ASTM G107-95(2002)

(Guide)Standard Guide for Formats for Collection and Compilation of Corrosion Data for Metals for Computerized Database Input

Standard Guide for Formats for Collection and Compilation of Corrosion Data for Metals for Computerized Database Input

SCOPE

1.1 This guide defines the data categories and specific data elements (fields) considered necessary to accommodate desired search strategies and reliable data comparisons in computerized corrosion databases. The data entries are designed to accommodate data relative to the basic forms of corrosion and to serve as guides for structuring multiple source database compilations capable of assessing compatibility of metals and alloys for a wide range of environments and exposure conditions.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G107–95 (Reapproved 2002)

Standard Guide for

Formats for Collection and Compilation of Corrosion Data

for Metals for Computerized Database Input

This standard is issued under the fixed designation G 107; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope G 78 Guide for Crevice Corrosion Testing of Iron-Base and

Nickel-Base Stainless Alloys in Seawater and Other

1.1 This guide defines the data categories and specific data

Chloride-Containing Aqueous Environments

elements(fields)considerednecessarytoaccommodatedesired

search strategies and reliable data comparisons in computer-

3. Terminology

ized corrosion databases. The data entries are designed to

3.1 Definitions—For definitions of terms applicable to this

accommodate data relative to the basic forms of corrosion and

guide see Practice E 1314 and Terminology G 15.

to serve as guides for structuring multiple source database

compilations capable of assessing compatibility of metals and

4. Significance and Use

alloys for a wide range of environments and exposure condi-

4.1 The guide is intended to facilitate the recording of

tions.

corrosion test results and does not imply or endorse any

particular database design or schema. It provides a useful

2. Referenced Documents

reference to be consulted before initiating a corrosion test to be

2.1 ASTM Standards:

2 sure plans are made to record all relevant data.

E 8 Test Methods forTensionTesting of Metallic Materials

4.2 Corrosion tests are usually performed following a pre-

E 527 Practice for Numbering Metals and Alloys (UNS)

scribed test procedure that is often not a standard test method.

E 1314 Practice for Structuring Terminological Records

Most corrosion tests involve concurrent exposure of multiple

Relating to Computerized Test Reporting and Materials

4 specimens of one or more materials (refer to 6.1.1).

Designation Formats

4.3 This guide is designed to record data for individual

E 1338 Guide for the Identification of Metals andAlloys in

4 specimens with groupings by separate tests (as contrasted to

Computerized Material Property Databases

separate test methods) as described in 4.2 and 6.1.1. Conse-

G 1 Practice for Preparing, Cleaning, and Evaluating Cor-

5 quently, some of the individual fields may apply to all of the

rosion Test Specimens

specimens in a single test, while others must be repeated as

G 15 Terminology Relating to Corrosion and Corrosion

5 often as necessary to record data for individual specimens.

Testing

4.4 The guidelines provided are designed for recording data

G 34 Test Method for Exfoliation Corrosion Susceptibility

for entry into computerized material performance databases.

in 2XXX and 7XXX Series Aluminum Alloys (EXCO

5 They may be useful for other applications where systematic

Test)

recording of corrosion data is desired.

G 46 Guide for Examination and Evaluation of Pitting

5 4.5 Reliable comparisons of corrosion data from multiple

Corrosion

sources will be expedited if data are provided for as many of

G 49 Practice for Preparation and Use of Direct Tension

5 the listed fields as possible. Comparisons are possible where

Stress-Corrosion Test Specimens

dataarelimited,butsomedegreeofuncertaintywillbepresent.

4.6 Certain specialized corrosion tests may require addi-

tional data elements to fully characterize the data recorded.

This guide is under the jurisdiction ofASTM Committee G01 on Corrosion of

This guide does not preclude these additions. Other ASTM

Metals and is the direct responsibility of Subcommittee G01.05 on Laboratory

guides for recording data from mechanical property tests may

Corrosion Tests.

be helpful.

Current edition approved Dec. 10, 1995. Published February 1996. Originally

published as G 107 – 91. Last previous edition G 107 – 91.

4.7 This guide does not cover the recording of data from

Annual Book of ASTM Standards, Vol 03.01.

electrochemical corrosion tests.

Annual Book of ASTM Standards, Vol 01.01.

4.8 These material identification guidelines are compatible

Annual Book of ASTM Standards, Vol 14.01.

