ASTM D6543-15

(Guide)Standard Guide to the Evaluation of Measurements Made by Online Coal Analyzers

Standard Guide to the Evaluation of Measurements Made by Online Coal Analyzers

SIGNIFICANCE AND USE

5.1 Online analyzers are used to provide quality data on lots of coal. The resulting quality data are used as a production tool or for some contractual application. This guide provides the means of evaluating the analyzer system and the data produced.

5.2 Become familiar with the document's terminology and layout. The section on test design and data collection will provide the means by which all the analysis data will be gathered. The test should be carefully designed to ensure the user’s requirements are met.

5.3 The procedures defined in this guide can be used to estimate the accuracy and precision of an online analyzer, (1) to conduct acceptance testing following installation and (2) to monitor the accuracy and precision (a) during routine use (quality control), (b) when significant changes are made to the analyzer, and (c) when a significant change in the coal being analyzed occurs (e.g., a different seam at a mine, or a new coal source at a power plant). These procedures can also be used for calibration purposes.

SCOPE

1.1 This guide provides techniques to be used for the evaluation of the measurement performance of online coal analyzers.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6543 − 15

Standard Guide to

the Evaluation of Measurements Made by Online Coal

Analyzers

This standard is issued under the fixed designation D6543; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.3 full-stream analyzer, n—an analyzer system that inter-

rogates the coal on a process belt.

1.1 This guide provides techniques to be used for the

evaluation of the measurement performance of online coal 3.2.4 Latent Variable Model, n—a mathematical model that

analyzers.

can estimate each system’s precision, when the analyzer is

compared to two independent reference systems.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.2.5 online analyzer, n—an analytical tool consisting of an

responsibility of the user of this standard to establish appro-

instrumentandsystems,whichtogetherprovidemeasurements,

priate safety and health practices and determine the applica-

or estimates, or both, of coal quality parameters.

bility of regulatory limitations prior to use.

3.2.6 outlier, n—an extreme value that statistical tests indi-

cate to be far enough from other results in a population under

2. Referenced Documents

consideration to cause suspicion that the value is not a member

2.1 ASTM Standards:

of the population.

D121 Terminology of Coal and Coke

3.2.7 reference material, n—material of stable composition

D2013 Practice for Preparing Coal Samples for Analysis

that may be used to generate static analyzer measurements.

D2234/D2234M Practice for Collection of a Gross Sample

of Coal

3.2.8 reference system, n—a measurement system used to

D6518 Practice for Bias Testing a Mechanical Coal Sam-

measure the characteristics of a lot of coal that are also

pling System (Withdrawn 2008)

measured by an online analyzer, and against which the online

D7430 Practice for Mechanical Sampling of Coal

analyzer measurements are compared.

E178 Practice for Dealing With Outlying Observations

3.2.9 sample stream analyzer, n—an analyzer system that is

fed a save or reject stream from a sampling system.

3. Terminology

3.2.10 standardization, n—calibration of an instrument to a

3.1 Definitions—For additional definitions of terms used in

reference material using static stability measurements.

this standard, refer to Terminology D121.

3.2.11 static stability, n—an estimate of the measurement

3.2 Definitions of Terms Specific to This Standard:

precision of an instrument obtained on material that is not

3.2.1 analyzer system, n—a coal quality measurement sys-

moving. The estimate normally is expressed as the standard

tem which includes an online coal analyzer and which may

deviation and average of the measurements for a given period

include one or more stages of a coal-sampling system.

of time.

3.2.2 calibration, n—mathematical modeling of analyzer

3.2.12 synchronization error, n—an error that occurs from

and comparative coal sampling and analysis data. Factors from

the model are used in the online analyzer control software. comparing measurements made by an online analyzer and a

reference system that are not measuring exactly the same lot

because of temporal and/or spatial offsets.

This guide is under the jurisdiction of ASTM Committee D05 on Coal and

Coke and is the direct responsibility of Subcommittee D05.23 on Sampling.

