ASTM B367-13

(Specification)Standard Specification for Titanium and Titanium Alloy Castings

Standard Specification for Titanium and Titanium Alloy Castings

ABSTRACT

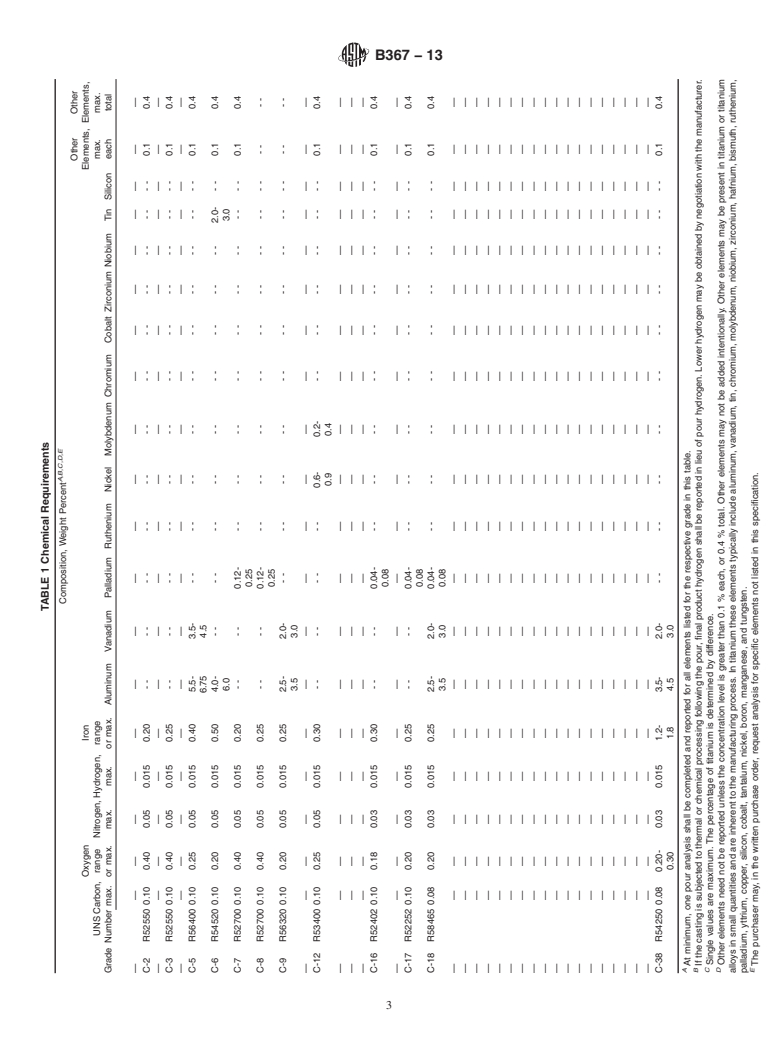

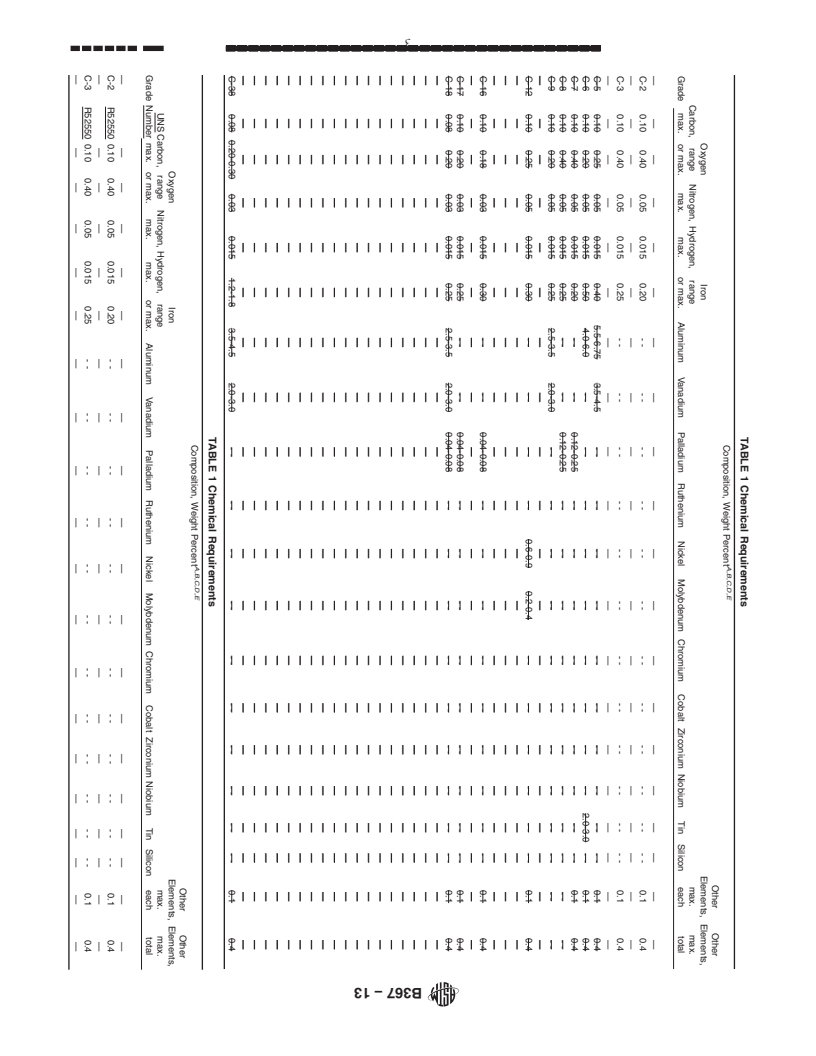

This specification covers the standard requirements for titanium and titanium alloy castings intended for general corrosion resistant and industrial applications. Materials for this specification shall be melted by conventional processes used for reactive metals such as consumable electrode and induction-slag, plasma arc, induction-skull, and electron beam melting processes. The materials shall undergo chemical, pour, and product analysis to determine the chemical composition which shall conform to the requirements for nitrogen, carbon, hydrogen, iron, oxygen, aluminum, vanadium, tin, ruthenium, palladium, cobalt, molybdenum, chromium, nickel, niobium, zirconium, silicon, and titanium. All castings shall be supplied in the as-cast condition except when post-weld heat treatment is required wherein it shall consist of a stress relief performed at certain temperatures. The surface of the castings shall be free of adhering mold material, scale, cracks, and hot tears as determined by visual inspection.