Annual Book of ASTM Standards, Vol 03.02. with Guide E 1338.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G107

5. Categorization of Corrosion Data 6.1.8 Results from a specific reference or source.

6.2 Additional information may be required to facilitate

5.1 This guide considers nine general categories for use in

supplementary search requirements. This guide does not pre-

documenting corrosion data. Categories, with input examples,

clude these additions.

are as follows:

5.1.1 Test Identification—Uniquecodetoidentifygroupings

7. Data Entry Fields

of multiple specimens exposed at the same time and under

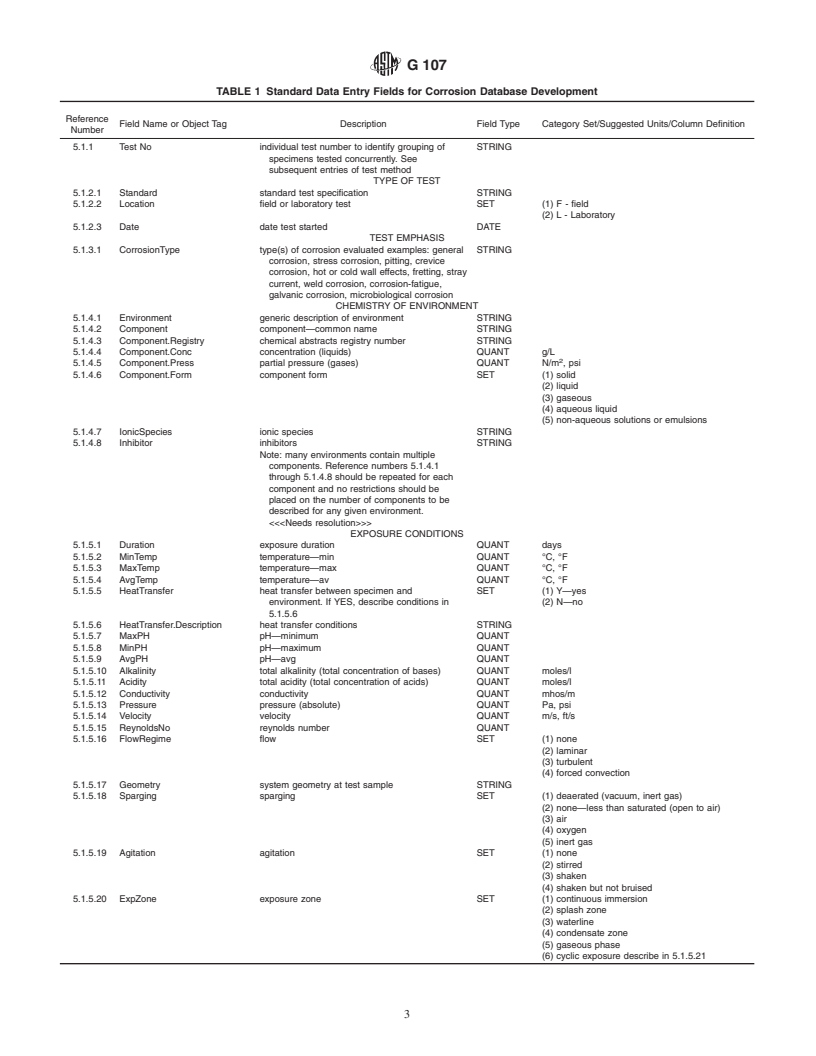

7.1 Data entry fields are listed inTable 1.The table contains

identical conditions.

the following information:

5.1.2 Type of Test—Standardized, laboratory, field tests; test

7.1.1 The reference number is a unique number the first

relation to specific process or application (for example, sulfide

three digits of which refer to the relevant paragraph numbers in

stress cracking test for sour gas production tubing).

this guide.

5.1.3 Test Emphasis—Specific form of corrosion or degra-

7.1.2 The field name or object tag is a concise label for the

dation (for example, pitting, corrosion-fatigue, crevice corro-

field. Tags are made up of one or more character strings

sion, etc.).

separated by periods. The first character in each string must be

5.1.4 Environment—Generic description; identification,

alphabetic (a–z, A–Z,”). Thereafter the characters may be

concentration, and state of principal components; contami-

alphanumeric (a–z, A–Z,”, 0–9).

nants, etc.

7.1.2.1 Periods are used to separate subdivisions inherent in

5.1.5 Exposure Conditions—Duration, temperature, pH, hy-

the information, for example “Component.Name,” “Compo-

drodynamic conditions, aeration, etc.

nent.Conc.”

5.1.6 Material Identification—Material class, subclass, and

7.1.2.2 Tags are case insensitive although mixed case is

family, common name, standard designation, condition, manu-

suggested for readability. Mixed case is used when a tag’s

facturing process, product form, etc.

meaning forms a single concept, for example “FlowRegime.”