4. Summary of Guide

Current edition approved Jan. 1, 2015. Published January 2015. Originally

approved in 2000. Last previous edition approved in 2014 as D6543-14b. DOI:

4.1 This guide describes how to measure performance of an

10.1520/D6543-15.

online analyzer using comparative measurements. The perfor-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mance evaluation consists of a paired comparison of analyses

Standards volume information, refer to the standard’s Document Summary page on

from a reference method using ASTM sampling, sample

the ASTM website.

preparation, and analysis methods for several lots of coal with

The last approved version of this historical standard is referenced on

www.astm.org. the analyses from the online analyzer for the same lots of coal.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6543 − 15

The data resulting from the comparative test may be evaluated 6.1.5 Additional changes which could merit performance

using graphical and statistical techniques outlined below. testing include a change in the material or width of the

conveyor, or coal flow rates (in the case of full-flow analyzers).

4.2 Varioustechniquesarerecommendedbyonlineanalyzer

manufacturers for standardization or static testing. These

6.2 Static Stability Measurements for Baseline

techniques are useful for establishing a benchmark before

Assessment—A reference material may be used to provide a

conducting a comparative test. These techniques may also be

baseline assessment of static measurement precision. The

used as diagnostic tests in accordance with methods recom-

reference material may be used to compare current mean and

mended by online analyzer manufacturers and graphical and

standard deviation values with mean and standard deviation

statistical techniques included in this guide.

values, previously collected in the same manner. The resulting

comparative data may help determine whether any apparent

5. Significance and Use

decline in analyzer dynamic performance may be attributed to

5.1 Online analyzers are used to provide quality data on lots

a change in the operating characteristics of the analyzer, in the

of coal.The resulting quality data are used as a production tool

absenceoftheinfluenceofsampling,preparation,andanalysis.

or for some contractual application. This guide provides the

6.2.1 The results of this evaluation can indicate whether

means of evaluating the analyzer system and the data pro-

analyzer precision has significantly degraded or whether a bias

duced.

may have occurred. If so, it may be possible to adjust the

5.2 Become familiar with the document’s terminology and analyzer to restore initial performance. If the user wishes only

layout. The section on test design and data collection will

to measure current static stability, any available coal may be

provide the means by which all the analysis data will be used in the analysis zone of the analyzer. Note, however, that

gathered. The test should be carefully designed to ensure the

the actual standard deviation in static stability tests might be

user’s requirements are met. influenced by the composition or mass of the coal being

examined or analyzer factors, such as the strength of the

5.3 The procedures defined in this guide can be used to

radioactive sources used by the analyzer or condition of

estimate the accuracy and precision of an online analyzer, (1)

analyzer electronic components.

to conduct acceptance testing following installation and (2) to

6.2.2 It is essential that the length of the analysis period be

monitor the accuracy and precision (a) during routine use

defined, (for example, one minute, two minutes, or five

(quality control), (b) when significant changes are made to the

minutes) and be constant in the static stability test. The

analyzer, and (c) when a significant change in the coal being

standard deviation resulting from the static stability test de-

analyzed occurs (e.g., a different seam at a mine, or a new coal

creases as the length of the analysis period increases.

source at a power plant).These procedures can also be used for

calibration purposes.

6.3 Comparison of Analyzer System to Reference System

Measurements:

6. Selection and Conduct of Performance Evaluations

6.3.1 Once an analyzer installation has been completed and

6.1 Introduction:

calibration adjustments have been made, the analyzer owner

6.1.1 Several techniques can be used to evaluate the perfor-

may require acceptance testing. Also, the analyzer owner may

mance of an online analyzer. These techniques provide data

decide to relocate the analyzer. In these cases, comparison

that can be evaluated by using the graphical and statistical

tests–that is, to compare the analyzer system results to conven-

methods described in Section 7 of this guide.

tional sampling and analysis techniques–will provide the user

6.1.2 At the time of installation, all of the graphical and

calibration verification data and/or data that could be used for

numerical methods outlined in this guide may prove useful. On

recalibration of the analyzer.

a routine basis, conducting any of the instrument stability

6.3.2 Sinceperformanceevaluationsusuallyconsistof30or

checks and comparative evaluations that do not disrupt normal

more comparisons, with each of these lasting from 30 minutes

operations may prove useful. Control charts may be applied to

to three hours, these comparisons may be conducted in a batch

all the performance measures that are gathered on a routine

over several hours or days, or continuously throughout the

basis, including mean analysis value of reference material,

operational life of the analyzer system.

