ASTM D153-84(2014)

(Test Method)Standard Test Methods for Specific Gravity of Pigments

Standard Test Methods for Specific Gravity of Pigments

ABSTRACT

These test methods cover three procedures for determining the specific gravity of pigments, as follows: Test Method A which is for routine testing of several samples simultaneously, Test Method B which is for tests requiring greater accuracy than Test Method A, and Test Method C which is for rapid and accurate testing of single samples. The specific gravity value obtained by these procedures may be used with the weight of a dry pigment to determine the volume occupied by the pigment in a coating formulation. For Test Method A, the following apparatus and materials shall be used: pycnometer, water bath, manometer, desiccator, vacuum pumps, thermometer, weighing bottle, and immersion liquid. For Test Method B, the following apparatus and materials shall be used: pycnometer, water bath, manometer, vacuum pump, thermometer, weighing bottle, bell jar, and bottle. For Test Method C, the following apparatus and materials shall be used: buret, flask, stopcocks, vacuum pump, manometer, thermometer, weighing bottle, and immersion liquid.

SCOPE

1.1 These test methods cover three procedures for determining the specific gravity of pigments, as follows:

Test Method A—For Routine Testing of Several Samples Simultaneously.

Test Method B—For Tests Requiring Greater Accuracy than Test Method A.

Test Method C—For Rapid and Accurate Testing of Single Samples.

1.2 The specific gravity value obtained by these procedures may be used with the weight of a dry pigment to determine the volume occupied by the pigment in a coating formulation.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Sections 5, 11, and 15.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D153 −84 (Reapproved 2014)

Standard Test Methods for

Specific Gravity of Pigments

This standard is issued under the fixed designation D153; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope TEST METHOD A—FOR ROUTINE TESTING OF

SEVERAL SAMPLES SIMULTANEOUSLY

1.1 These test methods cover three procedures for determin-

ing the specific gravity of pigments, as follows:

4. Apparatus and Materials

Test Method A—For Routine Testing of Several Samples

4.1 Pycnometer—A pycnometer (Note 1) having a 50-mL

Simultaneously.

capacity.

Test Method B—For Tests Requiring Greater Accuracy than

Test Method A.

NOTE 1—The Weld type with the cap seal on the outside of the neck of

Test Method C—For Rapid and Accurate Testing of Single

the bottle is preferred because there is less danger of trapping air just

Samples. under the capillary tube than with types having the ground glass seal on

the inside of the neck.

1.2 The specific gravity value obtained by these procedures

4.2 Water Bath, maintained at 25 6 0.5°C and equipped

may be used with the weight of a dry pigment to determine the

with a stirring device.

volume occupied by the pigment in a coating formulation.

4.3 Manometer, open- or closed-tube (see Part f of the

1.3 The values stated in SI units are to be regarded as the

apparatus for Test Method C), made of glass tubing 6 mm in

standard. The values given in parentheses are for information

diameter, fitted with rubber pressure tubing attached to a

only.

T-joint leading to the desiccator and the pump. For the

1.4 This standard does not purport to address all of the

open-tube type 860 mm of mercury shall be used. The

safety concerns, if any, associated with its use. It is the

difference in levels of the mercury in the manometer when the

responsibility of the user of this standard to establish appro-

system is in operation, subtracted from the barometer reading

priate safety and health practices and determine the applica-

taken at the same time, shall be considered the absolute

bility of regulatory limitations prior to use. For specific hazard

pressure of the system in millimetres of mercury.

statements, see Sections 5, 11, and 15.

4.4 Desiccator, glass, constructed with heavy walls to with-

stand a vacuum of one atmosphere, and with an opening at the

2. Referenced Documents

side.

2.1 ASTM Standards:

4.5 VacuumPumps—Alaboratory water vacuum-type pump

D1193 Specification for Reagent Water

(Note 2), to remove the greater portion of air in the desiccator,

and an oil vacuum-type pump, motor-driven, and capable of

3. Purity of Reagents

reducing the absolute pressure of the system to 3 mm.

3.1 PurityofWater—Reference to water shall be understood

NOTE 2—The water vacuum pump may be omitted if the rate of

to mean reagent water as defined by Type II of Specification

evacuation with the oil pump can be controlled so as to avoid a rapid

D1193.

ebullition of entrapped air and possible loss of specimen.

4.6 Thermometer, having a range from 0 to 60°C, and

graduated in 0.1°C divisions.

