ASTM D2808-69(1990)

(Test Method)Test Method for Compressive Strength of Corrugated Fiberboard (Short Column Test) (Withdrawn 1991)

Test Method for Compressive Strength of Corrugated Fiberboard (Short Column Test) (Withdrawn 1991)

General Information

Standards Content (Sample)

(#Tb Designation: D 2808 - 69 (Reapproved 1990)

Standard Test Method for

Compressive Strength of Corrugated Fiberboard (Short

Column Test)'

This standard is issued under the fixed designation D 2808; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

supemipt epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the

edgewise compressive strength, parallel to the flutes, of

single-wall, double-wall, or triple-wall corrugated fiberboard.

1.2 This standard does not purport to address the sajêty

problems associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and

health practices and determine the applicabilìly of regulatory

limitations prior to use.

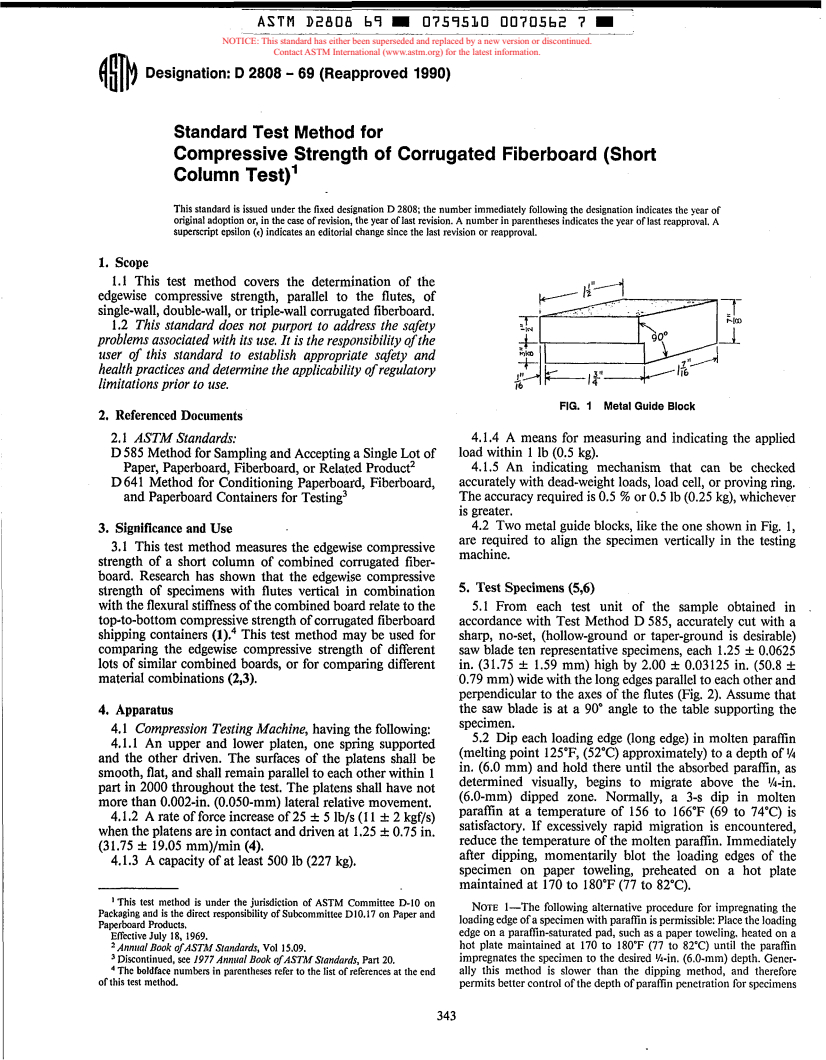

FIG. 1 Metal Guide Block

2. Referenced Documents

4.1.4 A means for measuring and indicating the applied

2,l ASTM Standards:

load within 1 lb (0.5 kg).

