ASTM D7436-11

(Classification)Standard Classification System for Unfilled Polyethylene Plastics Molding and Extrusion Materials with a Fractional Melt Index Using ISO Protocol and Methodology

Standard Classification System for Unfilled Polyethylene Plastics Molding and Extrusion Materials with a Fractional Melt Index Using ISO Protocol and Methodology

SCOPE

1.1 This classification system provides for the identification of unfilled polyethylene plastics molding and extrusion materials, with a melt index of 1g/10 min, in such a manner that the supplier and the user agree on the acceptability of different commercial lots or shipments. The tests involved in this specification are intended to provide information for identifying materials in accordance with the groups, classes, and grades covered. It is not the function of this classification system to provide specific engineering data for design purposes.

1.2 This classification system allows for the use of recycled polyethylene materials provided that the requirements as stated in this classification system are met. The proportions of recycled material used, as well as the nature and amount of any contaminant, however, will not be covered in this specification.

Note 1—See Guide D7209 for information and definitions related to recycled plastics.

1.3 The properties included in this classification system are those required to identify the compositions covered. There may be other requirements necessary to identify particular characteristics important to specialized applications. These shall be agreed upon between the user and the supplier by using the suffixes given in Section 5.

1.4 This classification system and subsequent line callout (specifications) are intended to provide a means of calling out plastic materials used in the fabrication of end items or parts. It is not intended for the selection of materials. Material selection should be made by those having expertise in the plastic field after careful consideration of the design and the performance requirements of the part, the environment to which it will be exposed, the fabrication process to be employed, the costs involved, and the inherent properties of the material other than those covered by this classification system.

1.5 The values stated in SI units are regarded as the standard.

1.6 The following precautionary caveat pertains to the test method portion only, Section 12 of this classification system. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.7 For information regarding plastic pipe materials, see Specification D3350. For information regarding wire and cable materials, see Specification D1248. For information regarding classification of PE molding and extrusion materials using ASTM test methods, see Specification D4976.

Note 2—There is no known ISO equivalent to this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7436 −11

StandardClassification System for

Unfilled Polyethylene Plastics Molding and Extrusion

Materials with a Fractional Melt Index Using ISO Protocol

and Methodology

This standard is issued under the fixed designation D7436; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This material specification is intended to provide a callout system for polyethylene utilizing

specimen preparation procedures and test methods based primarily on ISO standards.

1. Scope performance requirements of the part, the environment to

which it will be exposed, the fabrication process to be

1.1 This classification system provides for the identification

employed,thecostsinvolved,andtheinherentpropertiesofthe

of unfilled polyethylene plastics molding and extrusion

material other than those covered by this classification system.

materials, with a melt index of <1g/10 min, in such a manner

that the supplier and the user agree on the acceptability of 1.5 The values stated in SI units are regarded as the

different commercial lots or shipments. The tests involved in standard.

this specification are intended to provide information for

1.6 The following precautionary caveat pertains to the test

identifying materials in accordance with the groups, classes,

method portion only, Section 12 of this classification system.

and grades covered. It is not the function of this classification

This standard does not purport to address all of the safety

system to provide specific engineering data for design pur-

concerns, if any, associated with its use. It is the responsibility

poses.

of the user of this standard to establish appropriate safety and

health practices and determine the applicability of regulatory

1.2 This classification system allows for the use of recycled

limitations prior to use.

polyethylene materials provided that the requirements as stated

1.7 For information regarding plastic pipe materials, see

in this classification system are met. The proportions of

Specification D3350. For information regarding wire and cable

recycledmaterialused,aswellasthenatureandamountofany

materials, see Specification D1248. For information regarding

contaminant,however,willnotbecoveredinthisspecification.

NOTE 1—See Guide D7209 for information and definitions related to classification of PE molding and extrusion materials using

recycled plastics.

ASTM test methods, see Specification D4976.

NOTE 2—There is no known ISO equivalent to this standard.

1.3 The properties included in this classification system are

thoserequiredtoidentifythecompositionscovered.Theremay

2. Referenced Documents

be other requirements necessary to identify particular charac-

2.1 ASTM Standards:

teristics important to specialized applications. These shall be

D883 Terminology Relating to Plastics

agreed upon between the user and the supplier by using the

D1248 Specification for Polyethylene Plastics Extrusion

suffixes given in Section 5.

Materials for Wire and Cable

1.4 This classification system and subsequent line callout

D1600 TerminologyforAbbreviatedTermsRelatingtoPlas-

(specifications) are intended to provide a means of calling out

tics

plastic materials used in the fabrication of end items or parts.

