ASTM C635/C635M-13a

(Specification)Standard Specification for the Manufacture, Performance, and Testing of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings

Standard Specification for the Manufacture, Performance, and Testing of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings

ABSTRACT

This specification covers metal ceiling suspension systems used primarily to support acoustical tile or acoustical lay-in panels. Some suspension systems incorporate locking assembly details that enhance performance by providing some continuity or load transfer capability between adjacent sections of the ceiling grid. The structural classification or grade of ceiling suspension systems shall be determined by the capability of main runners or nailing bars to support a uniformly distributed load. These classifications shall be: light-duty systems; intermediate-duty systems; and heavy-duty systems. The structural classification of ceiling suspension systems shall be based on the load-carrying capacity of the main runners of the structural network. Suspension system structural members shall conform to the following tolerance requirements: metal thickness; straightness; length; overall cross-section dimensions; and section squareness.

SCOPE

1.1 This specification covers metal ceiling suspension systems used primarily to support acoustical tile or acoustical lay-in panels.

1.2 Some suspension systems incorporate locking assembly details that enhance performance by providing some continuity or load transfer capability between adjacent sections of the ceiling grid. The test methods included in this specification do not provide the means for making a complete evaluation of continuous beam systems, nor for assessing the continuity contribution to overall system performance. However, the test methods can be used for evaluating primary structural members in conjunction with secondary members that interlock, as well as with those of noninterlocking type.

1.3 While this specification is applicable to the exterior installation of metal suspension systems, the atmospheric conditions and wind loading require additional design attention to ensure safe implementation. For that reason, a specific review and approval should be solicited from the responsible architect and engineer, or both, for any exterior application of metal suspension systems in the construction of a new building or building modification.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 The following safety hazards caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C635/C635M −13a

Standard Specification for

the Manufacture, Performance, and Testing of Metal

Suspension Systems for Acoustical Tile and Lay-in Panel

1

Ceilings

This standard is issued under the fixed designation C635/C635M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope standard to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior

1.1 This specification covers metal ceiling suspension sys-

to use.

tems used primarily to support acoustical tile or acoustical

lay-in panels.

2. Referenced Documents

1.2 Some suspension systems incorporate locking assembly 2

2.1 ASTM Standards:

detailsthatenhanceperformancebyprovidingsomecontinuity

B117Practice for Operating Salt Spray (Fog) Apparatus

or load transfer capability between adjacent sections of the

D1735Practice for Testing Water Resistance of Coatings

ceiling grid. The test methods included in this specification do

Using Water Fog Apparatus

not provide the means for making a complete evaluation of

continuous beam systems, nor for assessing the continuity

3. Terminology

contribution to overall system performance. However, the test

3.1 Definitions:

methods can be used for evaluating primary structural mem-

3.1.1 Where these terms appear in this specification they

bers in conjunction with secondary members that interlock, as

shall have the meaning herein indicated as follows:

well as with those of noninterlocking type.

3.1.1.1 backing board—a flat sheet of gypsum board to

1.3 While this specification is applicable to the exterior

which acoustical tile is attached using adhesive, screws,

installation of metal suspension systems, the atmospheric

staples, or other suitable means (Fig. 1c).

