ASTM A466/A466M-07(2012)

(Specification)Standard Specification for Weldless Chain

Standard Specification for Weldless Chain

ABSTRACT

This specification covers weldless chain suitable for applications where a light and flexible chain is required. The material may be steel, brass, or bronze. The chain shall conform to the dimensional requirements as specified. Breaking force test shall be made to conform to the minimum requirements specified.

SCOPE

1.1 This specification covers weldless chain suitable for applications where a light and flexible chain is required. The material may be steel, brass, or bronze.

1.2 Seven classes of chain are covered:

1.2.1 Class SL—Single-loop chain.

1.2.2 Class DL—Double-loop chain.

1.2.3 Class SH—Sash chain.

1.2.4 Class SF—Plumbers' chain.

1.2.5 Class SJ—Single-jack chain.

1.2.6 Class DJ—Double-jack chain.

1.2.7 Class RG—Register chain.

1.3 The values stated in either SI units or in other units shall be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A466/A466M −07 (Reapproved 2012)

Standard Specification for

Weldless Chain

This standard is issued under the fixed designationA466/A466M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 3. Terminology

1.1 This specification covers weldless chain suitable for 3.1 Definitions of Terms Specific to This Standard:

applications where a light and flexible chain is required. The 3.1.1 breaking force, minimum, n—minimum force in

material may be steel, brass, or bronze. pounds or newtons at which the chain, during manufacture, has

beenfoundbyrepresentativetestingtobreakwhenaconstantly

1.2 Seven classes of chain are covered:

increasing force is applied in direct tension.

1.2.1 Class SL—Single-loop chain.

3.1.1.1 Discussion—This test is a manufacturer’s attribute

1.2.2 Class DL—Double-loop chain.

acceptance test and shall not be used as criteria for service.

1.2.3 Class SH—Sash chain.

3.1.2 lot, n—forthepurposeofacceptancetesting,alotshall

1.2.4 Class SF—Plumbers’ chain.

consist of 3000 ft [1000 m] or fraction, thereof, of the same

1.2.5 Class SJ—Single-jack chain.

grade and size chain. If a continuous length of chain exceeds

1.2.6 Class DJ—Double-jack chain.

3000 ft, it shall also be considered a lot.

1.2.7 Class RG—Register chain.

3.1.3 working load limit (WLL), n—maximum combined

1.3 The values stated in either SI units or in other units shall

static and dynamic load in pounds or kilograms that shall be

be regarded separately as standard. The values stated in each

applied in direct tension to an undamaged straight length of

system may not be exact equivalents; therefore, each system

chain.

must be used independently of the other, without combining

values in any way.

4. Ordering Information

2. Referenced Documents 4.1 It shall be the responsibility of the purchaser to specify

all requirements that are necessary for material ordered under

2.1 ASTM Standards:

this specification. Such requirements to be considered include,

A29/A29M SpecificationforGeneralRequirementsforSteel

but are not limited to, the following:

Bars, Carbon and Alloy, Hot-Wrought

4.1.1 Product to conform to Specification A466/A466M and

A366/A366M Specification for Commercial Steel (CS)

year of issue,

Sheet, Carbon, (0.15 Maximum Percent) Cold-Rolled

3 4.1.2 Class of chain,

(Withdrawn 2000)

4.1.3 Material size or trade size of chain,

A569/A569M Specification for Steel, Carbon (0.15

4.1.4 Material of chain (steel, brass, or bronze),

Maximum,Percent),Hot-RolledSheetandStripCommer-

4.1.5 Quantity of chain in feet [metres],

cial (Withdrawn 2000)

4.1.6 Length of each piece, if required,

B248 Specification for General Requirements for Wrought

4.1.7 Finish, if required,

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

4.1.8 Certification of test(s), if required, and

Bar

4.1.9 Acceptance of inspection by purchaser, if required.

5. Materials and Manufacture

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

5.1 The selection of the base material is left to the judgment

A01.27 on Steel Chain.

of the individual chain manufacturer provided that the chain

Current edition approved Nov. 1, 2012. Published November 2012. Originally

approved in 1962. Last previous edition approved in 2007 as A466/A466M – 07.

complies with the requirements contained within this specifi-

DOI: 10.1520/A0466_A0466M-07R12.

cation.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 The methods utilized to produce the chain are left to the

Standards volume information, refer to the standard’s Document Summary page on

judgment of the individual chain manufacturer provided the

the ASTM website.

