ASTM B781-93a(1999)

(Guide)Standard Guide for Silver-Cadmium Oxide Contact Material

Standard Guide for Silver-Cadmium Oxide Contact Material

SCOPE

1.1 This guide provides guidelines for users and manufacturers of silver-cadmium oxide material produced in strip, rod, wire, and part form for electrical contact applications.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 It is the responsibility of the user to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet for this product/materials as provided by the manufacturer.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B781–93a(Reapproved1999)

Standard Guide for

Silver-Cadmium Oxide Contact Material

This standard is issued under the fixed designation B 781; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope loads. Silver-cadmium oxide is a composite material consisting

of a metal matrix, silver, with a metal oxide, cadmium oxide,

1.1 This guide provides guidelines for users and manufac-

dispersed throughout the matrix. Compositions of up to 30 %

turers of silver-cadmium oxide material produced in strip, rod,

cadmium are made, but most applications use silver-cadmium

wire, and part form for electrical contact applications.

oxide in the range of 10 to 15 % cadmium oxide by weight.

1.2 This standard does not purport to address all of the

Several different processes are used for manufacturing silver-

safety problems, if any, associated with its use. It is the

cadmium oxide material and it should be understood that the

responsibility of the user of this standard to establish appro-

manufacturing method has an influence on the properties of the

priate safety and health practices and determine the applica-

material such as arc erosion resistance, welding resistance, arc

bility of regulatory limitations prior to use.

mobility and contact resistance. Since the performance of

1.3 It is the responsibility of the user to become familiar

contacts in a device is dependent on numerous factors outside

with all hazards including those identified in the appropriate

the contact itself (opening speed, closing speed, contact pres-

Material Safety Data Sheet for this product/materials as pro-

sure, contact bounce and many more device parameters), the

vided by the manufacturer.

guide cannot ensure performance in specific applications.

2. Referenced Documents

4.2 Arc erosion resistance and welding resistance are im-

proved by the addition of cadmium oxide to the silver matrix.

2.1 ASTM Standards:

The contact resistance is raised by this addition but still is low.

B311 Test Method for Density Determination for Powder

Cadmium oxide and silver do not alloy so the silver matrix

Metallurgy (P/M) Materials Containing Less Than Two

retains its high conductivity. Silver-cadmium oxide contacts

Percent Porosity

are used in current ranges of a few amperes to several hundred

B 476 Specification for General Requirements for Wrought

amperes.

Precious Metal Electrical Contact Materials

4.3 Silver-cadmium oxide contact material is available as

C 914 Test Method for Bulk Density and Volume of Solid

wire, silver-clad wire, sheet, strip, toplay, inlay and overlay

Refractories by Wax Immersion

sheet or strip, discrete contact parts, brazed contact assemblies,

NOTE 1—Test Method B311 is applicable to fully dense forms.

solid and composite rivet contacts and clad contact tapes.

Specification B 476 is applicable to strip, rod, or wire only. Test Method

4.4 Materials with higher cadmium oxide contents have

C 914 is applicable to forms less than 99 % dense.

lower material costs but may have higher processing costs due

3. Terminology to lower formability.

3.1 lot—(usage involving discrete manufactured parts)—all

5. Manufacture

parts of the same form, and dimensions, from the same alloy

5.1 Since the manufacturing method has a significant influ-

melt or batch of particulate (if manufactured by consolidation),

ence on the properties and microstructure of silver-cadmium

processedunderthesameconditions,andsubmittedforinspec-

oxide materials, it is important to understand some basic

tion at the same time.

information on the types of manufacturing. Silver-cadmium

4. Significance and Use oxide manufacturing can be first divided in two categories:

Internal Oxidation and Power Metallurgy.

4.1 Silver-cadmium oxide is a popular contact material that

5.1.1 Internal oxidation means that the cadmium oxide

has been used in a wide range of applications in switches,

particles are formed by diffusion of oxygen into the silver alloy

relays and contactors for switching lamps, motors and resistive

to combine with cadmium atoms to form cadmium oxide

particles. This process can be further divided into the catego-

This test method is under the jurisdiction of ASTM Committee B02 on ries of post and pre-oxidized materials. The post-oxidized

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

process consists of performing the diffusion process after the

B2.05 on Precious Metals.

finished parts have been formed. The pre-oxidized process

Current edition approved Aug. 15, 1993. Published October 1993. Originally

published as B 781 – 87. Last previous edition B 781 – 93.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B781–93a (1999)

TABLE 1 Suggested Chemistries and Theoretical Densities

consists of oxidation of slugs and the forming of wire or strip

from the oxidized slugs and then forming the final parts. The

86.5 Silver/

cadmium oxide particle size distribution is dependent upon the 90 Silver/10 85 Silver/15 80 Silver/20

13.5

Cadmium- Cadmium- Cadmium-

grain structure of the silver cadmium alloy, any additive

Cadmium-

Oxide Oxide Oxide

Oxide

concentration, and oxidation conditions (for example, tempera-

Chemistry

ture, oxygen partial pressure).

