testing to develop this test method to determine an unleaded automotive spark-ignition engine fuel's propensity to form intake valve deposits. This testing concluded that if an automotive spark-ignition engine fuel could keep intake valve deposits at or below a certain average weight per valve at the end of mileage accumulation, then that automotive spark-ignition engine fuel could be used in the BMW vehicle-engine combination for a specified period without intake valve deposits causing driveability degradation. Minimizing intake valve deposits may be necessary to maintain vehicle driveability and tailpipe emissions control.

5.1.1 State and Federal Legislative and Regulatory Action—Legislative activity and rulemaking primarily by California Air Resources Board8 and the Environmental Protection Agency9 necessitate the acceptance of a standardized test method to evaluate the intake system deposit forming tendency of an automotive spark-ignition engine fuel.

5.1.2 Relevance of Results—The operating conditions and design of the engine and vehicle used in this test method are not representative of all modern automobiles. These factors shall be considered when interpreting test results.

5.2 Test Validity:

5.2.1 Procedural Compliance—The test results are not considered valid unless the test is completed in compliance with all requirements of this test method. Deviations from the parameter limits presented in Sections 10 and 11 will result in an invalid test. Engineering judgment shall be applied during conduct of the test method when assessing any anomalies to ensure validity of the test results.

5.2.2 Vehicle Compliance—A test is not considered valid unless the vehicle met the quality control inspection requirements as described in...

SCOPE

1.1 This test method covers a vehicle test procedure for evaluation of intake valve deposit formation of unleaded spark-ignition engine fuels. This test method uses a 1985 model BMW 318i2 vehicle. Mileage is accumulated following a specified driving schedule on either public road or test track. This test method is adapted from the original BMW of North America/Southwest Research Institute Intake Valve Deposit test and maintains as much commonality as possible with the original test. Chassis dynamometers shall not be used for this test procedure as the BMW NA/SwRI IVD Test was not intended to be applicable to chassis dynamometers and no correlation between road operation and chassis dynamometers has been established.

Note 1: If there is any doubt as to the latest edition of Test Method D5500, contact ASTM International.

1.2 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific statements on hazards are given throughout this test method.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5500 − 98(Reapproved 2014)

Standard Test Method for

Vehicle Evaluation of Unleaded Automotive Spark-Ignition

Engine Fuel for Intake Valve Deposit Formation

This standard is issued under the fixed designation D5500; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ANSI Standard:

MC96.1AmericanNationalStandardforTemperatureMea-

1.1 This test method covers a vehicle test procedure for

surement Thermocouples

evaluation of intake valve deposit formation of unleaded

spark-ignition engine fuels. This test method uses a 1985

3. Terminology

model BMW 318i vehicle. Mileage is accumulated following

3.1 Definitions of Terms Specific to This Standard:

a specified driving schedule on either public road or test track.

3.1.1 alternate mileage accumulation (AMA) driving cycle,

This test method is adapted from the original BMW of North

n—a driving schedule that is based on the U.S. Environmental

America/Southwest Research Institute Intake Valve Deposit

Protection Agency Durability Driving Schedule, which con-

test and maintains as much commonality as possible with the

tains various driving patterns for durability testing of emission

original test. Chassis dynamometers shall not be used for this

control systems.

test procedure as the BMW NA/SwRI IVD Test was not

intended to be applicable to chassis dynamometers and no

3.1.2 base fuel, n—unleaded automotive spark-ignition en-

correlation between road operation and chassis dynamometers

gine fuel that does not contain a deposit control additive, but

has been established.

may contain antioxidants, corrosion inhibitors, metal

deactivators, and oxygenates.

NOTE 1—If there is any doubt as to the latest edition of Test Method

D5500, contact ASTM International.

3.1.3 deposit control additive, n—materialaddedtothebase

fuel to prevent or remove deposits in the entire engine intake

1.2 The values stated in SI units are to be regarded as

system.

standard. The values in parentheses are for information only.