RMSD, etc.

6.3.3 If two independent conventional coal-sampling and

6.1.3 Whenever there is a major change to the operating

laboratory analysis measurements can be made from each of a

parameters, the configuration, the calibration, the processes, or

series of batches of coal interrogated by the analyzer, the

the hardware associated with the analyzer or the reference

Latent Variable Model (LVM) can be used to provide unbiased

system, the user may wish to perform comparative tests. In

estimates of the measurement precision of the analyzer and of

addition to comparative tests, standardization or static tests, or

the conventional sampling and analysis systems.

both, as recommended by the online analyzer manufacturer,

may be helpful. 6.3.4 Any two series of measurements are independent if

6.1.4 Changes in coal characteristics may also impact ana- their measurement errors are uncorrelated. Correlation of

lyzer performance. Particle size, source of coal, mining measurement errors can be avoided and independence assured

techniques, and degree of preparation, which if changed from by use of a true random selection of physical increments or

previous test periods and which are not in the analyzer samples of material or by using different schemes and equip-

calibration database, may affect analyzer precision and accu- ment for collection, preparation, and laboratory analysis of the

racy. samples, or both. A complete treatment of the subject of

D6543 − 15

independence of measurements and the various means of

assuring independence is beyond the scope of this guide.

6.4 Sampling Considerations:

6.4.1 Selection of Appropriate Sampling and Sample Prepa-

ration Methods—Decisions regarding sample collection should

be governed by Practices D2234/D2234M and D7430 as

appropriate. The method to be used for sample preparation

should be determined before the beginning of increment

collection. Sample preparation techniques should remain con-

sistent (see Practice D2013). Before installation of the

analyzer, consideration should be given to the ability to obtain

representative samples for comparison to analyzer measure-

ments and the regimen for sample handling and analysis. For

the use of mechanical sampling systems, inspection (see

Practice D7430, Part C) and bias testing (see Practice D7430,

Part D) are good methods for evaluation of the system’s

suitability for the test.

