ASTM C1274-10

(Test Method)Standard Test Method for Advanced Ceramic Specific Surface Area by Physical Adsorption

Standard Test Method for Advanced Ceramic Specific Surface Area by Physical Adsorption

SIGNIFICANCE AND USE

Advanced ceramic powders and porous ceramic bodies often have a very fine particulate morphology and structure that are marked by high surface-to-volume (S-V) ratios. These ceramics with high S-V ratios commonly exhibit enhanced chemical reactivity and lower sintering temperatures. Results of many intermediate and final ceramic processing steps are controlled by, or related to, the specific surface area of the advanced ceramic. The functionality of ceramic adsorbents, separation filters and membranes, catalysts, chromatographic carriers, coatings, and pigments often depends on the amount and distribution of the porosity and its resulting effect on the specific surface area.

This test method determines the specific surface area of advanced ceramic powders and porous bodies. Both suppliers and users of advanced ceramics can use knowledge of the surface area of these ceramics for material development and comparison, product characterization, design data, quality control, and engineering/ production specifications.

SCOPE

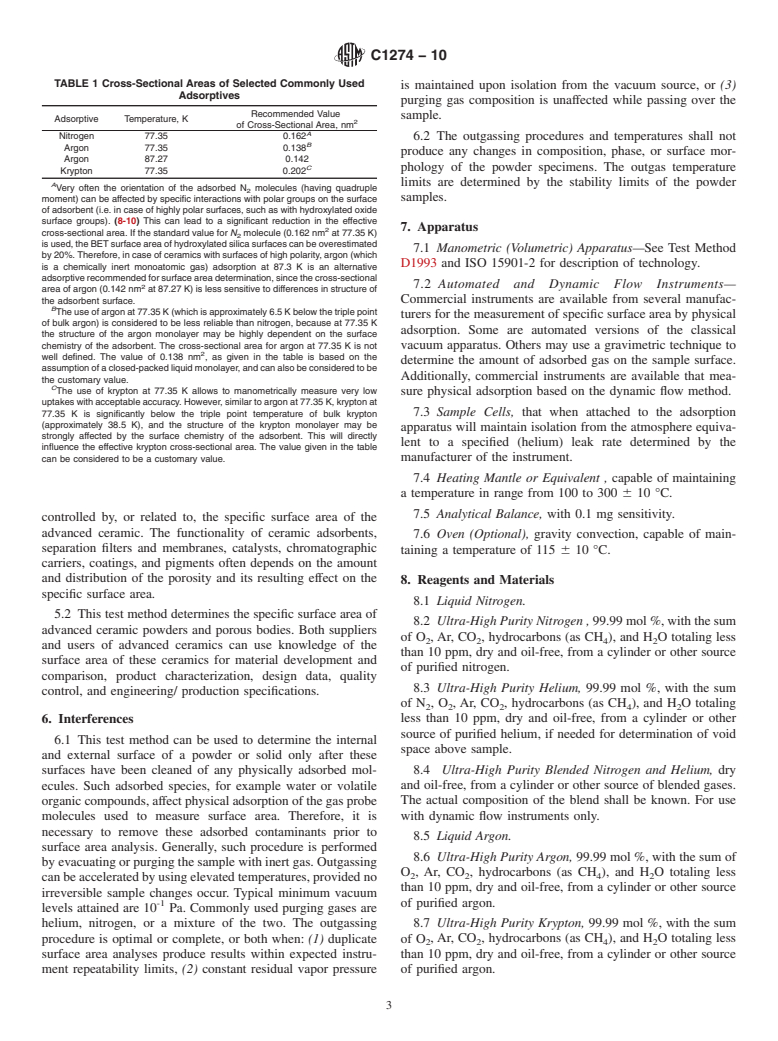

1.1 This test method covers the determination of the surface area of advanced ceramic materials (in a solid form) based on multilayer physisorption of gas in accordance with the method of Brunauer, Emmett, and Teller (BET) (1) and based on IUPAC Recommendations (1984 and 1994) (2) and (3). This test method specifies general procedures that are applicable to many commercial physical adsorption instruments. This test method provides specific sample outgassing procedures for selected common ceramic materials, including: amorphous and crystalline silicas, TiO2, kaolin, silicon nitride, silicon carbide, zirconium oxide, etc. The multipoint BET (1) equation along with the single point approximation of the BET equation are the basis for all calculations. This test method is appropriate for measuring surface areas of advanced ceramic powders down to at least 0.05 m2 (if in addition to nitrogen, krypton at 77.35 K is utilized as an adsorptive).