3.1.3.1 Discussion—Forthepurposeofthistestmethod,the

1.3 This standard does not purport to address all of the

performance evaluation of a deposit control additive is limited

safety concerns, if any, associated with its use. It is the

to the tulip area of intake valves.

responsibility of the user of this standard to establish appro-

3.1.4 driveability, n—the quality of a vehicle’s performance

priate safety and health practices and determine the applica-

characteristics as perceived by the operator in response to

bility of regulatory limitations prior to use.Specificstatements

changes in throttle position.

on hazards are given throughout this test method.

3.1.4.1 Discussion—The performance characteristics may

include cold starting and warm-up, acceleration, vapor lock,

2. Referenced Documents

3 and hot starting.

2.1 ASTM Standards:

3.1.5 intake system, n—components of the engine whose

D235Specification for Mineral Spirits (Petroleum Spirits)

function it is to prepare and deliver an air/fuel mixture to the

(Hydrocarbon Dry Cleaning Solvent)

combustion chamber and includes the throttle, intake manifold

hot spot and runners, exhaust gas recirculation (EGR) and

positive crankcase ventilation (PCV) ports, cylinder head

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of runners and ports, intake valves, and fuel injectors.

Subcommittee D02.A0.01 on Gasoline and Gasoline-Oxygenate Blends.

3.1.6 intake valve deposit, n—material accumulated on the

Current edition approved Oct. 1, 2014. Published November 2014. Originally

tulip area of the intake valve, generally composed of carbon,

approved in 1994. Last previous edition approved in 2008 as D5500–98(2008).

DOI: 10.1520/D5500-98R14.

other fuel, lubricant, and additive decomposition products, and

OriginallyobtainedfromBMWNAnewcardealershipsintheUnitedStatesas

atmospheric contaminants.

a 1985 model year vehicle, the vehicle is currently available through the used

vehicle market.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Standards volume information, refer to the standard’s Document Summary page on 4th Floor, New York, NY 10036, http://www.ansi.org.

the ASTM website. Code of Federal Regulations, Title 40, Part 86, Appendix IV.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5500 − 98 (2014)

3.1.7 merit rating, n—the visual evaluation by a trained to develop this test method to determine an unleaded automo-

rater of the volume of deposits accumulated on a specific tive spark-ignition engine fuel’s propensity to form intake

engine component based on a comparison with a reference valve deposits. This testing concluded that if an automotive

scale (see CRC Manual 16 ). spark-ignition engine fuel could keep intake valve deposits at

or below a certain average weight per valve at the end of

3.1.8 test fuel, n—base fuel with or without the addition of

mileage accumulation, then that automotive spark-ignition

a deposit control additive which is used to accumulate mileage

engine fuel could be used in the BMW vehicle-engine combi-

as described in this test method.

nation for a specified period without intake valve deposits

3.1.9 vehicle exhaust emissions (tailpipe), n—combustion

causing driveability degradation. Minimizing intake valve

products from the test fuel including unburned hydrocarbons

deposits may be necessary to maintain vehicle driveability and

(HC), carbon monoxide (CO), carbon dioxide (CO ), oxygen

tailpipe emissions control.

(O ), and oxides of nitrogen (NO ).

2 x

5.1.1 State and Federal Legislative and Regulatory

Action—LegislativeactivityandrulemakingprimarilybyCali-

4. Summary of Test Method

forniaAir Resources Board and the Environmental Protection

4.1 This test method utilizes a 1985 BMW 318i vehicle

Agency necessitate the acceptance of a standardized test

equipped with a four-speed automatic transmission and air

methodtoevaluatetheintakesystemdepositformingtendency

conditioning.Thisvehicleisequippedwithafour-strokecycle,

of an automotive spark-ignition engine fuel.

four-cylinder engine having a total displacement of 1.8 L. The

5.1.2 Relevance of Results—The operating conditions and

cylinder head is an aluminum alloy casting and the cylinder

design of the engine and vehicle used in this test method are

block is cast iron. The engine features an overhead camshaft,

not representative of all modern automobiles. These factors

hemispherical combustion chambers, two valves per cylinder,

shall be considered when interpreting test results.

and electronic port fuel injection.

