ASTM D3684-01

(Test Method)Standard Test Method for Total Mercury in Coal by the Oxygen Bomb Combustion/Atomic Absorption Method

Standard Test Method for Total Mercury in Coal by the Oxygen Bomb Combustion/Atomic Absorption Method

SCOPE

1.1 This test method describes a procedure for the analysis of total mercury in coal.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 8.3.1.

1.3 The values stated in SI units (IEEE/ASTM SI 10) shall be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3684 – 01

Standard Test Method for

Total Mercury in Coal by the Oxygen Bomb

1

Combustion/Atomic Absorption Method

This standard is issued under the fixed designation D 3684; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

NOTE 1—Mercury and mercury salts can be volatilized at low tempera-

1. Scope

tures. Precautions against inadvertent mercury loss should be taken when

1.1 This test method describes a procedure for the analysis

using this method.

of total mercury in coal.

1.2 This standard does not purport to address all of the 4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 The possible emission of mercury that may be found in

responsibility of the user of this standard to establish appro-

coal from coal combustion is an environmental concern.

priate safety and health practices and determine the applica-

4.2 When test portions are burned according to this proce-

bility of regulatory limitations prior to use. Specific precau-

dure, the total mercury is quantitatively retained and is repre-

tionary statements are given in 8.3.1.

sentative of concentrations in the whole coal.

1.3 The values stated in SI units (IEEE/ASTM SI 10) shall

be regarded as the standard. 5. Apparatus

5.1 Combustion Bomb—The combustion bomb shall be

2. Referenced Documents

constructedofmaterialsthatarenotaffectedbythecombustion

2.1 ASTM Standards:

process or products. The bomb must be designed so that all

2

D 1193 Specification for Reagent Water

liquid combustion products can be completely recovered by

3

D 2013 Method of Preparing Coal Samples for Analysis

washing the inner surfaces. There must be no gas leakage

D 3173 Test Method for Moisture in theAnalysis Sample of

during the test. The bomb must be capable of withstanding a

3

Coal and Coke

hydrostatic pressure test to gage pressure of 20 MPa (approxi-

D 3180 Practice for Calculating Coal and Coke Analyses

mately3000psig)atroomtemperaturewithoutstressinganyof

3

from As-Determined to Different Bases

the parts beyond the elastic limit.

D 5142 Test Methods for the Proximate Analysis of the

5.2 Water Bath—A container shall be large enough to hold

Analysis Sample of Coal and Coke by Instrumental

the combustion bomb, and enough cooling water shall be used

3

Procedures

to dissipate the heat generated during the combustion process.

E 144 Practice for Safe Use of Oxygen Combustion

The container should be designed to allow a constant flow of

4

Bombs

water around the combustion bomb.

IEEE/ASTM SI 10 Standard for Use of International Sys-

5.3 Combustion Crucibles—Samples shall be burned in an

4

tem of Units (SI): The Modern Metric System

open crucible of platinum, quartz, or acceptable base-metal

alloy.

3. Summary of Test Method

5.4 Firing Wire, 100 mm of either No. 34 B&S (0.160-mm)

3.1 Total mercury is determined in this test method by

nickel-chromium alloy, No. 34 B&S iron, or No. 38 B&S

combusting a weighed sample in an oxygen bomb with dilute

(0.101-mm) gage platinum wire.

nitric acid absorbing the mercury vapors. The bomb is rinsed

5.5 Firing Circuit—A 6- to 16-V alternating or direct

into a reduction vessel with dilute nitric acid, and the mercury

current is required for ignition purposes with an ammeter or

is determined by the flameless cold vapor atomic absorption

pilot light in the circuit to indicate when current is flowing. A

technique.

stepdown transformer connected to an alternating current

lighting circuit or batteries may be used. The ignition circuit

switch shall be of the momentary double-contact type, nor-

1

This test method is under the jurisdiction of ASTM Committee D05 on Coal

mally open, except when held closed by the operator. The

and Coke and is the direct responsibility of Subcommittee D05.29 on Major

Elements in Ash and Trace Elements of Coal.

switchshouldbedepressedonlylongenoughtofirethecharge.

Current edition approved October 10, 2001. Published December 2001. Origi-

5.6 Analytical Balance, with a sensitivity of 0.1 mg.

nally published as D 3684 – 78. Last previous edition D 3684 – 94 (2000).

2

Annual Book of ASTM Standards, Vol 11.01.

3

Annual Book of ASTM Standards, Vol 05.06.

4

Annual Book of ASTM Standards, Vol 14.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

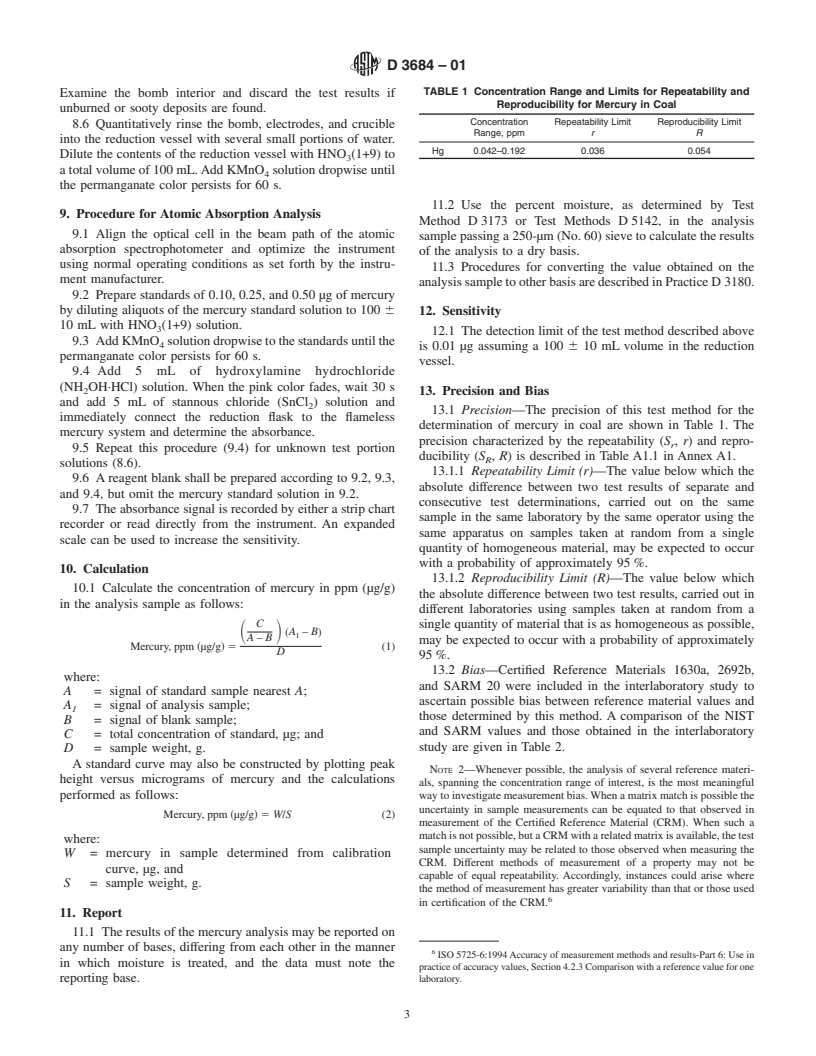

---------------------- Page: 1 ----------------------

D3684–01

5.7 Atomic Absorption Spectrophotometer, with a flameless 8. Procedure for Bomb Combustion

cold-vapor mercury analysis system comprised of either a

8.1 Thoroughly mix the analysis sample of coal in the

closed re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.