ASTM D7044-04

(Specification)Standard Specification for Biodegradable Fire Resistant Hydraulic Fluids

Standard Specification for Biodegradable Fire Resistant Hydraulic Fluids

SCOPE

1.1 This specification covers performance classifications for biodegradable fire resistant hydraulic fluids that are used in the industrial/mobile and mining industries.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

An American National Standard

Designation: D 7044 – 04

Standard Specification for

Biodegradable Fire Resistant Hydraulic Fluids

This standard is issued under the fixed designation D 7044; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Properties of Lubricating Fluids (Four-Ball Method)

D 2882 Test Method for Indicating theWear Characteristics

1.1 This specification covers performance classifications for

of Petroleum and Non-Petroleum Hydraulic Fluids in a

biodegradable fire resistant hydraulic fluids that are used in the

Constant Volume Vane Pump

industrial/mobile and mining industries.

D 3427 Test Method for Gas Bubble Separation Time of

1.2 This standard does not purport to address all of the

Petroleum Oils

safety concerns, if any, associated with its use. It is the

D 4052 Test Method for Density and Relative Density of

responsibility of the user of this standard to establish appro-

Liquids by Digital Density Meter

priate safety and health practices and to determine the

D 5182 Test Method for Evaluating the Scuffing (Scoring)

applicability of regulatory limitations prior to use.

Load Capacity of Oils (FZG Visual Method)

2. Referenced Documents

D 5306 Test Method for Linear Flame Propagation Rate of

Lubricating Oils and Hydraulic Fluids

2.1 ASTM Standards:

D 6046 Classification of Hydraulic Fluids for Environmen-

D 92 Test Method for Flash and Fire Points by Cleveland

tal Impact

Open Cup

D 6304 Test Method for Determination of Water in Petro-

D 95 Test Method for Water in Petroleum Products and

leum Products, Lubricating Oils, andAdditives by Coulo-

Bituminous Materials by Distillation

metric Karl Fischer Titration

D 240 Test Method for Heat of Combustion of Liquid

D 6546 Test Methods for and Suggested Limits for Deter-

Hydrocarbon Fuels by Bomb Calorimeter

mining Compatibility of Elastomer Seals for Industrial

D 664 TestMethodforAcidNumberofPetroleumProducts

Hydraulic Fluid Applications

by Potentiometric Titration

E 70 Test Method for pH of Aqueous Solutions with Glass

D 892 Test Method for Foaming Characteristics of Lubri-

Electrode

cating Oils

E 659 Test Method for Autoignition Temperature of Liquid

D 943 Test Method for Oxidation Characteristics of Inhib-

Chemicals

ited Mineral Oils

2.2 DIN Standards:

D 974 Test Method for Acid and Base Number by Color-

DIN 51348 Testing of fire resistant governor fluids; deter-

Indicator Titration

mination of hydrolytic stability

D 1298 Practice for Density, Relative Density (Specific

DIN 51354-2 Testing of Lubricants; FZG Gear Test Rig –

Gravity), or API Gravity of Crude Petroleum and Liquid

Part 1: Method A/8,3/90 for Lubricating Oils

Petroleum Products by Hydrometer Method

DIN 51373 Testing of Fire Resistant Heat Transfer Fluids;

D 1401 Test Method for Water Separability of Petroleum

Determination of Resistance to Oxidation Including an

Oils and Synthetic Fluids

Assessment of the Catalyst Plates

D 2422 Classification of Industrial Fluid Lubricants by

DIN 51389-2 Determination of lubricants; mechanical test-

Viscosity Grade

ing of hydraulic fluids in the vane-cell-pump; method A

D 2532 Test Method for Viscosity and Viscosity Change

foranhydrous hydraulic fluids

after Standing at Low Temperature of Aircraft Turbine

DIN 51777-2 Testing of Mineral Oil Hydrocarbons and

Lubricants

Solvents; Determination of Water Content according to

D 2783 Test Method for Measurement of Extreme-Pressure

Karl Fischer; Indirect Method

2.3 ISO Standards:

This specification is under the jurisdiction ofASTM Committee D02 and is the

direct responsibility of Subcommittee D02.N0 on Hydraulic Fluids.

Current edition approved May 1, 2004. Published July 2004.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Deutsches Institut für Normung e. V. (DIN), 10772, Berlin,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Germany.