6.4.2 Selection of Reference Sample Point(s):

6.4.2.1 Comparative tests can be used to evaluate the

performance of either the analyzer itself or the “analyzer

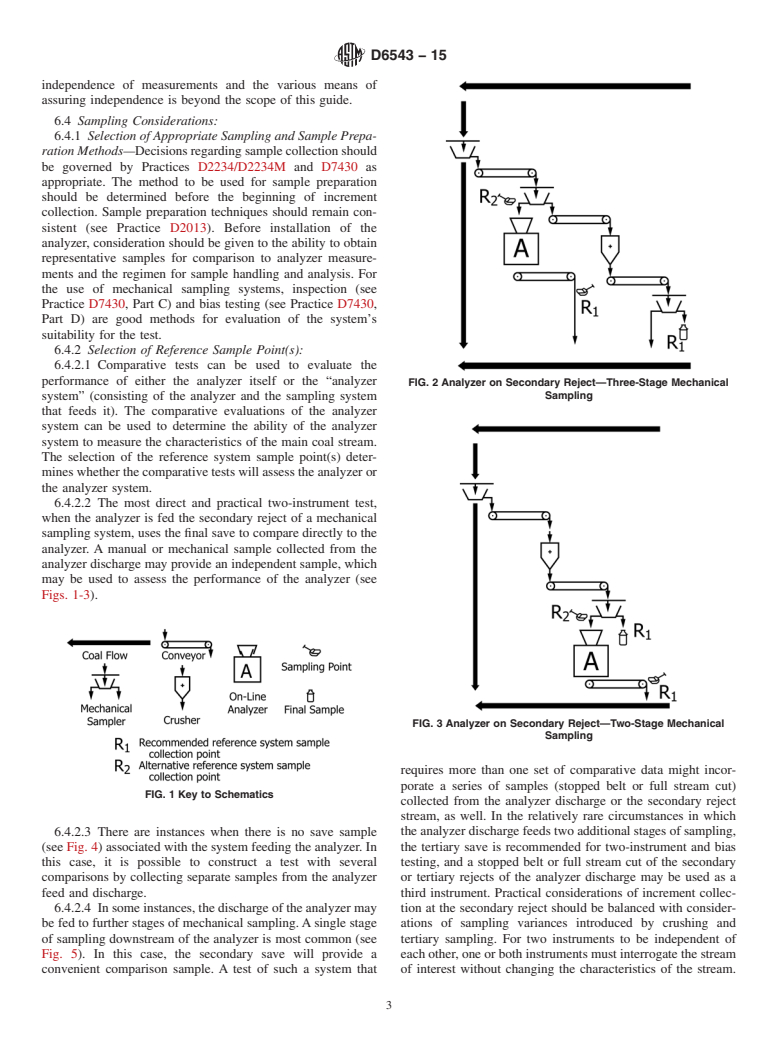

FIG. 2 Analyzer on Secondary Reject—Three-Stage Mechanical

Sampling

system” (consisting of the analyzer and the sampling system

that feeds it). The comparative evaluations of the analyzer

system can be used to determine the ability of the analyzer

system to measure the characteristics of the main coal stream.

The selection of the reference system sample point(s) deter-

mines whether the comparative tests will assess the analyzer or

the analyzer system.