5.1.7 Specimen Identification—Specimen number, size, ge-

7.1.3 The field description is a textual description of the

ometry, surface condition, composition, properties.

field.

5.1.8 Specimen Performance—Mass change, property

7.1.4 The field type describes the format and allowed

change, performance relative to specific corrosion, or degrada-

contents for the field. The field may be one of the following

tion mechanism.

types:

5.1.9 Data Source or Reference.

7.1.4.1 String (STRING)—A string is an undifferentiated

5.2 This guide permits supplementary notes to document

series of characters. Strings may contain punctuation charac-

supplementary information considered important in interpret-

ters except for a tab, new line, or leading semicolon.

ing data.

7.1.4.2 Quantity (QUANT)—A quantity is a data aggregate

6. Data Searching

made of a real number and a unit. The last column of the table

gives suggested units for the field. Alternative units may be

6.1 This guide considers data to accommodate searches for

used.

identifying and locating data and metadata in eight specific

7.1.4.3 Data (DATE)—A date is a string of eight numeric

areas as follows:

characters encoding year, month, and day in the order

6.1.1 Multiple specimens of one material included in same

YYYYMMDD.

test (that is, exposed in same or companion test rack exposed

7.1.4.4 Time (TIME)—A time is a string of six numeric

under identical conditions in same or companion test vessel).

characters encoding hour, minute and second in the order

6.1.2 Different materials included in same test.

HHMMSS.

6.1.3 Material evaluated by specific standard test methods

7.1.4.5 Category Set (SET—Acategorysetisaclosedlistof

(by standardized test number).

values for a particular field.Adatabase uses an integer value to

6.1.4 Materials exposed to specific environments with en-

record the member of the category set. Category sets should

vironments defined by generic description (for example, sour

not be used for quantities. Use the quantity type, instead. The

gas) or by specific components (for example,

last column of the table gives a list of acceptable values and

hydrocarbon + H S).

their meaning for each category set field.

6.1.5 Specific materials, defined by class (for example,

7.1.4.6 Tabular (TABLE)—A tabular field is made up of a

metals), subclass (for example, wrought aluminum), family

group of values. The last column gives the title and type of

(for example, Al-Si alloys), standard designation (UNS No.,

each value.

ASTM specification), or common name.

6.1.6 Specific application or process (for example, sour gas

8. Keywords

production tubing, pulp bleaching).

6.1.7 Type of corrosion or degradation mechanism (for 8.1 computerization;corrosion;data;database;materialper-

formance; metal

example, pitting, corrosion fatigue, etc.).

G107

TABLE 1 Standard Data Entry Fields for Corrosion Database Development

Reference

Field Name or Object Tag Description Field Type Category Set/Suggested Units/Column Definition

Number

5.1.1 Test No individual test number to identify grouping of STRING

specimens tested concurrently. See

subsequent entries of test method

TYPE OF TEST

5.1.2.1 Standard standard test specification STRING

5.1.2.2 Location field or laboratory test SET (1) F - field

(2) L - Laboratory

5.1.2.3 Date date test started DATE

TEST EMPHASIS

5.1.3.1 CorrosionType type(s) of corrosion evaluated examples: general STRING

corrosion, stress corrosion, pitting, crevice

corrosion, hot or cold wall effects, fretting, stray

current, weld corrosion, corrosion-fatigue,

galvanic corrosion, microbiological corrosion

CHEMISTRY OF ENVIRONMENT

5.1.4.1 Environment generic description of environment STRING

5.1.4.2 Component component—common name STRING

5.1.4.3 Component.Registry chemical abstracts registry number STRING

5.1.4.4 Component.Conc concentration (liquids) QUANT g/L

5.1.4.5 Component.Press partial pressure (gases) QUANT N/m , psi

5.1.4.6 Component.Form component form SET (1) solid

(2) liquid

(3) gaseous

(4) aqueous liquid

(5) non-aqueous solutions or emulsions

5.1.4.7 IonicSpecies ionic species STRING

5.1.4.8 Inhibitor inhibitors STRING

Note: many environments contain multiple

components. Reference numbers 5.1.4.1

through 5.1.4.8 should be repeated for each

component and no restrictions should be

placed on the number of components to be

described for any given environment.