3 chain complies with the requirements contained within this

The last approved version of this historical standard is referenced on

www.astm.org. specification.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A466/A466M−07 (2012)

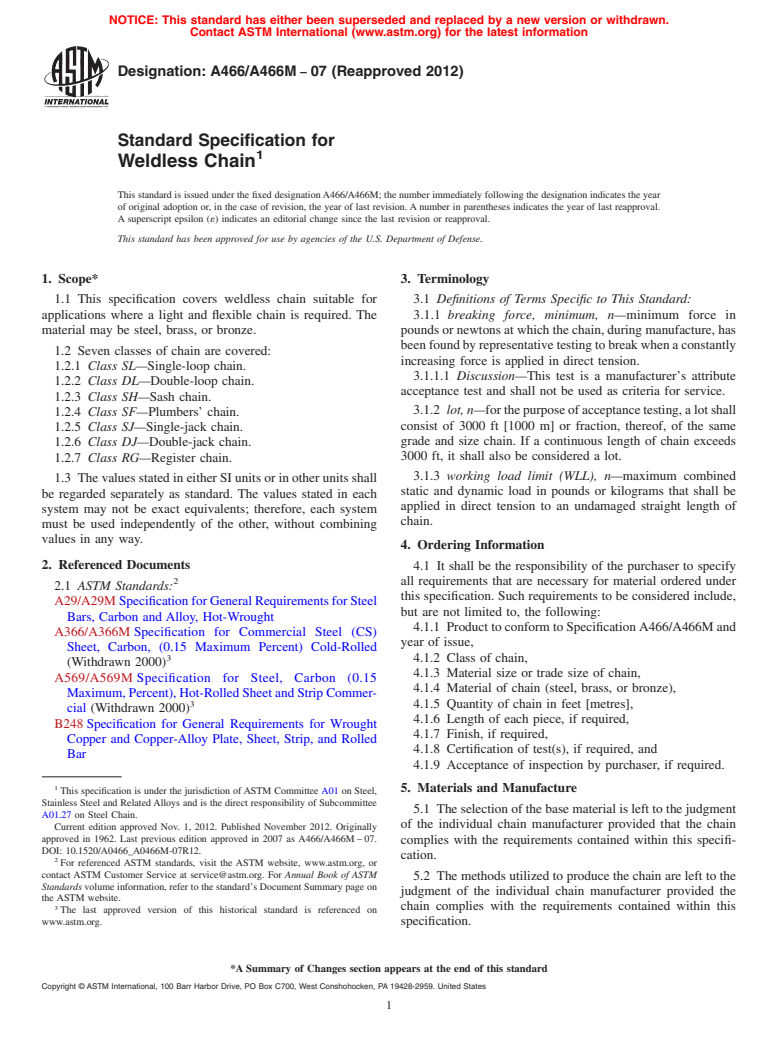

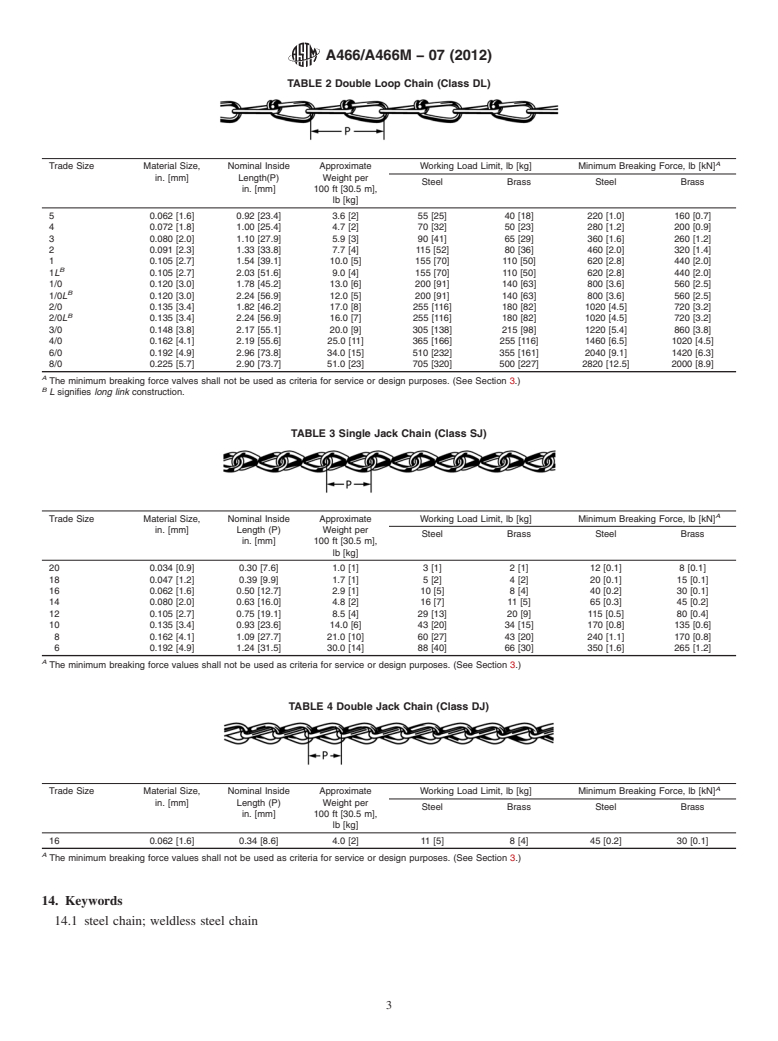

6. Dimensional Requirements test specimens from the same lot may be tested. If both

additional specimens conform to the minimum breaking force

6.1 The chain shall conform to the dimensional require-

requirements, the chain will be considered acceptable.

ments as specified in Tables 1-7. The tolerance is 67 % from

the specified nominal dimensions for all chain classes except

10. Rework and Retreatment

Class SF. Class SF has a maximum length criterion. The inside

10.1 Materials that fail to comply to the requirements for

length dimension can be measured either by individual link or

dimensions and mechanical tests may be resubmitted after

by measuring the span of 100 links and dividing by 100.

being reworked.

6.2 Material Diameter/Thickness—The diameter or thick-

nessofthematerialfromwhichthechainismanufacturedshall

11. Inspection

be at least the dimension shown in Tables 1-7, subject to the

11.1 Prior to testing and inspection at the manufacturer’s

normal commercial tolerances listed in Specifications A29/

plant, the chain shall be free of paint or other coatings which

A29M, A366/A366M, A569/A569M, and B248. Oversized

would tend to conceal defects.

material may be used for all applications.

11.2 Themanufacturershallaffordthepurchaser’sinspector

7. Finish

all reasonable facilities necessary to satisfy him that the

7.1 The manufacturers may apply a surface treatment or material is being produced and furnished in accordance with

finish of their own choice for identification or corrosion this specification. Mill inspection by the purchaser shall not