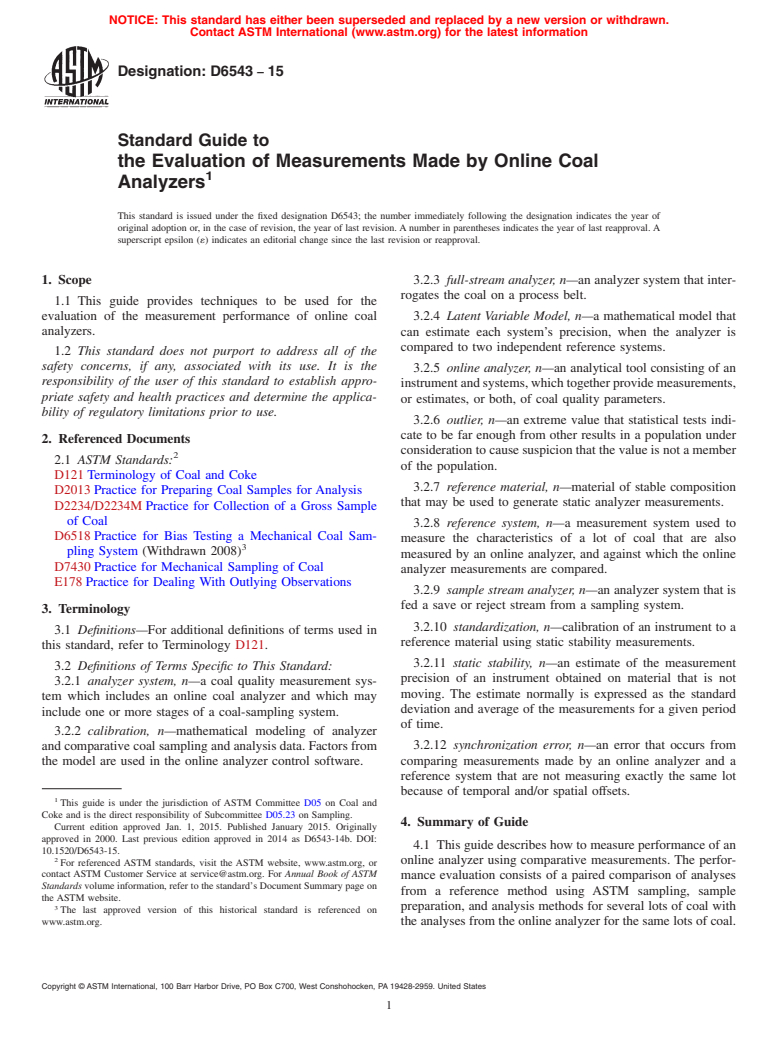

6.4.2.2 The most direct and practical two-instrument test,

when the analyzer is fed the secondary reject of a mechanical

sampling system, uses the final save to compare directly to the

analyzer. A manual or mechanical sample collected from the

analyzer discharge may provide an independent sample, which

may be used to assess the performance of the analyzer (see

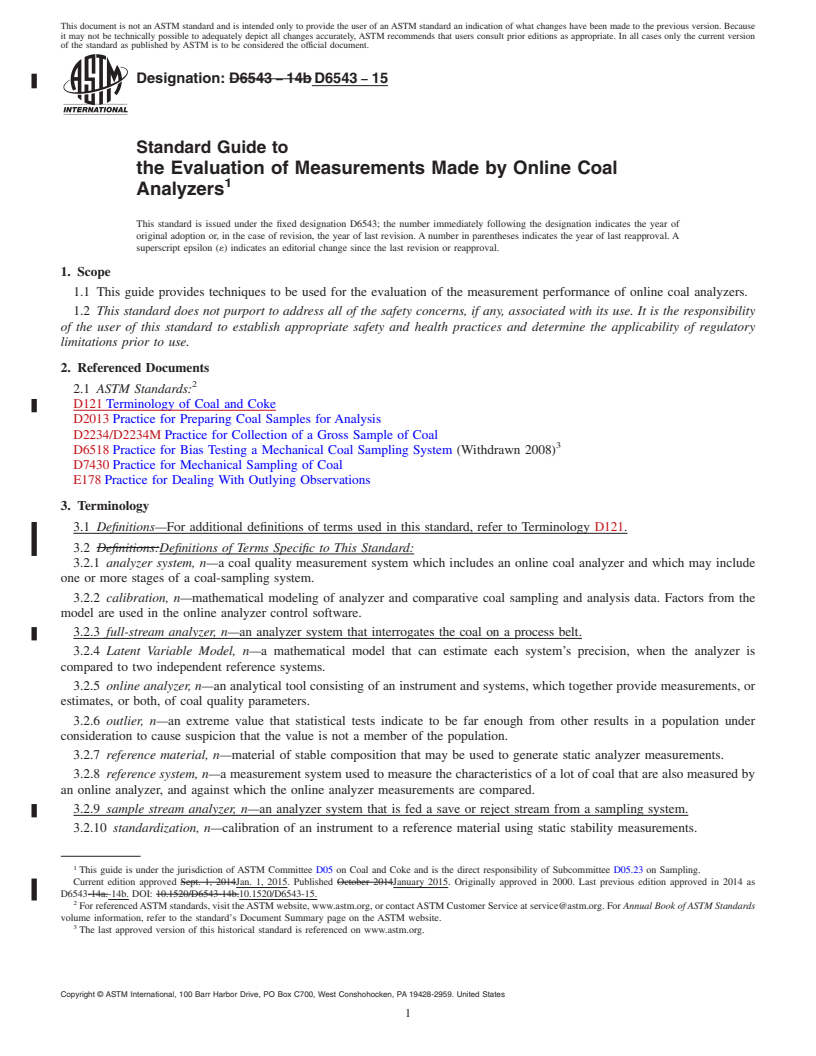

Figs. 1-3).

