ASTM C1574-04

(Guide)Standard Guide for Determining Blown Density of Pneumatically Applied Loose-Fill Mineral Fiber Thermal Insulation

Standard Guide for Determining Blown Density of Pneumatically Applied Loose-Fill Mineral Fiber Thermal Insulation

SIGNIFICANCE AND USE

Blown density is used to develop loose-fill coverage charts. Data for blown density vs thickness is used in the develpoment of a variable blown density presentation for loose-fill insulation.

Thermal resistance (and conductivity) of loose-fill mineral fiber insulation depends on density, thickness. The resulting blown density data is useful in developing an expression for apparent thermal conductivity as a function of density. This will in turn aid the manufacturer in developing coverage information for packages of loose-fill insulation.

The blown density obtained in this method is for the thickness of the test only. The relationship of blown density with thickness can be determined by repeating the procedures outlined here using different thicknesses.

These procedures are not the same as the test method described in Test Method C1374. Depending on the test conditions utilized, the blown density may, or may not, represent the installed density values obtained by using Test Method C 1374.

This guide can be used to develop appropriate blowing machine settings to achieve a target blown density at a predetermined thickness.

SCOPE

1.1 This guide describes two alternate procedures for determining blown density at a predetermined thickness or a range of thicknesses expected in field applications of mineral fiber loose-fill insulation.

1.2 This guide involves blowing a sample of loose-fill insulation into a test frame of known volume, measuring the weight of the insulation captured and calculating the blown density.

1.3 This guide is intended for pneumatically-applied loose-fill mineral fiber insulation designed for use in horizontal open attic spaces.

1.4 This guide is intended for product design and product auditing by manufacturers of loose-fill insulation. This guide is adaptable as a plant quality control procedure.

1.5 This guide does not predict the aged density of the mineral fiber loose-fill insulation.

1.6 This standard does not purport to address all the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

1.7 The values stated in inch-pound units are to be regarded as the standard. The SI unit values given in parentheses are approximate and are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1574–04

Standard Guide for

Determining Blown Density of Pneumatically Applied Loose-

Fill Mineral Fiber Thermal Insulation

This standard is issued under the fixed designation C 1574; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This guide describes two alternate procedures for deter- 3.1 Definitions—Terminology C 168 is applicable to the

mining blown density at a predetermined thickness or a range terms used in this standard.

of thicknesses expected in field applications of mineral fiber 3.2 Definitions of Terms Specific to This Standard:

loose-fill insulation. 3.2.1 Variable blown density—change in density exhibited

1.2 This guide involves blowing a sample of loose-fill by loose-fill insulation as a function of thickness.

insulation into a test frame of known volume, measuring the 3.2.1.1 Discussion—Someloose-fillinsulationmaterialsex-

weight of the insulation captured and calculating the blown hibit an increase in blown density when thickness increases.

density. Also, the original thickness may or may not decrease with time

1.3 This guide is intended for pneumatically-applied loose- resulting in the same or somewhat higher densities. This

fill mineral fiber insulation designed for use in horizontal open thickness vs density relationship should be considered when

attic spaces. developing coverage information for the bag label.

1.4 This guide is intended for product design and product

4. Significance and Use

auditing by manufacturers of loose-fill insulation.This guide is

4.1 Blown density is used to develop loose-fill coverage

adaptable as a plant quality control procedure.

1.5 This guide does not predict the aged density of the charts. Data for blown density vs thickness is used in the

develpoment of a variable blown density presentation for

mineral fiber loose-fill insulation.

1.6 This standard does not purport to address all the safety loose-fill insulation.

4.2 Thermal resistance (and conductivity) of loose-fill min-

concerns, if any, associated with its use. It is the responsibility

eral fiber insulation depends on density, thickness. The result-

of the user of this standard to establish appropriate safety and

health practices and to determine the applicability of regula- ing blown density data is useful in developing an expression

for apparent thermal conductivity as a function of density.This

tory limitations prior to use.

1.7 The values stated in inch-pound units are to be regarded will in turn aid the manufacturer in developing coverage

information for packages of loose-fill insulation.

as the standard. The SI unit values given in parentheses are

approximate and are provided for information only. 4.3 The blown density obtained in this method is for the

thickness of the test only. The relationship of blown density

2. Referenced Documents

with thickness can be determined by repeating the procedures

2.1 ASTM Standards: outlined here using different thicknesses.

C 168 Terminology Relating to Thermal Insulation 4.4 These procedures are not the same as the test method

C 1374 Test Method for Determination of Installed Thick- described in Test Method C1374. Depending on the test

ness of PneumaticallyApplied Loose-Fill Building Insula- conditions utilized, the blown density may, or may not,

tion represent the installed density values obtained by using Test

Method C 1374.