5.2 Test Validity:

4.2 Each test begins with a clean, rebuilt cylinder head that

5.2.1 Procedural Compliance—The test results are not con-

meets a rigid set of specifications. New, weighed intake valves

sideredvalidunlessthetestiscompletedincompliancewithall

are used to rebuild the cylinder head. A standard engine oil is

requirements of this test method. Deviations from the param-

used for each test and a new oil filter is installed. All routine

eter limits presented in Sections 10 and 11 will result in an

vehicle maintenance is performed in accordance with BMW

invalid test. Engineering judgment shall be applied during

Schedule I and Schedule II service lists.The test vehicle’s fuel

conduct of the test method when assessing any anomalies to

system is flushed of fuel from the previous test. The vehicle

ensure validity of the test results.

fuel tank is then filled with the new test fuel. The vehicle is

5.2.2 Vehicle Compliance—A test is not considered valid

subjected to a rigorous quality control procedure to verify

unless the vehicle met the quality control inspection require-

proper engine and overall vehicle operation. To ensure com-

ments as described in Section 10.

pliance to the test objective, a data logger is active at all times

after the test has begun, during all mileage accumulation and

6. Apparatus

soak time.

6.1 Automobile—The test automobile used for this proce-

4.3 The vehicle is operated on a cycle consisting of 10%

dure is a 1985 model BMW 318i. The powerplant is a 1.8

(based on mileage) city (part of the AMA driving schedule),

L-line four-cylinder, four-stroke cycle engine with single

20%suburban,and70%highwaymodeperday.Thiscycleis

overheadcamshaft,twovalvespercylinder,andelectronicport

repeated to accumulate a minimum of 16 090 km (10 000

fuel injection. Vehicles equipped with four-speed automatic

miles) but no more than 16 250 km (10 100 miles).

transmissions and air conditioning are required for the test

method. Both 49 state and California engine calibrations are

4.4 After the required mileage (see 10.4.5) has been

allowed for this test method.

accumulated,thecylinderheadisremovedfromtheengineand

6.1.1 Engine Cooling System—Experience has shown that

disassembled.The valves are weighed, visually assigned merit

the original equipment cooling system has marginal perfor-

ratings,andphotographed.Operationalandmechanicalcriteria

mance at ambient conditions above approximately 35°C

are then reviewed to determine if the test shall be considered

(95°F).To ensure engine coolant temperature compliance with

valid.

test validity criteria in 10.4.3, the vehicle may be retrofitted

5. Significance and Use with the radiator and other appropriate components as outlined

in Annex A1.

5.1 Test Method— It was determined through field testing

6.1.2 Electronic Port Fuel Injectors — Prior to installation,

that intake valve deposits could adversely affect the driveabil-

all injectors shall be evaluated for conformance to spray-

ity of certain automobiles. Southwest Research Institute and

pattern and flow rate acceptance criteria (see 8.5). Injectors

BMWof NorthAmerica (BMWNA) jointly conducted testing

may be reused if the criteria are satisfied.

CRC Manual 16, Carburetor and Induction System Rating Manual. Available

from the Coordinating Research Council Inc., 219 Perimeter Center Parkway, State of California Air Resources Board-Stationary Source Division, Test

Atlanta, GA 30346. MethodforEvaluatingIntakeValveDeposits(IVDs)inVehicleEngines(California

Bitting, B., et al., “Intake Valve Deposits-Fuel Detergency Revisited,” SAE Code of Regulations, Title 13, Section 2257).

872117, Society of Automotive Engineers, 1987. Clean Air Act Amendments of 1990.

D5500 − 98 (2014)

