ASTM D7944-22

(Practice)Standard Practice for Recovery of Emulsified Asphalt Residue Using a Vacuum Oven

Standard Practice for Recovery of Emulsified Asphalt Residue Using a Vacuum Oven

SIGNIFICANCE AND USE

4.1 This practice can be used to obtain residues of emulsified asphalts. The residue may be used for further testing.

4.2 As approximately 5 g of residue is typically obtained, limited testing is possible.

Note 1: Rheological characterization as described in Test Methods D7175 and D7405 are suitable test methods. Additional test methods are being developed suited to the small amounts of residue obtained.

SCOPE

1.1 This practice is suitable for recovery of the residue of emulsified asphalts composed principally of a semisolid or liquid asphaltic base, water, and an emulsifying agent. Asphalt base may be pre-modified with polymeric modifiers or latex polymer modifiers may be incorporated into the emulsified asphalt through co-milling or post emulsified asphalt production blending.

1.2 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D7944 −22

Standard Practice for

Recovery of Emulsified Asphalt Residue Using a Vacuum

1

Oven

This standard is issued under the fixed designation D7944; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.2 AASHTO Standards:

R28 Accelerated Aging of Asphalt Binder Using a Pressur-

1.1 This practice is suitable for recovery of the residue of

ized Aging Vessel (PAV)

emulsified asphalts composed principally of a semisolid or

PP 72 Standard Practice for Recovery Residue from Emul-

liquid asphaltic base, water, and an emulsifying agent.Asphalt

sifiedAsphalt Using Low-Temperature Evaporative Tech-

base may be pre-modified with polymeric modifiers or latex

niques

polymer modifiers may be incorporated into the emulsified

asphalt through co-milling or post emulsified asphalt produc-

3. Summary of Practice

tion blending.

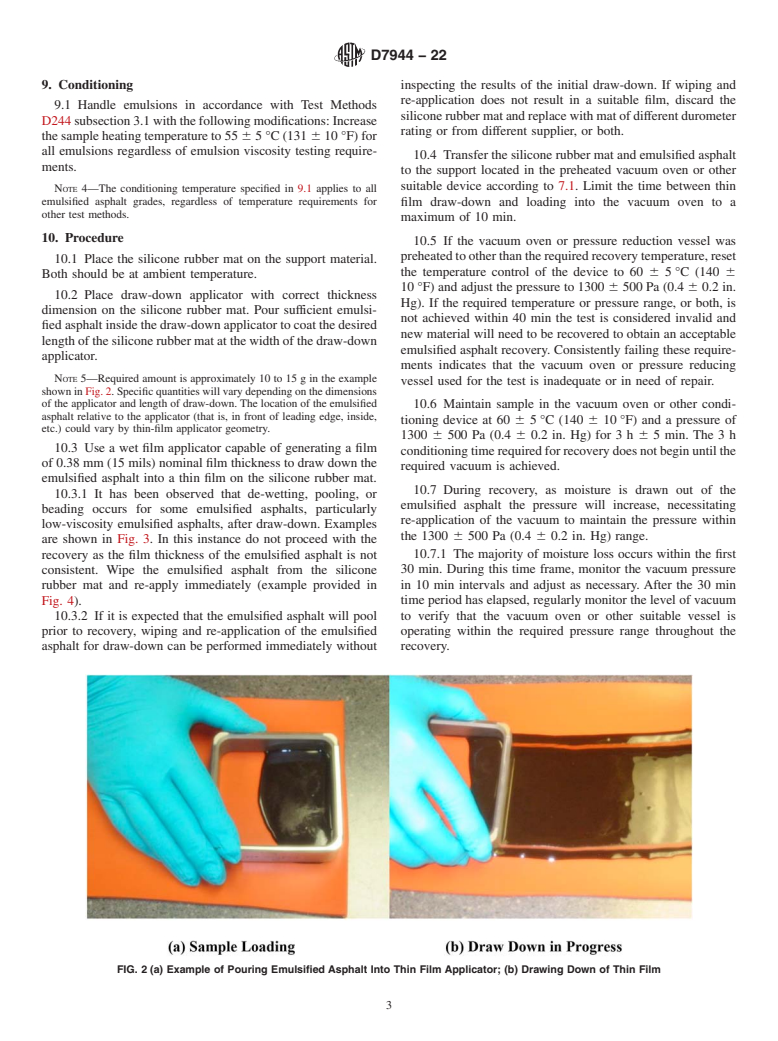

3.1 Asampleofemulsifiedasphaltisspreadinathinfilmon

1.2 The text of this standard references notes and footnotes

a silicone rubber mat and conditioned in a vacuum oven or

which provide explanatory material. These notes and footnotes

other suitable vacuum chamber to remove the water.

(excluding those in tables and figures) shall not be considered

as requirements of the standard.