4.5 This guide can be used to develop appropriate blowing

This guide is under the jurisdiction of ASTM Committee C16 on Thermal

machine settings to achieve a target blown density at a

Insulation and is the direct responsibility of Subcommittee C16.32 on Mechanical

predetermined thickness.

Properties.

Current edition approved Sept. 1, 2004. Published October 2004.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5. Summary of Guide

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 A standardized test chamber of fixed volume is used to

Standards volume information, refer to the standard’s Document Summary page on

collect the pneumatically-applied insulation.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1574–04

5.2 Therearetwotypesoftestchambersthatareincommon eight 90-degree bends and no bends may be less than 4 ft (1.2

use: m) radius. After 50 h of usage, the last 50 ft (15 m) section at

5.2.1 Procedure A uses a moveable test box having a the discharge end shall be discarded. A new 50 ft (15 m) shall

minimum volume of 20 cubic feet (0.56 m ) . The blown be attached directly to the blowing wool machine. The remain-

material is weighed while still in the test box and the density is ing 100 ft (30 m) shall then be attached to the end of the new

calculated. hose. This creates a hose replacement rotation.

5.2.2 Procedure B uses a fixed frame assembly in a test 6.3 Scales—platform scales or load cells accurate to 1 %.

room or blowing shack to simulate an attic application. The 6.4 Specimen Preparation Room—an enclosed area where

blown material is removed from the test frame and weighed the test material is to be blown into the test chamber. This area

separately to calculate the density. is required to protect the blowing operation from wind or

5.3 After the insulation is blown into the chamber, the strong air currents. Room geometry should provide adequate

weight of the insulation is determined. clearance around the test chamber and large enough not to

5.4 From the volume of the sample and its weight, the influence the blowing stream from the hose.

blown density is determined. 6.5 Hose Nozzle Stand—a hose stand on swivel casters that

holds the blowing hose at a fixed height of 36 to 48 in. (0.9 to

6. Apparatus

1.2 m) and is on a swivel that allows the operator to swing the

6.1 Blowing Machine—a commercial pneumatic blowing hose horizontally back and forth while slowly moving back-

machine, designed for handling mineral fiber loose-fill insula- wards and forwards to fill the test chamber. A typical hose

tion materials, shall be used for blowing the insulation into the nozzle stand is shown in Fig. 1. Use of the hose stand is

test chamber.This machine shall have throughput and handling optional.