resistance unless otherwise specified by the customer in the interfere unnecessarily with the manufacturer’s operations.All

purchase order. The surface treatment or finish shall not alter tests and inspections shall be made at the place of manufacture,

the chain in a manner that would cause the chain to not meet unless otherwise agreed.

the other provisions of this standard.

11.3 Thepurchasermaymaketeststogoverntheacceptance

or rejection of the material at his own laboratory or elsewhere.

8. Mechanical Requirements

The tests shall be made at the expense of the purchaser.

8.1 Breaking Force Test:

8.1.1 The breaking force test specimen shall consist of a

12. Rejection and Rehearing

length not less than 1 ft [0.3 m] from the lot of chain.

12.1 Unlessotherwisespecified,anyrejectionbasedontests

8.1.2 Fixtures for securing chain in a testing machine shall

made in accordance with 11.3 shall be reported to the manu-

be properly designed to securely support the shoulder of the

facturer within five working days from the date of testing by

link. The opening in the fixture shall be not more than 25 %

the purchaser.

larger than the material diameter of the chain being tested.

12.2 Chains tested in accordance with 11.3 that represent

Links in the testing fixture shall not be considered part of the

rejected material shall be preserved for two weeks from the

test specimen.

date of the test report. In case of dissatisfaction with the results

8.1.3 Test specimens shall conform to the minimum break-

of the tests, the manufacturer may make claim for a rehearing

ing requirements as prescribed in Tables 1-7 for their respec-

within that time.

tive sizes and classes.

8.1.4 Number of Tests—The manufacturer shall perform at

13. Certification and Reports

least one test per lot of chain.

13.1 A manufacturer’s certification that the chain conforms

9. Retests

to Specificati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.