ASTM D4475-21

(Test Method)Standard Test Method for Apparent Horizontal Shear Strength of Pultruded Reinforced Plastic Rods By the Short-Beam Method

Standard Test Method for Apparent Horizontal Shear Strength of Pultruded Reinforced Plastic Rods By the Short-Beam Method

SIGNIFICANCE AND USE

5.1 Apparent shear strength determined by this test method is useful for quality control and specification purposes. It is also applicable to research and development programs concerned with interlaminar-shear strength. The apparent shear strength obtained by this test method is not intended for design purposes, but allowed to be utilized for comparative testing of composite materials, if all failures are in horizontal shear.

5.2 It is recommended that control samples be fabricated with each research test series and that care be used to compare each set of controls with corresponding test series run at different times.

SCOPE

1.1 This test method covers the determination of the apparent horizontal shear strength of fiber reinforced plastic rods. The specimen is a short beam in the form of lengths of pultruded rods. This test method is applicable to all types of parallel-fiber-reinforced plastic rod samples.

1.2 This test method is primarily used for quality control and specification purposes (see 5.1).

1.3 The values stated in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D4475 −21

Standard Test Method for

Apparent Horizontal Shear Strength of Pultruded Reinforced

1

Plastic Rods By the Short-Beam Method

This standard is issued under the fixed designation D4475; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 This test method covers the determination of the appar- 3.1 Terms used in this standard are defined in accordance

ent horizontal shear strength of fiber reinforced plastic rods. with Terminology D883, unless otherwise specified. For terms

The specimen is a short beam in the form of lengths of relating to precision and bias and associated issues, the terms

pultruded rods. This test method is applicable to all types of used in this standard are defined in accordance with Terminol-

parallel-fiber-reinforced plastic rod samples. ogy E456.

1.2 This test method is primarily used for quality control

4. Summary of Test Method

and specification purposes (see 5.1).