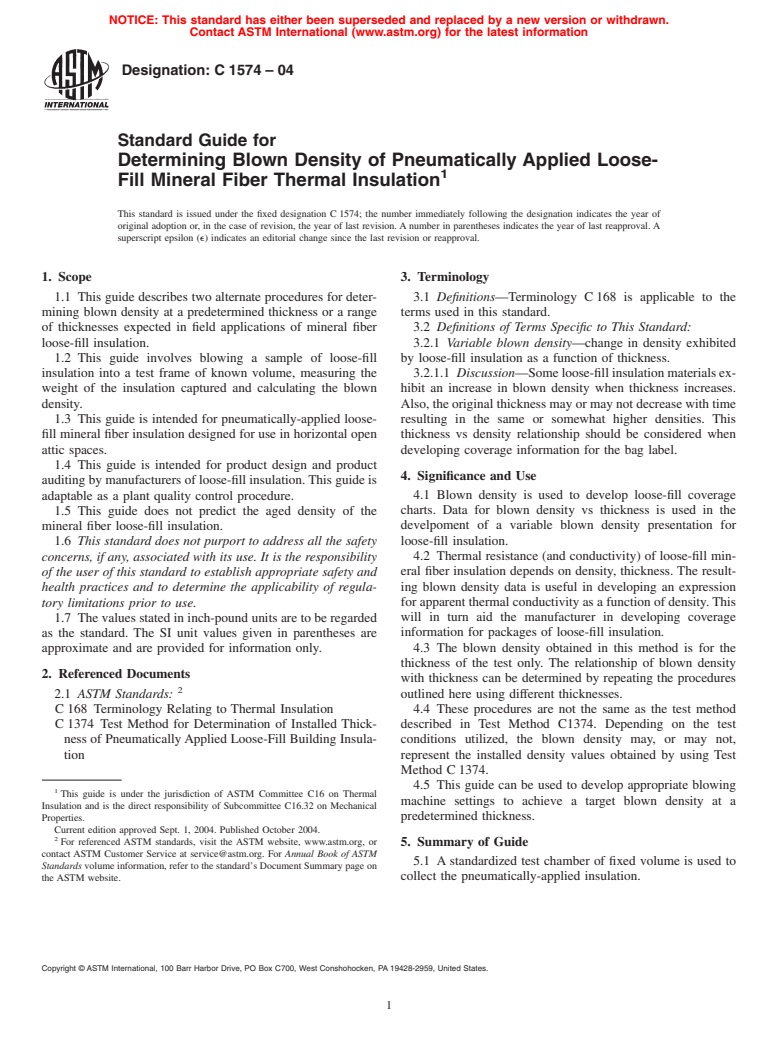

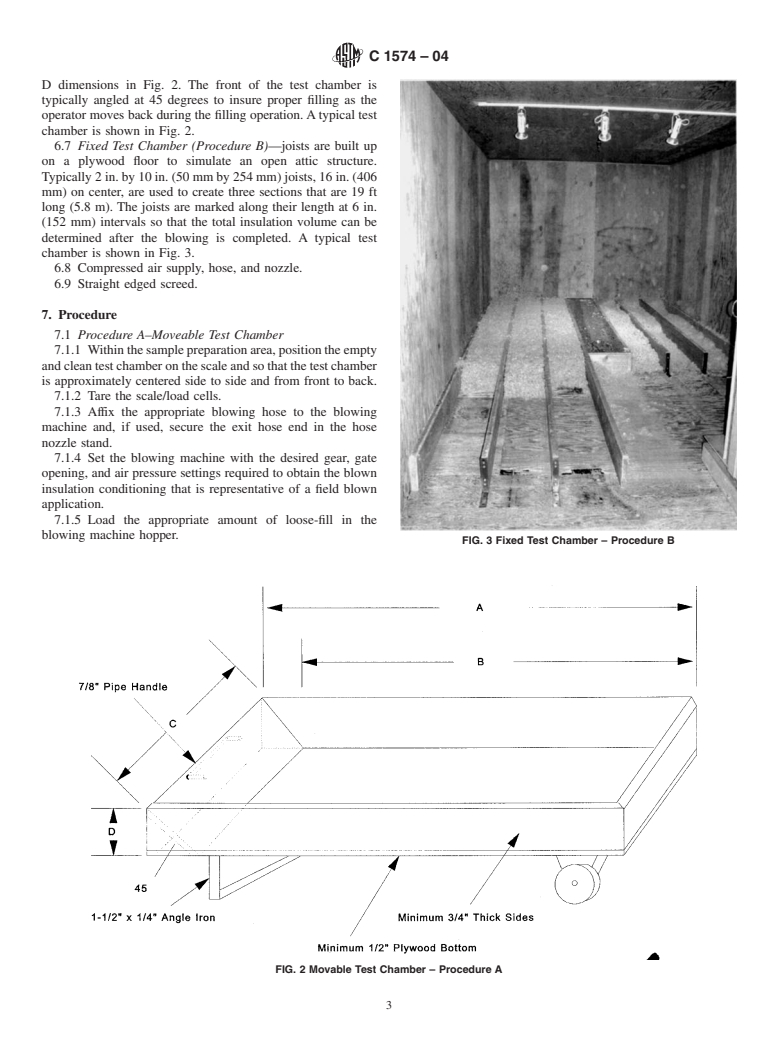

characteristics similar to that used in field applications. 6.6 Moveable Test Chamber (Procedure A)—a wooden

6.2 Blowing Hose—the machine shall utilize three (3) 50 ft open container to collect the insulation. The chamber shall

3 3

(15 m) sections to make up 150 ft (46 m) of a minimum of 3 have a minimum capacity of 20 ft (0.57 m ) and have the

in.(76mm)diameterflexiblecorrugatedblowinghose.Atleast minimuminsidedimensionsof11in.highby28in.wideby80

100 ft. (30 m) of the hose shall be elevated between 10 and 20 in. long (279 mm by 711 mm by 2032 mm). Note that these

ft (3 and 6 m) above the blowing machine to simulate a typical minimum dimensions by themselves do not produce the

installation configuration. The hose shall have no more than required volume but simply represent the minimum B, C, and

FIG. 1 Hose Nozzle Stand

C1574–04

D dimensions in Fig. 2. The front of the test chamber is

typically angled at 45 degrees to insure

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.