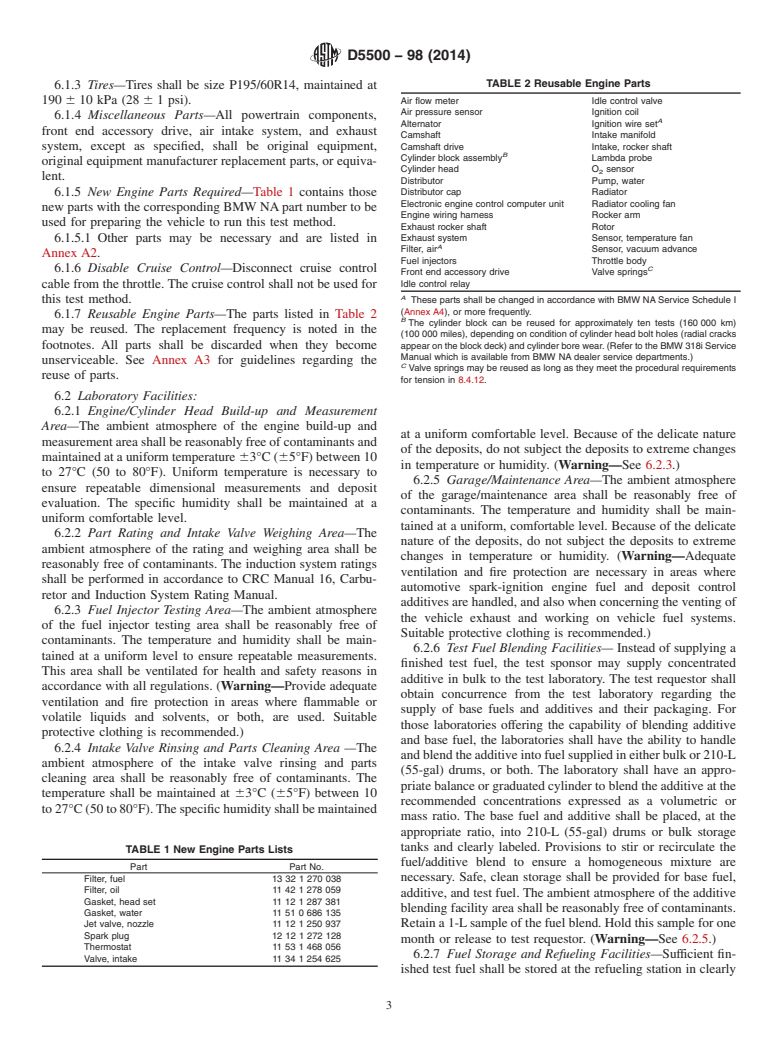

TABLE 2 Reusable Engine Parts

6.1.3 Tires—Tires shall be size P195/60R14, maintained at

190 610 kPa (28 61 psi). Air flow meter Idle control valve

Air pressure sensor Ignition coil

6.1.4 Miscellaneous Parts—All powertrain components,

A

Alternator Ignition wire set

front end accessory drive, air intake system, and exhaust

Camshaft Intake manifold

system, except as specified, shall be original equipment, Camshaft drive Intake, rocker shaft

B

Cylinder block assembly Lambda probe

original equipment manufacturer replacement parts, or equiva-

Cylinder head O sensor

lent.

Distributor Pump, water

Distributor cap Radiator

6.1.5 New Engine Parts Required—Table 1 contains those

Electronic engine control computer unit Radiator cooling fan

new parts with the corresponding BMWNApart number to be

Engine wiring harness Rocker arm

used for preparing the vehicle to run this test method.

Exhaust rocker shaft Rotor

6.1.5.1 Other parts may be necessary and are listed in Exhaust system Sensor, temperature fan

A

Filter, air Sensor, vacuum advance

Annex A2.

Fuel injectors Throttle body

C

6.1.6 Disable Cruise Control—Disconnect cruise control

Front end accessory drive Valve springs

Idle control relay

cable from the throttle.The cruise control shall not be used for

A

this test method.

These parts shall be changed in accordance with BMW NA Service Schedule I

(Annex A4), or more frequently.

6.1.7 Reusable Engine Parts—The parts listed in Table 2

B

The cylinder block can be reused for approximately ten tests (160 000 km)

may be reused. The replacement frequency is noted in the

(100 000 miles), depending on condition of cylinder head bolt holes (radial cracks

footnotes. All parts shall be discarded when they become appear on the block deck) and cylinder bore wear. (Refer to the BMW 318i Service

Manual which is available from BMW NA dealer service departments.)

unserviceable. See Annex A3 for guidelines regarding the

C

Valve springs may be reused as long as they meet the procedural requirements

reuse of parts.

for tension in 8.4.12.