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D7044–04

ISO 2049 Petroleum Products - Determination of Color ISO 14935 Petroleum and Related Products – Determina-

(ASTM Scale) tion of Wick Flame Persistence of Fire Resistant Fluids

ISO 15029-1 Petroleum and Related Products – Determina-

ISO 2160 Petroleum Products - Corrosiveness to Copper –

Copper Strip Test tion of Spray Ignition Characteristics of Fire Resistant

Fluids – Part 1: Spray Flame Persistence – Hollow-Cone

ISO 2592 Determination of Flash and Fire Points – Cleve-

Nozzle Method

land Open Cup Method

ISO/FDIS 15380 Lubricants, Industrial Oils and Related

ISO 3104 Petroleum Products - Transparent and Opaque

Products (Class L)—Family H (Hydraulic Systems)—

Liquids - Determination of Kinematic Viscosity and

Specifications for Categories HETG, HEPG, HEES, and

Calculation of Dynamic Viscosity

HEPR

ISO 3105 Glass Capillary Kinematic Viscometers—

2.4 Lux Standards:

Specifications and Operating Instructions

Lux 3.1.3 Stabilized Flame Heat Release – Spray Test

ISO 3448 Industrial Liquid Lubricants - ISO Viscosity

Lux 5.2.3 Determination of the Emulsion Stability of HFB

Classification

Fluids at Medium Temperature

ISO 3675 Crude Petroleum and Liquid Petroleum Products

Lux 5.2.4 Determination of the Emulsion Stability of

- Laboratory Determination of Density - Hydrometer

HFB…LT Fluids at Low Temperature

Method

Lux 5.3.1 Determination of aging Properties of HFC Fluids

ISO 3733 Petroleum Products and Bituminous Materials –

Lux 5.8 Determination of the Shear Stability of Hydraulic

Determination of Water - Distillation Method

Fluids

ISO 4263-1 Petroleum and Related Products - Determina-

Lux 5.9.1 Determination of the Corrosion Inhibiting Prop-

tion of the Aging Behavior of Inhibited Oils and Fluids –

erties of HFA, HFC, and HFD Fluids

TOST Test – Part 1: Procedure for Mineral Oils

MSHASchedule 30, 43 FR 12317 (WickTest) Part 35: Fire

ISO 4404-1 Petroleum and Related Products - Determina-

Resistant Hydraulic Fluids

tion of the Corrosion Resistance of Fire-Resistant Fluids –

NBSIR 81-2312: MSHAWick Test for Hydraulic Fluids: A

Part 1: Water-Containing Fluids

Preliminary Evaluation

ISO 5884 Aerospace—Fluid Systems and Components—

2.5 Other Standards:

Methods for System Sampling and Measuring the Solid

CETOP RP 65H Manifold Ignition Test

Particle Contamination of Hydraulic Fluids

CETOP RP 67H Antiwear Vane Pump Test for Hydraulic

ISO 6072 Compatibility between Fluids and Standard Elas-

Fluids

tomeric Materials

IP 281

ISO 6245 Petroleum Products - Determination of Ash

ISO 6247 Petroleum Products - Determination of Foaming

3. Terminology

Characteristics of Lubricating Oils

3.1 Definitions:

ISO 6296 Petroleum Products - Determination of Water –

3.1.1 bioaccumulation, n—the net accumulation of a sub-

Potentiometric Karl Fischer Titration Method

stance by an organism as a result of uptake from all environ-

ISO 6618 Petroleum Products and Lubricants - Determina-

mental sources.

tion of Acid or Base Number – Color Indicator Titration

3.1.2 biodegradable, n—any substance containing <10 %

Method

wt. O content which undergoes $60 % biodegradation as

ISO 6619 Petroleum Products and Lubricants—

theoretical CO in 28 days and $67 % biodegradation as

Neutralization Number—Potentiometric Titration Method

theoretical O uptake in 28 days, or any hydraulic fluid

ISO 6743-4 Lubricants, Industrial Oils and Related Prod-

containing $10 % wt. O content which undergoes $60 %

ucts (class L) – Classification – Part 4: Family H (Hy-

biodegradation as theoretical CO or as theoretical O uptake

2 2

draulic Systems)

in 28 days.

ISO 7120 Petroleum Products and Lubricants – Petroleum

3.1.3 biodegradation, n—the process of chemical break-

Oils and Other Fluids - Determination of Rust Preventing

down or transformation of a material caused by organisms or

Characteristics in the Presence of Water

their enzymes.

ISO 7745 Hydraulic Fluid Power—Fire-resistant (FR)

3.1.3.1 Discussion—Biodegradation is only one mechanism

Fluids—Guidelines for Use

by which materials are transformed in the environment.