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 This practice can be used to obtain residues of emulsi-

safety concerns, if any, associated with its use. It is the

fied asphalts. The residue may be used for further testing.

responsibility of the user of this standard to establish appro-

4.2 As approximately 5 g of residue is typically obtained,

priate safety, health, and environmental practices and deter-

limited testing is possible.

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

NOTE 1—Rheological characterization as described in Test Methods

D7175 and D7405 are suitable test methods. Additional test methods are

dance with internationally recognized principles on standard-

being developed suited to the small amounts of residue obtained.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5. Apparatus

mendations issued by the World Trade Organization Technical

4

5.1 Silicone rubber mat approximately 30 by 20 by 0.3 cm

Barriers to Trade (TBT) Committee.

(approximately 12 by 9 by 0.15 in.), minimum of 40A

2. Referenced Documents

durometer.

2

2.1 ASTM Standards:

5.2 Supports for Silicone Rubber Mat—Provide adequate

D244 Test Methods and Practices for Emulsified Asphalts

support of the silicone rubber mat during draw-down of the

D7175 Test Method for Determining the Rheological Prop-

film, while transporting to the vacuum oven or other suitable

erties of Asphalt Binder Using a Dynamic Shear Rheom-

vacuum conditioning chamber, and while recovering the emul-

eter

sified asphalt residue. The procedure uses two separate

D7405 Test Method for Multiple Stress Creep and Recovery

supports, one at ambient temperature for draw-down and

(MSCR) of Asphalt Binder Using a Dynamic Shear

transfer, and a second to support the silicone rubber mat and

Rheometer

emulsified asphalt during residue recovery. Adequate supports

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and

3

Paving Materials and is the direct responsibility of Subcommittee D04.42 on Available from American Association of State Highway and Transportation

Emulsified Asphalt Test. Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

Current edition approved July 1, 2022. Published August 2022. Originally http://www.transportation.org.

4

approved in 2015. Last previous edition approved in 2015 as D7944 – 15. DOI: The sole source of supply of the apparatus (referred to as “Silicone Rubber

10.1520/D7944-22. Sheeting” in catalog) known to the committee at this time is McMaster Carr, 200

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or New Canton Way, Robbinsville, NJ 08691-2343, www.mcmaster.com. If you are

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM aware of alternative suppliers, please provide this information to ASTM Interna-

Standards volume information, refer to the standard’s Document Summary page on tional Headquarters.Your comments will receive careful consideration at a meeting

1

the ASTM website. of the responsible technical committee, which

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7944 − 15 D7944 − 22

Standard Practice for

Recovery of Emulsified Asphalt Residue Using a Vacuum

1

Oven

This standard is issued under the fixed designation D7944; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice is suitable for recovery of the residue of emulsified asphalts composed principally of a semisolid or liquid

asphaltic base, water, and an emulsifying agent. Asphalt base may be pre-modified with polymeric modifiers or latex polymer

modifiers may be incorporated into the emulsified asphalt through co-milling or post emulsified asphalt production blending.

1.2 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D244 Test Methods and Practices for Emulsified Asphalts

D7175 Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer

D7405 Test Method for Multiple Stress Creep and Recovery (MSCR) of Asphalt Binder Using a Dynamic Shear Rheometer

3

2.2 AASHTO Standards:

R28R 28 Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV)

PP 72 Standard Practice for Recovery Residue from Emulsified Asphalt Using Low-Temperature Evaporative Techniques

3. Summary of Practice

3.1 A sample of emulsified asphalt is spread in a thin film on a silicone rubber mat and conditioned in a vacuum oven or other

suitable vacuum chamber to remove the water.

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.42 on Emulsified

Asphalt Test.

Current edition approved Oct. 1, 2015July 1, 2022. Published December 2015August 2022. Originally approved in 2015. Last previous edition approved in 2015 as

D7944 – 15. DOI: 10.1520/D7944-15.10.1520/D7944-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Association of State Highway and Transportation Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7944 − 22

4. Significance and Use

4.1 This practice can be used to obtain residues of emulsified asphalts. The residue may be used for further testing.

4.2 As approximately 5 g of residue is typically obtained, limited testing is possible.

NOTE 1—Rheological characterization as described in Test Methods D7175 and D7405 are suitable test methods. Additional test methods are being

developed suited to the small amounts of residue obtained.

5. Apparatus

4

5.1 Silicone rubber mat approximately 30 by 20 by 0.3 cm (approximately 12 by 9 by 0.15 in.), minimum of 40A durometer.

5.2 Supports for Silicone Rubber Mat—Provide adequate support of the silicone rubber mat during draw down draw-down of the

film, while transporting to the vacuum oven or other suitable vacuum conditioning chamber, and while recovering the emulsified

asphalt residue. The procedure uses two separate supports, one at ambient temperature for draw down draw-down and transfer, and

a second to support the silicone rubber mat and emulsified asphalt during residue recovery. Adequate supports include but are not

limited to a metal plate or tile wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.