ASTM C1487-02(2007)

(Guide)Standard Guide for Remedying Structural Silicone Glazing

Standard Guide for Remedying Structural Silicone Glazing

SCOPE

1.1 This guide provides recommendations for remedying existing structural sealant glazing (hereinafter called SSG) installations in situ. Remedial work may be necessary when a lite of glass is replaced, for routine maintenance, or after distress is discovered. This guide focuses on large-scale remedies.

1.2 Committee C24 is not aware of any comparable standards published by other organizations.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1487 – 02 (Reapproved 2007)

Standard Guide for

Remedying Structural Silicone Glazing

This standard is issued under the fixed designation C1487; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 distress, n—theindividualorcollectivephysicalmani-

festations of a failure as perceivable problems. For structural

1.1 This guide provides recommendations for remedying

sealant glazing, such distress may include sealant adhesive

existing structural sealant glazing (hereinafter called SSG)

failure, sealant cohesive failure, shifting of a lite, loss of a lite,

installations in situ. Remedial work may be necessary when a

or water infiltration (see Guide C1394).

lite of glass is replaced, for routine maintenance, or after

3.2.2 qualified person, n—one with a recognized degree or

distress is discovered. This guide focuses on large-scale

professional registration and extensive knowledge and experi-

remedies.

ence in the field of structural sealant glazing, and who is

1.2 Committee C24 is not aware of any comparable stan-

capable of design, analysis, and evaluation in the subject.

dards published by other organizations.

4. Significance and Use

2. Referenced Documents

4.1 Guidelines are provided for remedying existing SSG

2.1 ASTM Standards:

installations. Refer to Guide C1401 for a complete discussion

C717 Terminology of Building Seals and Sealants

of proper SSG design, installation, and materials.

C1392 Guide for Evaluating Failure of Structural Sealant

4.2 Duetotheunlimitedrangeofmaterialsthatmaybeused

Glazing

in a particular building, and because each design is unique, the

C1394 Guide for In-Situ Structural Silicone Glazing Evalu-

information contained in this guide is general in nature.

ation

4.3 This guide should not be the only reference consulted

C1401 Guide for Structural Sealant Glazing

when designing remedies for SSG. For example, the local

E330 Test Method for Structural Performance of Exterior

building code and the manufacturers’ product literature for the

Windows, Doors, Skylights and Curtain Walls by Uniform

actual materials used, if known, also should be considered.The

Static Air Pressure Difference

sealant manufacturer(s) should be involved fully with the

E997 Test Method for Structural Performance of Glass in

remedial design.

Exterior Windows, Curtain Walls, and Doors Under the

4.4 This guide is intended to be a resource, but it is not a

Influence of Uniform Static Loads by Destructive Methods

substitute for experience and judgement in designing remedies

E1233 Test Method for Structural Performance of Exterior

for the specialized types of construction discussed. It is

Windows, Doors, Skylights, and Curtain Walls by Cyclic

intended to be used in conjunction with other resources as an

Air Pressure Differential

aid in remedying problems with existing SSG.

3. Terminology

5. Introduction

3.1 Definitions—Definitions of the terms used in this guide

5.1 There are numerous reasons that a building owner or

are found in Terminology C717.

manager, hereinafter referred to as owner, may choose to

3.2 Definitions of Terms Specific to This Standard:

remedy an SSG system, including routine maintenance or to

correct discovered deficiencies. Regardless of the reason that

ThisguideisunderthejurisdictionofASTMCommitteeC24onBuildingSeals such a remedy is undertaken, it is recommended that the

and Sealants and is the direct responsibility of Subcommittee C24.10 on Specifi-

remedial design and construction be performed under the

cations, Guides and Practices.

supervision of a qualified person.

CurrenteditionapprovedJune1,2007.PublishedJuly2007.Originallyapproved

5.2 It is essential to begin the remedial process with a

in 2000. Last previous edition approved in 2002 as C1487–02. DOI: 10.1520/

C1487-02R07.

comprehensive evaluation, in accordance with the guidelines

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

established in Guide C1394. The underlying cause of failure

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

must be understood fully prior to implementing a remedy;

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. otherwise, the failure may be repeated.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1487 – 02 (2007)

5.3 Based on the outcome of the evaluation, various rem- components other than those actually scheduled for permanent

edies may be indicated. The potential remedies include, de- adhesion because the adhesion characteristics can vary with

pending on the pervasiveness and the nature of the problem, exposure and manufacturing processes.