These test methods are under the jurisdiction of ASTM Committee D01 on

4.7 WeighingBottle, wide-mouth cylindrical glass (about 30

Paint and Related Coatings, Materials, and Applications and are the direct

responsibility of Subcommittee D01.31 on Pigment Specifications.

mm in height and 70 mm in diameter), provided with a

Current edition approved Dec. 1, 2014. Published December 2014. Originally

ground-glass stopper.

approved in 1923. Last previous edition approved in 2008 as D153 – 84 (2008).

DOI: 10.1520/D0153-84R14.

4.8 Immersion Liquid—Kerosine has been found to be a

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

good wetting vehicle for most pigments, and shall be used

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

generally as the immersion liquid. Refined, white kerosine of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. narrow evaporation and boiling range shall be used.With some

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D153−84 (2014)

pigments that are not wetted well with kerosine, other immer- pigments very rapidly, then this action gradually decreases and

sion liquids such as glycerin, ethylene glycol, finally stops. The time required for complete removal of air

tetrahydronaphthalene, etc., may be substituted. The liquid may vary from 30 min to 24 h, depending upon the nature of

must have a low evaporation rate and narrow boiling range, the pigment. When no more bubbles can be seen, it may be

and the same procedure shall be followed as with kerosine. assumed that the occluded air has been removed and that the

Water is not a preferred liquid because of the possibility of pigment is thoroughly wet with kerosine. Then slowly admit

frothing. air to the desiccator by means of the pinchcock.

7.6 Filling and Bringing to Temperature—Remove the py-

5. Hazards

cnometer from the desiccator, fill with kerosine at 24 to 25°C

5.1 Before a desiccator is used for the first time, wrap it in

taking care to add a sufficient quantity to prevent air bubbles

a towel and test under an absolute pressure of under 3 mm.

wherethepycnometerisclosed,andpermittocometoconstant

Exercise care in handling the desiccator when under vacuum,

temperature at 25 6 0.5°C in the water bath. Carefully stopper

since a sudden jar may cause it to collapse.

the pycnometer and remove excess kerosine with lens paper.

Take the pycnometer out of the bath, allow to come to room

6. Standardization of Pycnometer

temperature, and weigh.

6.1 Fill the pycnometer with freshly boiled water at 23 to

8. Calculation

24°C, gradually bring to 25 6 0.5°C, and then dry and weigh

as specified in 7.6. Empty the pycnometer, and clean, dry, and

8.1 Calculate the specific gravity, S, of the pigment as

reweigh it. Next fill the pycnometer with kerosine at 23 to

follows:

24°C, bring to 25 6 0.5°C, dry, and weigh as before. Calculate

P

the specific gravity, S, of the kerosine at 25/25°C as follows: S 5 (2)

K

W 2

S 5A/B (1)

D

where:

where:

A = weight of kerosine, g, and

P = weight of pigment used, g,

B = weight of water, g.

W = weight of water to fill the pycnometer, g,

K = weight of kerosine added to the pigment, g, and

7. Procedure

D = specific gravity of the kerosine.

7.1 Drying—Dry the pigment, preferably in an electric

9. Precision

oven, at 105 6 2°C for 2 h.

9.1 Duplicate determinations by this test method should not

7.2 Weighing—Transfer to a clean, dry, weighed

differ by more than 0.02.