6.2 Laboratory Facilities:

6.2.1 Engine/Cylinder Head Build-up and Measurement

Area—The ambient atmosphere of the engine build-up and

at a uniform comfortable level. Because of the delicate nature

measurementareashallbereasonablyfreeofcontaminantsand

of the deposits, do not subject the deposits to extreme changes

maintainedatauniformtemperature 63°C(65°F)between10

in temperature or humidity. (Warning—See 6.2.3.)

to 27°C (50 to 80°F). Uniform temperature is necessary to

6.2.5 Garage/Maintenance Area—The ambient atmosphere

ensure repeatable dimensional measurements and deposit

of the garage/maintenance area shall be reasonably free of

evaluation. The specific humidity shall be maintained at a

contaminants. The temperature and humidity shall be main-

uniform comfortable level.

tained at a uniform, comfortable level. Because of the delicate

6.2.2 Part Rating and Intake Valve Weighing Area—The

nature of the deposits, do not subject the deposits to extreme

ambient atmosphere of the rating and weighing area shall be

changes in temperature or humidity. (Warning—Adequate

reasonably free of contaminants. The induction system ratings

ventilation and fire protection are necessary in areas where

shall be performed in accordance to CRC Manual 16, Carbu-

automotive spark-ignition engine fuel and deposit control

retor and Induction System Rating Manual.

additivesarehandled,andalsowhenconcerningtheventingof

6.2.3 Fuel Injector Testing Area—The ambient atmosphere

the vehicle exhaust and working on vehicle fuel systems.

of the fuel injector testing area shall be reasonably free of

Suitable protective clothing is recommended.)

contaminants. The temperature and humidity shall be main-

6.2.6 Test Fuel Blending Facilities— Instead of supplying a

tained at a uniform level to ensure repeatable measurements.

finished test fuel, the test sponsor

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5500 − 98 (Reapproved 2008) D5500 − 98 (Reapproved 2014)

Standard Test Method for

Vehicle Evaluation of Unleaded Automotive Spark-Ignition

Engine Fuel for Intake Valve Deposit Formation

This standard is issued under the fixed designation D5500; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a vehicle test procedure for evaluation of intake valve deposit formation of unleaded spark-ignition

engine fuels. This test method uses a 1985 model BMW 318i vehicle. Mileage is accumulated following a specified driving

schedule on either public road or test track. This test method is adapted from the original BMW of North America/Southwest

Research Institute Intake Valve Deposit test and maintains as much commonality as possible with the original test. Chassis

dynamometers shall not be used for this test procedure as the BMW NA/SwRI IVD Test was not intended to be applicable to

chassis dynamometers and no correlation between road operation and chassis dynamometers has been established.

NOTE 1—If there is any doubt as to the latest edition of Test Method D5500, contact ASTM International.

1.2 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific statements on hazards are given throughout this test method.

2. Referenced Documents

2.1 ASTM Standards:

D235 Specification for Mineral Spirits (Petroleum Spirits) (Hydrocarbon Dry Cleaning Solvent)

2.2 ANSI Standard:

MC 96.1 American National Standard for Temperature Measurement Thermocouples

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 alternate mileage accumulation (AMA) driving cycle, n—a driving schedule that is based on the U.S. Environmental

Protection Agency Durability Driving Schedule, which contains various driving patterns for durability testing of emission control

systems.

3.1.2 base fuel, n—unleaded automotive spark-ignition engine fuel that does not contain a deposit control additive, but may

contain antioxidants, corrosion inhibitors, metal deactivators, and oxygenates.

3.1.3 deposit control additive, n—material added to the base fuel to prevent or remove deposits in the entire engine intake

system.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.A0.01 on Gasoline and Gasoline-Oxygenate Blends.

Current edition approved July 1, 2008Oct. 1, 2014. Published September 2008 November 2014. Originally approved in 1994. Last previous edition approved in 20032008

ε1

as D5500–98(2003)D5500 – 98 .(2008). DOI: 10.1520/D5500-98R08.10.1520/D5500-98R14.

Originally obtained from BMW NA new car dealerships in the United States as a 1985 model year vehicle, the vehicle is currently available through the used vehicle

market.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Code of Federal Regulations, Title 40, Part 86, Appendix IV.

3.1.3.1 Discussion—

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5500 − 98 (2014)

For the purpose of this test method, the performance evaluation of a deposit control additive is limited to the tulip area of intake

valves.