SCOPE

1.1 This specification covers titanium and titanium alloy castings intended for general corrosion resistant and industrial applications. as follows:

1.1.1 Grade C-2—UNS R52550. Unalloyed titanium,

1.1.2 Grade C-3—UNS R52550. Unalloyed titanium,

1.1.3 Grade C-5—UNS R56400. Titanium alloy (6 % aluminum, 4 % vanadium),

1.1.4 Grade C-7—UNS R52700. Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.5 Grade C-8—UNS R52700. Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.6 Grade C-9—UNS R56320. Titanium alloy (3 % aluminum, 2.5 % vanadium),

1.1.7 Grade C-12—UNS R53400. Titanium alloy (0.3 % molybdenum, 0.8 % nickel),

1.1.8 Grade C-16—UNS R52402. Unalloyed titanium plus 0.04 to 0.08 % palladium,

1.1.9 Grade C-17—UNS R52252. Unalloyed titanium plus 0.04 to 0.08 % palladium, and

1.1.10 Grade C-38—UNS R54250. Titanium alloy (4 % aluminum, 2.5 % vanadium, 1.5 % iron).

1.2 This specification is intended for use of purchasers and/or producers of reactive metal castings for defining the requirements and assuring the properties of castings for unique corrosion-resistant applications, that is, not for commodity items which must meet all potential purchasers' requirements.