pycnometer,sufficientsampletoformalayerapproximately20

mm ( ⁄4 in.) deep. For black, blue, and lake pigments of low

TEST METHOD B—FOR TESTS REQUIRING

specific gravity, use about1gof sample; for inert crystalline

GREATER ACCURACY THAN TEST METHOD A

pigments, about 4 g; for opaque white pigments, 7 to 10 g; and

for red lead, from 15 to 20 g.Weigh pigments of a hydroscopic

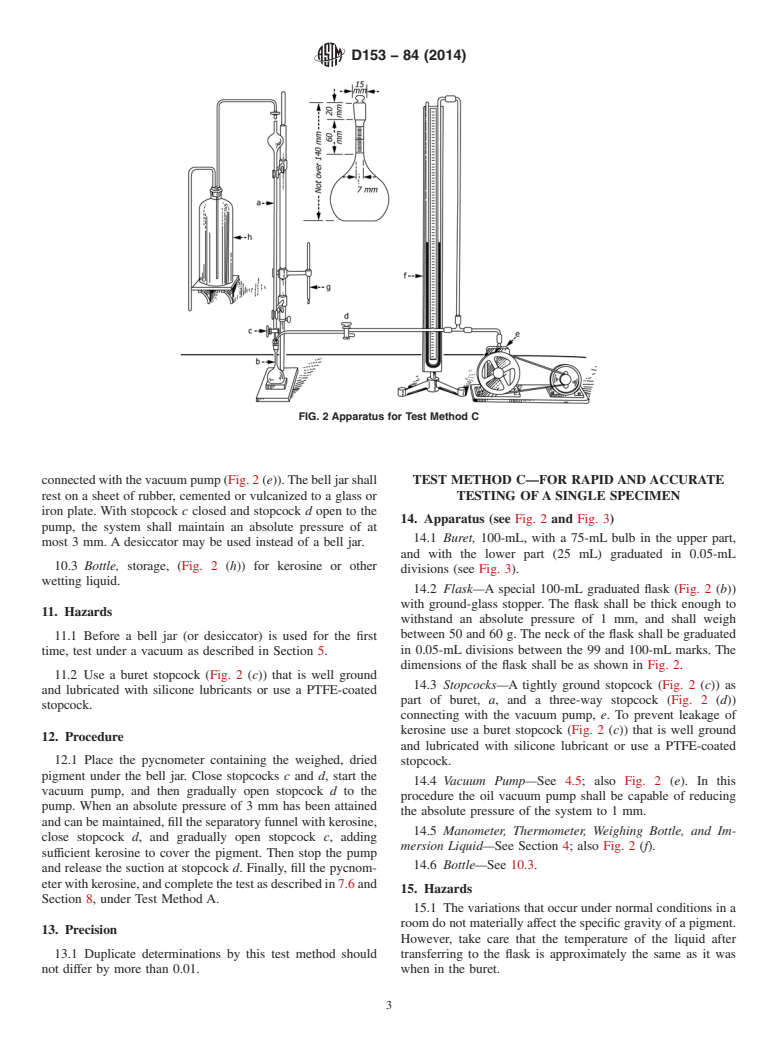

10. Apparatus (see Fig. 1 and Fig. 2)

nature from the weighing bottle.

10.1 Pycnometer, Water Bath, Manometer, Vacuum Pump,

7.3 Number of Specimens—Run all samples at least in

Thermometer, Weighing Bottle, and Immersion Liquid—See

duplicate.

Section 4; also Fig. 2 (e) and (f ).

7.4 Addition of Kerosine—Add enough kerosine to the

10.2 BellJar,glass,withatwo-holerubberstopper.Intoone

pycnometer to form a clear layer approximately ⁄4 in. (6 mm)

hole of the stopper shall be fitted a separatory funnel with a

above the pigment. When necessary, stir the specimen with a

well-ground stopcock (Fig. 1 (c)), extending into the pycnom-

polished round-bottom glass rod until completely covered by

eter. Into the other hole of the stopper shall be fitted a glass

kerosine, adding more kerosine if necessary.Wash the rod with

tube with a well-ground three-way stopcock (Fig. 2 (d)) and

kerosine, adding the washings to the pycnometer.

7.5 Removal of Occluded Air—Place the pycnometer in the

desiccator. Close the desiccator and attach to the water pump

until the greater part of the air is removed from the system.

Complete this procedure within a period of 5 to 10 min. Close

the system with a pinchcock and attach the desiccator to the oil

pump for the removal of the small amounts of air given off at

the low pressures obtainable with the oil pump. Use the

manometer to indicate whether the oil pump is giving the

proper vacuum. When the manometer indicates that the abso-

lute pressure is 3 mm and constant, cut off the oil pump for

short periods, taking care that

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D153 − 84 (Reapproved 2008) D153 − 84 (Reapproved 2014)

Standard Test Methods for

Specific Gravity of Pigments

This standard is issued under the fixed designation D153; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods cover three procedures for determining the specific gravity of pigments, as follows:

Test Method A—For Routine Testing of Several Samples Simultaneously.

Test Method B—For Tests Requiring Greater Accuracy than Test Method A.

Test Method C—For Rapid and Accurate Testing of Single Samples.

1.2 The specific gravity value obtained by these procedures may be used with the weight of a dry pigment to determine the

volume occupied by the pigment in a coating formulation.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Sections 5, 11, and 15.

2. Referenced Documents

2.1 ASTM Standards:

D1193 Specification for Reagent Water

3. Purity of Reagents

3.1 Purity of Water—Reference to water shall be understood to mean reagent water as defined by Type II of Specification

D1193.

TEST METHOD A—FOR ROUTINE TESTING OF SEVERAL SAMPLES SIMULTANEOUSLY

4. Apparatus and Materials

4.1 Pycnometer—A pycnometer (Note 1) having a 50-mL capacity.

NOTE 1—The Weld type with the cap seal on the outside of the neck of the bottle is preferred because there is less danger of trapping air just under

the capillary tube than with types having the ground glass seal on the inside of the neck.