ISO 9120 Petroleum and Related Products - Determination

ofAirReleasePropertiesofSteamTurbineandOtherOils

– Impinger Method 5

European Commission, Safety and Health Commission for the Mining and

ISO 12185 Crude Petroleum and Petroleum Products – Other Extractive Industries, “Requirements and Tests Applicable to Fire-Resistant

Hydraulic Fluids Used for Power Transmission and Control (Hydrostatic and

Determination of Density - Oscillating U-Tube Method

Hydrokinetic),” Seventh Edition, Doc. N4746/10/91 EN, Luxembourg, April 1994.

ISO 12922 Lubricants, Industrial Oils and Related Products

The Bureau of Mines, Federal Register, vol. 24, No. 245, December 17, 1959,

(classL)–FamilyH(HydraulicSystems)–Specifications

revised March 24, 1978.

National Bureau of Standards, Washington, DC, July 1981.

for Categories HFAE, HFAS, HFB, HFC, HFDR, and

Available from the Comité Européen des Transmissions Oléohydrauliques et

HFDU

Pneumatiques (CETOP), Lyoner Straße 18, 60528, Frankfurt am Main, Germany.

ISO 12937 Petroleum Products - Determination of Water –

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

Coulometric Karl Fischer Titration Method U.K.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D7044–04

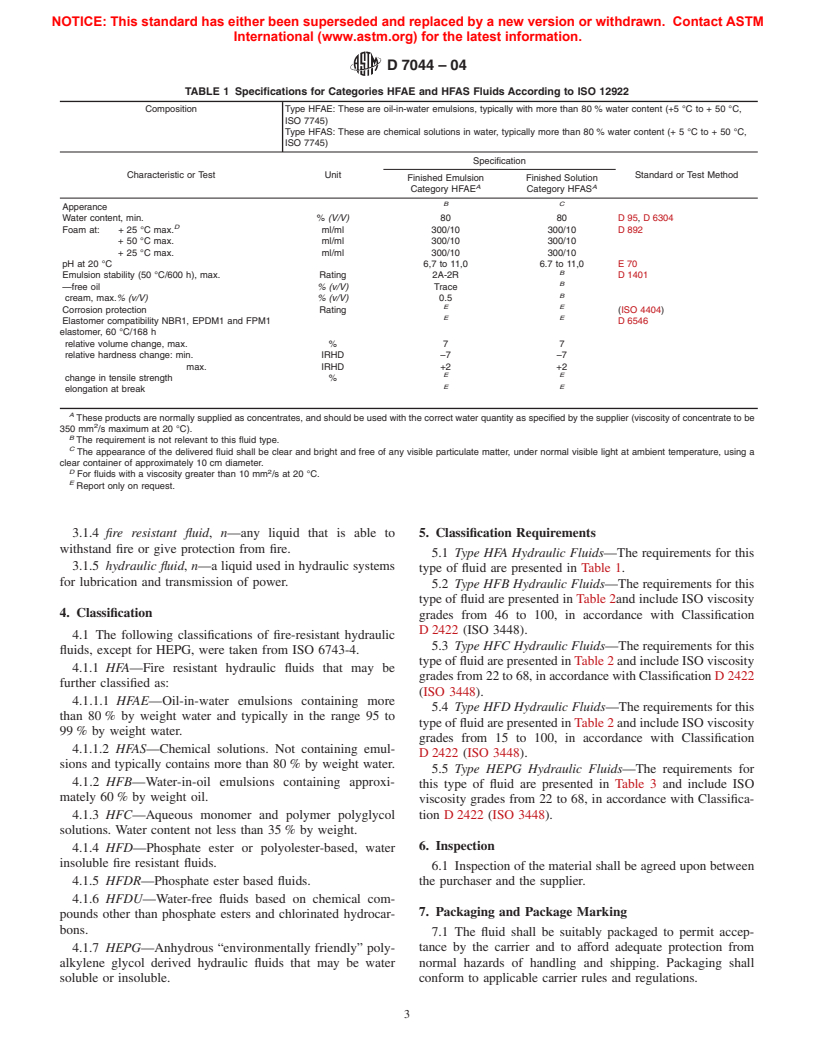

TABLE 1 Specifications for Categories HFAE and HFAS Fluids According to ISO 12922

Composition Type HFAE: These are oil-in-water emulsions, typically with more than 80 % water content (+5 °C to + 50 °C,

ISO 7745)

Type HFAS: These are chemical solutions in water, typically more than 80 % water content (+ 5 °C to + 50 °C,

ISO 7745)