D 585 Method for Sampling and Accepting a Single Lot of

4.1.5 An indicating mechanism that can be checked

Paper, Paperboard, Fiberboard, or Related Product'

accurately with dead-weight loads, load cell, or proving ring.

D 64 1 Method for Conditioning Paperboard, Fiberboard,

The accuracy required is 0.5 ?6 or 0.5 Ib (0.25 kg), whichever

and Paperboard Containers for Testing3

is greater.

4.2 Two metal guide blocks, like the one shown in Fig. 1,

3. Significance and Use

are required to align the specimen vertically in the testing

3.1 This test method measures the edgewise compressive

machine.

strength of a short column of combined corrugated fiber-

board. Research has shown that the edgewise compressive

5. Test Specimens (5,6)

strength of specimens with flutes vertical in combination

with the flexural stiffness of the combined board relate to the 5.1 From each test unit of the sample obtained in

top-to-bottom compressive strength of corrugated fiberboard accordance with Test Method D 585, accurately cut with a

shipping containers (i)? This test method may be used for sharp, no-set, (hollow-ground or taper-ground is desirable)

comparing the edgewise compressive strength of different saw blade ten representative specimens, each 1.25 f 0.0625

lots of similar combined boards, or for comparing different in. (31.75 & 1.59 mm) high by 2.00 f 0.03125 in. (50.8 f

material combinations (2,3). 0.79 mm) wide with the long edges parallel to each other and

perpendicular to the axes of the flutes (Fig. 2). Assume that

the saw blade is at a 90" angle to the table supporting the

4. Apparatus

specimen.

4.1 Compression Testing Machine, having the following:

5.2 Dip each loading edge (long edge) in molten parafin

4.1.1 An upper and lower platen, one spnng supported

(melting point 125"F, (52°C) approximately) to a depth of YI

and the other driven. The surfaces of the platens shall be

in. (6.0 mm) and hold there until the absorbed parafin, as

smooth, fiat, and shall remain parallel to each other within 1

determined visually, begins to migrate above the Y4-in.

part in 2000 throughout the test. The platens shall have not

(6.0-mm) dipped zone. Normally, a 3-s dip in molten

more than 0.002-in. (0.050-mm) lateral relative movement.

parafin at a temperature of 156 to 166°F (69 to 74°C) is

4.1.2 A rate of force increase of 25 I 5 lb/s (I 1 f 2 kgf/s)

satisfactory. If excessively rapid migration is encountered,

when the platens are in contact and driven at 1.25 f 0.75 in.

reduce the temperature of the molten paraffin. Immediately

(31.75 f 19.05 mm)/min (4).

after dipping, momentarily blot the loading edges of the

4.1.3 A capacity of at least 500 lb (227 kg).

specimen on paper toweling, preheated on a hot plate

maintained at 170 to 180°F (77 to 82°C).

I This test method is under the jurisdiction of ASTM Committee D-10 on

NOTE 1-The following alternative procedure for impregnating the

Packaging and is the direct responsibility of Subcommittee D10.17 on Paper and

a specimen with paraffin is permissible: Place the loading

loading edge of

Paperboard Products.

edge on a parafin-saturated pad, such as a paper toweling. heated on a

Effective July 18, 1969.

hot plate maintained at 170 to 189°F (77 to 82'C) until the parafin

- Annrral Book of ASTM Standards, Vol 15.09.

impregnates the specimen to the desired %-in. (6.0-mm) depth. Gener-

Discontinued, see i977 Anniral Book ofASTAf Standards, Part 20.

The boldface numbers in parentheses refer to the list of references at the end ally this method is slower than the dipping method, and therefore

of this test method. permits better control of the depth of paraffin penetration for specimens

343

---------------------- Page: 1 ----------------------

ASTM D2808 b9 = 0759530 00705b3 9 W

platen movement rate determined in 6.2. When the load

...