4.2 Water Bath, maintained at 25 6 0.5°C and equipped with a stirring device.

4.3 Manometer, open- or closed-tube (see Part f of the apparatus for Test Method C), made of glass tubing 6 mm in diameter,

fitted with rubber pressure tubing attached to a T-joint leading to the desiccator and the pump. For the open-tube type 860 mm of

mercury shall be used. The difference in levels of the mercury in the manometer when the system is in operation, subtracted from

the barometer reading taken at the same time, shall be considered the absolute pressure of the system in millimetres of mercury.

4.4 Desiccator, glass, constructed with heavy walls to withstand a vacuum of one atmosphere, and with an opening at the side.

4.5 Vacuum Pumps—A laboratory water vacuum-type pump (Note 2), to remove the greater portion of air in the desiccator, and

an oil vacuum-type pump, motor-driven, and capable of reducing the absolute pressure of the system to 3 mm.

These test methods are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.31 on Pigment Specifications.

Current edition approved Feb. 1, 2008Dec. 1, 2014. Published February 2008December 2014. Originally approved in 1923. Last previous edition approved in 20032008

as D153 – 84 (2003).(2008). DOI: 10.1520/D0153-84R08.10.1520/D0153-84R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D153 − 84 (2014)

NOTE 2—The water vacuum pump may be omitted if the rate of evacuation with the oil pump can be controlled so as to avoid a rapid ebullition of

entrapped air and possible loss of specimen.

4.6 Thermometer, having a range from 0 to 60°C, and graduated in 0.1°C divisions.

4.7 Weighing Bottle, wide-mouth cylindrical glass (about 30 mm in height and 70 mm in diameter), provided with a

ground-glass stopper.

4.8 Immersion Liquid—Kerosine has been found to be a good wetting vehicle for most pigments, and shall be used generally

as the immersion liquid. Refined, white kerosine of narrow evaporation and boiling range shall be used. With some pigments that

are not wetted well with kerosine, other immersion liquids such as glycerin, ethylene glycol, tetrahydronaphthalene, etc., may be

substituted. The liquid must have a low evaporation rate and narrow boiling range, and the same procedure shall be followed as

with kerosine. Water is not a preferred liquid because of the possibility of frothing.

5. Hazards

5.1 Before a desiccator is used for the first time, wrap it in a towel and test under an absolute pressure of under 3 mm. Exercise

care in handling the desiccator when under vacuum, since a sudden jar may cause it to collapse.

6. Standardization of Pycnometer

6.1 Fill the pycnometer with freshly boiled water at 23 to 24°C, gradually bring to 25 6 0.5°C, and then dry and weigh as

specified in 7.6. Empty the pycnometer, and clean, dry, and reweigh it. Next fill the pycnometer with kerosine at 23 to 24°C, bring

to 25 6 0.5°C, dry, and weigh as before. Calculate the specific gravity, S, of the kerosine at 25/25°C as follows:

S 5 A/B (1)

where:

A = weight of kerosine, g, and

B = weight of water, g.

7. Procedure

7.1 Drying—Dry the pigment, preferably in an electric oven, at 105 6 2°C for 2 h.

7.2 Weighing—Transfer to a clean, dry, weighed pycnometer, sufficient sample to form a layer approximately 20 mm ( ⁄4 in.)

deep. For black, blue, and lake pigments of low specific gravity, use about 1 g of sample; for inert crystalline pigments, about 4

g; for opaque white pigments, 7 to 10 g; and for red lead, from 15 to 20 g. Weigh pigments of a hydroscopic nature from the

weighing bottle.

7.3 Number of Specimens—Run all samples at least in duplicate.

7.4 Addition of Kerosine—Add enough kerosine to the pycnometer to form a clear layer approximately ⁄4 in. (6 mm) above the

pigment. When necessary, stir the specimen with a polished round-bottom glass rod until completely covered by kerosine, adding

more kerosine if necessary. Wash the rod with kerosine, adding the washings to the pycnometer.

7.5 Removal of Occluded Air—Place the pycnometer in the desiccator. Close the desiccator and attach to the water pump until

the greater part of the air is removed from the system. Complete this procedure within a period of 5 to 10 min. Close the system

with a pinchcock and attach the desiccator to the oil pump for the removal of the small amounts of air given off at the low pressures

obtainable with the oil pump. Use the manometer to indicate whether the oil pump is giving the proper vacuum. When the

manometer indicates that the absolute pressure is 3 mm and constant, cut off the oil pump for short periods, taking care that the

vacuum does not change materially due to leakage. At first bubbles of air rise from the pigments very rapidly, then this action

gradually decreases and finally stops. The time required for complete removal of air may vary from 30 min to 24 h, depending

upon the nature of the pigment. When no more bubbles can be seen, it may be assumed that the occluded air has been removed

and that the pigment is thoroughly wet with kerosine. Then slowly admit air to the desiccator by means of the pinchcock.