conditionsandwindloadingrequireadditionaldesignattention

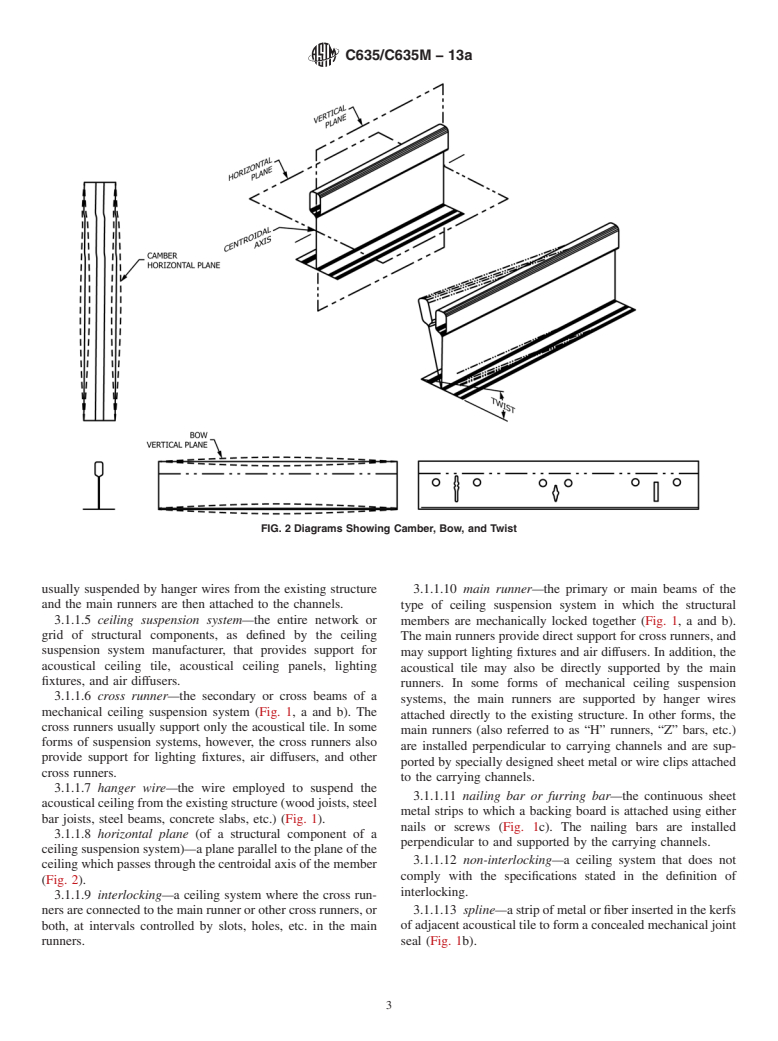

3.1.1.2 bow—the maximum component of deviation in the

to ensure safe implementation. For that reason, a specific

vertical plane of a main runner, cross runner, or wall molding

review and approval should be solicited from the responsible

where the centroidal axis of these structural components has

architect and engineer, or both, for any exterior application of

been permanently deformed from end to end into the shape of

metalsuspensionsystemsintheconstructionofanewbuilding

a simple regular curve during the manufacturing process (Fig.

or building modification.

2).

1.4 The values stated in either SI units or inch-pound units

NOTE1—Themeaningsfor bowand cambergivenheremaydifferfrom

are to be regarded separately as standard. The values stated in those applied elsewhere.

each system may not be exact equivalents; therefore, each

3.1.1.3 camber—the maximum component of deviation in

system shall be used independently of the other. Combining

the horizontal plane of a main runner, cross runner, or wall

values from the two systems may result in non-conformance

molding where the centroidal axis of these structural compo-

with the standard.

nents has been permanently deformed from end to end into the

shape of a simple regular curve during the manufacturing

1.5 The following safety hazards caveat pertains only to the

process (Fig. 2).

testmethodsdescribedinthisspecification. This standard does

3.1.1.4 carrying channel or hanging channel—the three-

not purport to address all of the safety concerns, if any,

sided or “[”-shaped metal sections that support the entire

associated with its use. It is the responsibility of the user of this

structural grid network in some forms of mechanical ceiling

suspension systems (Fig. 1b). The carrying channels are

1

This specification is under the jurisdiction of ASTM Committee E33 on

Building and Environmental Acoustics and is the direct responsibility of Subcom-

2

mittee E33.04 on Application of Acoustical Materials and Systems. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2013. Published December 2013. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1969. Last previous edition approved in 2013 as C635–13. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0635_C0635M-13A. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C635/C635M − 13a

FIG. 1 Three Types of Ceiling Suspension Systems Showing All Components

2

---------------------- Page: 2 ----------------------

C635/C635M − 13a

FIG. 2 Diagrams Showing Camber, Bow, and Twist

usuall

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C635/C635M − 13 C635/C635M − 13a

Standard Specification for

the Manufacture, Performance, and Testing of Metal

Suspension Systems for Acoustical Tile and Lay-in Panel

1

Ceilings

This standard is issued under the fixed designation C635/C635M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers metal ceiling suspension systems used primarily to support acoustical tile or acoustical lay-in

panels.

1.2 Some suspension systems incorporate locking assembly details that enhance performance by providing some continuity or

load transfer capability between adjacent sections of the ceiling grid. The test methods included in this specification do not provide

the means for making a complete evaluation of continuous beam systems, nor for assessing the continuity contribution to overall

system performance. However, the test methods can be used for evaluating primary structural members in conjunction with

secondary members that interlock, as well as with those of noninterlocking type.

