ASTM D6584-00

(Test Method)Test Method for Determination of Free and Total Glycerine in B-100 Biodiesel Methyl Esters by Gas Chromatography

Test Method for Determination of Free and Total Glycerine in B-100 Biodiesel Methyl Esters by Gas Chromatography

SCOPE

1.1 This test method provides for the quantitative determination of free and total glycerin in B-100 methyl esters by gas chromatography. The range of detection for free glycerin is 0.005 to 0.05 mass %, and total glycerin from 0.05 to 0.5 mass %. This procedure is not applicable to vegetable oil methyl esters obtained from lauric oils, such as coconut oil and palmkernel oil.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D6584–00

Test Method for

Determination of Free and Total Glycerin in B-100 Biodiesel

Methyl Esters By Gas Chromatography

This standard is issued under the fixed designation D 6584; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

4.1 The sample is analyzed by gas chromatography, after

1.1 This test method provides for the quantitative determi-

nation of free and total glycerin in B-100 methyl esters by gas silyating with N-methyl-N-trimethylsilyltrifluoracetamide

chromatography. The range of detection for free glycerin is (MSTFA). Calibration is achieved by the use of two internal

0.005 to 0.05 mass %, and total glycerin from 0.05 to 0.5 mass standards and four reference materials. Mono-, di-, and trig-

%. This procedure is not applicable to vegetable oil methyl lycerides are determined by comparing to monoolein, diolein,

esters obtained from lauric oils, such as coconut oil and and triolein standards respectively.Average conversion factors

palmkernel oil. are applied to the mono-, di-, and triglycerides to calculate the

1.2 The values stated in SI units are to be regarded as the bonded glycerin content of the sample.

standard.

5. Significance and Use

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 5.1 Free and bonded glycerin content reflects the quality of

biodiesel. A high content of free glycerin may cause problems

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- during storage, or in the fuel system, due to separation of the

glycerin. A high total glycerin content can lead to injector

bility of regulatory limitations prior to use.

fouling and may also contribute to the formation of deposits at

2. Referenced Documents

injection nozzles, pistons, and valves.

2.1 ASTM Standards:

6. Apparatus

D 4307 Practice for Preparation of Liquid Blends for Use as

6.1 Chromatographic System—See Practice D 355 for spe-

Analytical Standards

E 355 Practice for Gas Chromatography Terms and Rela- cific designations and definitions.

tionships 6.1.1 Gas Chromatograph (GC)—the system must be ca-

pable of operating at the conditions given in Table 1.

E 594 Practice for Testing Flame Ionization Detectors Used

in Gas or Supercritical Fluid Chromatography 6.1.2 Column, open tubular column with a 5 % phenylpoly-

dimethylsiloxane bonded and cross linked phase internal coat-

3. Terminology

ing. The column should have an upper temperature limit of at

3.1 Definitions: least 400°C. Columns, either 10 m or 15 m in length, with a

3.1.1 biodiesel (B-100), n—fuel comprised of mono-alkyl 0.32 mm internal diameter, and a 0.1 µm film thickness have

esters of long chain fatty acids derived from vegetable oils or been found satisfactory. Any column with better or equivalent

animal fats. chromatographic efficiency and selectivity can be used. It is

3.1.2 bonded glycerin, n—is the glycerin portion of the recommended thata2to5 metre 0.53 mm high temperature

mono-, di-, and triglyceride molecules. guard column be installed from the injector to the analytical

3.1.3 total glycerin, n—is the sum of free and bonded column. This allows the use of autoinjectors and also increases

glycerin. column life.

3.2 This test method makes reference to many common gas 6.2 Electronic Data Acquisition System:

chromatographicprocedures,terms,andrelationships.Detailed 6.2.1 Integrator or Computer, capable of providing real

definitions can be found in Practices E 355 and E 594. time graphic and digital presentation of the chromatographic

data is recommended for use. Peak areas and retention times

shall be measured by computer or electronic integration.

This test method is under the jurisdiction of ASTM Committee D02 on

6.2.2 This device must be capable of performing multilevel

Petroleum Products and Lubricants and is the direct responsibility of D02.04 on

internal-standard-type calibrations and be able to calculate the

Hydrocarbon Analysis.

Current edition approved Aug. 10, 2000. Published September 2000.

correlation coefficient (r ) and internal standard calculations

Annual Book of ASTM Standards, Vol 05.02.