D1693 Test Method for Environmental Stress-Cracking of

It is not intended for the selection of materials. Material

Ethylene Plastics

selection should be made by those having expertise in the

D2565 Practice for Xenon-Arc Exposure of Plastics In-

plastic field after careful consideration of the design and the

tended for Outdoor Applications

ThisclassificationsystemisunderthejurisdictionofASTMCommitteeD20on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Materials. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Nov. 15, 2011. Published December 2011. Standards volume information, refer to the standard’s Document Summary page on

DOI:10.1520/D7436-11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7436−11

D3350 Specification for Polyethylene Plastics Pipe and Fit- 4. Classification

tings Materials

4.1 Unfilled polyethylene plastic materials are classified

D3763 Test Method for High Speed Puncture Properties of

into groups in accordance with molecular structure. These

Plastics Using Load and Displacement Sensors

groups are subdivided into classes and grades as shown in

D3892 Practice for Packaging/Packing of Plastics

Table PE (Basic Property Table). Material classification call-

D4000 Classification System for Specifying Plastic Materi-

outs used in this system and in Specification D4976 look

als

similar but decode into dramatically different materials. In

D4329 Practice for Fluorescent UV Exposure of Plastics

order to differentiate materials classified under this system

D4703 Practice for Compression Molding Thermoplastic

from those classified under other systems, materials classified

Materials into Test Specimens, Plaques, or Sheets

herein are preceded with the classification system D7436.

D4976 Specification for Polyethylene Plastics Molding and

Extrusion Materials

NOTE 3—An example of this classification system is as follows: The

D6436 Guide for Reporting Properties for Plastics and

designation D7436 PE 232 would indicate PE, polyethylene as found in

Thermoplastic Elastomers

Terminology D1600, 2 (group) linear, 3 (class) high density, 2 (grade) >7

D7209 Guide for Waste Reduction, Resource Recovery, and to# 11 melt flow rate (190°C/21.6Kg).

Use of Recycled Polymeric Materials and Products NOTE 4—It is recognized that some high-density polyethylene plastics

of very high molecular weight may have densities slightly less than 0.960,

E29 Practice for Using Significant Digits in Test Data to

yet in all other respects they are characteristic of Class 4 materials.

Determine Conformance with Specifications

Similarly, there are other polyethylene plastics of very high molecular

2.2 ISO Standards:

weight having densities less than 0.941 that, in all other aspects, are more

ISO 293 Plastics—Compression Molding of Test Speci-

characteristic of Class 2 than of Class 3 materials.

mens of Thermoplastic Materials

NOTE 5—Use the following terms in describing polyethylene plastics:

ISO 527-1 Plastics—Determination of Tensile Properties—

Class 1 (0.910 to 0.925) = low density

Part 1: General Principles

Class 2 (>0.925 to 0.940) = medium density

Class 3 (>0.940 to 0.960) = high density-low range

ISO 527-2 Plastics—Determination of Tensile Properties—

Class 4 (>0.960) = high density-high range

Part 2: Test Conditions for Moulding and Extrusion

Plastics 4.1.1 Specific requirements for variations of polyethylene

ISO 1133 Plastics—Determination of the Melt Mass-Flow materials shall be indicated by a six-character designator. The

Rate (MFR) and Melt Volume-Flow Rate (MVR) of

designation will consist of the letter “A” and the five digits

Thermoplastics comprising the cell numbers for the property requirements in

ISO 1183-2 Plastics—Methods for Determining the Density

the order as they appear in Table A.

and Relative Density of Non-Cellular Plastics—Density

4.1.2 Although the values listed are necessary to include the

Gradient Column Method

range of properties available in the existing materials, users

ISO 1872-2 Plastics—Polyethylene (PE) Moulding and Ex-

shall not assume that every combination of properties are

trusion Materials—Part2: Preparation of Test Specimens

attainable or exist.

and Determination of Properties

4.1.3 When the cell designation is not known or is not

ISO 2818 Preparation of Test Specimens by Machining

required, the use of a “0” designation shall be used (see Note

ISO 3167 Dimensions of Test Specimens

6).

2.3 SAE Standards:

SAE J2412 Accelerated Exposure of Automotive Interior

NOTE 6—An example of a high density polyethylene material of this

Trim Components Using a Controlled Irradiance Xenon-

classification system is as follows. The designation D7436 PE230A34350

Arc Apparatus would indicate the following material requirements from Table A:

SAE J2527 Performance Based Standard for Accelerated PE230 = High Density Polyethylene, from Table PE of this standard,

A = Table A for property requirements,

Exposure of Automotive Exterior Materials Using a Con-

3 = tensile strength, 12 MPa, min,

trolled Irradiance Xenon-Arc Apparatus

4 = tensile break elongation, 400 %, min,

3 = tensile modulus, 200 MPa, min,

3. Terminology

5 = environmental stress-crack resistance, 336 F hours, min

0 = unspecified

3.1 Definitions—For definitions of technical terms pertain-

ingtoplasticsusedinthisspecification,seeTerminologyD883

If no properties are specified, the designation would be D7436

PE230A00000.

and Terminology D1600.