FIG. 3 Analyzer on Secondary Reject—Two-Stage Mechanical

Sampling

requires more than one set of comparative data might incor-

porate a series of samples (stopped belt or full stream cut)

FIG. 1 Key to Schematics

collected from the analyzer discharge or the secondary reject

stream, as well. In the relatively rare circumstances in which

6.4.2.3 There are instances when there is no save sample the analyzer discharge feeds two additional stages of sampling,

(see Fig. 4) associated with the system feeding the analyzer. In the tertiary save is recommended for two-instrument and bias

this case, it is possible to construct a test with several testing, and a stopped belt or full stream cut of the secondary

comparisons by collecting separate samples from the analyzer or tertiary rejects of the analyzer discharge may be used as a

feed and discharge. third instrument. Practical considerations of increment collec-

6.4.2.4 In some instances, the discharge of the analyzer may tion at the secondary reject should be balanced with consider-

be fed to further stages of mechanical sampling.Asingle stage ations of sampling variances introduced by crushing and

of sampling downstream of the analyzer is most common (see tertiary sampling. For two instruments to be independent of

Fig. 5). In this case, the secondary save will provide a each other, one or both instruments must interrogate the stream

convenient comparison sample. A test of such a system that of interest without changing the characteristics of the stream.

D6543 − 15

FIG. 6 Analyzer Distinct from Reference

rations. In the case of flow-through analyzers that require a

sample, the independence of systems is obtained in a case in

which the primary coal stream is sampled by one instrument

beforebeingsampledbyanotherinstrument(seeFig.6).Inthis

case, the two systems may be evaluated by comparing the

FIG. 4 Single-Stage Mechanica

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6543 − 14b D6543 − 15

Standard Guide to

the Evaluation of Measurements Made by Online Coal

Analyzers

This standard is issued under the fixed designation D6543; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide provides techniques to be used for the evaluation of the measurement performance of online coal analyzers.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D121 Terminology of Coal and Coke

D2013 Practice for Preparing Coal Samples for Analysis

D2234/D2234M Practice for Collection of a Gross Sample of Coal

D6518 Practice for Bias Testing a Mechanical Coal Sampling System (Withdrawn 2008)

D7430 Practice for Mechanical Sampling of Coal

E178 Practice for Dealing With Outlying Observations

3. Terminology

3.1 Definitions—For additional definitions of terms used in this standard, refer to Terminology D121.

3.2 Definitions:Definitions of Terms Specific to This Standard:

3.2.1 analyzer system, n—a coal quality measurement system which includes an online coal analyzer and which may include

one or more stages of a coal-sampling system.

3.2.2 calibration, n—mathematical modeling of analyzer and comparative coal sampling and analysis data. Factors from the

model are used in the online analyzer control software.

3.2.3 full-stream analyzer, n—an analyzer system that interrogates the coal on a process belt.

3.2.4 Latent Variable Model, n—a mathematical model that can estimate each system’s precision, when the analyzer is

compared to two independent reference systems.

3.2.5 online analyzer, n—an analytical tool consisting of an instrument and systems, which together provide measurements, or

estimates, or both, of coal quality parameters.

3.2.6 outlier, n—an extreme value that statistical tests indicate to be far enough from other results in a population under

consideration to cause suspicion that the value is not a member of the population.

3.2.7 reference material, n—material of stable composition that may be used to generate static analyzer measurements.

3.2.8 reference system, n—a measurement system used to measure the characteristics of a lot of coal that are also measured by

an online analyzer, and against which the online analyzer measurements are compared.

3.2.9 sample stream analyzer, n—an analyzer system that is fed a save or reject stream from a sampling system.

3.2.10 standardization, n—calibration of an instrument to a reference material using static stability measurements.

This guide is under the jurisdiction of ASTM Committee D05 on Coal and Coke and is the direct responsibility of Subcommittee D05.23 on Sampling.

Current edition approved Sept. 1, 2014Jan. 1, 2015. Published October 2014January 2015. Originally approved in 2000. Last previous edition approved in 2014 as

D6543-14a.-14b. DOI: 10.1520/D6543-14b.10.1520/D6543-15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6543 − 15

3.2.11 static stability, n—an estimate of the measurement precision of an instrument obtained on material that is not moving.

The estimate normally is expressed as the standard deviation and average of the measurements for a given period of time.

3.2.12 synchronization error, n—an error that occurs from comparing measurements made by an online analyzer and a reference

system that are not measuring exactly the same lot because of temporal and/or spatial offsets.