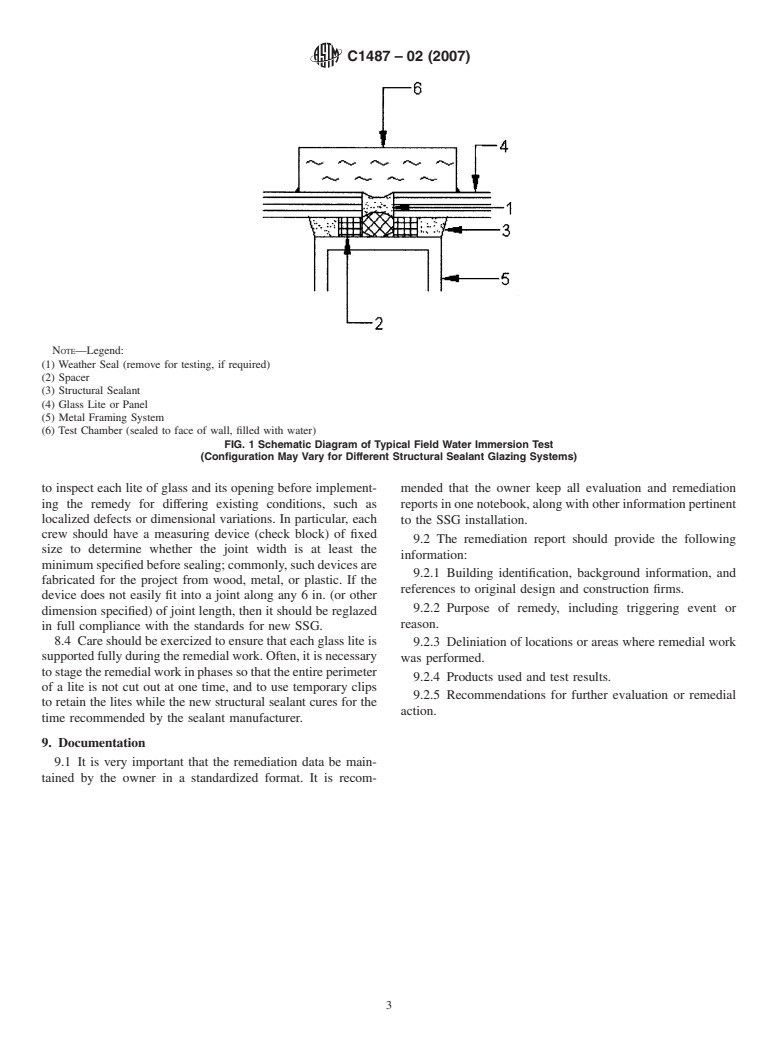

the following: 7.3 Because the field test procedure may be cumbersome

5.3.1 Isolated repairs (such as the replacement of an indi- and expensive to perform, it is recommended to perform

vidual lite of glass) can be performed by a competent glazier pretesting to screen possible combinations of products. These

trained in the proper installation of SSG. If the original SSG preliminary tests may be performed in the laboratory or in the

was properly performed, then such minor repairs can be field on convenient surfaces of the components, rather than the

effected by careful duplication of the original procedures. actual adhesion surfaces.

5.3.2 In-situ remedial work is necessary where pervasive 7.4 To verify adhesion with the final product combination,

problems exist in an SSG application, such as due to poor one field test procedure is as follows:

design or workmanship during original construction. 7.4.1 Perform a minimum of three tests in selected mock-up

5.3.3 Complete reglazing may be necessary in extreme areas. More tests should be performed depending on the

cases or at the end of the useful service life, in accordance with reasons for repair, or if the existing conditions vary with

the principles for new SSG. For example, if the existing joint exposure or other variables.

configuration does not allow adequate cleaning to replace a 7.4.2 Apply structural sealant and accessories to actual

structural joint, it may be necessary to reglaze, because adhesion surfaces exactly as they are intended to be installed

adhesion is critical to the performance of SSG and cleaning is during full-scale production work.

critical to adhesion. 7.4.3 Adjust the installation so that the structural sealant is

5.4 The remainder of this guide particularly addresses the exposed, for example, a weatherseal joint may have to be

type of in-situ remedial SSG projects as described in 5.3.2,to omitted during testing.

correct a pervasive problem without comprehensive reglazing. 7.4.4 After the cure time recommended by the sealant

manufacturer, install chambers over the test joints and adjacent

6. Remedial Design

substrates. Bed chambers in sealant and adhere to the face of

6.1 If it is determined that a large-scale remedial program is

the metal and glass, leaving the top open for filling. See Fig. 1.

necessary, then a remedial design should be developed by a

7.4.5 Fill the chambers with distilled water, causing the face

qualified person.

of the test joints to be completely immersed in water. Seal the

6.2 Depending on the cause of the problem(s) with the

top edge of the chambers after filling, to prevent evaporation.

existing installation, it may no

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.