for each data set.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6584–00

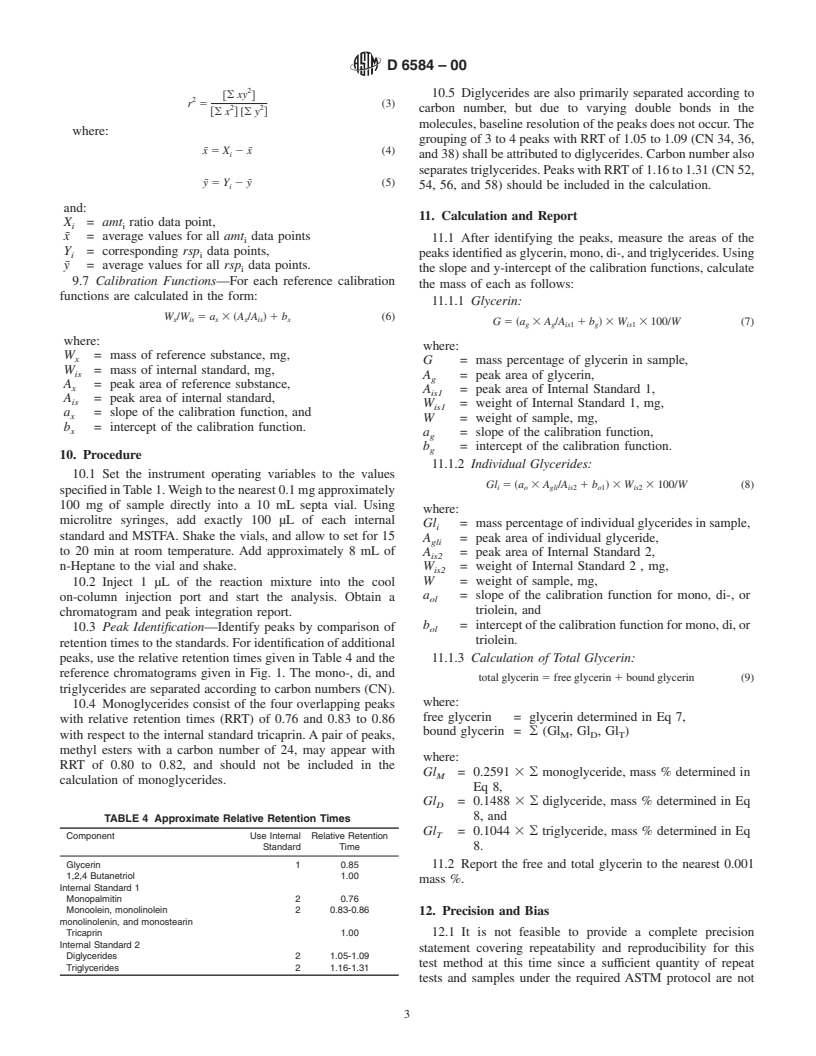

TABLE 1 Operating Conditions TABLE 2 Stock Solutions

Injector Compound CAS No. Approximate Volumetric

Cool on column injection Mass (mg) Flask Size

Sample size 1 µl (mL)

Column Temperature Program

Glycerin 56-81-5 25 50

Initial temperature 50°C hold 1 min

1-Mono [cis-9-octadecenoyl]-rac- 111-03-5 50 10

Rate 1 15°C / min to 180°C

glycerol (monoolein)

Rate 2 7°C / min to 230°C

1,3-Di [cis-octadecenoyl]glycerol 2465-32-9 50 10

Rate 3 30°C / min 380°C hold 10 min

(diolein)

Defector

1,2,3-Tri [cis-octadecenoyl]glycerol 122-32-7 50 10

Type Flame ionization

(triolein)

Temperature 380°C

(S) - (-) -1,2,4-Butanetriol - (Internal 42890-76-6 25 25

Carrier Gas

Standard 1)

Type Hydrogen or helium measured at

1,2,3-Tridecanolylglycerol (tricaprin) - 621-7-6 80 10

50°C

(Internal Standard 2)

Flow rate 3 mL/min

9.2 Standard Solutions—Prepare the five standard solutions

7. Reagents and Materials

in Table 3 by transferring the specified volumes by means of

7.1 Purity of Reagents—Reagent grade chemicals shall be

microlitresyringesto10mLseptavials.Addtoeachofthefive

used in all tests. Unless otherwise indicated, it is intended that

standardsolutions100µLofMSTFA.Closethevialandshake.

all reagents conform to the specifications of the Committee on

Allow the vial to stand for 15 to 20 min at room temperature.

Analytical Reagents of the American Chemical Society where

Add approximately 8 mL n-Heptane to the vial and shake.

such specifications are available. Other grades may be used

9.3 Chromatographic Analysis—If using an automatic sam-

provided it is first ascertained that the reagent is of sufficient

pler, transfer an aliquot of the solution into a glass GC vial and

purity to permit its use without lessening the accuracy of the

seal with a TFE-fluorocarbonlined cap.

determination.

9.4 Standardization:

7.2 n-Heptane, reagent grade.

9.5 Analyze the calibration standards under the same oper-

7.3 N-Methyl-N-trimethylsilyltrifluoroacetamide (MSTFA),

ating conditions as the sample solutions. Inject 1 µL of the

reagent grade.

reaction mixture into the cool on-column injection port and

7.4 Pyridine, reagent grade.

start the analysis. Obtain a chromatogram and peak integration

7.5 Carrier Gas, hydrogen or helium of high purity. Addi-

report. For each reference substance, determine the response

tional purification is recommended by the use of molecular

ratio (rsp) and amount ratio (amt) for each component using

i i

sieves or other suitable agents to remove water, oxygen, and

Eq 1 and 2

hydrocarbons.Available pressure must be sufficient to ensure a

rsp 5 ~A /A ! (1)

i i s

constant carrier gas flow rate.

7.6 Microlitre Syringes, 100 µl and 250 µl capacity.

where:

7.7 Screw Cap Vials, with polytetrafluoroethylene (PTFE)-

A = area of reference substance, and

i

faced septa, 10 mL capacity.

A = area of internal standard.

s

amt 5 ~W /W ! (2)

i i s

8. Preparation of Apparatus

8.1 Install and condition the column in accordance with

where:

manufacturer or supplier’s instructions. After conditioning,

W = mass of reference substance, and

i

attach column outlet to flame ionization detector inlet and W = mass of internal standard.

s

check for leaks throughout the system. If leaks are found,

Prepare a calibration curve for each reference component by

tightenorreplacefittingsandrecheckforleaksbeforeproceed- plotting the response rat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.