Specification

Characteristic or Test Unit Standard or Test Method

Finished Emulsion Finished Solution

A A

Category HFAE Category HFAS

BC

Apperance

Water content, min. % (V/V) 80 80 D95, D 6304

D

Foam at: + 25 °C max. ml/ml 300/10 300/10 D 892

+ 50 °C max. ml/ml 300/10 300/10

+ 25 °C max. ml/ml 300/10 300/10

pH at 20 °C 6,7 to 11,0 6.7 to 11,0 E70

B

Emulsion stability (50 °C/600 h), max. Rating 2A-2R D 1401

B

—free oil % (v/V) Trace

B

cream, max.% (v/V) % (v/V) 0.5

EE

Corrosion protection Rating (ISO 4404)

EE

Elastomer compatibility NBR1, EPDM1 and FPM1 D 6546

elastomer, 60 °C/168 h

relative volume change, max. % 7 7

relative hardness change: min. IRHD –7 –7

max. IRHD +2 +2

EE

change in tensile strength %

EE

elongation at break

A

These products are normally supplied as concentrates, and should be used with the correct water quantity as specified by the supplier (viscosity of concentrate to be

350 mm /s maximum at 20 °C).

B

The requirement is not relevant to this fluid type.

C

The appearance of the delivered fluid shall be clear and bright and free of any visible particulate matter, under normal visible light at ambient temperature, using a

clear container of approximately 10 cm diameter.

D 2

For fluids with a viscosity greater than 10 mm /s at 20 °C.

E

Report only on request.

3.1.4 fire resistant fluid, n—any liquid that is able to 5. Classification Requirements

withstand fire or give protection from fire.

5.1 Type HFA Hydraulic Fluids—The requirements for this

3.1.5 hydraulic fluid, n—a liquid used in hydraulic systems

type of fluid are presented in Table 1.

for lubrication and transmission of power.

5.2 Type HFB Hydraulic Fluids—The requirements for this

type of fluid are presented in Table 2and include ISO viscosity

4. Classification

grades from 46 to 100, in accordance with Classification

D 2422 (ISO 3448).

4.1 The following classifications of fire-resistant hydraulic

5.3 Type HFC Hydraulic Fluids—The requirements for this

fluids, except for HEPG, were taken from ISO 6743-4.

type of fluid are presented inTable 2 and include ISO viscosity

4.1.1 HFA—Fire resistant hydraulic fluids that may be

gradesfrom22to68,inaccordancewithClassificationD 2422

further classified as:

(ISO 3448).

4.1.1.1 HFAE—Oil-in-water emulsions containing more

5.4 Type HFD Hydraulic Fluids—The requirements for this

than 80 % by weight water and typically in the range 95 to

type of fluid are presented inTable 2 and include ISO viscosity

99 % by weight water.

grades from 15 to 100, in accordance with Classification

4.1.1.2 HFAS—Chemical solutions. Not containing emul-

D 2422 (ISO 3448).

sions and typically contains more than 80 % by weight water.

5.5 Type HEPG Hydraulic Fluids—The requirements for

4.1.2 HFB—Water-in-oil emulsions containing approxi-

this type of fluid are presented in Table 3 and include ISO

mately 60 % by weight oil.

viscosity grades from 22 to 68, in accordance with Classifica-

4.1.3 HFC—Aqueous monomer and polymer polyglycol tion D 2422 (ISO 3448).

solutions. Water content not less than 35 % by weight.

6. Inspection

4.1.4 HFD—Phosphate ester or polyolester-based, water

insoluble fire resistant fluids.

6.1 Inspection of the material shall be agreed upon between

4.1.5 HFDR—Phosphate ester based fluids. the purchaser and the supplier.

4.1.6 HFDU—Water-free fluids based on chemical com-

7. Packaging and Package Marking

pounds other than phosphate esters and chlorinated hydrocar-

bons.

7.1 The fluid shall be suitably packaged to permit accep-

4.1.7 HEPG—Anhydrous “environmentally friendly” poly- tance by the carrier and to afford adequate protection from

alkylene glycol derived hydraulic fluids that may be water normal hazards of handling and shipping. Packaging shall

soluble or insoluble. conform to applicable carrier rules and regulations.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D7044–04

TABLE 2 Specifications for Categories HFB, HFC and HFD Fluids According to ISO 12922

Type HFB: These are water-in-oil emulsions (+5 °C to + 50 °C, ISO 7745)

Type HFC: These are water polymer solutions, typically with more than 35 % water content

(−20 °C to +50 °C, ISO 7745)

Composition

Type HFDR: These are synthetic fluids free of water consisting of phosphate esters

A

(−2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.