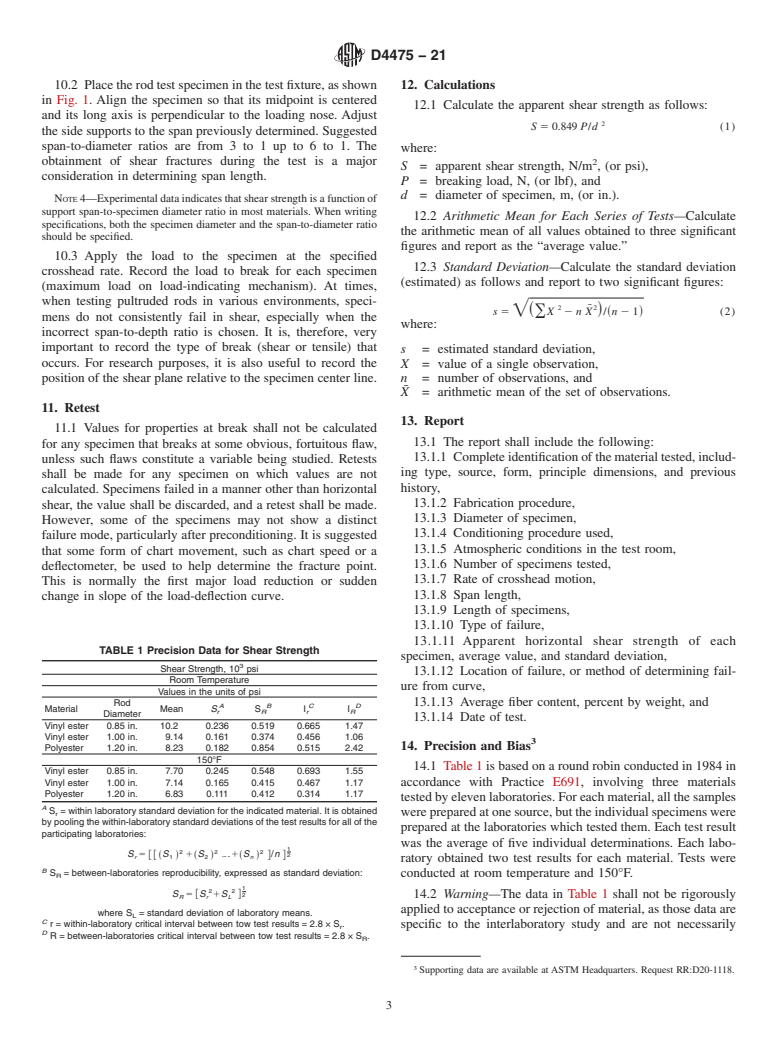

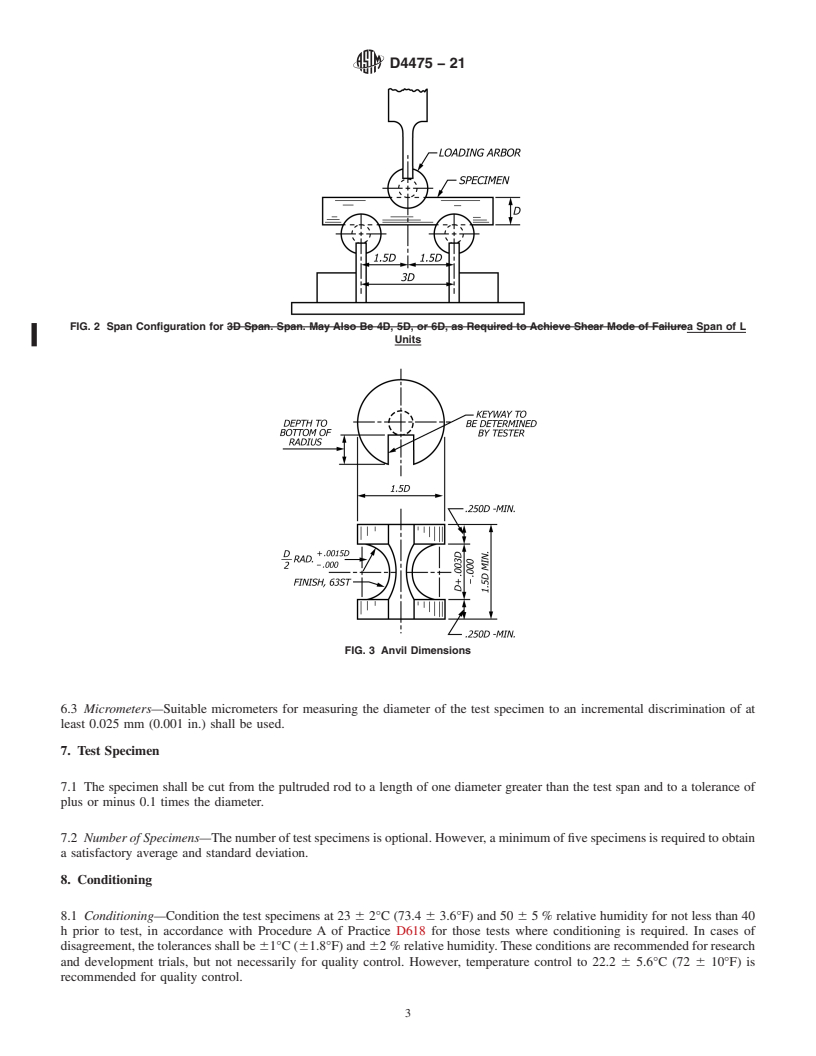

4.1 The horizontal-shear test specimen is center-loaded as

1.3 The values stated in SI units are to be regarded as

shown in Fig. 1. The ends of the specimens rest on two

standard.

supports that allow the specimen to bend, the load being

1.4 This standard does not purport to address all of the

applied by means of a loading nose at midpoint along the

safety concerns, if any, associated with its use. It is the

support span, as shown in Fig. 2.

responsibility of the user of this standard to establish appro-

4.2 The specimen is deflected until a shear failure occurs at

priate safety, health, and environmental practices and deter-

the midplane of the horizontally supported rod.Adjust the span

mine the applicability of regulatory limitations prior to use.

to achieve the required shear mode of failure.

