ASTM E518/E518M-10

(Test Method)Standard Test Methods for Flexural Bond Strength of Masonry

Standard Test Methods for Flexural Bond Strength of Masonry

SIGNIFICANCE AND USE

These test methods are intended to provide simplified and economical means for gathering comparative research data on the flexural bond strength developed with different types of masonry units and mortar or for the purpose of checking job quality control (materials and workmanship).

Note 1—These test methods are not intended for use in establishing design stresses. For this purpose, Methods E72 should be used.

SCOPE

1.1 These test methods cover determination of the flexural bond strength of unreinforced masonry assemblages. Two procedures are provided:

1.1.1 Test Method A—Simply supported beam with third-point loading.

1.1.2 Test Method B—Simply supported beam with uniform loading.

1.2 These test methods cover the application of the tests using either inch-pound or SI units. The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the inch-pound units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E518/E518M − 10

StandardTest Methods for

1

Flexural Bond Strength of Masonry

This standard is issued under the fixed designation E518/E518M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E72 Test Methods of Conducting Strength Tests of Panels

for Building Construction

1.1 These test methods cover determination of the flexural

E575 Practice for Reporting Data from Structural Tests of

bond strength of unreinforced masonry assemblages. Two

Building Constructions, Elements, Connections, and As-

procedures are provided:

semblies

1.1.1 Test Method A—Simply supported beam with third-

point loading.

3. Significance and Use

1.1.2 Test Method B—Simply supported beam with uniform

loading.

3.1 These test methods are intended to provide simplified

and economical means for gathering comparative research data

1.2 These test methods cover the application of the tests

on the flexural bond strength developed with different types of

using either inch-pound or SI units. The values stated in either

masonry units and mortar or for the purpose of checking job

SI units or inch-pound units are to be regarded separately as

quality control (materials and workmanship).

standard. Within the text, the inch-pound units are shown in

brackets. The values stated in each system may not be exact

NOTE 1—These test methods are not intended for use in establishing

equivalents;therefore,eachsystemshallbeusedindependently

design stresses. For this purpose, Methods E72 should be used.

of the other. Combining values from the two systems may

result in nonconformance with the standard. 4. Apparatus

1.3 This standard does not purport to address all of the

4.1 Testing Machine, conforming to the requirements of

safety concerns, if any, associated with its use. It is the

Practices E4.

responsibility of the user of this standard to establish appro-

4.2 Test Method A—The third-point loading method is

priate safety and health practices and determine the applica-

illustrated in Fig. 1.The minimum span between supports shall

bility of regulatory limitations prior to use.

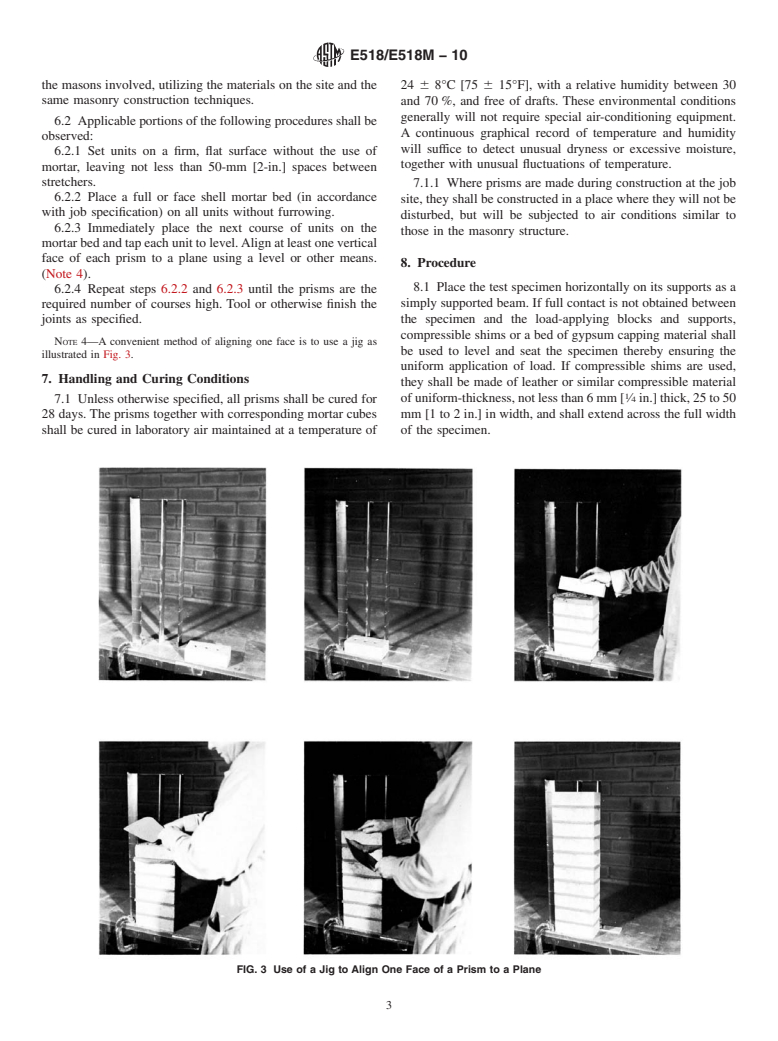

not be less than 2.5 multiplied by the average depth of the

specimen. The distance between each support and the adjacent

2. Referenced Documents

distributed point load shall be one-third of the span length

2

2.1 ASTM Standards:

63 mm [0.1 in.]. Steel rods with a maximum diameter of 25

C67 Test Methods for Sampling and Testing Brick and

mm [1 in.] shall be used to support the specimen and apply the

Structural Clay Tile

load. The steel rods shall extend over the full width of the

C78 Test Method for Flexural Strength of Concrete (Using

specimen and shall have the same nominal diameter.