This May Also Interest You

ABSTRACT

This test method measures the formaldehyde concentration in air and emission rate from wood products containing formaldehyde by the use of a large chamber under specific test conditions of temperature and relative humidity, or conditions designed to simulate product use. This method employs a single set of environmental conditions but different product loading ratios to assess formaldehyde concentrations in air and emission rates from certain wood products. The conditions controlled in the procedure are the conditioning of specimens prior to testing, exposed surface area of the specimens in the test chamber, test chamber temperature and relative humidity, number of air changes per hour, and air circulation within the chamber. At the end of a specified time period in the test chamber, the air is sampled, and the concentration of formaldehyde in the air and emission rate are determined.

SIGNIFICANCE AND USE

4.1 Significance and Use:

4.1.1 Limitations on formaldehyde concentrations in air have been established for some building products permanently installed in manufactured and conventional homes. This test method provides a standard means of testing typical product sizes, such as 1.2 m by 2.4 m (4 ft by 8 ft) sheets, at product loadings consistent with product end use.

4.2 Summary of Test Method:

4.2.1 This test method incorporates a chamber of 22 m3 (800 ft3) minimum size to evaluate formaldehyde concentrations in air and emission rates from building products over a specified duration of time. This test method employs a single set of environmental conditions but different product loading ratios to assess formaldehyde concentrations in air and emission rates from certain wood products. Conditions controlled in the procedure are as follows:

4.2.1.1 Conditioning of specimens prior to testing,

4.2.1.2 Exposed surface area of the specimens in the test chamber,

4.2.1.3 Test chamber temperature and relative humidity,

4.2.1.4 Number of air changes per hour, and

4.2.1.5 Air circulation within the chamber.

4.2.1.6 At the end of a 16 to 20-h period in the test chamber, the air is sampled and the concentration of formaldehyde in air and emission rate are determined.

Note 3: Care must be exercised in the extension of the results to formaldehyde concentrations in air and emission rates from products under different conditions of air change rate or loading ratio, or both.

SCOPE

1.1 This test method measures the formaldehyde concentration in air and emission rate from wood products containing formaldehyde under conditions designed to simulate product use (see 11.5 and Note 9). The concentration in air and emission rate is determined in a large chamber under specific test conditions of temperature and relative humidity. The general procedures are also intended for testing product combinations at product-loading ratios and at air-exchange rates typical of the indoor environment (1).2 The products tested, the loading ratios and the air exchange rates employed are described in the test report.

1.2 This test method determines the average formaldehyde concentration in air and emission rate from a number of large size samples. The average concentration and emission rate reported, thus, will not provide information on higher or lower emitting panels in the test lot.

1.3 This method is primarily used for testing newly manufactured panel products that are shipped for testing either seal-wrapped in polyethylene or with waster sheets, or with both. When this test method is used for evaluating other than newly manufactured panel products (after original application, installation or use), the method of packaging and shipping the product for testing shall be described in the test report.

1.4 The quantity of formaldehyde in the air sample taken from the chamber is determined by an adaptation of the National Institute for Occupational Safety and Health (NIOSH) chromotropic acid test procedure. If ...

- Standard13 pagesEnglish languagesale 15% off

- Standard13 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The ability to quickly and accurately evaluate and predict long-term weathering performance of factory-applied coatings is of paramount importance in making sound business and technical decisions.

5.2 It is important to include control specimens of known field performance to determine the efficacy of this practice for specific substrate(s) and coating system(s). These control specimens may include materials known to possess acceptable and unacceptable field performance for the defect(s) under consideration.

5.3 Results derived from this practice are best used to compare the relative performance of materials tested at the same time in the same device.

5.4 The inclusion of control specimens and their resulting data will assist in dealing with test variability caused by seasonal or annual variations in important climatic factors.

5.5 Extensive research was performed during the development of this standard practice. This research showed that this practice is not useful for determination of quantitative acceleration factors. However, this practice is very useful for comparing the performance of different materials.

5.6 A minimum of two replicates for both control specimens and test specimens is recommended to allow statistical evaluation of results. Refer to Practice G169 for additional guidance on establishing the number of replicates.

