ASTM D5530-15

(Test Method)Standard Test Method for Total Moisture of Hazardous Waste Fuel by Karl Fischer Titrimetry

Standard Test Method for Total Moisture of Hazardous Waste Fuel by Karl Fischer Titrimetry

SIGNIFICANCE AND USE

4.1 The determination of total moisture is important for assessing the quality of fuels. Water content will affect the heating value of fuels directly and can contribute to instability in the operation of an industrial furnace. Additionally, high water contents can present material handling and storage problems during winter months or in cold environments.

SCOPE

1.1 This test method covers the determination by Karl Fischer (KF) titrimetry of total moisture in solid or liquid hazardous waste fuels used by industrial furnaces.

1.2 This test method has been used successfully on numerous samples of hazardous waste fuel composed of solvents, spent oils, inks, paints, and pigments. The range of applicability for this test method is between 1.0 and 100 %; however, this evaluation was limited to samples containing approximately 5 to 50 % water.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5530 − 15

Standard Test Method for

Total Moisture of Hazardous Waste Fuel by Karl Fischer

1

Titrimetry

This standard is issued under the fixed designation D5530; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope weighed portion of the sample is dissolved in KF solvent and

titrated with reagent to dryness. If solid material interferes (see

1.1 This test method covers the determination by Karl

5.3) with the electrode or does not dissolve sufficiently, an

Fischer (KF) titrimetry of total moisture in solid or liquid

extraction using KF solvent is performed prior to introduction

hazardous waste fuels used by industrial furnaces.

into the titration flask. The total moisture in the sample is then

1.2 This test method has been used successfully on numer-

determined. The final total moisture percent is an average of

ous samples of hazardous waste fuel composed of solvents,

two trials for each sample.

spent oils, inks, paints, and pigments. The range of applicabil-

3.2 The contents of the titration flask may be retained and

ityforthistestmethodisbetween1.0and100 %;however,this

used for additional analyses. The contents of the titration flask

evaluation was limited to samples containing approximately 5

will need to be emptied and replaced with new solvent when

to 50 % water.

the capacity of the flask is nearly exhausted or when solid

1.3 The values stated in SI units are to be regarded as

material affects the sensing by the electrode.

standard. No other units of measurement are included in this

standard.

4. Significance and Use

1.4 This standard does not purport to address all of the

4.1 The determination of total moisture is important for

safety concerns, if any, associated with its use. It is the

assessing the quality of fuels. Water content will affect the

responsibility of the user of this standard to establish appro-

heating value of fuels directly and can contribute to instability

priate safety and health practices and determine the applica-

in the operation of an industrial furnace. Additionally, high

bility of regulatory limitations prior to use.

water contents can present material handling and storage

problems during winter months or in cold environments.

2. Referenced Documents

2

2.1 ASTM Standards:

5. Interferences

D1193 Specification for Reagent Water

5.1 Asmall number of oxidants such as ferric and chromate

D4017 Test Method for Water in Paints and Paint Materials

salts can oxidize iodide and may produce artificially low

by Karl Fischer Method

results.

E691 Practice for Conducting an Interlaboratory Study to

5.2 Certain reductants oxidized by iodine such as

Determine the Precision of a Test Method

mercaptans, thioacetate, thiosulfate, stannous chloride,

3. Summary of Test Method

sulfides, hydroquinone, and phenylenediamines can consume

iodine and may cause artificially high results. Basic materials

3.1 An amount of solvent (see 7.3) sufficient to immerse the

such as hydroxides, oxides, and inorganic carbonates may

electrode in the titration flask fully (see Note 1) is titrated to

cause artificially high results by water-forming reactions.

dryness as explained in 9.1, and the Karl Fischer reagent factor

is determined by titration of measured amounts of water. A

5.3 Sometypesofsolidmaterialfoundinwaste-derivedfuel

may interfere with the electrode by blocking its contact with

the solvent. Depending on the nature of the solid material,

1

This test method is under the jurisdiction of ASTM Committee D34 on Waste

Management and is the direct responsibility of Subcommittee D34.01.06 on artificially high or low results can occur.

Analytical Methods.

Current edition approved Sept. 1, 2015. Published September 2015. Originally

6. Apparatus

approvedin1994.Lastpreviouseditionapprovedin2009asD5530-94(2009).DOI:

10.1520/D5530-15.

6.1 Karl Fischer Potentiometric Titration Unit, automated

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

or semi-automated, equipped with a magnetic vessel stirrer.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The user must follow the manufacturer’s instructions for

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. installation and use.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