4. Summary of Guide

4.1 This guide describes how to measure performance of an online analyzer using comparative measurements. The performance

evaluation consists of a paired comparison of analyses from a reference method using ASTM sampling, sample preparation, and

analysis methods for several lots of coal with the analyses from the online analyzer for the same lots of coal. The data resulting

from the comparative test may be evaluated using graphical and statistical techniques outlined below.

4.2 Various techniques are recommended by online analyzer manufacturers for standardization or static testing. These

techniques are useful for establishing a benchmark before conducting a comparative test. These techniques may also be used as

diagnostic tests in accordance with methods recommended by online analyzer manufacturers and graphical and statistical

techniques included in this guide.

5. Significance and Use

5.1 Online analyzers are used to provide quality data on lots of coal. The resulting quality data are used as a production tool

or for some contractual application. This guide provides the means of evaluating the analyzer system and the data produced.

5.2 Become familiar with the document’s terminology and layout. The section on test design and data collection will provide

the means by which all the analysis data will be gathered. The test should be carefully designed to ensure the user’s requirements

are met.

5.3 The procedures defined in this guide can be used to estimate the accuracy and precision of an online analyzer, (1) to conduct

acceptance testing following installation and (2) to monitor the accuracy and precision (a) during routine use (quality control), (b)

when significant changes are made to the analyzer, and (c) when a significant change in the coal being analyzed occurs (e.g., a

different seam at a mine, or a new coal source at a power plant). These procedures can also be used for calibration purposes.

6. Selection and Conduct of Performance Evaluations

6.1 Introduction:

6.1.1 Several techniques can be used to evaluate the performance of an online analyzer. These techniques provide data that can

be evaluated by using the graphical and statistical methods described in Section 7 of this guide.

6.1.2 At the time of installation, all of the graphical and numerical methods outlined in this guide may prove useful. On a routine

basis, conducting any of the instrument stability checks and comparative evaluations that do not disrupt normal operations may

prove useful. Control charts may be applied to all the performance measures that are gathered on a routine basis, including mean

analysis value of reference material, RMSD, etc.

6.1.3 Whenever there is a major change to the operating parameters, the configuration, the calibration, the processes, or the

hardware associated with the analyzer or the reference system, the user may wish to perform comparative tests. In addition to

comparative tests, standardization or static tests, or both, as recommended by the online analyzer manufacturer, may be helpful.

6.1.4 Changes in coal characteristics may also impact analyzer performance. Particle size, source of coal, mining techniques,

and degree of preparation, which if changed from previous test periods and which are not in the analyzer calibration database, may

affect analyzer precision and accuracy.

6.1.5 Additional changes which could merit performance testing include a change in the material or width of the conveyor, or

coal flow rates (in the case of full-flow analyzers).

6.2 Static Stability Measurements for Baseline Assessment—A reference material may be used to provide a baseline assessment

of static measurement precision. The reference material may be used to compare current mean and standard deviation values with

mean and standard deviation values, previously collected in the same manner. The resulting comparative data may help determine

whether any apparent decline in analyzer dynamic performance may be attributed to a change in the operating characteristics of

the analyzer, in the absence of the influence of sampling, preparation, and analysis.

6.2.1 The results of this evaluation can indicate whether analyzer precision has significantly degraded or whether a bias may

have occurred. If so, it may be possible to adjust the analyzer to restore initial performance. If the user wishes only to measure

current static stability, any available coal may be used in the analysis zone of the analyzer. Note, however, that the actual standard

deviation in static stability tests might be influenced by the composition or mass of the coal being examined or analyzer factors,

such as the strength of the radioactive sources used by the analyzer or condition of analyzer electronic components.

6.2.2 It is essential that the length of the analysis period be defined, (for example, one minute, two minutes, or five minutes)

and be constant in the static stability test. The standard deviation resulting from the static stability test decreases as the length of

the analysis period increases.