Simple Beam with Third-Point Loading)

NOTE 2—The loading apparatus is intended to be similar to that used in

C140 Test Methods for Sampling and Testing Concrete

Test Method C78 to reduce the need for redundant testing equipment.

Masonry Units and Related Units

4.3 Test Method B—The uniform loading method is illus-

C270 Specification for Mortar for Unit Masonry

trated in Fig. 2. The minimum span between supports shall not

C778 Specification for Sand

be less than 2.5 multiplied by the average depth of the

E4 Practices for Force Verification of Testing Machines

specimen. Uniformly distributed transverse load shall be ap-

pliedbyairpressureusinganairbagoverthefullsurfaceofthe

specimen. The air bag reaction frame shall fully contact one

1

These test methods are under the jurisdiction of ASTM Committee C15 on

surface of the air bag and shall be sufficiently stiff as to not

Manufactured Masonry Units and are the direct responsibility of Subcommittee

deflect more than the span divided by 600 during testing.

C15.04 on Research.

CurrenteditionapprovedJune1,2010.PublishedJuly2010.Originallyapproved

NOTE 3—Air bags manufactured using 0.5 mm [0.02 in.] thick

in 1974. Last previous edition approved in 2009 as E518 – 09. DOI: 10.1520/E0518

polyvinyl chloride have been successfully used with this test. When

_E0518M-10.

2

testing specimens constructed with a high bond-strength mortar, or whose

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

thickness is greater than a nominal 100 mm [4 in.], the applied load

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on required to fail the specimen may be such as to rupture the seams of the

the ASTM website. air bag. In such cases Test Method A is recommended.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E518–09 Designation: E518/E518M – 10

Standard Test Methods for

1

Flexural Bond Strength of Masonry

This standard is issued under the fixed designation E518/E518M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 Thesetestmethodscoverdeterminationoftheflexuralbondstrengthofunreinforcedmasonryassemblages.Twoprocedures

are provided:

1.1.1 Test Method A—Simply supported beam with third-point loading.

1.1.2 Test Method B—Simply supported beam with uniform loading.

1.2The values stated in SI units are to be regarded as the standard.The inch-pound units given in parentheses are for information

only.

1.2 These test methods cover the application of the tests using either inch-pound or SI units. The values stated in either SI units

or inch-pound units are to be regarded separately as standard. Within the text, the inch-pound units are shown in brackets. The

values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other.

Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C67 Test Methods for Sampling and Testing Brick and Structural Clay Tile

C78 Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading)

C140 Test Methods for Sampling and Testing Concrete Masonry Units and Related Units

C270 Specification for Mortar for Unit Masonry

C778 Specification for Standard Sand

E4 Practices for Force Verification of Testing Machines

E72 Test Methods of Conducting Strength Tests of Panels for Building Construction

E575 Practice for Reporting Data from Structural Tests of Building Constructions, Elements, Connections, and Assemblies

3. Significance and Use

3.1 These test methods are intended to provide simplified and economical means for gathering comparative research data on the

flexuralbondstrengthdevelopedwithdifferenttypesofmasonryunitsandmortarorforthepurposeofcheckingjobqualitycontrol

(materials and workmanship).

NOTE 1—These test methods are not intended for use in establishing design stresses. For this purpose, Methods E72 should be used.

4. Apparatus

4.1 Testing Machine, conforming to the requirements of Practices E4.

4.2 Test Method A—The third-point loading method is illustrated in Fig. 1. The minimum span between supports shall not be

less than 2.5 multiplied by the average depth of the specimen.The distance between each support and the adjacent distributed point

load shall be one-third of the span length 63 mm (0.1 in.). 63 mm [0.1 in.]. Steel rods with a maximum diameter of 25 mm (1

1

These test methods are under the jurisdiction of ASTM Committee C15 on Manufactured Masonry Units and are the direct responsibility of Subcommittee C15.04 on

Research.

Current edition approved June 15, 2009.1, 2010. Published July 2009.2010. Originally approved in 1974. Last previous edition approved in 20032009 as E518 – 039. DOI:

10.1520/E0518_E0518M-109.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E518/E518M – 10

FIG. 1 The Third-Point Loading Method (Test Method A)

in.)[1 in.] shall be used to support the specimen and apply the load. The steel rods shall extend over the full width of the specimen

and shall have the same nominal diameter.

NOTE 2—The loading apparatus is intended to be similar to that used in Test Method C78 to reduce the need for redundant testing equipment.

4.3 Test Method B—The uniform loading method is illustrated in Fig. 2. The minimum span betwee

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.