1

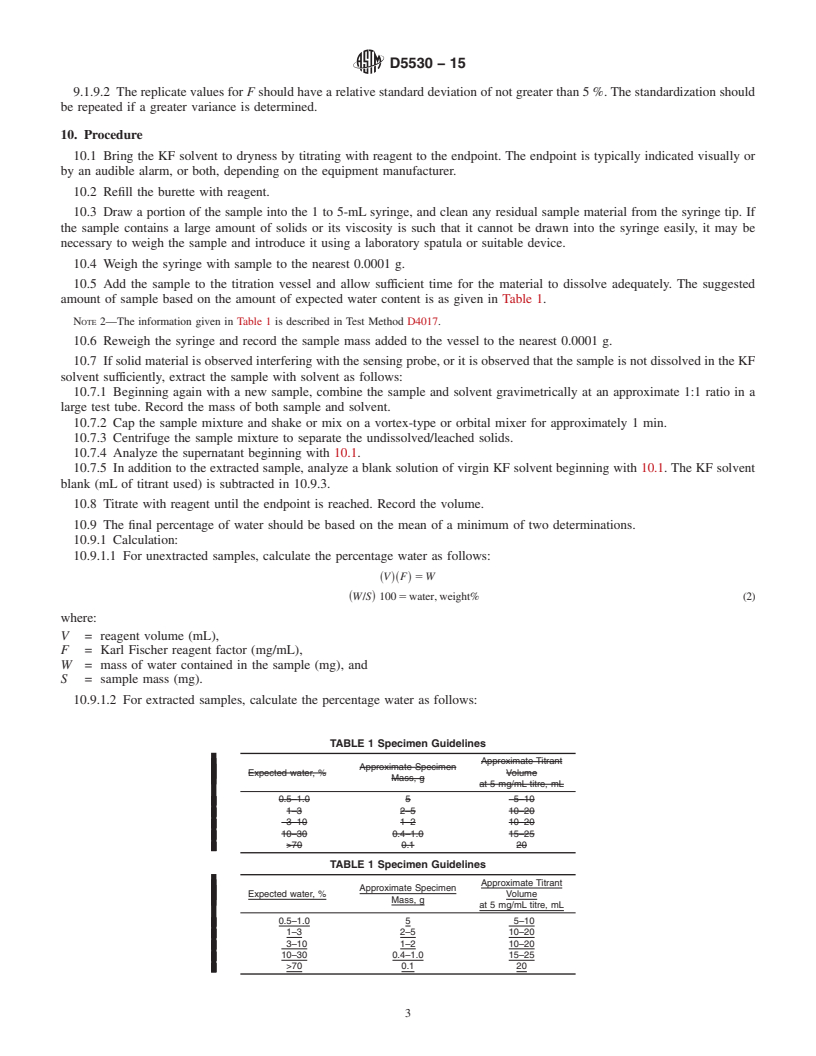

---------------------- Page: 1 ----------------------

D5530 − 15

NOTE 1—The Karl Fischer unit used for developing this test method

9.1.3 Bring the KF solvent to dryness by titrating with

was equipped with a twin platinum elec

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5530 − 94 (Reapproved 2009) D5530 − 15

Standard Test Method for

Total Moisture of Hazardous Waste Fuel by Karl Fischer

1

Titrimetry

This standard is issued under the fixed designation D5530; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination by Karl Fischer (KF) titrimetry of total moisture in solid or liquid hazardous waste

fuels used by industrial furnaces.

1.2 This test method has been used successfully on numerous samples of hazardous waste fuel composed of solvents, spent oils,

inks, paints, and pigments. The expected range of applicability for this test method is between 1.0 and 100 %; however, this

evaluation was limited to samples containing approximately 5 to 50 % water.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D4017 Test Method for Water in Paints and Paint Materials by Karl Fischer Method

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Summary of Test Method

3.1 An amount of solvent (see 7.3) sufficient to immerse the electrode in the titration flask fully (see Note 1) is titrated to dryness

as explained in 9.1, and the Karl Fischer reagent factor is determined by titration of measured amounts of water. A weighed portion

of the sample is dissolved in KF solvent and titrated with reagent to dryness. If solid material interferes (see 5.3) with the electrode

or does not dissolve sufficiently, an extraction using KF solvent is performed prior to introduction into the titration flask. The total

moisture in the sample is then determined. The final total moisture percent is an average of two trials for each sample.

3.2 The contents of the tirationtitration flask may be retained and used for additional analyses. The contents of the titration flask

will need to be emptied and replaced with new solvent when the capacity of the flask is nearly exhausted or when solid material

affects the sensing by the electrode.

4. Significance and Use

4.1 The determination of total moisture is important for assessing the quality of fuels. Water content will affect the heating value

of fuels directly and can contribute to instability in the operation of an industrial furnace. Additionally, high water contents can

present material handling and storage problems during winter months or in cold environments.

5. Interferences

5.1 A small number of oxidants such as ferric and chromate salts can oxidize iodide and may produce artificially low results.

1

This test method is under the jurisdiction of ASTM Committee D34 on Waste Management and is the direct responsibility of Subcommittee D34.01.06 on Analytical

Methods.

Current edition approved Feb. 1, 2009Sept. 1, 2015. Published March 2009September 2015. Originally approved in 1994. Last previous editioedition approved in

20032009 as D5530-94(2003).D5530-94(2009). DOI: 10.1520/D5530-94R09.10.1520/D5530-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5530 − 15

5.2 Certain reductants oxidized by iodine such as mercaptans, thioacetate, thiosulfate, stannous chloride, sulfides,

hydroquinone, and phenylenediamines can consume iodine and may cause artificially high results. Basic materials such as

hydroxides, oxides, and inorganic carbonates may cause artificially high results by water-forming reactions.

5.3 Some types of solid material found in waste-derived fuel may interfere with the electrode by blocking its contact with the

solvent. Depending on the nature of the solid materi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.