NOTE 1—There is no known ISO equivalent to this standard. NOTE 2—Using a span of three times the diameter of rod typically

causes shear failure. If needed, that span can be adjusted up to six times

1.5 This international standard was developed in accor-

the diameter of the rod.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

5. Significance and Use

Development of International Standards, Guides and Recom-

5.1 Apparent shear strength determined by this test method

mendations issued by the World Trade Organization Technical

is useful for quality control and specification purposes. It is

Barriers to Trade (TBT) Committee.

also applicable to research and development programs con-

cerned with interlaminar-shear strength. The apparent shear

2. Referenced Documents

strength obtained by this test method is not intended for design

2

2.1 ASTM Standards:

purposes, but allowed to be utilized for comparative testing of

D618 Practice for Conditioning Plastics for Testing

composite materials, if all failures are in horizontal shear.

D883 Terminology Relating to Plastics

5.2 It is recommended that control samples be fabricated

E4 Practices for Force Verification of Testing Machines

with each research test series and that care be used to compare

E456 Terminology Relating to Quality and Statistics

each set of controls with corresponding test series run at

E691 Practice for Conducting an Interlaboratory Study to

different times.

Determine the Precision of a Test Method

6. Apparatus

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

6.1 TestingMachine—Aproperly calibrated testing machine

and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermoset-

that can be operated at a constant rate of crosshead motion, and

ting Plastics.

in which the error in the load measuring system shall not

Current edition approved July 1, 2021. Published July 2021. Originally approved

exceed 61 % of the maximum load expected to be measured.

in 1985. Last previous edition approved in 2016 as D4475 - 02(2016). DOI:

10.1520/D4475-21.

The load-indicating mechanism shall be essentially free of

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

inertia lag at the crosshead rate used. The accuracy of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

testing machine shall be verified in accordance with Practices

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. E4.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harb

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4475 − 02 (Reapproved 2016) D4475 − 21

Standard Test Method for

Apparent Horizontal Shear Strength of Pultruded Reinforced

1

Plastic Rods By the Short-Beam Method

This standard is issued under the fixed designation D4475; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers the determination of the apparent horizontal shear strength of fiber reinforced plastic rods. The

specimen is a short beam in the form of lengths of pultruded rods. This test method is applicable to all types of

parallel-fiber-reinforced plastic rod samples.

1.2 This test method is primarily used for quality control and specification purposes (see 4.15.1).

1.3 The values stated in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

E4 Practices for Force Verification of Testing Machines

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Terms used in this standard are defined in accordance with Terminology D883, unless otherwise specified. For terms relating

to precision and bias and associated issues, the terms used in this standard are defined in accordance with Terminology E456.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermosetting

Plastics.

Current edition approved April 1, 2016July 1, 2021. Published April 2016July 2021. Originally approved in 1985. Last previous edition approved in 20082016 as

D4475 - 02(2008).D4475 - 02(2016). DOI: 10.1520/D4475-02R16.10.1520/D4475-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4475 − 21

4. Summary of Test Method

4.1 The horizontal-shear test specimen is center-loaded as shown in Fig. 1. The ends of the specimens rest on two supports that

allow the specimen to bend, the load being applied by means of a loading nose at midpoint along the support span, as shown in

Fig. 2.

4.2 The specimen is deflected until a shear failure occurs at the midplane of the horizontally supported rod. Adjust the span to

achieve the required shear mode of failure.

NOTE 2—Using a span of three times the diameter of rod typically causes shear failure. If needed, that span can be adjusted up to six times the diameter

of the rod.

5. Significance and Use

5.1 Apparent shear strength determined by this test method is useful for quality control and specification purposes. It is also

applicable to research and development programs concerned with interlaminar-shear strength. The apparent shear strength obtained

by this test method cannot be usedis not intended for design purposes, but can allowed to be utilized for comparative testing of

composite materials, if all failures are in horizontal shear.

5.2 It is recommended that control samples be fabricated with each research test series and that care be used to compare each set

of controls with corresponding test series run at different times.

6. Apparatus

6.1 Testing Machine—A properly calibra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.