D7436−11

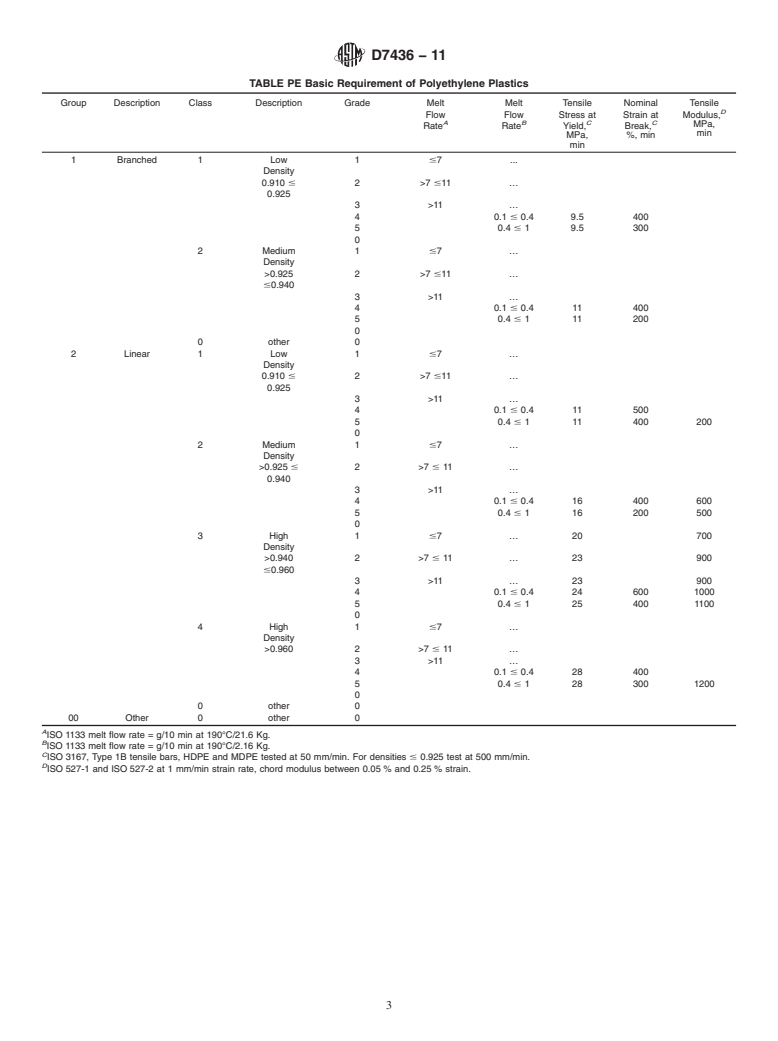

TABLE PE Basic Requirement of Polyethylene Plastics

Group Description Class Description Grade Melt Melt Tensile Nominal Tensile

D

Flow Flow Stress at Strain at Modulus,

A B C C

MPa,

Rate Rate Yield, Break,

min

MPa, %, min

min

1 Branched 1 Low 1 #7 .

Density

0.910# 2>7#11 …

0.925

3>11 …

40.1# 0.4 9.5 400

50.4# 1 9.5 300

2 Medium 1 #7…

Density

>0.925 2>7#11 …

#0.940

3>11 …

40.1# 0.4 11 400

50.4# 1 11 200

0 other 0

2 Linear 1 Low 1 #7…

Density

0.910# 2>7#11 …

0.925

3>11 …

40.1# 0.4 11 500

50.4# 1 11 400 200

2 Medium 1 #7…

Density

>0.925# 2>7# 11 …

0.940

3>11 …

40.1# 0.4 16 400 600

50.4# 1 16 200 500

3 High 1 #7 … 20 700

Density

>0.940 2>7# 11 … 23 900

#0.960

3 >11 … 23 900

40.1# 0.4 24 600 1000

50.4# 1 25 400 1100

4 High 1 #7…

Density

>0.960 2 >7# 11 …

3>11 …

40.1# 0.4 28 400

50.4# 1 28 300 1200

0 other 0

00 Other 0 other 0

A

ISO 1133 melt flow rate = g/10 min at 190°C/21.6 Kg.

B

ISO 1133 melt flow rate = g/10 min at 190°C/2.16 Kg.

C

ISO 3167, Type 1B tensile bars, HDPE and MDPE tested at 50 mm/min. For densities# 0.925 test at 500 mm/min.