1.3 While this specification is applicable to the exterior installation of metal suspension systems, the atmospheric conditions and

wind loading require additional design attention to ensure safe implementation. For that reason, a specific review and approval

should be solicited from the responsible architect and engineer, or both, for any exterior application of metal suspension systems

in the construction of a new building or building modification.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.5 The following safety hazards caveat pertains only to the test methods described in this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B117 Practice for Operating Salt Spray (Fog) Apparatus

D1735 Practice for Testing Water Resistance of Coatings Using Water Fog Apparatus

3. Terminology

3.1 Definitions:

3.1.1 Where these terms appear in this specification they shall have the meaning herein indicated as follows:

3.1.1.1 backing board—a flat sheet of gypsum board to which acoustical tile is attached using adhesive, screws, staples, or other

suitable means (Fig. 1c).

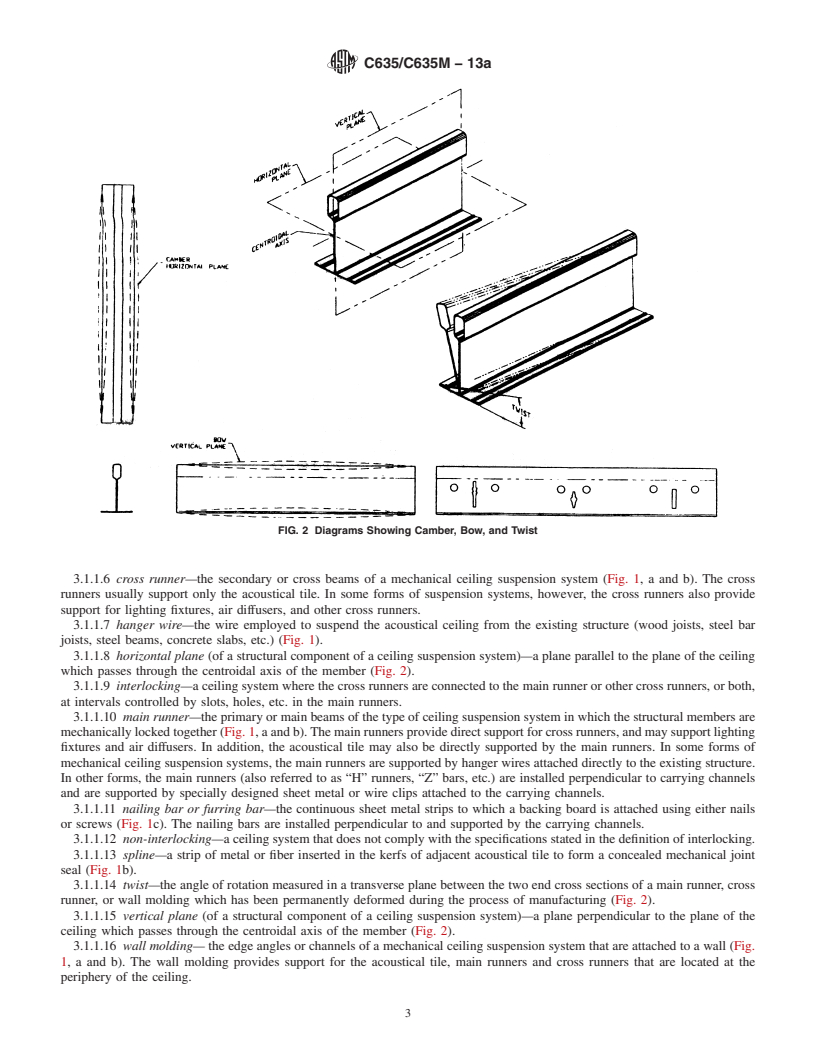

3.1.1.2 bow—the maximum component of deviation in the vertical plane of a main runner, cross runner, or wall molding where

the centroidal axis of these structural components has been permanently deformed from end to end into the shape of a simple

regular curve during the manufacturing process (Fig. 2).

1

This specification is under the jurisdiction of ASTM Committee E33 on Building and Environmental Acoustics and is the direct responsibility of Subcommittee E33.04

on Application of Acoustical Materials and Systems.

Current edition approved May 1, 2013Sept. 1, 2013. Published May 2013December 2013. Originally approved in 1969. Last previous edition approved in 20122013 as

C635 – 12.C635 – 13. DOI: 10.1520/C0635_C0635M-13.10.1520/C0635_C0635M-13A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C635/C635M − 13a

FIG. 1 Three Types of Ceiling Suspension Systems Showing All Components

NOTE 1—The meanings for bow and camber given here may differ from those applied elsewhere.

3.1.1.3 camber—the maximum component of deviation in the horizontal plane of a main runner, cross runner, or wall molding

where the centroidal axis of these structural components has been perman

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.