Cadmium-Oxide 10.0 6 1.0 13.5 6 1.0 15.0 6 1.0 20.0 6 1.0

5.1.2 For powder metallurgy silver-cadmium oxide, the

weight %

material is made from a blend of silver and cadmium oxide

Silver weight % , 89.0 85.5 84.0 79.0

min

powder or other cadmium compounds such as cadmium

Other elements (see 6.2)

carbonate, which can be thermally decomposed to cadmium

Theoretical Densities at Nominal Composition:

oxide in a subsequent step. There are two basic types of this

Mg/m 10.2 10.1 10.1 9.92

troy oz./in. 5.37 5.32 5.30 5.23

process, one in which the contacts are pressed and sintered and

repressed into the final shape, and the other where a billet is

made from blended powder which is then formed into strip and

TABLE 2 Typical Part Properties Made by Powder Metallurgy

wire and made into the final contact shapes.

A

(Annealed State)

5.1.3 All of these processes have many variations.There are

NOTE 1—Due to lack of commercially available information, some

also hybrid processes such as internally oxidized powders

values are not listed.

which are then processed by powder metallurgy. The user

should obtain the basic information as to the type of material

90 Silver/10 86.5 Silver/13.5 85 Silver/15 80 Silver/20

being purchased.

Cadmium- Cadmium- Ox- Cadmium- Ox- Cadmium- Ox-

Oxide ide ide ide

5.1.4 For purposes of attachment to bare metal supports,

silver-cadmium oxide contact material is often produced with a Type A: Parts processed so as to be “full dense.”

conductive or brazable layer of material or backing. Incorpo-

Density:

ration of such a layer is often an integral part of the silver- 3

Mg/m ,min 9.96 9.89 9.82 9.73

troy oz/in. 5.25 5.21 5.17 5.13

cadmium oxide manufacturing process.

Electrical

5.1.5 Silver-cadmium oxide materials vary from full theo-

resistivity:

retical density to about 95 % of theoretical density depending

nVm, min 19.2 20.3 21.0 22.4

nVm, max 23.9 23.9 26.9 27.4

on the specific manufacturing method.

Electrical

5.1.6 The flexibility of the silver-cadmium oxide materials

conductivity:

system allows many additional manufacturing methods to be

% IACS, min 72 72 64 63

% IACS, max 90 85 82 77

introduced, and those mentioned here are not a comprehensive

B

Hardness:

listing. The cadmium-oxide particle size, distribution, and

HR30T

...

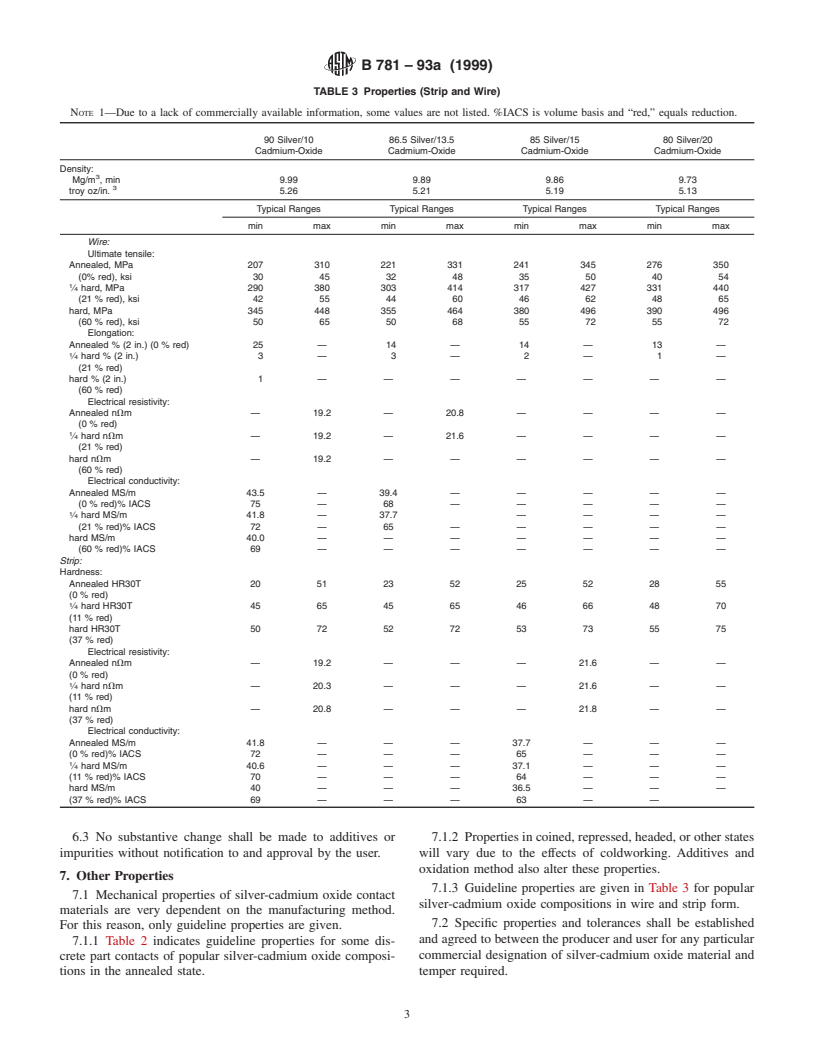

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.