ASTM D5516-17

(Test Method)Standard Test Method for Evaluating the Flexural Properties of Fire-Retardant Treated Softwood Plywood Exposed to Elevated Temperatures

Standard Test Method for Evaluating the Flexural Properties of Fire-Retardant Treated Softwood Plywood Exposed to Elevated Temperatures

SIGNIFICANCE AND USE

5.1 The flexural properties evaluated by this test method are intended to provide any one or all of the following:

5.1.1 Data on the comparative effects of fire-retardant chemical formulations and environmental conditions on the flexural properties of plywood.

5.1.2 Data for use in developing modification factors for the allowable design properties of treated plywood when exposed to elevated temperatures and humidities.

5.1.3 Data comparing variables, such as other plywood species and dimensions.

5.2 Results obtained from tests conducted and analyzed in accordance with the procedures of this test method may be used with other information to establish recommended roof sheathing spans for fire-retardant treated plywood.

Note 1: Temperatures lower than the test temperature specified in this test method and the cumulative effects of the elevated temperatures and humidity exposures expected to be encountered in service should be taken into account when recommended roof sheathing spans are established.

Note 2: Practice D6305 can be used to extend the laboratory strength data obtained by this test method to design value recommendations. The test data determined by this test method are used to develop adjustment factors for fire-retardant treatments to apply to untreated plywood design values. The test data are used in conjunction with climate models and other factors.

SCOPE

1.1 This test method is designed to determine the effect of exposure to high temperatures and humidities on the flexure properties of fire-retardant treated softwood plywood. In this test method, plywood is exposed to a temperature of 77°C (170°F).

1.2 The purpose of the test method is to compare the flexural properties of fire-retardant treated plywood relative to untreated plywood. The results of tests conducted in accordance with this test method provide a reference point for estimating strength temperature relationships. This test method is intended to provide an accelerated test at elevated temperatures and controlled humidities of plywood sheathing treated with the same chemical formulation(s) and processing conditions as plywood used commercially.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5516 − 17

Standard Test Method for

Evaluating the Flexural Properties of Fire-Retardant Treated

1

Softwood Plywood Exposed to Elevated Temperatures

This standard is issued under the fixed designation D5516; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method is designed to determine the effect of 2.1 ASTM Standards:

exposure to high temperatures and humidities on the flexure D9 Terminology Relating to Wood and Wood-Based Prod-

properties of fire-retardant treated softwood plywood. In this ucts

test method, plywood is exposed to a temperature of 77°C D1165 Nomenclature of Commercial Hardwoods and Soft-

(170°F). woods

D2915 Practice for Sampling and Data-Analysis for Struc-

1.2 The purpose of the test method is to compare the

tural Wood and Wood-Based Products

flexural properties of fire-retardant treated plywood relative to

D3043 Test Methods for Structural Panels in Flexure

untreated plywood. The results of tests conducted in accor-

D4933 Guide for Moisture Conditioning of Wood and

dance with this test method provide a reference point for

Wood-Based Materials

estimating strength temperature relationships.This test method

D6305 Practice for Calculating Bending Strength Design

is intended to provide an accelerated test at elevated tempera-

Adjustment Factors for Fire-Retardant-Treated Plywood

tures and controlled humidities of plywood sheathing treated

Roof Sheathing

with the same chemical formulation(s) and processing condi-

E84 Test Method for Surface Burning Characteristics of

tions as plywood used commercially.

Building Materials

1.3 The values stated in SI units are to be regarded as

E176 Terminology of Fire Standards

standard. The values given in parentheses are mathematical

E2768 Test Method for Extended Duration Surface Burning

conversions to inch-pound units that are provided for informa-

CharacteristicsofBuildingMaterials(30minTunnelTest)

tion only and are not considered standard.

2.2 Other Standards:

1.4 This standard does not purport to address all of the

AWPA C-27 Plywood-Fire Retardant Treatment by Pressure

3

safety concerns, if any, associated with its use. It is the

Processes

responsibility of the user of this standard to establish appro-

AWPA U1 Use Category System: User Specification for

3

priate safety and health practices and determine the applica-

Treated Wood

bility of regulatory limitations prior to use.

NFPA 703 Standard for Fire Retardant Impregnated Wood

4

1.5 This international standard was developed in accor-

and Fire Retardant Coatings for Building Materials

5

dance with internationally recognized principles on standard-

PS 1 U.S. Product Standard for Structural Plywood

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical 2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Barriers to Trade (TBT) Committee. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This test method is under the jurisdiction of ASTM Committee D07 on Wood Available from American Wood Protection Association (AWPA), P.O. Box

and is the direct responsibility of Subcommittee D07.07 on Fire Performance of 361784, Birmingham, AL 35236-1784, http://www.awpa.com.

4

Wood. Available from National Fire Protection Association (NFPA), 1 Batterymarch

Current edition approved April 15, 2017. Published June 2017. Originally Park, Quincy, MA 02169-7471, http://www.nfpa.org.

