ASTM C1265-22

(Test Method)Standard Test Method for Determining the Tensile Properties of an Insulating Glass Edge Seal for Structural Glazing Applications

Standard Test Method for Determining the Tensile Properties of an Insulating Glass Edge Seal for Structural Glazing Applications

SIGNIFICANCE AND USE

5.1 Frequently IG units are adhered with a structural sealant to a metal framing system. In such applications, only the inward lite of glass is usually adhered to the frame. As a result, a significant portion of any outward-acting or negative wind load must be carried in tension by the joint seal between the two lites of the IG unit. This test will not provide information on the integrity of the IG unit primary seal; however, it may provide data on load sharing between the primary IG vapor seal and the secondary structural sealant.

5.2 Although this test method prescribes one environmental condition, other environmental conditions and exposure cycles can be employed for specific project evaluation. Such deviations should be described when reporting the data.

SCOPE

1.1 This test method covers a laboratory procedure for quantitatively measuring the tensile strength, stiffness, and adhesion properties of insulating glass edge seals that are used in structural sealant glazing applications. Edge seals for these applications use a structural sealant to bond both glass lites and the edge spacer into a monolithic sealed insulating glass unit. In typical applications, the structural sealant acts to hold the outside lite in place under wind and gravity load and to maintain the edge spacer in its proper position. Hereafter, the term “insulating glass” will be abbreviated as “IG.”

1.2 The characterization of the IG secondary sealant properties, as defined by this test method, are strongly dependent on glass and edge spacer cleaning procedures, IG spacer profile, location of spacer, and primary IG sealant application. Users of this test method must recognize that the IG edge seal assembly influences the secondary sealant properties.

1.3 The values determined by this test method will be characteristic of the particular edge seal assembly that is tested.

Note 1: Presently, only elastomeric, chemically curing silicone sealants specifically formulated for use as the secondary seal of IG units are recognized as having the necessary durability for use in structural sealant glazing applications.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1265 − 22

Standard Test Method for

Determining the Tensile Properties of an Insulating Glass

1

Edge Seal for Structural Glazing Applications

This standard is issued under the fixed designation C1265; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This test method covers a laboratory procedure for

quantitatively measuring the tensile strength, stiffness, and

2. Referenced Documents

adhesion properties of insulating glass edge seals that are used

2

2.1 ASTM Standards:

in structural sealant glazing applications. Edge seals for these

C717 Terminology of Building Seals and Sealants

applications use a structural sealant to bond both glass lites and

the edge spacer into a monolithic sealed insulating glass unit.

3. Terminology

In typical applications, the structural sealant acts to hold the

3.1 Definitions—Refer to Terminology C717 for definitions

outside lite in place under wind and gravity load and to

of the following terms used in this test method: adhesive

maintain the edge spacer in its proper position. Hereafter, the

failure, cohesive failure, elastomeric, glazing, lite, primer, seal,

term “insulating glass” will be abbreviated as “IG.”

sealant, silicone sealant, structural sealant, substrate, stan-

1.2 The characterization of the IG secondary sealant

dard conditions.

properties, as defined by this test method, are strongly depen-

dent on glass and edge spacer cleaning procedures, IG spacer

4. Summary of Test Method

profile, location of spacer, and primary IG sealant application.

4.1 Five specimens are fabricated to duplicate the edge seal

Users of this test method must recognize that the IG edge seal

design of an IG unit for structural glazing applications. After

assembly influences the secondary sealant properties.

the secondary structural sealant is cured the specimens are

1.3 The values determined by this test method will be

tested to failure in tension. Testing is conducted at 23 °C

characteristicoftheparticularedgesealassemblythatistested.

6 2 °C(74 °F 6 3.6 °F)atarateof5 mm 60.5 mm(0.2 in. 6

0.02 in.) per minute. Strength, load-displacement response,

NOTE 1—Presently, only elastomeric, chemically curing silicone seal-

ants specifically formulated for use as the secondary seal of IG units are

failure mode, and primary IG edge seal behavior are recorded.

recognized as having the necessary durability for use in structural sealant

glazing applications.