1.2 This test method does not include all existing procedures appropriate for outgassing of advanced ceramic materials. However, it provides a comprehensive summary of procedures recommended in the literature for selected types of ceramic materials. The investigator shall determine the appropriateness of listed procedures.

1.3 The values stated in SI units are to be regarded as standard. State all numerical values in terms of SI units unless specific instrumentation software reports surface area using alternate units. In this case, provide both reported and equivalent SI units in the final written report. It is commonly accepted and customary (in physical adsorption and related fields) to report the (specific) surface area of solids as m2/g, and, as a convention, many instruments (as well as certificates of reference materials) report surface area as m2 g-1, instead of using SI units (m2 kg-1).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1274 −10

StandardTest Method for

Advanced Ceramic Specific Surface Area by Physical

1

Adsorption

This standard is issued under the fixed designation C1274; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of the surface

responsibility of the user of this standard to establish appro-

area of advanced ceramic materials (in a solid form) based on

priate safety and health practices and determine the applica-

multilayer physisorption of gas in accordance with the method

2 bility of regulatory limitations prior to use.

of Brunauer, Emmett, and Teller (BET) (1) and based on

IUPAC Recommendations (1984 and 1994) (2) and (3). This

2. Referenced Documents

test method specifies general procedures that are applicable to

3

many commercial physical adsorption instruments. This test 2.1 ASTM Standards:

method provides specific sample outgassing procedures for D1993 Test Method for Precipitated Silica-Surface Area by

selected common ceramic materials, including: amorphous and Multipoint BET Nitrogen Adsorption

crystalline silicas, TiO , kaolin, silicon nitride, silicon carbide, E177 Practice for Use of the Terms Precision and Bias in

2

zirconium oxide, etc. The multipoint BET (1) equation along ASTM Test Methods

4

with the single point approximation of the BET equation are

2.2 ISO Standards:

thebasisforallcalculations.Thistestmethodisappropriatefor

ISO 9277 Determination of specific surface area of solids by

measuring surface areas of advanced ceramic powders down to

gas adsorption using the BET method

2

at least 0.05 m (if in addition to nitrogen, krypton at 77.35 K

ISO 15901-2:2006 Pore size distribution and porosity of

is utilized as an adsorptive).

solid materials by mercury porosimetry and gas adsorp-

tion-Part2Analysisofmesoporesandmacroporesbygas

1.2 This test method does not include all existing proce-

adsorption

dures appropriate for outgassing of advanced ceramic materi-

ISO 8213:1986 Chemical products for industrial use -

als. However, it provides a comprehensive summary of proce-

Sampling techniques-Solid chemical products in the form

dures recommended in the literature for selected types of

of particles varying from powders to coarse lumps

ceramic materials. The investigator shall determine the appro-

ISO 18757 Fine ceramics (advanced ceramics, advanced

priateness of listed procedures.

technical ceramics) – Determination of specific surface

1.3 The values stated in SI units are to be regarded as

area of ceramic powders by gas adsorption using the BET

standard. State all numerical values in terms of SI units unless

method

specific instrumentation software reports surface area using

alternate units. In this case, provide both reported and equiva-

3. Terminology

lentSIunitsinthefinalwrittenreport.Itiscommonlyaccepted

5

3.1 Definitions:

and customary (in physical adsorption and related fields) to

2

3.1.1 adsorbate, n—material that has been retained by the

report the (specific) surface area of solids as m /g, and, as a

process of adsorption.

convention, many instruments (as well as certificates of refer-

2 -1

ence materials) report surface area as m g , instead of using

3.1.2 adsorbent, n—any solid having the ability to concen-

2 -1

SI units (m kg ).

trate significant quantities of other substances on its surface.

