ASTM A494/A494M-17a

(Specification)Standard Specification for Castings, Nickel and Nickel Alloy

Standard Specification for Castings, Nickel and Nickel Alloy

ABSTRACT

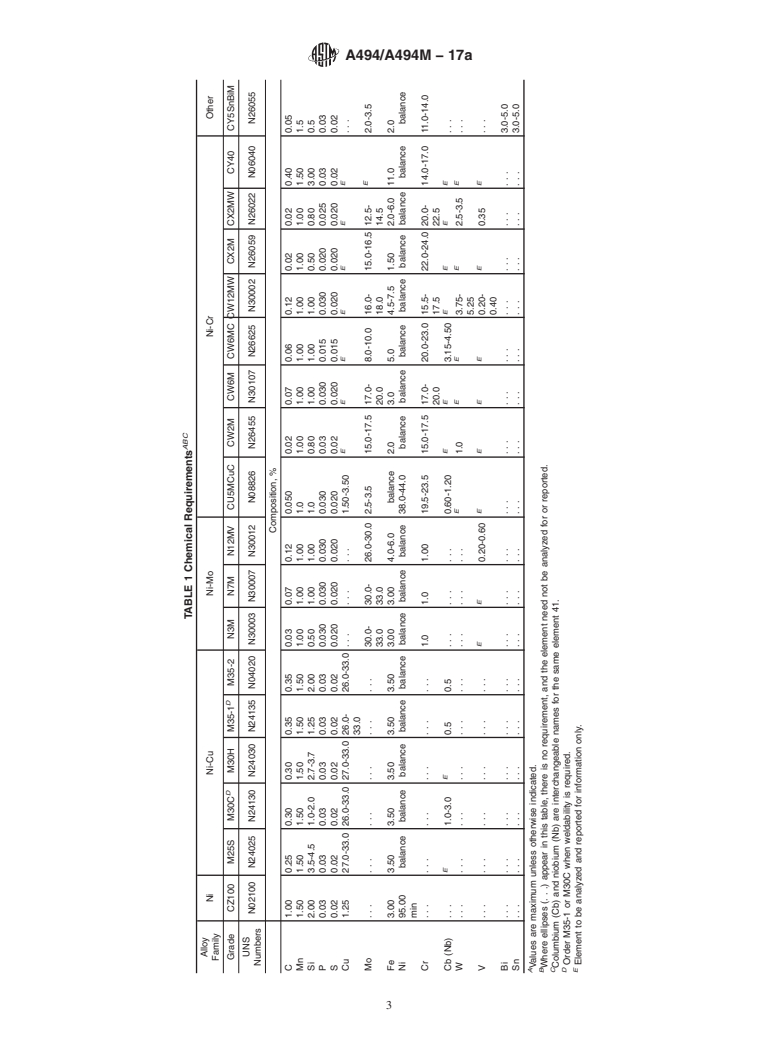

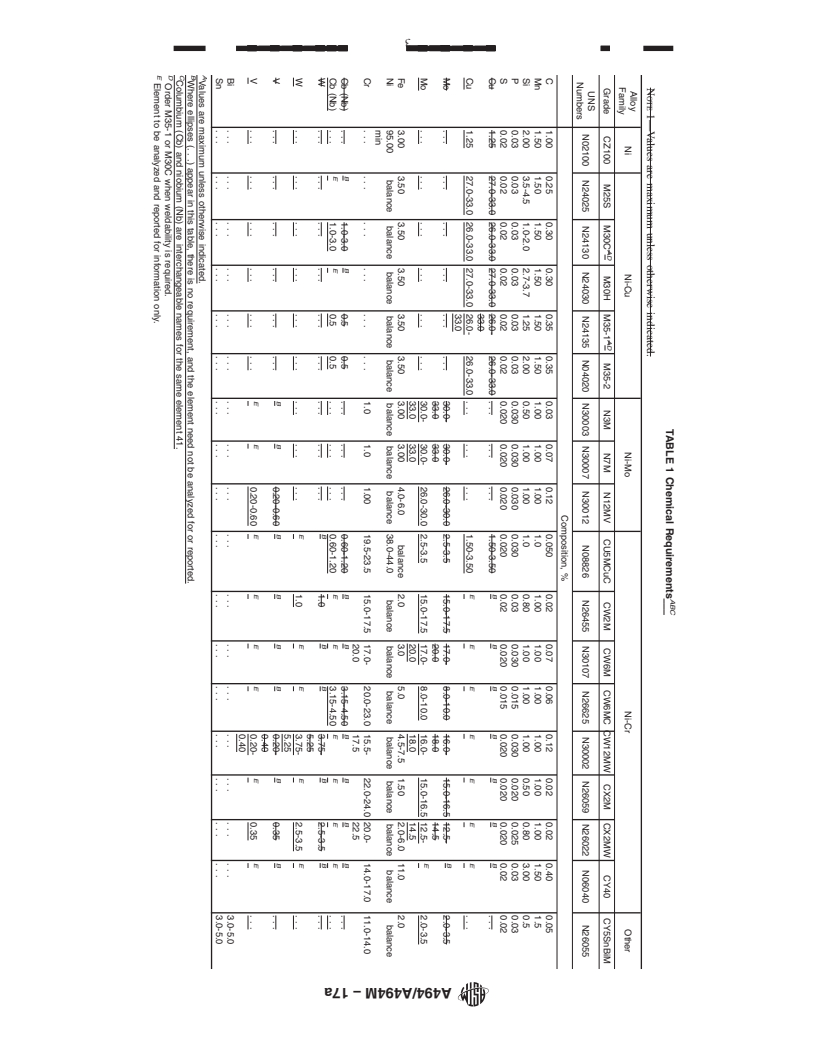

This specification covers nickel, nickel-copper, nickel-copper-silicon, nickel-molybdenum, nickel-chromium, and nickel-molybdenum-chromium alloy castings for corrosion resistant service. The castings shall be heat treated. When Class 1 is specified, grades CY40 and M25S shall be supplied in the as-cast condition. When Class 2 is specified, grades CY40 and M25S shall be supplied in the solution treated condition. When Class 3 is specified, grade M25S shall be supplied in the age-hardened condition. The chemical composition requirements of the alloys are presented. The tensile property requirements including the heat treatment procedure for the castings are presented in detail. It is required that one tension test shall be made from each master heat except for grades M25S and CY5SnBiM when the master heat is used to pour the castings. One tension test shall be made from each melt except for grades M25S and CY5SnBiM. Test results shall conform to the specified tensile requirements.

SCOPE

1.1 This specification covers nickel, nickel-copper, nickel-copper-silicon, nickel-molybdenum, nickel-chromium, and nickel-molybdenum-chromium alloy castings for corrosion-resistant service.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A494/A494M −17a

Standard Specification for

1

Castings, Nickel and Nickel Alloy