SCOPE

1.1 This practice covers techniques to accelerate weathering effects of factory-coated embossed hardboard using Cycle 1 of Practice G90 (concentrated natural sunlight with periodic surface water spray) plus a soak-freeze thaw cycle (see Section 5 of this practice).

1.2 Testing by use of the methods described in this practice may be employed in the qualitative assessment of weathering effects. The relative durability of coated hardboards may be best determined by comparison of their test results with those of control specimens derived from real time exposure test experience.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The flexural properties evaluated by this test method are intended to provide any one or all of the following:

5.1.1 Data on the comparative effects of fire-retardant chemical formulations and environmental conditions on the flexural properties of plywood.

5.1.2 Data for use in developing modification factors for the allowable design properties of treated plywood when exposed to elevated temperatures and humidities.

5.1.3 Data comparing variables, such as other plywood species and dimensions.

5.2 Results obtained from tests conducted and analyzed in accordance with the procedures of this test method are suitable for use with other information to establish recommended roof sheathing spans for fire-retardant treated plywood.

Note 1: Temperatures lower than the test temperature specified in this test method and the cumulative effects of the elevated temperatures and humidity exposures expected to be encountered in service should be taken into account when recommended roof sheathing spans are established.

Note 2: Practice D6305 can be used to extend the laboratory strength data obtained by this test method to design value recommendations. The test data determined by this test method are used to develop adjustment factors for fire-retardant treatments to apply to untreated plywood design values. The test data are used in conjunction with climate models and other factors.

SCOPE

1.1 This test method is designed to determine the effect of exposure to high temperatures and humidities on the flexure properties of fire-retardant treated softwood plywood. In this test method, plywood is exposed to a temperature of 77°C (170°F).

1.2 The purpose of the test method is to compare the flexural properties of fire-retardant treated plywood relative to untreated plywood. The results of tests conducted in accordance with this test method provide a reference point for estimating strength temperature relationships. This test method is intended to provide an accelerated test at elevated temperatures and controlled humidities of plywood sheathing treated with the same chemical formulation(s) and processing conditions as plywood used commercially.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard7 pagesEnglish languagesale 15% off

- Standard7 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The flexural properties evaluated by this test method are intended to provide any one or all of the following:

5.1.1 Data on the comparative effects of fire-retardant chemical formulations and environmental conditions on the flexural properties of plywood.

5.1.2 Data for use in developing modification factors for the allowable design properties of treated plywood when exposed to elevated temperatures and humidities.

5.1.3 Data comparing variables, such as other plywood species and dimensions.

5.2 Results obtained from tests conducted and analyzed in accordance with the procedures of this test method may be used with other information to establish recommended roof sheathing spans for fire-retardant treated plywood.

Note 1: Temperatures lower than the test temperature specified in this test method and the cumulative effects of the elevated temperatures and humidity exposures expected to be encountered in service should be taken into account when recommended roof sheathing spans are established.

Note 2: Practice D6305 can be used to extend the laboratory strength data obtained by this test method to design value recommendations. The test data determined by this test method are used to develop adjustment factors for fire-retardant treatments to apply to untreated plywood design values. The test data are used in conjunction with climate models and other factors.

SCOPE

1.1 This test method is designed to determine the effect of exposure to high temperatures and humidities on the flexure properties of fire-retardant treated softwood plywood. In this test method, plywood is exposed to a temperature of 77°C (170°F).

1.2 The purpose of the test method is to compare the flexural properties of fire-retardant treated plywood relative to untreated plywood. The results of tests conducted in accordance with this test method provide a reference point for estimating strength temperature relationships. This test method is intended to provide an accelerated test at elevated temperatures and controlled humidities of plywood sheathing treated with the same chemical formulation(s) and processing conditions as plywood used commercially.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard7 pagesEnglish languagesale 15% off

- Standard7 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The ability to quickly and accurately evaluate and predict long-term weathering performance of factory-applied coatings is of paramount importance in making sound business and technical decisions.