D

ISO 527-1 and ISO 527-2 at 1 mm/min strain rate, chord modulus between 0.05 % and 0.25 % strain.

D7436−11

A

TABLE A Detail Requirements for Polyethylene Plastics

Designation or Property 0 12345678 9

Order No.

B C

1 Tensile stress at yield, unspecified 4 8 12 16 21 30 35 … specify value

MPa ISO 527-1 and ISO 527-2, min

B C

2 Nominal strain at break, %, unspecified 25 50 200 400 600 800 1000 … specify value

ISO 527-1 and ISO 527-2, min

D C

3 Tensile Modulus, unspecified 50 100 200 400 600 800 1000 … specify value

MPa, ISO 527-1 and ISO 527-2, min

C

4 Environmental stress-crack resistance, unspecified 24 48 96 168 336 672 1008 … specify value

E

hrs, min F , Test Method D1693

C

5 To be determined unspecified specify value

A

It is recognized that detailed test values may not predict nor even correlate with performance of parts molded of these materials.

B

ISO 3167, Type 1B tensile bars, HDPE and MDPE tested at 50 mm/min. For densities <0.925 test at 500 mm/min.

C

If a specific value is required, it must appear on the drawing or contract, or both.

D

ISO 527-1 and ISO 527-2 at 1 mm/min strain rate, chord modulus between 0.05 % and 0.25 % strain.

E

F is the time required for failure of 50 % of the samples tested in accordance with Test Method D1693 using undiluted Igepal CO-630. Mold samples in accordance

with Procedure C of Practice D4703, Annex A1.

5. Suffixes

Second Digit

0 = To be specified by user.

5.1 When additional requirements are needed that are not

1 = 6 Joules, min

covered by the basic or cell table requirements, they shall be

2 = 9 Joules, min

3 = 12 Joules, min

indicated through the use of suffixes. The following suffixes

4 = 18 Joules, min

may be used for specific requirements of the material for the

5 = 21 Joules, min

application intended. In general, the suffix letter indicates the

6 = 24 Joules, min

7 = 27 Joules, min

requirement needed; the first number (digit) indicates the test

condition, and the second number (digit) indicates the speci- 5.1.3 E = Environmental Stress-Crack Resistance, hours, as

men requirement. The suffixes are as follows: designated by the following digits:

5.1.1 W = Weatherability requirements, as designated by

First Digit

0 = To be specified by user

the following digits:

1 = ESCR in accordance to Test Method D1693 Undiluted surface

First Digit

active agent Igepal CO-630 and a graphical method time of F .

0 = To be specified.

2 = ESCR in accordance to Test Method D1693 Undiluted surface

1 = Specimens exposed to xenon-arc type light source, in

active agent and a graphical method time of F .

accordance with Practice D2565, Cycle 1. Specimens shall conform

Second Digit

to ISO 3167 tensile bars.

0 = To be specified by user

2 = Specimens exposed to fluorescent-UV-condensation type

1 = 24 hours, min

apparatus, in accordance with Practice D4329, Cycle A. Specimens

2 = 48 hours, min

shall conform to ISO 3167 tensile bars.

3 = 96 hours, min

3 = Specimens exposed to xenon-arc type light source in accor-

4 = 168 hours, min

dance to SAE J2412. (Typically used to represent the effects of ex-

5 = 336 hours, min

posure to window glass filtered solar radiation). Specimens shall

6 = 672 hours, min

conform to ISO 3167 tensile bars.

7 = 1008 hours, min

4 = Specimens exposed to xenon-arc type light source in accor-

5.1.4 Z = Other special requirements (for example, internal

dance to SAE J2527. (Typically used to represent the effects of di-

rect exposure to solar radiation). Specimens shall conform to

mold release agent) not covered by existing callout capabilities

ISO 3167 tensile bars.

may be assigned by the user.These will be spelled out in detail

Second Digit

1 = 601.6 kJ/m @ 340 nm and identified in sequence, that is, 01 UV-stabilized, 02 special

2 = 1200 kJ/m @ 340 nm

color, and 03 etc.

3 = 2500 kJ/m @ 340 nm

5.2 A list of suffixes can also be found in Classification

5.1.1.1 The exposed specimens shall not exhibit surface

D4000 (Table 3) and used for additional requirements, as

changes (such as dulling or chalking) or deep-seated changes

appropriate. Additional suffixes will be added to that classifi-

(such as checking, crazing or warping). The tensile stress at

cation system as test methods and requirements are developed

yield after exposure shall be no less than 50 % of the original.

and requested.

5.1.2 P = Impact requirements, Total Energy in Joules at

Maximum Load, as designated by the following digits:

6. Basic Requirements

First Digit

0 = To be specified by user. 6.1 Basic requirements from property

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.