1.2.1 Users are advised to use the specification as a basis for obtaining castings which will meet minimum acceptance requirements established and revised by consensus of the members of the committee.

1.2.2 User requirements considered more stringent may be met by the addition to the purchase order of one or more supplementary requirements, which may include, but are not limited to, those listed in Sections S1 through S8.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B367 −13

Standard Specification for

1

Titanium and Titanium Alloy Castings

This standard is issued under the fixed designation B367; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

1.1 This specification covers titanium and titanium alloy

conversions to SI units that are provided for information only

castings intended for general corrosion resistant and industrial

and are not considered standard.

applications. as follows:

1.1.1 Grade C-2—UNS R52550. Unalloyed titanium,

2. Referenced Documents

1.1.2 Grade C-3—UNS R52550. Unalloyed titanium,

2

2.1 ASTM Standards:

1.1.3 Grade C-5—UNS R56400. Titanium alloy (6 %

A802/A802M Practice for Steel Castings, Surface Accep-

aluminum, 4 % vanadium),

tance Standards, Visual Examination

1.1.4 Grade C-7—UNS R52700. Unalloyed titanium plus

E8 Test Methods for Tension Testing of Metallic Materials

0.12 to 0.25 % palladium,

E10 Test Method for Brinell Hardness of Metallic Materials

1.1.5 Grade C-8—UNS R52700. Unalloyed titanium plus

E18 Test Methods for Rockwell Hardness of Metallic Ma-

0.12 to 0.25 % palladium,

terials

1.1.6 Grade C-9—UNS R56320. Titanium alloy (3 %

E29 Practice for Using Significant Digits in Test Data to

aluminum, 2.5 % vanadium),

Determine Conformance with Specifications

1.1.7 Grade C-12—UNS R53400. Titanium alloy (0.3 %

E94 Guide for Radiographic Examination

molybdenum, 0.8 % nickel),

E142 Method for Controlling Quality of Radiographic Test-

1.1.8 Grade C-16—UNS R52402. Unalloyed titanium plus

3

ing (Withdrawn 2000)

0.04 to 0.08 % palladium,

E165 Practice for Liquid Penetrant Examination for General

1.1.9 Grade C-17—UNS R52252. Unalloyed titanium plus

Industry

0.04 to 0.08 % palladium, and

E446 Reference Radiographs for Steel Castings Up to 2 in.

1.1.10 Grade C-38—UNS R54250. Titanium alloy (4 %

(50.8 mm) in Thickness

aluminum, 2.5 % vanadium, 1.5 % iron).

E539 TestMethodforAnalysisofTitaniumAlloysbyX-Ray

1.2 This specification is intended for use of purchasers

Fluorescence Spectrometry

and/or producers of reactive metal castings for defining the

E1409 Test Method for Determination of Oxygen and Nitro-

requirements and assuring the properties of castings for unique

gen in Titanium and Titanium Alloys by the Inert Gas

corrosion-resistant applications, that is, not for commodity

Fusion Technique

items which must meet all potential purchasers’ requirements.

E1447 Test Method for Determination of Hydrogen in Tita-

1.2.1 Usersareadvisedtousethespecificationasabasisfor

nium and Titanium Alloys by Inert Gas Fusion Thermal

obtaining castings which will meet minimum acceptance

Conductivity/Infrared Detection Method

requirements established and revised by consensus of the

E1941 Test Method for Determination of Carbon in Refrac-

members of the committee.

tory and Reactive Metals andTheirAlloys by Combustion

1.2.2 User requirements considered more stringent may be

Analysis

met by the addition to the purchase order of one or more

E2371 Test Method for Analysis of Titanium and Titanium

supplementary requirements, which may include, but are not

Alloys by Direct Current Plasma and Inductively Coupled

limited to, those listed in Sections S1 through S8.