6.3 Comparison of Analyzer System to Reference System Measurements:

D6543 − 15

6.3.1 Once an analyzer installation has been completed and calibration adjustments have been made, the analyzer owner may

require acceptance testing. Also, the analyzer owner may decide to relocate the analyzer. In these cases, comparison tests–that is,

to compare the analyzer system results to conventional sampling and analysis techniques–will provide the user calibration

verification data and/or data that could be used for recalibration of the analyzer.

6.3.2 Since performance evaluations usually consist of 30 or more comparisons, with each of these lasting from 30 minutes to

three hours, these comparisons may be conducted in a batch over several hours or days, or continuously throughout the operational

life of the analyzer system.

6.3.3 If two independent conventional coal-sampling and laboratory analysis measurements can be made from each of a series

of batches of coal interrogated by the analyzer, the Latent Variable Model (LVM) can be used to provide unbiased estimates of

the measurement precision of the analyzer and of the conventional sampling and analysis systems.

6.3.4 Any two series of measurements are independent if their measurement errors are uncorrelated. Correlation of measurement

errors can be avoided and independence assured by use of a true random selection of physical increments or samples of material

or by using different schemes and equipment for collection, preparation, and laboratory analysis of the samples, or both. A

complete treatment of the subject of independence of measurements and the various means of assuring independence is beyond

the scope of this guide.

6.4 Sampling Considerations:

6.4.1 Selection of Appropriate Sampling and Sample Preparation Methods—Decisions regarding sample collection should be

governed by Practices D2234/D2234M and D7430 as appropriate. The method to be used for sample preparation should be

determined before the beginning of increment collection. Sample preparation techniques should remain consistent (see Practice

D2013). Before installation of the analyzer, consideration should be given to the ability to obtain representative samples for

comparison to analyzer measurements and the regimen for sample handling and analysis. For the use of mechanical sampling

systems, inspection (see Practice D7430, Part C) and bias testing (see Practice D7430, Part D) are good methods for evaluation

of the system’s suitability for the test.

6.4.2 Selection of Reference Sample Point(s):

6.4.2.1 Comparative tests can be used to evaluate the performance of either the analyzer itself or the “analyzer system”

(consisting of the analyzer and the sampling system that feeds it). The comparative evaluations of the analyzer system can be used

to determine the ability of the analyzer system to measure the characteristics of the main coal stream. The selection of the reference

system sample point(s) determines whether the comparative tests will assess the analyzer or the analyzer system.

6.4.2.2 The most direct and practical two-instrument test, when the analyzer is fed the secondary reject of a mechanical

sampling system, uses the final save to compare directly to the analyzer. A manual or mechanical sample collected from the

analyzer discharge may provide an independent sample, which may be used to assess the performance of the analyzer (see Figs.

1-3).

FIG. 1 Key to Schematics

6.4.2.3 There are instances when there is no save sample (see Fig. 4) associated with the system feeding the analyzer. In this

case, it is possible to construct a test with several comparisons by collecting separate samples from the analyzer feed and discharge.

6.4.2.4 In some instances, the discharge of the analyzer may be fed to further stages of mechanical sampling. A single stage of

sampling downstream of the analyzer is most common (see Fig. 5). In this case, the secondary save will provide a convenient

comparison sample. A test of such a system that requires more than one set of comparative data might incorporate a series of

samples (stopped belt or full stream cut) collected from the analyzer discharge or the secondary reject stream, as well. In the

relatively rare circumstances in which the analyzer discharge feeds two additional stages of sampling, the tertiary save is

recommended for two-instrument and bias testing, and a stopped belt or full stream cut of the secondary or tertiary rejects of the

analyzer discharge may be used as a third instrument. Practical considerations of increment collection at the secondary reject

should be balanced with considerations of sampling variances introduced by crushing and tertiary sampling. For two instruments

to be independent of each other, one or both instruments must interrogate the stream of interest without changing the characteristics

of the stream. This may be true in some through-belt noncontacting configurations. In the case of flow-through analyzers that

D6543 − 15

FIG. 2 Analyzer on Secondary Reject—Three-Stage M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.