3.1.4 driveability, n—the quality of a vehicle’s performance characteristics as perceived by the operator in response to changes

in throttle position.

3.1.4.1 Discussion—

The performance characteristics may include cold starting and warm-up, acceleration, vapor lock, and hot starting.

3.1.5 intake system, n—components of the engine whose function it is to prepare and deliver an air/fuel mixture to the

combustion chamber and includes the throttle, intake manifold hot spot and runners, exhaust gas recirculation (EGR) and positive

crankcase ventilation (PCV) ports, cylinder head runners and ports, intake valves, and fuel injectors.

3.1.6 intake valve deposit, n—material accumulated on the tulip area of the intake valve, generally composed of carbon, other

fuel, lubricant, and additive decomposition products, and atmospheric contaminants.

3.1.7 merit rating, n—the visual evaluation by a trained rater of the volume of deposits accumulated on a specific engine

component based on a comparison with a reference scale (see CRC Manual 16 ).

3.1.8 test fuel, n—base fuel with or without the addition of a deposit control additive which is used to accumulate mileage as

described in this test method.

3.1.9 vehicle exhaust emissions (tailpipe), n—combustion products from the test fuel including unburned hydrocarbons (HC),

carbon monoxide (CO), carbon dioxide (CO ), oxygen (O ), and oxides of nitrogen (NO ).

2 2 x

4. Summary of Test Method

4.1 This test method utilizes a 1985 BMW 318i vehicle equipped with a four-speed automatic transmission and air conditioning.

This vehicle is equipped with a four-stroke cycle, four-cylinder engine having a total displacement of 1.8 L. The cylinder head is

an aluminum alloy casting and the cylinder block is cast iron. The engine features an overhead camshaft, hemispherical combustion

chambers, two valves per cylinder, and electronic port fuel injection.

4.2 Each test begins with a clean, rebuilt cylinder head that meets a rigid set of specifications. New, weighed intake valves are

used to rebuild the cylinder head. A standard engine oil is used for each test and a new oil filter is installed. All routine vehicle

maintenance is performed in accordance with BMW Schedule I and Schedule II service lists. The test vehicle’s fuel system is

flushed of fuel from the previous test. The vehicle fuel tank is then filled with the new test fuel. The vehicle is subjected to a

rigorous quality control procedure to verify proper engine and overall vehicle operation. To ensure compliance to the test objective,

a data logger is active at all times after the test has begun, during all mileage accumulation and soak time.

4.3 The vehicle is operated on a cycle consisting of 10 % (based on mileage) city (part of the AMA driving schedule), 20 %

suburban, and 70 % highway mode per day. This cycle is repeated to accumulate a minimum of 16 090 km (10 000 miles) but no

more than 16 250 km (10 100 miles).

4.4 After the required mileage (see 10.4.5) has been accumulated, the cylinder head is removed from the engine and

disassembled. The valves are weighed, visually assigned merit ratings, and photographed. Operational and mechanical criteria are

then reviewed to determine if the test shall be considered valid.

5. Significance and Use

5.1 Test Method— It was determined through field testing that intake valve deposits could adversely affect the driveability of

certain automobiles. Southwest Research Institute and BMW of North America (BMW NA) jointly conducted testing to develop

this test method to determine an unleaded automotive spark-ignition engine fuel’s propensity to form intake valve deposits. This

testing concluded that if an automotive spark-ignition engine fuel could keep intake valve deposits at or below a certain average

weight per valve at the end of mileage accumulation, then that automotive spark-ignition engine fuel could be used in the BMW

vehicle-engine combination for a specified period without intake valve deposits causing driveability degradation. Minimizing

intake valve deposits may be necessary to maintain vehicle driveability and tailpipe emissions control.

5.1.1 State and Federal Legislative and Regulatory Action—Legislative activity and rulemaking primarily by California Air

8 9

Resources Board and the Environmental Protection Agency necessitate the acceptance of a standardized test method to evaluate

the intake system deposit forming tendency of an automotive spark-ignition engine fuel.

CRC Manual 16, Carburetor and Induction System Rating Manual. Available from the Coordinating Research Council Inc., 219 Perimeter Center Parkway, Atlanta, GA

30346.