5.2 It is important to include control specimens of known field performance to determine the efficacy of this practice for specific substrate(s) and coating system(s). These control specimens may include materials known to possess acceptable and unacceptable field performance for the defect(s) under consideration.

5.3 Results derived from this practice are best used to compare the relative performance of materials tested at the same time in the same device.

5.4 The inclusion of control specimens and their resulting data will assist in dealing with test variability caused by seasonal or annual variations in important climatic factors.

5.5 Extensive research was performed during the development of this standard practice. This research showed that this practice is not useful for determination of quantitative acceleration factors. However, this test is very useful as a comparative test.

5.6 A minimum of two replicates for both control specimens and test specimens is recommended to allow statistical evaluation of results. Refer to Practice G169 for additional guidance on establishing the number of replicates.

SCOPE

1.1 This practice covers techniques to accelerate weathering effects of factory-coated embossed hardboard using Cycle 1 of Practice G90 (concentrated natural sunlight with periodic surface water spray) plus a soak-freeze thaw cycle (see Section 5 of this practice).

1.2 Testing by use of the methods described in this practice may be employed in the qualitative assessment of weathering effects. The relative durability of coated hardboards may be best determined by comparison of their test results with those of control specimens derived from real time exposure test experience.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

- Standard3 pagesEnglish languagesale 15% off

- Standard3 pagesEnglish languagesale 15% off

ABSTRACT

This test method measures the formaldehyde concentration in air and emission rate from wood products containing formaldehyde by the use of a large chamber under specific test conditions of temperature and relative humidity, or conditions designed to simulate product use. This method employs a single set of environmental conditions but different product loading ratios to assess formaldehyde concentrations in air and emission rates from certain wood products. The conditions controlled in the procedure are the conditioning of specimens prior to testing, exposed surface area of the specimens in the test chamber, test chamber temperature and relative humidity, number of air changes per hour, and air circulation within the chamber. At the end of a specified time period in the test chamber, the air is sampled, and the concentration of formaldehyde in the air and emission rate are determined.

SIGNIFICANCE AND USE

4.1 Significance and Use:

4.1.1 Limitations on formaldehyde concentrations in air have been established for some building products permanently installed in manufactured and conventional homes. This test method provides a standard means of testing typical product sizes, such as 1.2 by 2.4 m (4 by 8 ft) sheets, at product loadings consistent with product end use.

4.2 Summary of Test Method:

4.2.1 This test method incorporates a chamber of 22 m3 (800 ft3) minimum size to evaluate formaldehyde concentrations in air and emission rates from building products over a specified duration of time. This test method employs a single set of environmental conditions but different product loading ratios to assess formaldehyde concentrations in air and emission rates from certain wood products. Conditions controlled in the procedure are as follows:

4.2.1.1 Conditioning of specimens prior to testing,

4.2.1.2 Exposed surface area of the specimens in the test chamber,

4.2.1.3 Test chamber temperature and relative humidity,

4.2.1.4 Number of air changes per hour, and

4.2.1.5 Air circulation within the chamber.

4.2.1.6 At the end of a 16 to 20-h period in the test chamber, the air is sampled and the concentration of formaldehyde in air and emission rate are determined.

Note 3: Care must be exercised in the extension of the results to formaldehyde concentrations in air and emission rates from products under different conditions of air change rate or loading ratio, or both.

SCOPE

1.1 This test method measures the formaldehyde concentration in air and emission rate from wood products containing formaldehyde under conditions designed to simulate product use (see 11.5 and Note 9). The concentration in air and emission rate is determined in a large chamber under specific test conditions of temperature and relative humidity. The general procedures are also intended for testing product combinations at product-loading ratios and at air-exchange rates typical of the indoor environment (1).2 The products tested, the loading ratios and the air exchange rates employed are described in the test report.

1.2 This test method determines the average formaldehyde concentration in air and emission rate from a number of large size samples. The average concentration and emission rate reported, thus, will not provide information on higher or lower emitting panels in the test lot.