Plasma Atomic Emission Spectrometry (Performance-

Based Test Methodology)

1 2

This specification is under the jurisdiction of ASTM Committee B10 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Reactive and Refractory Metals and Alloys and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee B10.01 on Titanium. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2013. Published August 2013. Originally the ASTM website.

3

approved in 1961. Last previous edition approved in 20098 as B367 – 09. DOI: The last approved version of this historical standard is referenced on

10.1520/B0367-13. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B367−13

E2626 Guide for Spectrometric Analysis of Reactive and 6.4 Sampling—Samples for chemical analysis may be made

Refractory Metals by the purchaser on a representative casting from any lot. Due

to the possibility

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B367 − 09 B367 − 13

Standard Specification for

1

Titanium and Titanium Alloy Castings

This standard is issued under the fixed designation B367; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers titanium and titanium alloy castings intended for general corrosion resistant and industrial

applications. as follows:

1.1.1 Grade C-2—UNS R52550. Unalloyed titanium,

1.1.2 Grade C-3—UNS R52550. Unalloyed titanium,

1.1.3 Grade C-5—UNS R56400. Titanium alloy (6 % aluminum, 4 % vanadium),

1.1.4 Grade C-7—UNS R52700. Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.5 Grade C-8—UNS R52700. Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.6 Grade C-9—UNS R56320. Titanium alloy (3 % aluminum, 2.5 % vanadium),

1.1.7 Grade C-12—UNS R53400. Titanium alloy (0.3 % molybdenum, 0.8 % nickel),

1.1.8 Grade C-16—UNS R52402. Unalloyed titanium plus 0.04 to 0.08 % palladium,

1.1.9 Grade C-17—UNS R52252. Unalloyed titanium plus 0.04 to 0.08 % palladium, and

1.1.10 Grade C-38—UNS R54250. Titanium alloy (4 % aluminum, 2.5 % vanadium, 1.5 % iron).

1.2 This specification is intended for use of purchasers and/or producers of reactive metal castings for defining the requirements

and assuring the properties of castings for unique corrosion-resistant applications, that is, not for commodity items which must

meet all potential purchasers’ requirements.

1.2.1 Users are advised to use the specification as a basis for obtaining castings which will meet minimum acceptance

requirements established and revised by consensus of the members of the committee.

1.2.2 User requirements considered more stringent may be met by the addition to the purchase order of one or more

supplementary requirements, which may include, but are not limited to, those listed in Sections S1 through S8.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A802/A802M Practice for Steel Castings, Surface Acceptance Standards, Visual Examination

E8 Test Methods for Tension Testing of Metallic Materials

E10 Test Method for Brinell Hardness of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E94 Guide for Radiographic Examination

3

E142 Method for Controlling Quality of Radiographic Testing (Withdrawn 2000)

E165 Practice for Liquid Penetrant Examination for General Industry

E446 Reference Radiographs for Steel Castings Up to 2 in. (50.8 mm) in Thickness

E539 Test Method for Analysis of Titanium Alloys by X-Ray Fluorescence Spectrometry

1

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.01 on Titanium.

Current edition approved May 1, 2009July 1, 2013. Published June 2009August 2013. Originally approved in 1961. Last previous edition approved in 200820098 as

B367 – 08b.B367 – 09. DOI: 10.1520/B0367-09.10.1520/B0367-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B367 − 13

E1409 Test Method for Determination of Oxygen and Nitrogen in Titanium and Titanium Alloys by the Inert Gas Fusion

Technique

E1447 Test Method for Determination of Hydrogen in Titanium and Titanium Alloys by Inert Gas Fusion Thermal

Conductivity/Infrared Detection Method

E1941 Test Method for Determination of Carbon in Refractory and Reactive Metals and Their Alloys by Combustion Analysis

E2371 Test Method for Analysis of Titanium

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.