Bitting, B., et al., “Intake Valve Deposits-Fuel Detergency Revisited,” SAE 872117, Society of Automotive Engineers, 1987.

State of California Air Resources Board-Stationary Source Division, Test Method for Evaluating Intake Valve Deposits (IVDs) in Vehicle Engines (California Code of

Regulations, Title 13, Section 2257).

Clean Air Act Amendments of 1990.

D5500 − 98 (2014)

5.1.2 Relevance of Results—The operating conditions and design of the engine and vehicle used in this test method are not

representative of all modern automobiles. These factors shall be considered when interpreting test results.

5.2 Test Validity:

5.2.1 Procedural Compliance—The test results are not considered valid unless the test is completed in compliance with all

requirements of this test method. Deviations from the parameter limits presented in Sections 10 and 11 will result in an invalid

test. Engineering judgment shall be applied during conduct of the test method when assessing any anomalies to ensure validity of

the test results.

5.2.2 Vehicle Compliance—A test is not considered valid unless the vehicle met the quality control inspection requirements as

described in Section 10.

6. Apparatus

6.1 Automobile—The test automobile used for this procedure is a 1985 model BMW 318i. The powerplant is a 1.8 L-line

four-cylinder, four-stroke cycle engine with single overhead camshaft, two valves per cylinder, and electronic port fuel injection.

Vehicles equipped with four-speed automatic transmissions and air conditioning are required for the test method. Both 49 state and

California engine calibrations are allowed for this test method.

6.1.1 Engine Cooling System—Experience has shown that the original equipment cooling system has marginal performance at

ambient conditions above approximately 35°C (95°F). To ensure engine coolant temperature compliance with test validity criteria

in 10.4.3, the vehicle may be retrofitted with the radiator and other appropriate components as outlined in Annex A1.

6.1.2 Electronic Port Fuel Injectors — Prior to installation, all injectors shall be evaluated for conformance to spray-pattern and

flow rate acceptance criteria (see 8.5). Injectors may be reused if the criteria are satisfied.

6.1.3 Tires—Tires shall be size P195/60R14, maintained at 190 6 10 kPa (28 6 1 psi).

6.1.4 Miscellaneous Parts—All powertrain components, front end accessory drive, air intake system, and exhaust system,

except as specified, shall be original equipment, original equipment manufacturer replacement parts, or equivalent.

6.1.5 New Engine Parts Required—Table 1 contains those new parts with the corresponding BMW NA part number to be used

for preparing the vehicle to run this test method.

6.1.5.1 Other parts may be necessary and are listed in Annex A2.

6.1.6 Disable Cruise Control—Disconnect cruise control cable from the throttle. The cruise control shall not be used for this

test method.

6.1.7 Reusable Engine Parts—The parts listed in Table 2 may be reused. The replacement frequency is noted in the footnotes.

All parts shall be discarded when they become unserviceable. See Annex A3 for guidelines regarding the reuse of parts.

6.2 Laboratory Facilities:

6.2.1 Engine/Cylinder Head Build-up and Measurement Area—The ambient atmosphere of the engine build-up and

measurement area shall be reasonably free of contaminants and maintained at a uniform temperature 63°C (65°F) between 10

to 27°C (50 to 80°F). Uniform temperature is necessary to ensure repeatable dimensional measurements and deposit evaluation.

The specific humidity shall be maintained at a uniform comfortable level.

6.2.2 Part Rating and Intake Valve Weighing Area—The ambient atmosphere of the rating and weighing area shall be reasonably

free of contaminants. The induction system ratings shall be performed in accordance to CRC Manual 16, Carburetor and Induction

System Rating Manual.

6.2.3 Fuel Injector Testing Area—The ambient atmosphere of the fuel injector testing area shall be reasonably free of

contaminants. The temperature and humidity shall be maintained at a uniform level to ensure repeatable measurements. This area

shall be ventilated for health and safety reasons in accordance with all regulations. (Warning—Provide adequate ventilation and

fire protection in areas where flammable or volatile liquids and solvents, or both, are used. Suitable protective clothing is

recommended.)