1.3 This method is primarily used for testing newly manufactured panel products that are shipped for testing either seal-wrapped in polyethylene or with waster sheets, or with both. When this test method is used for evaluating other than newly manufactured panel products (after original application, installation or use), the method of packaging and shipping the product for testing shall be described in the test report.

1.4 The quantity of formaldehyde in the air sample taken from the chamber is determined by an adaptation of the National Institute for Occupational Safety and Health (NIOSH) chromotropic acid test procedure. If anoth...

- Standard13 pagesEnglish languagesale 15% off

- Standard13 pagesEnglish languagesale 15% off

ABSTRACT

This test method measures the formaldehyde concentration in air and emission rate from wood products containing formaldehyde by the use of a large chamber under specific test conditions of temperature and relative humidity, or conditions designed to simulate product use. This method employs a single set of environmental conditions but different product loading ratios to assess formaldehyde concentrations in air and emission rates from certain wood products. The conditions controlled in the procedure are the conditioning of specimens prior to testing, exposed surface area of the specimens in the test chamber, test chamber temperature and relative humidity, number of air changes per hour, and air circulation within the chamber. At the end of a specified time period in the test chamber, the air is sampled, and the concentration of formaldehyde in the air and emission rate are determined.

SIGNIFICANCE AND USE

Significance and Use:

Limitations on formaldehyde concentrations in air have been established for some building products permanently installed in manufactured and conventional homes. This test method provides a standard means of testing typical product sizes, such as 1.2 by 2.4 m (4 by 8 ft) sheets, at product loadings consistent with product end use.

Summary of Test Method:

This test method incorporates a chamber of 22 m3 (800 ft3) minimum size to evaluate formaldehyde concentrations in air and emission rates from building products over a specified duration of time. This test method employs a single set of environmental conditions but different product loading ratios to assess formaldehyde concentrations in air and emission rates from certain wood products. Conditions controlled in the procedure are as follows:

Conditioning of specimens prior to testing,

Exposed surface area of the specimens in the test chamber,

Test chamber temperature and relative humidity,

Number of air changes per hour, and

Air circulation within the chamber.

At the end of a 16 to 20-h period in the test chamber, the air is sampled and the concentration of formaldehyde in air and emission rate are determined.

Note 3—Care must be exercised in the extension of the results to formaldehyde concentrations in air and emission rates from products under different conditions of air change rate or loading ratio, or both.

SCOPE

1.1 This test method measures the formaldehyde concentration in air and emission rate from wood products containing formaldehyde under conditions designed to simulate product use (see 11.5 and Note 9). The concentration in air and emission rate is determined in a large chamber under specific test conditions of temperature and relative humidity. The general procedures are also intended for testing product combinations at product-loading ratios and at air-exchange rates typical of the indoor environment (1). The products tested, the loading ratios and the air exchange rates employed are described in the test report.

1.2 This test method determines the average formaldehyde concentration in air and emission rate from a number of large size samples. The average concentration and emission rate reported, thus, will not provide information on higher or lower emitting panels in the test lot.

1.3 This method is primarily used for testing newly manufactured panel products that are shipped for testing either seal-wrapped in polyethylene or with waster sheets, or with both. When this test method is used for evaluating other than newly manufactured panel products (after original application, installation or use), the method of packaging and shipping the product for testing shall be described in the test report.

1.4 The quantity of formaldehyde in the air sample taken from the chamber is determined by an adaptation of the National Institute for Occupational Safety and Health (NIOSH) chromotropic acid test procedure. If another analytical procedure is used to determine the quantity of formaldehyde ...

- Standard13 pagesEnglish languagesale 15% off

- Standard13 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

The flexural properties evaluated by this test method are intended to provide any one or all of the following:

Data on the comparative effects of fire-retardant chemical formulations and environmental conditions on the flexural properties of plywood.

Data for use in developing modification factors for the allowable design properties of treated plywood when exposed to elevated temperatures and humidities.