5. Significance and Use

1.4 The values stated in SI units are to be regarded as

5.1 Frequently IG units are adhered with a structural sealant

standard. The values given in parentheses after SI units are

to a metal framing system. In such applications, only the

provided for information only and are not considered standard.

inward lite of glass is usually adhered to the frame.As a result,

1.5 This standard does not purport to address all of the

a significant portion of any outward-acting or negative wind

safety concerns, if any, associated with its use. It is the

load must be carried in tension by the joint seal between the

responsibility of the user of this standard to establish appro-

two lites of the IG unit. This test will not provide information

priate safety, health, and environmental practices and deter-

on the integrity of the IG unit primary seal; however, it may

mine the applicability of regulatory limitations prior to use.

providedataonloadsharingbetweentheprimaryIGvaporseal

1.6 This international standard was developed in accor-

and the secondary structural sealant.

dance with internationally recognized principles on standard-

5.2 Although this test method prescribes one environmental

ization established in the Decision on Principles for the

condition, other environmental conditions and exposure cycles

Development of International Standards, Guides and Recom-

can be employed for specific project evaluation. Such devia-

tions should be described when reporting the data.

1

This test method is under the jurisdiction of ASTM Committee of C24 on

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.30

2

on Adhesion. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2022.PublishedJuly2022.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in1994.Lastpreviousedi

...