<<>>

EXPOSURE CONDITIONS

5.1.5.1 Duration exposure duration QUANT days

5.1.5.2 MinTemp temperature—min QUANT °C, °F

5.1.5.3 MaxTemp temperature—max QUANT °C, °F

5.1.5.4 AvgTemp temperature—av QUANT °C, °F

5.1.5.5 HeatTransfer heat transfer between specimen and SET (1) Y—yes

environment. If YES, describe conditions in (2) N—no

5.1.5.6

5.1.5.6 HeatTransfer.Description heat transfer conditions STRING

5.1.5.7 MaxPH pH—minimum QUANT

5.1.5.8 MinPH pH—maximum QUANT

5.1.5.9 AvgPH pH—avg QUANT

5.1.5.10 Alkalinity total alkalinity (total concentration of bases) QUANT moles/l

5.1.5.11 Acidity total acidity (total concentration of acids) QUANT moles/l

5.1.5.12 Conductivity conductivity QUANT mhos/m

5.1.5.13 Pressure pressure (absolute) QUANT Pa, psi

5.1.5.14 Velocity velocity QUANT m/s, ft/s

5.1.5.15 ReynoldsNo reynolds number QUANT

5.1.5.16 FlowRegime flow SET (1) none

(2) laminar

(3) turbulent

(4) forced convection

5.1.5.17 Geometry system geometry at test sample STRING

5.1.5.18 Sparging sparging SET (1) deaerated (vacuum, inert gas)

(2) none—less than saturated (open to air)

(3) air

(4) oxygen

(5) inert gas

5.1.5.19 Agitation agitation SET (1) none

(2) stirred

(3) shaken

(4) shaken but not bruised

5.1.5.20 ExpZone exposure zone SET (1) continuous immersion

(2) splash zone

(3) waterline

(4) condensate zone

(5) gaseous phase

(6) cyclic exposure describe in 5.1.5.21

G107

TABLE 1 Continued

Reference

Field Name or Object Tag Description Field Type Category Set/Suggested Units/Column Definition

Number

5.1.5.21 ExpZone.Cycle cyclic exposure cycle (immersion/air exposure, STRING

etc.)

5.1.5.22 Process process relation STRING

examples: pulp bleaching, sour gas production,

solvent extraction, gas scrubbing, etc.

5.1.5.23 Application application relation STRING

examples: heat exchanger tubing, fasteners,

pumps, valves, scrubber ducting, etc.

2 2

5.1.5.24 AV Ratio ratio of specimen surface area to corrodent QUANT mm /L, in. /L

volume

MATERIAL IDENTIFICATION

reference numbers 5.1.6.1 through 5.1.6.6 are

basic fields for use in material identification in

database. Refer to Guide E 1338 on the

identification of Metals and Alloys in

computerized material property databases.

5.1.6.1 Matl.Class material class STRING

5.1.6.2 Matl.SubClass sub-division of class STRING

5.1.6.3 Matl.SubSubClass finer sub-division of class STRING

5.1.6.4 Matl.TradeName common name/trade name STRING

5.1.6.5 Matl.UNSNo material designation—UNS number STRING

5.1.6.6 Matl.Spec specification/standard STRING

5.1.6.7 Shape product shape SET (1)pipe/tube

(2) plate

(3) sheet/strip

(4) wire/rod/bar

(5) other—describe in 5.1.6.8

5.1.6.8 Shape.Description description for (5) in 5.1.6.7 STRING

5.1.6.9 ProdMethod product production method (1) extrusion

(2) forging

(3) casting

(4) rolling

(5) powder compaction

(6) other—describe, in 5.1.6.10

5.1.6.10 ProdMethod.Description description of (6) in 5.1.6.9 STRING

5.1.6.11 Lot.ID heat/lot identification STRING

5.1.6.12 Lot.Analysis heat/lot chemical analysis STRING

SPECIMEN IDENTIFICATION

5.1.7.1 Specimen.Thickness specimen thickness QUANT mm, in.

5.1.7.2 Specimen.Width specimen width/diameter QUANT mm, in.

5.1.7.3 Specimen.Length specimen length QUANT mm, in.

2 2

5.1.7.4 Specimen.Area specimen surface area QUANT mm ,in.

3 3

5.1.7.5 Density density QUANT kg/m , lb/in.

5.1.7.6 Weld welded specimen SET (1) Y—yes

(2) N—no

5.1.7.7 Weld.Type type of weld (see section 5.1.7.8 for additional SET (1) autogenous

detail)

(2) matching filler

(3) dissimilar metal weld

5.1.7.8 Weld.Description weld details

examples: preheat, welding process, no. of

passes, heat input, joint shape, cover gas, etc.

5.1.7.9 Weld.Surface welds ground or machined SET (1) ground

(2) machined

(3) as deposited

(4) glass bead blasted

5.1.7.10 Thermomechanical thermomechanical condition SET (1) stan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.