Data comparing variables, such as other plywood species and dimensions.

Results obtained from tests conducted and analyzed in accordance with the procedures of this test method may be used with other information to establish recommended roof sheathing spans for fire-retardant treated plywood.

Note 1—Temperatures lower than the test temperature specified in this test method and the cumulative effects of the elevated temperatures and humidity exposures expected to be encountered in service should be taken into account when recommended roof sheathing spans are established.

SCOPE

1.1 This test method is designed to determine the effect of exposure to high temperatures and humidities on the flexure properties of fire-retardant treated softwood plywood. In this test method, plywood is exposed to a temperature of 77°C (170°F).

1.2 The purpose of the test method is to compare the flexural properties of fire-retardant treated plywood relative to untreated plywood. The results of tests conducted in accordance with this test method provide a reference point for estimating strength temperature relationships. This test method is intended to provide an accelerated test at elevated temperatures and controlled humidities of plywood sheathing treated with the same chemical formulation(s) and processing conditions as plywood used commercially.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

- Standard7 pagesEnglish languagesale 15% off

- Standard7 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

The ability to quickly and accurately evaluate and predict long-term weathering performance of factory-applied coatings is of paramount importance in making sound business and technical decisions.

It is important to include control specimens of known field performance to determine the efficacy of this practice for specific substrate(s) and coating system(s). These control specimens may include materials known to possess acceptable and unacceptable field performance for the defect(s) under consideration.

Results derived from this practice are best used to compare the relative performance of materials tested at the same time in the same device.

The inclusion of control specimens and their resulting data will assist in dealing with test variability caused by seasonal or annual variations in important climatic factors.

Extensive research was performed during the development of this standard practice. This research showed that this practice is not useful for determination of quantitative acceleration factors. However, this test is very useful as a comparative test.

A minimum of two replicates for both control specimens and test specimens is recommended to allow statistical evaluation of results. Refer to Practice G 169 for additional guidance on establishing the number of replicates.

SCOPE

1.1 This practice covers techniques to accelerate weathering effects of factory-coated embossed hardboard using Cycle 1 of Practice G 90 (concentrated natural sunlight with periodic surface water spray) plus a soak-freeze thaw cycle (see Section 5 of this practice).

1.2 Testing by use of the methods described in this practice may be employed in the qualitative assessment of weathering effects. The relative durability of coated hardboards may be best determined by comparison of their test results with those of control specimens derived from real time exposure test experience.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

- Standard3 pagesEnglish languagesale 15% off

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

The ability to quickly and accurately evaluate and predict long-term weathering performance of factory-applied coatings is of paramount importance in making sound business and technical decisions.

It is important to include control specimens of known field performance to determine the efficacy of this practice for specific substrate(s) and coating system(s). These reference specimens may include materials known to possess acceptable and unacceptable field performance for the defect(s) under consideration.

Results derived from this practice are best used to compare the relative performance of materials tested at the same time in the same device.

The inclusion of control specimens and their resulting data will assist in dealing with test variability caused by seasonal or annual variations in important climatic factors. However, quantitative service life approximations “acceleration factors” based on the above data are not recommended unless a sufficient number of field/accelerated test comparisons have been analyzed to compute the statistical significance of the “time to failure” estimate for each exposure.

A minimum of two replicates for both control specimens and test specimens is recommended to allow statistical evaluation of results.

SCOPE

1.1 This practice covers techniques to accelerate weathering effects of factory-coated embossed hardboard using apparatus described in Practice G 90.

1.2 This practice is based upon Cycle 1 of Practice G 90 (concentrated natural sunlight with periodic surface water spray) plus a soak-freeze-thaw cycle (see 5 of this practice).

1.3 Testing by use of the methods described in this practice may be employed in the qualitative assessment of weathering effects. The relative durability of coated hardboards may be best determined by comparison of their test results with those of pass-fail control specimens derived from real time exposure test experience (see 8.2 for specific guidelines).

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

- Standard3 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.