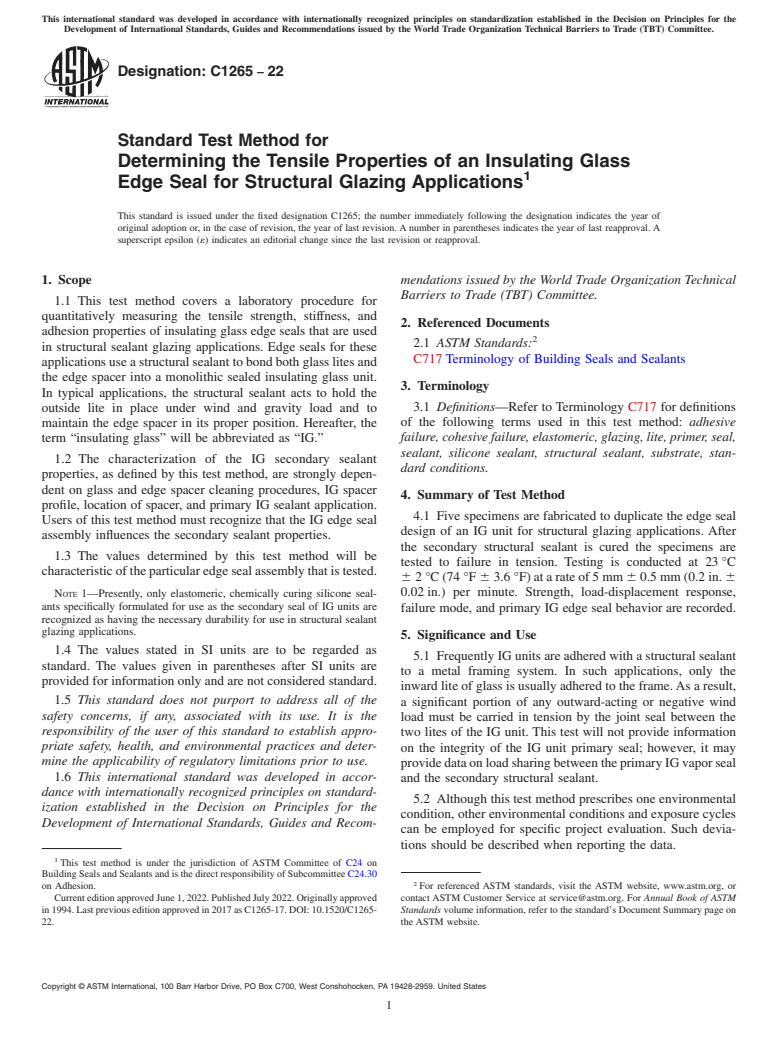

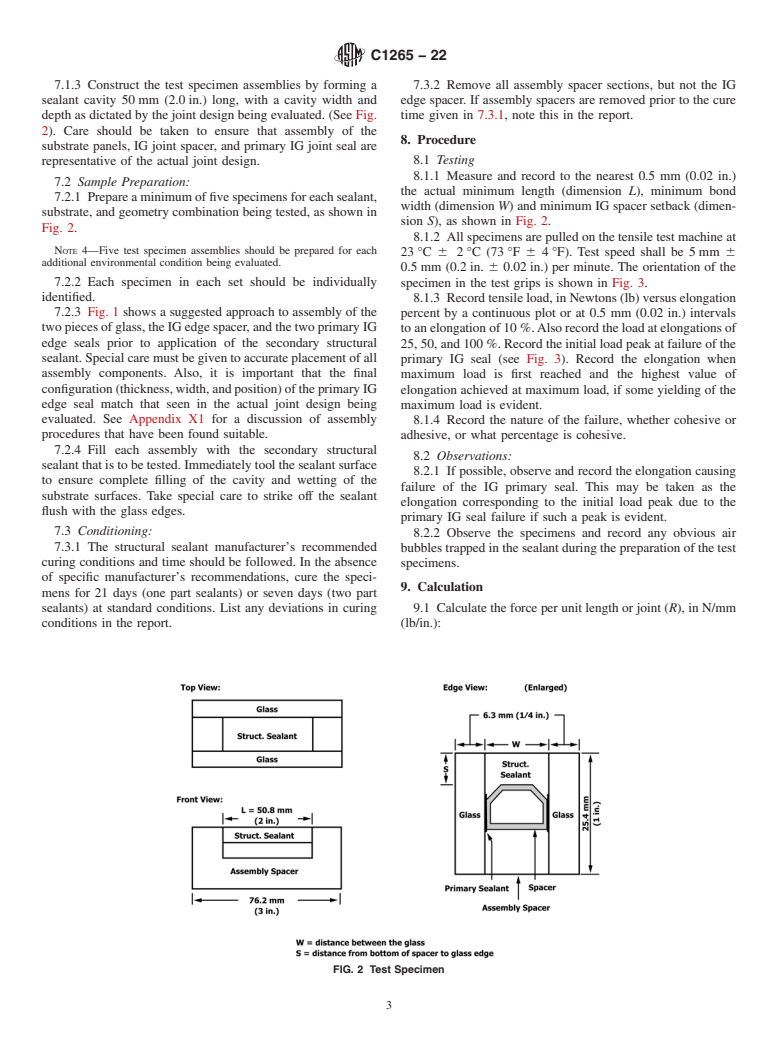

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1265 − 17 C1265 − 22

Standard Test Method for

Determining the Tensile Properties of an Insulating Glass

1

Edge Seal for Structural Glazing Applications

This standard is issued under the fixed designation C1265; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a laboratory procedure for quantitatively measuring the tensile strength, stiffness, and adhesion

properties of insulating glass edge seals that are used in structural sealant glazing applications. Edge seals for these applications

use a structural sealant to bond both glass lites and the edge spacer into a monolithic sealed insulating glass unit. In typical

applications, the structural sealant acts to hold the outside lite in place under wind and gravity load and to maintain the edge spacer

in its proper position. Hereafter, the term “insulating glass” will be abbreviated as “IG.”

1.2 The characterization of the IG secondary sealant properties, as defined by this test method, are strongly dependent on glass

and edge spacer cleaning procedures, IG spacer profile, location of spacer, and primary IG sealant application. Users of this test

method must recognize that the IG edge seal assembly influences the secondary sealant properties.

1.3 The values determined by this test method will be characteristic of the particular edge seal assembly that is tested.

NOTE 1—Presently, only elastomeric, chemically curing silicone sealants specifically formulated for use as the secondary seal of IG units are recognized

as having the necessary durability for use in structural sealant glazing applications.

1.4 The values stated in SI (metric) units are to be regarded as the standard. The inch-pound values given in parentheses are

approximate equivalents, after SI units are provided for information purposes. only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C717 Terminology of Building Seals and Sealants

1

This test method is under the jurisdiction of ASTM Committee of C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.30 on

Adhesion.

Current edition approved Sept. 15, 2017June 1, 2022. Published October 2011July 2022. Originally approved in 1994. Last previous edition approved in 20112017 as

C1265-94(2011).C1265-17. DOI: 10.1520/C1265-17.10.1520/C1265-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1265 − 22

3. Terminology

3.1 Definitions—Refer to Terminology C717 for definitions of the following terms used in this test method: adhesive failure,

cohesive failure, elastomeric, glazing, lite, primer, seal, sealant, silicone sealant, structural sealant, substrate, standard conditions.

4. Summary of Test Method

4.1 Five specimens are fabricated to duplicate the edge seal design of an IG unit for structural glazing applications. After the

secondary structural sealant is cured the specimens are tested to failure in tension. Testing is conducted at 23 6 2°C (74

6 3.6°F)23 °C 6 2 °C (74 °F 6 3.6 °F) at a rate of 5 6 0.5 mm (0.2 6 0.02 in.) 5 mm 6 0.5 mm (0.2 in. 6 0.02 in.) per minute.

Strength, load-displacement response, failure mode, and primary IG edge seal behavior are recorded.

5. Significance and Use

5.1 Frequently IG units are adhered with a structural sealant to a metal framing system. In su

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.