6.2.4 Intake Valve Rinsing and Parts Cleaning Area —The ambient atmosphere of the intake valve rinsing and parts cleaning

area shall be reasonably free of contaminants. The temperature shall be maintained at 63°C (65°F) between 10 to 27°C (50 to

80°F). The specific humidity shall be maintained at a uniform comfortable level. Because of the delicate nature of the deposits,

do not subject the deposits to extreme changes in temperature or humidity. (Warning—See 6.2.3.)

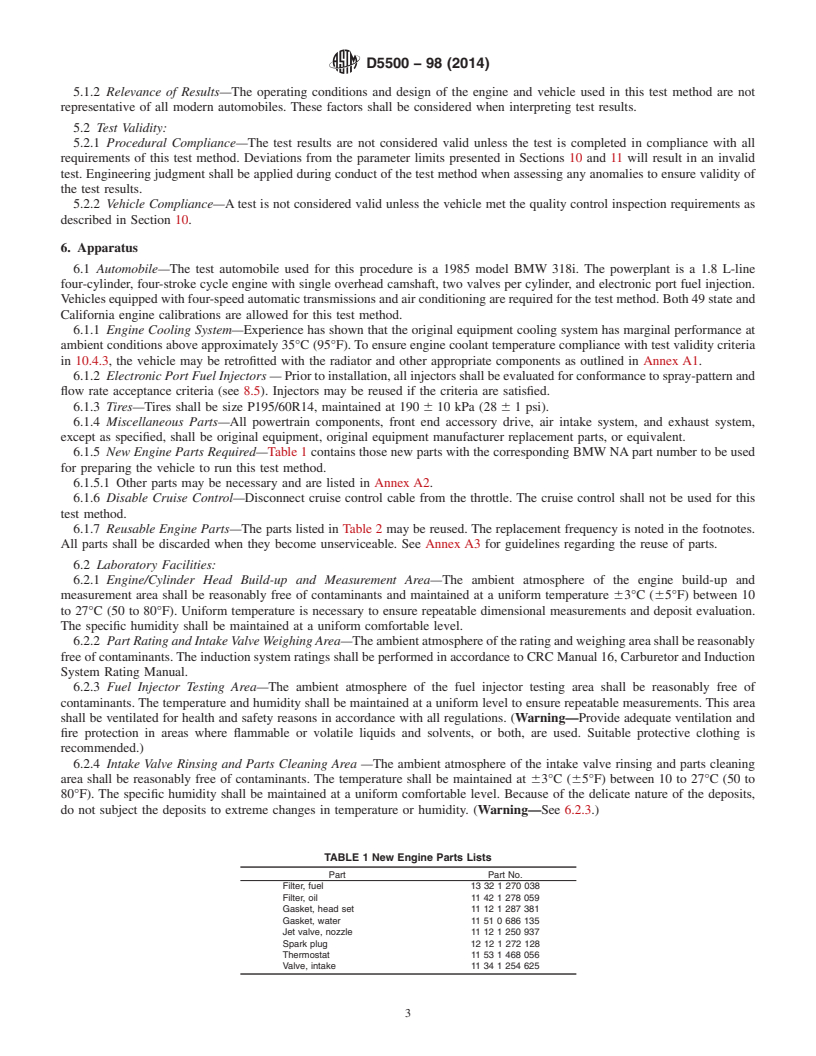

TABLE 1 New Engine Parts Lists

Part Part No.

Filter, fuel 13 32 1 270 038

Filter, oil 11 42 1 278 059

Gasket, head set 11 12 1 287 381

Gasket, water 11 51 0 686 135

Jet valve, nozzle 11 12 1 250 937

Spark plug 12 12 1 272 128

Thermostat 11 53 1 468 056

Valve, intake 11 34 1 254 625

D5500 − 98 (2014)

TABLE 2 Reusable Engine Parts

Air flow meter Idle control valve

Air pressure sensor Ignition coil

A

Alternator Ignition wire set

Camshaft Intake manifold

Camshaft drive Intake, rocker shaft

B

Cylinder block assembly Lambda probe

Cylinder head O sensor

Distributor Pump, water

Distributor cap Radiator

Electronic engine control computer unit Radiator cooling fan

Engine wiring harness Rocker arm

Exh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.