7.6 Filling and Bringing to Temperature—Remove the pycnometer from the desiccator, fill with kerosine at 24 to 25°C taking

care to add a sufficient quantity to prevent air bubbles where the pycnometer is closed, and permit to come to constant temperature

at 25 6 0.5°C in the water bath. Carefully stopper the pycnometer and remove excess kerosine with lens paper. Take the

pycnometer out of the bath, allow to come to room temperature, and weigh.

8. Calculation

8.1 Calculate the specific gravity, S, of the pigment as follows:

P

S 5 (2)

K

W 2

D

D153 − 84 (2014)

where:

P = weight of pigment used, g,

W = weight of water to fill the pycnometer, g,

K = weight of kerosine added to the pigment, g, and

D = specific gravity of the kerosine.

9. Precision

9.1 Duplicate determinations by this test method should not differ by more than 0.02.

TEST METHOD B—FOR TESTS REQUIRING GREATER ACCURACY THAN TEST METHOD A

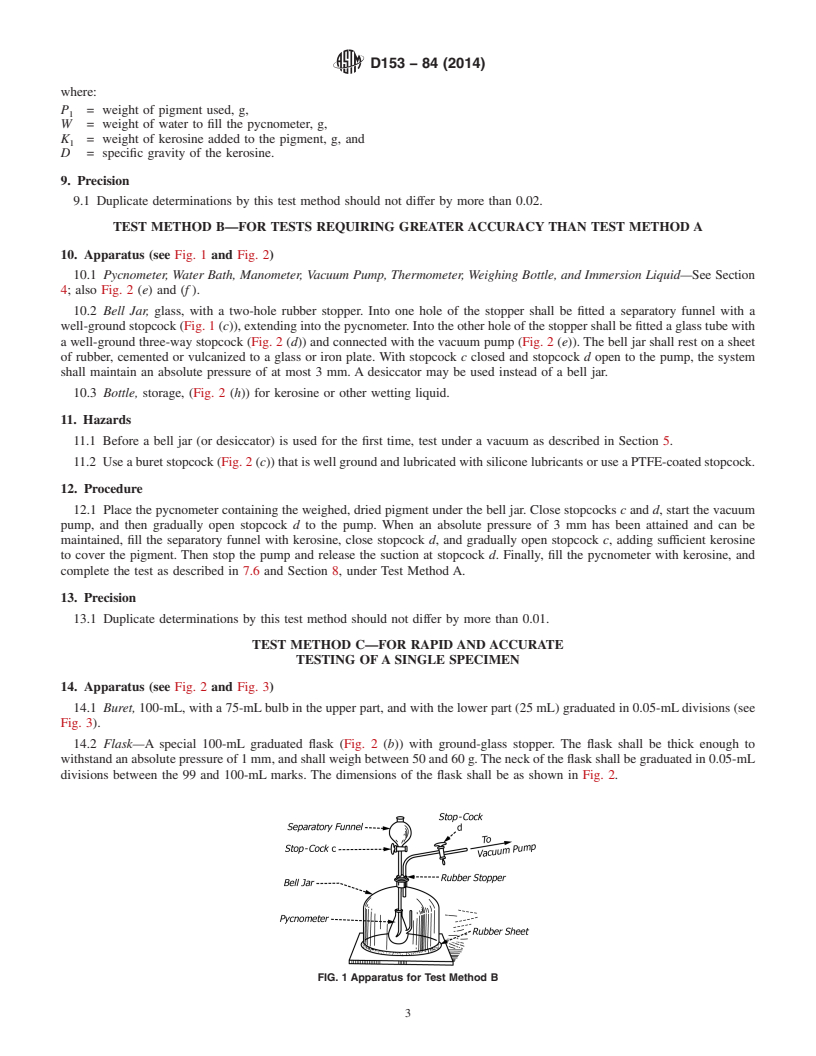

10. Apparatus (see Fig. 1 and Fig. 2)

10.1 Pycnometer, Water Bath, Manometer, Vacuum Pump, Thermometer, Weighing Bottle, and Immersion Liquid—See Section

4; also Fig. 2 (e) and (f ).

10.2 Bell Jar, glass, with a two-hole rubber stopper. Into one hole of the stopper shall b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.