This standard is issued under the fixed designationA494/A494M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* E8Test Methods for Tension Testing of Metallic Materials

E29Practice for Using Significant Digits in Test Data to

1.1 This specification covers nickel, nickel-copper, nickel-

Determine Conformance with Specifications

copper-silicon, nickel-molybdenum, nickel-chromium, and

E30TestMethodsforChemicalAnalysisofSteel,CastIron,

nickel-molybdenum-chromium alloy castings for corrosion-

3

Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

resistant service.

E38Methods for Chemical Analysis of Nickel-Chromium

1.2 The values stated in either SI units or inch-pound units 3

and Nickel-Chromium-Iron Alloys (Withdrawn 1989)

are to be regarded separately as standard. The values stated in

E76Test Methods for Chemical Analysis of Nickel-Copper

each system may not be exact equivalents; therefore, each 3

Alloys (Withdrawn 2003)

system shall be used independently of the other. Combining

E354 Test Methods for Chemical Analysis of High-

values from the two systems may result in nonconformance

Temperature,Electrical,Magnetic,andOtherSimilarIron,

with the standard.

Nickel, and Cobalt Alloys

1.3 This international standard was developed in accor-

3. Terminology

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3.1 Definitions:

Development of International Standards, Guides and Recom-

3.1.1 master heat—a single furnace charge of refined alloy,

mendations issued by the World Trade Organization Technical

whichmayeitherbepoureddirectlyintocastingsorintoremelt

Barriers to Trade (TBT) Committee.

alloy for individual melts.

3.1.2 melts—a single furnace charge poured into castings.