1 3

This test method is under the jurisdiction of ASTM Committee C28 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Advanced Ceramics and is the direct responsibility of Subcommittee C28.03 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Physical Properties and Non-Destructive Evaluation. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2010. Published February 2011. Originally the ASTM website.

4

approved in 1994. Last previous edition approved in 2006 as C1274 – 00 (2006). Available from International Organization for Standardization (ISO), 1, ch. de

DOI: 10.1520/C1274-10. la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

2

The boldface numbers in parenthesis refer to the list of references at the end of www.iso.ch.

5

this standard. Compilation of ASTM Standard Terminology, 8th ed, 1994.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

-----------

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1274–00 (Reapproved 2006) Designation: C1274 – 10

Standard Test Method for

Advanced Ceramic Specific Surface Area by Physical

1

Adsorption

This standard is issued under the fixed designation C1274; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This test method covers determination of surface area of advanced ceramic materials. This test method specifies general

procedures that are applicable to many commercial physical adsorption instruments. This test method provides specific sample

outgassing procedures for listed materials, including silicon carbide, silicon nitride, and zirconium oxide. It includes additional

general outgassing instructions for other advanced ceramic materials. The multipoint equation of Brunauer, Emmett and Teller*

1.1 This test method covers the determination of the surface area of advanced ceramic materials (in a solid form) based on

2

multilayer physisorption of gas in accordance with the method of Brunauer, Emmett, and Teller (BET) (1) (BET) along with the

single point approximation of the BET equation form the basis for all calculations.

1.2This test method does not include all existing procedures appropriate for outgassing advanced ceramic materials. The

included procedures provided acceptable results for samples analyzed during round robin testing.The investigator must determine

the appropriateness of listed procedures.

1.3This test method uses SI units as standard. State all numerical values in terms of SI units unless specific instrumentation

software reports surface area using alternate units. In this case, present both reported and equivalent SI units in the final written

and based on IUPAC Recommendations (1984 and 1994) (2) and (3). This test method specifies general

report. Many instruments report surface area as m

procedures that are applicable to many commercial physical adsorption instruments. This test method provides specific sample outgassing procedures for selected common

, kaolin, silicon nitride, silicon carbide, zirconium

2

ceramic materials, including: amorphous and crystalline silicas, TiO/g, instead of using correct SI units (m

oxide, etc. The multipoint BET (1) equation along with the single point approximation of the BET equation are the basis for all calculations. This test method is appropriate

2

for measuring surface areas of advanced ceramic powders down to at least 0.05 m/kg). (if in addition to nitrogen, krypton at 77.35 K is utilized as

an adsorptive).

1.2 This test method does not include all existing procedures appropriate for outgassing of advanced ceramic materials.

However, it provides a comprehensive summary of procedures recommended in the literature for selected types of ceramic

materials. The investigator shall determine the appropriateness of listed procedures.

1.3 The values stated in SI units are to be regarded as standard. State all numerical values in terms of SI units unless specific

instrumentation software reports surface area using alternate units. In this case, provide both reported and equivalent SI units in

the final written report. It is commonly accepted and customary (in physical adsorption and related fields) to report the (specific)

2

surfaceareaofsolidsasm /g,and,asaconvention,manyinstruments(aswellascertificatesofreferencematerials)reportsurface

2 -1 2 -1

area as m g , instead of using SI units (m kg ).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

D1993 Test Method for Precipitated Silica-Surface Area by Multipoint BET Nitrogen Adsorption

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC28onAdvancedCeramicsandisthedirectresponsibilityofSubcommitteeC28.03onPhysicalProperties

and Performance.

Current edition approved Jan. 1, 2006. Published January 2006. Originally approved in 1994. Last previous edition approved in 2000 as C1274–00. DOI:

10.1520/C1274-00R06.on Physical Properties and Non-Destructive Evaluation.

Current edition approved Dec. 1, 2010. Published February 201

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.