5

approved in 1991 as ES 20 – 91. Last previous edition approved in 2009 as Available from the U.S. Department of Commerce, 1401 Constitution Ave.,

D5516 – 09. DOI: 10.1520/D5516-17. NW Washington, DC 20230, http://ts.nist.gov/Standards/Conformity/vps.cfm.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5516 − 17

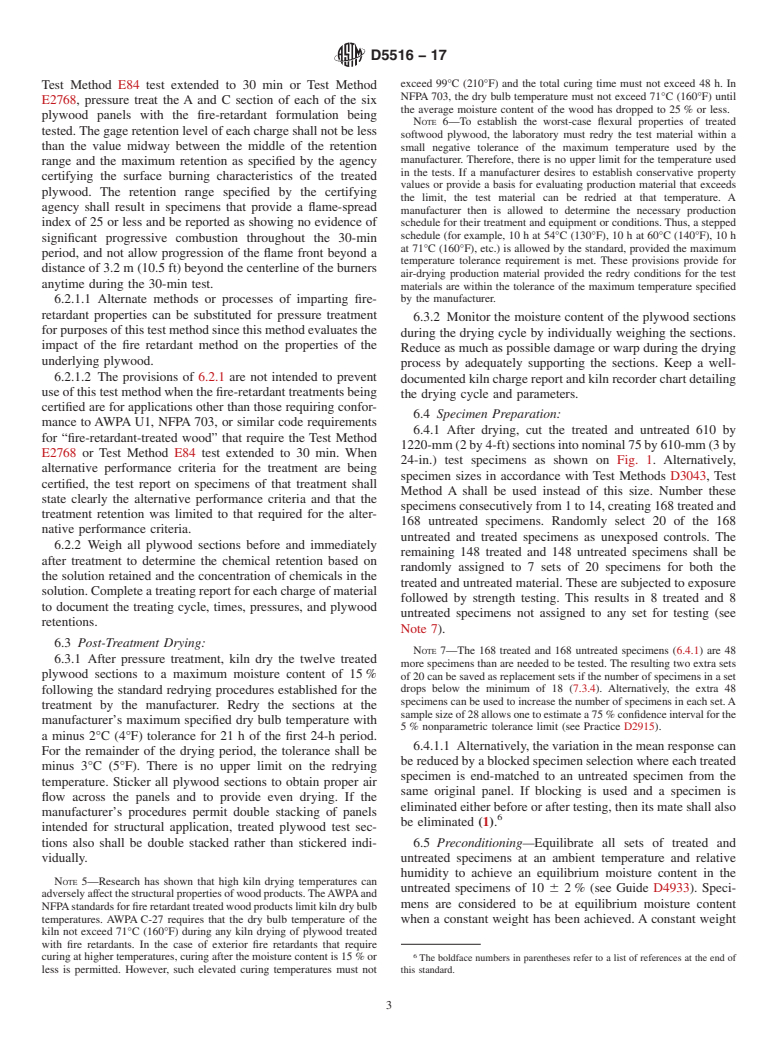

PS 2 U.S. Product Standard for Wood-Based Structural Use 6. Test Specimens

5

Panels

6.1 Material Selection:

6.1.1 Source panels for this test shall be selected from grade

3. Terminology

marked PS 1 or PS 2 commercially available 3, 4, or 5 ply

3.1 Definitions—Definitions used in this test method are in panels of a single thickness, grade, construction, and bond

accordance with Terminologies D9 and E176 and Nomencla- durability. The nominal panel thickness shall be between 12

15 5

ture D1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5516 − 09 D5516 − 17

Standard Test Method for

Evaluating the Flexural Properties of Fire-Retardant Treated

1

Softwood Plywood Exposed to Elevated Temperatures

This standard is issued under the fixed designation D5516; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is designed to determine the effect of exposure to high temperatures and humidities on the flexure

properties of fire-retardant treated softwood plywood. In this test method, plywood is exposed to a temperature of 77°C (170°F).

1.2 The purpose of the test method is to compare the flexural properties of fire-retardant treated plywood relative to untreated

plywood. The results of tests conducted in accordance with this test method provide a reference point for estimating strength

temperature relationships. This test method is intended to provide an accelerated test at elevated temperatures and controlled

humidities of plywood sheathing treated with the same chemical formulation(s) and processing conditions as plywood used

commercially.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions

to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D9 Terminology Relating to Wood and Wood-Based Products

D1165 Nomenclature of Commercial Hardwoods and Softwoods

D2915 Practice for Sampling and Data-Analysis for Structural Wood and Wood-Based Products

D3043 Test Methods for Structural Panels in Flexure

D4933 Guide for Moisture Conditioning of Wood and Wood-Based Materials

D6305 Practice for Calculating Bending Strength Design Adjustment Factors for Fire-Retardant-Treated Plywood Roof

Sheathing

E84 Test Method for Surface Burning Characteristics of Building Materials

E176 Terminology of Fire Standards

E2768 Test Method for Extended Duration Surface Burning Characteristics of Building Materials (30 min Tunnel Test)

2.2 Other Standards:

3

AWPA C-27 Plywood-Fire Retardant Treatment by Pressure Processes

3

AWPA U1 Use Category System: User Specification for Treated Wood

4

NFPA 703 Standard for Fire Retardant Impregnated Wood and Fire Retardant Coatings for Building Materials

5

PS 1 U.S. Product Standard for Structural Plywood

1

This test method is under the jurisdiction of ASTM Committee D07 on Wood and is the direct responsibility of Subcommittee D07.07 on Fire Performance of Wood.

Current edition approved May 15, 2009April 15, 2017. Published June 2009June 2017. Originally approved in 1991 as ES 20 – 91. Last previous edition approved in

20032009 as D5516 – 03.D5516 – 09. DOI: 10.1520/D5516-09.10.1520/D5516-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Wood Protection Association (AWPA), P.O. Box 361784, Birmingham, AL 35236-1784, http://www.awpa.com.

4

Available from National Fire Protection Association (NFPA), 1 Batterymarch Park, Quincy, MA 02169-7471, http://www.nfpa.org.

5

Available from the U.S. Department of Commerce, 1401 Constitution Ave., NW Washington, DC 20230, http://ts.nist.gov/Standards/Conformity/vps.cfm.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5516 − 17

5

PS 2 U.S. Product Standard for Wood-Based Structural Use Panels

3. Terminology

3.1 Definitions—Definitions used in this test method are in accordance with Terminol

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.