2. Referenced Documents

When master heats are used to prepare melts, a melt analysis

2

2.1 ASTM Standards:

shall be reported.

A370Test Methods and Definitions for Mechanical Testing

of Steel Products

4. General Conditions for Delivery

A488/A488MPractice for Steel Castings, Welding, Qualifi-

4.1 Except for investment castings, castings furnished to

cations of Procedures and Personnel

this specification shall conform to the requirements of Speci-

A732/A732MSpecification for Castings, Investment, Car-

fication A781/A781M, including any supplementary require-

bon and Low Alloy Steel for General Application, and

ments that are indicated on the purchase order. Failure to

Cobalt Alloy for High Strength at Elevated Temperatures

comply with the general requirements of Specification A781/

A781/A781MSpecification for Castings, Steel and Alloy,

A781M constitutes nonconformance with this specification. In

Common Requirements, for General Industrial Use

case of conflict between the requirements of this specification

A957/A957MSpecification for Investment Castings, Steel

and Specification A781/A781M, this specification shall pre-

andAlloy, Common Requirements, for General Industrial

vail.

Use

4.2 Investment castings furnished to this specification shall

conform to the requirements of Specification A957/A957M,

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

includinganysupplementaryrequirementsthatareindicatedin

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

the purchase order. Failure to comply with the general require-

A01.18 on Castings.

ments of Specification A957/A957M constitutes nonconfor-

Current edition approved Nov. 1, 2017. Published November 2017. Originally

approved in 1963. Last previous edition approved in 2017 as A494/A494M–17.

mance with this specification. In case of conflict between the

DOI: 10.1520/A0494_A0494M-17A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A494/A494M−17a

requirements of this specification and Specification A957/ 8. Tensile Properties

A957M, Specification A957/A957M shall prevail.

8.1 One tension test shall be ma

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A494/A494M − 17 A494/A494M − 17a

Standard Specification for

1

Castings, Nickel and Nickel Alloy

This standard is issued under the fixed designation A494/A494M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers nickel, nickel-copper, nickel-copper-silicon, nickel-molybdenum, nickel-chromium, and nickel-

molybdenum-chromium alloy castings for corrosion-resistant service.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in nonconformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A488/A488M Practice for Steel Castings, Welding, Qualifications of Procedures and Personnel

A732/A732M Specification for Castings, Investment, Carbon and Low Alloy Steel for General Application, and Cobalt Alloy

for High Strength at Elevated Temperatures

A781/A781M Specification for Castings, Steel and Alloy, Common Requirements, for General Industrial Use

A957/A957M Specification for Investment Castings, Steel and Alloy, Common Requirements, for General Industrial Use

E8 Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3

E30 Test Methods for Chemical Analysis of Steel, Cast Iron, Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

3

E38 Methods for Chemical Analysis of Nickel-Chromium and Nickel-Chromium-Iron Alloys (Withdrawn 1989)

3

E76 Test Methods for Chemical Analysis of Nickel-Copper Alloys (Withdrawn 2003)

E354 Test Methods for Chemical Analysis of High-Temperature, Electrical, Magnetic, and Other Similar Iron, Nickel, and

Cobalt Alloys

3. Terminology

3.1 Definitions:

3.1.1 master heat—a single furnace charge of refined alloy, which may either be poured directly into castings or into remelt alloy

for individual melts.

3.1.2 melts—a single furnace charge poured into castings. When master heats are used to prepare melts, a melt analysis shall

be reported.

4. General Conditions for Delivery

4.1 Except for investment castings, castings furnished to this specification shall conform to the requirements of Specification

A781/A781M, including any supplementary requirements that are indicated on the purchase order. Failure to comply with the

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.18

on Castings.

Current edition approved March 15, 2017Nov. 1, 2017. Published March 2017November 2017. Originally approved in 1963. Last previous edition approved in 20152017

as A494/A494M – 15.A494/A494M – 17. DOI: 10.1520/A0494_A0494M-17.10.1520/A0494_A0494M-17A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A494/A494M − 17a

general requirements of Specification A781/A781M constitutes nonconformance with this specification. In case of conflict between

the requirements of this specification and Specification A781/A781M, this specification shall prevail.

4.2 Investment castings furnished to this specification shall conform to the requirements of Specification A957/A957M,

incl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.